Beruflich Dokumente

Kultur Dokumente

PD Pace

Hochgeladen von

lalitmlk19Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PD Pace

Hochgeladen von

lalitmlk19Copyright:

Verfügbare Formate

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

Information on Pavement Design

With reference to MPW Memo dated 07-04-2007, the requested information regarding

pavement design is being provided herein.

A. Information Request on Specific Parameters:

A1: Adopted Classification system for vehicles

A2: Equivalent single axle load assumed per each vehicle classification

A3: Design sub-grade CBR, MR, R-value which one used in design

A4: Coefficient of layer (a)

B. Detailed Design information by ASSHTO 1993

The details of above are given in following paragraph.

A1: ADOPTED CLASSIFICATION SYSTEM FOR VEHICLES

The classification system for vehicles has been covered under Para 7.2.4 Design

Traffic Loading and Table 7.1: Types and composition of commercial Vehicles of

Preliminary Design Report submitted to MPW. The same has been reiterated here.

Traffic for pavement design purpose constitutes using commercial vehicles

having at least one axle with dual wheels and /or having more than two axles.

The base year traffic in different categories for various links is estimated and

projected by adopted growth rates for the entire design period and have been

derived from the data provided in Traffic Report and Concept Design Report.

A ratio of commercial vehicles, comprised of buses and trucks, to the total traffic

stream has been taken as 5%, as mentioned in the Traffic Report. Further, in

view of the prevailing vehicles type in the State of Kuwait, the axle configuration

of the traffic composition adopted for the commercial vehicles is given below:

Table A1.1: Types and Composition of Commercial Vehicles

Designation

Mini Bus

Regular Bus

2-Axle

3-Axle

4- Axle

5 -Axle

6 Axle

April 2007

Gross Weight in

Tons

3.5 tons

12 tons

18 tons

24 tons

30 tons

42 tons

58 tons

% of Total commercial

Vehicles in ADT

33%

22%

16%

14%

9%

4%

2%

Page 1 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

A2: EQUIVALENT SINGLE AXLE LOAD ASSUMED PER EACH VEHICLE

CLASSIFICATION

Pavement Structural design requires a quantification of all expected loads a pavement

will encounter over its design life. One of the methods used to determine these

cumulative loads is Equivalent Single Axle Loads (ESALs) approach.

The load equivalency factors (LEFs) recommended by AASHTO 1993, (Table D.4 of

Appendix-D-6) have been adopted for the project. Typical values of LEFs, assuming

SN=5 and Pt=2.5 are given in Table A2.1 below:

Table A2.1: Typical Values of LEFs (Assumption SN=5 and Pt=2.5)

Axle Type

Single Axle

Tandem Axle

Axle Load

(kN)

8.9

44.5

62.3

80.0

89.0

133.4

8.9

44.5

62.3

80.0

89.0

133.4

151.2

177.9

222.4

(lbs)

2,000

10,000

14,000

18,000

20,000

30,000

2,000

10,000

14,000

18,000

20,000

30,000

34,000

40,000

50,000

Load Equivalency

Factor (LEF)

0.0002

0.088

0.360

1.00

1.51

7.0

0.000

0.007

0.027

0.077

0.121

0.658

1.09

2.08

4.86

In order to compute the exact values of the load equivalency factors, one should have

the axle loads together with the axle configurations for the predicted traffic composition

of the project being studied. By considering the maximum loads for different vehicle

types and their computed equivalency factors were applied as follows:

Table A2.2 : Vehicle Type and Load Equivalency Factors

Vehicle Type

Mini Bus

Bus

2-Axle Truck

3-Axle Truck

4-Axle Truck

5-Axle Truck

6-Axle Truck

Gross Weight

3.5 tons

12 tons

18 tons

24 tons

30 tons

42 tons

58 tons

Axle Configuration

2.45 ton SXL + 1.05 ton SXL

8.40 ton SXL + 3.60 ton SXL

11 ton SXL + 7 ton SXL

18 ton TXL + 6 ton SXL

18 ton TXL + (2x6) ton SXL

18 ton TXL + 16 ton TXL + 8 ton SXL

30 ton TrXL + 18 ton TXL + 10 ton SXL

LEF

0.0073

1.240

3.855

2.103

2.126

4.455

8.090

SXL: Single Axle Load, TXL: Tandem Axle Load, TrXL: Tridem Axle Load

The above values of LEFs were used to compute the cumulative 18-kip ESAL values

over the design period of 20 years. The computed 18-kip ESAL values were then used

in the structural design of pavement layers.

April 2007

Page 2 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

A3: DESIGN SUBGRADE CBR, MR, R-VALUE WHICH ONE USED IN DESIGN

Sub-grade resilient Modulus

Sub-grade support is characterised by the sub-grades resilient modulus (MR).

The correlations between MR and CBR developed by Heukelom and Klomp,

which are given in ASSHTO (Para. 1.5) is as follows:

MR (psi) 1500 x CBR

For design purpose CBR value of 10% (soaked) has been considered.

Hence, the Road Bed Modulus MR = 1500 x 10 = 15000 psi

The above relationship, as recommended in AASHTO, holds good for fine

grained soil with soaked CBR of 10 or less. Therefore the modulus has also been

cross checked by other correlations given in AASHTO.

As per Figure 2.7 of AASHTO 1993, the Resilient Modulus for sub-grade is found

around 11,000. Since soaked CBR is taken, no reduction for relative damage due

to rains has been considered. The conservative value of Resilient Modulus for

sub-grade soil of 11000 is taken for pavement design.

A4: COEFFICIENT OF LAYER (a)

Based on the recommendations given in Para 2.3.5 of AASHTO 1993, the

following values of layer coefficient for the different pavement materials have

been adopted for pavement design. Pavement structural strength and layer

strength coefficient are presented in Table A4.1.

Table A4.1: Pavement Layers and Strength Coefficient

Pavement Material

ai

MR (psi)

Asphalt Concrete (AC)

0.42

EAC =400,000

Dense Bituminous Macadam (DBM)

0.35

EDBM =300,000

Wet Mix Macadam (WMM)

0.14

EBS =32,000

Granular Sub base (GSB)

0.12

EBS =15,000

B: DETAILED DESIGN INFORMATION BY AASHTO 1993

April 2007

Page 3 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

B1: Design Considerations

The AASHTO design method requires the parameters to take into account the

following aspects:

pavement performance;

traffic;

sub-grade soil strength;

materials of construction;

environment;

drainage; and,

reliability.

The AASHTO (1993) relationship used for the design of flexible pavement is as

under:

PSI

log10

.

4.2 15

log10 W18 ZR So 9.36 log10 SN 1 0.20

2.32 log10 MR 8.07

1094

0.40

SN 15.19

Where,

W18

is predicted number of 18000-pound equivalent single axle load application.

ZR

is standard normal deviate.

So

is combined standard error of the traffic prediction and performance prediction.

PSI

is difference between the initial design serviceability index, po, and the design terminal

serviceability index, pt.

MR

is resilient modulus.

SN

is structural number indicative of the total pavement thickness required:

= ai Di mi

where,

ai is ith layer coefficient.

Di is ith layer thickness (inch).

mi is ith layer drainage coefficient.

The mi values recommended by AASHTO (1993) are as given under:

Drainage Quality

April 2007

mi value/ % of Time Pavement Structure is Exposed

to Moisture Levels Approaching Saturation

< 1%

1-5%

5-25%

> 25%

Excellent

1.40-1.25

1.35-1.30

1.30-1.20

1.20

Good

1.35-1.25

1.25-1.15

1.15-1.10

1.00

Page 4 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

Fair

1.25-1.15

1.15-1.05

1.00-0.80

0.80

Poor

1.15-1.05

1.05-0.80

0.80-0.60

0.60

Very Poor

1.05-0.95

0.95-0.75

0.75-0.40

0.40

For the present design, the value of mi has been taken as 1.0 corresponding to

drainage quality as Good with the pavement structure exposed to >25% of time

exposed to moisture approaching saturation.

The MR values of unbound granular materials have been estimated using the

following relationship (AASHTO, 1993):

MR = k1 k2

where,

k1, k2

is the stress state. The values of within the base courses vary depending on the resilient

modulus of soil and the asphalt layer thickness. The values used in the design are

(AASHTO, 1993):

are

AC Thickness

Roadbed Soil

(inch)

Resilient Modulus, MR (psi)

3000

7500

15000

<2

20

25

30

24

10

15

20

46

10

15

>6

regression coefficients which are dependent of the material type used in the

pavement courses. The suggested values of k1 and k2 are given below:

Moisture Condition

k1 (Note 1)

k2 (Note 1)

Base

Dry

6000 - 10000

0.5 - 0.7

Damp

4000 - 6000

0.5 - 0.7

Wet

2000 - 4000

0.5 - 0.7

Sub-Base

Dry

6000 - 8000

0.4 - 0.6

Damp

4000 - 6000

0.4 - 0.6

Wet

1500 - 4000

0.4 - 0.6

Note: (1) Range in k1 and k2 is a function of the material quality.

For this important project, it is envisaged that high quality materials

would be used and strict quality control of works would be imposed.

April 2007

Page 5 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

Based on the above considerations and also keeping in mind the ISOHDM

(1995) recommendations, the following values of layer coefficient for the different

pavement materials have been adopted for pavement design: Pavement

structural strength and layer strength coefficient derived from various agencies is

presented in Table 3.6.

Table 3.6

Pavement Material

ai

MR (psi)

Asphalt Concrete (AC)

0.42

EAC =400,000

Dense Bituminous Macadam (DBM)

0.35

EDBM =300,000

Wet Mix Macadam (WMM)

0.14

EBS =32,000

Granular Sub base (GSB)

0.12

EBS =15,000

The values of ZR and So have been assumed based on the following:

The pavement is for a heavily trafficked rural highway, which has been designed for Service Level

B. The overall reliability level for the facility has, therefore, been assumed as 90 per cent. For a

two-stage strategy i.e. initial pavement plus one overlay, the design reliability for each stage should

0.50

or 0.95 per cent.

be 0.90

The value of the normal deviate, ZR, corresponding to 95 per cent reliability has been taken as

1.645 (AASHTO, 1993)

The overall standard deviation suitable for the design of flexible pavements range between 0.40 and

0.50. The overall standard deviation, So, has been taken as 0.40 on the assumption that the

projection of the future traffic represents the most likely scenario.

The values of initial serviceability index, pi, and terminal serviceability index, pt,

have been assumed as under:

The pi value of 4.5 has been adopted on the basis of the consideration that the implementation of the

project would be done with strict adherence of quality control norms for materials and works.

For this heavily trafficked important road, the value of the terminal serviceability index, pt, i.e., the

lowest acceptable level of serviceability before the resurfacing would be necessary has been taken

as 2.5.

B2: Road Bed Modulus

For design purpose CBR value of 10% (soaked) has been considered.

Road Bed Modulus Mr = 1500 x 10 = 15000 psi

As per Figure 2.7 of AASHTO 1993, the Resilient Modulus for sub-grade is found

around 11,000. Since soaked CBR is taken, no reduction for relative damage due

to rains has been considered. The conservative value of Resilient Modulus for

sub-grade soil, as 11000 is taken for pavement design.

B3: Design of Pavement

The thickness requirements for the pavement have been worked out based on

the preceding discussions. The basic steps followed for the computation of the

composition requirements are as under:

April 2007

Page 6 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

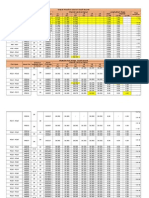

B4: Calculation of W18 for different SN Value

For different SN values, the Cumulative Standard Axles (W18) have been

calculated and given in Table B1.1.

Table B1.1: SN Value and Design Loading (msa)

Road Name

Projected Number of

Standard Axles

(W18)

SN Value and Design

Loading (W18)

SN

Allowable

Cumulative Traffic

Main Line

Nasser Road

32.3 x 10^6

5.07

32.73 x 10^6

Jahra Road

29.7 x 10^6

5.02

30.45 x 10^6

Nasser Road

5.2 x 10^6

3.9

5.23 x 10^6

Jahra Road

15.3 x 10^6

4.6

16.26 x 10^6

4th Ring Road

33.3 x 10^6

5.1

34.18 x 10^6

Al-Jahez Road

21.0 x 10^6

4.8

22.02 x 10^6

Ghazali Road

9.8 x 10^6

4.3

10.15 x 10^6

Airport Road

18.8 x 10^6

4.7

18.94 x 10^6

2nd Ring Road

17.1 x 10^6

4.65

17.55 x 10^6

Service Road

Note: (1) W18 is cumulative number of equivalent standard axle.

3.3.2.4

Proposed Pavement Composition

Determination of the structural layer thickness

The overall structural number for each respective ESAL is given in Table B1.1.

Hence, the Structural number for the asphalt layer (SNAL) consists of Wearing

course and binder course can be calculated as follow:

SNAL=SN - ai x di x mi

Where

SN is the overall structural number above the sub-grade layer

ai is the pavement layer coefficient,

Di is the layer thickness; and

Mi is the drainage coefficient

April 2007

Page 7 of 8

Upgrade of Jamal Abdul Nasser Street and Jahra Road

Information on Pavement Design

By taking the base course and sub-base course thicknesses of 250mm and

200mm, respectively, then

SNAL = SN (0.0394 x (0.14 x 250 x 1.0 + 0.12 x 200 x 1.0)

The thickness of the asphalt layer (DAL) = D1 wearing course + D2 asphalt base

A wearing course thickness 50mm and 40mm for ESAL of more than 10msa and

less than 10msa respectively. Based on this assumption, the thickness worked

out for wearing course and asphalt base for all road segments is given in table

B1.2 below:

Table B1.2: Pavement Structure based on AASHTO-1993

Road Section

Nasser Road

(ML)

Jahra Road

(ML)

Nasser Road

(SR)

Jahra Road

(SR)

4th Ring

Road (SR)

Al-Jahez

Road (SR)

Ghazali Road

(SR)

Airport Road

(SR)

2nd Ring

Road (ML)

ESAL

Required

SN

Proposed Pavement Layers (mm) and SN Value

ACWC

ACBC

CABC

GSBC

Total

5.07

50

150

250

200

650

5.18

29.7 x 10^6

5.02

50

140

250

200

640

5.04

5.2 x 10^6

3.90

40

75

250

200

565

3.98

15.3 x 10^6

4.60

50

110

250

200

610

4.63

33.3 x 10^6

5.10

50

150

250

200

650

5.18

21.0 x 10^6

4.80

50

125

250

200

625

4.84

9.8 x 10^6

4.30

40

100

250

200

590

4.33

18.8 x 10^6

4.70

50

120

250

200

620

4.77

17.10 x 10^6

4.65

50

120

250

200

620

4.77

32.3 x 10^

(ML): Main Line, (SR): Service Road

ACWC: Asphalt Concrete Wearing Course, Type III of Clause 404

ACBC: Asphalt Concrete Base Course, Type II of Clause 404

CABC: Crushed Aggregate Base Course

GSBC: Granular Sub base Course

April 2007

Page 8 of 8

SN

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Capacity Service ManualDokument182 SeitenCapacity Service Manualrive201168% (22)

- 2014 Acel Rates: (Minimum Operation 8 Hrs. Per Day)Dokument1 Seite2014 Acel Rates: (Minimum Operation 8 Hrs. Per Day)Rachel Tagolimot100% (2)

- LMC Trucks Catalogue CompleteDokument132 SeitenLMC Trucks Catalogue CompletedgibNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Engine Detroit S-60Dokument76 SeitenEngine Detroit S-60josue100% (3)

- Wa600-3 PDFDokument143 SeitenWa600-3 PDFanggieNoch keine Bewertungen

- (MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDokument500 Seiten(MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDaniel Reconco88% (8)

- Volvo FMX 460 8x4 19 5 Cu M Tipper Data SheetDokument4 SeitenVolvo FMX 460 8x4 19 5 Cu M Tipper Data SheetAshu Sri0% (1)

- Bedford Tucks Range (1957) BrochureDokument29 SeitenBedford Tucks Range (1957) BrochureNickiedeposieNoch keine Bewertungen

- Cosibo Scania en WebDokument757 SeitenCosibo Scania en WebВиктор Долгов100% (1)

- Brochure 80 160nDokument6 SeitenBrochure 80 160ntmg16Noch keine Bewertungen

- Dev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishDokument4 SeitenDev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishBBBBBBNoch keine Bewertungen

- Udcg02 - 02GB DCG180-330Dokument350 SeitenUdcg02 - 02GB DCG180-330Souhailee raihanouneeNoch keine Bewertungen

- Renault Magnum 400 - 440 - 480 Service ManualDokument251 SeitenRenault Magnum 400 - 440 - 480 Service ManualMihai CostasNoch keine Bewertungen

- Curriculum Vitae: Ved ParkashDokument2 SeitenCurriculum Vitae: Ved Parkashlalitmlk19Noch keine Bewertungen

- Holiday List 2016Dokument1 SeiteHoliday List 2016lalitmlk19Noch keine Bewertungen

- IRC SP 88 - Road Safety ChecklistDokument25 SeitenIRC SP 88 - Road Safety Checklistlalitmlk19Noch keine Bewertungen

- Holiday List 2015Dokument1 SeiteHoliday List 2015lalitmlk19Noch keine Bewertungen

- Delhi Metro Route MapDokument1 SeiteDelhi Metro Route Mapnakulyadav7Noch keine Bewertungen

- TOC Comparison SheetDokument3 SeitenTOC Comparison Sheetlalitmlk19Noch keine Bewertungen

- Oil InterceptorsDokument4 SeitenOil Interceptorslalitmlk19Noch keine Bewertungen

- Spout Schedule - Complete - 17-12-2014Dokument4.298 SeitenSpout Schedule - Complete - 17-12-2014lalitmlk19Noch keine Bewertungen

- Vertical ChevronDokument1 SeiteVertical Chevronlalitmlk19Noch keine Bewertungen

- 1460 NEW - ADT 4x4 Mk3 Tier 4f Broch23581019 US EnglishwebDokument12 Seiten1460 NEW - ADT 4x4 Mk3 Tier 4f Broch23581019 US EnglishwebelizabeththeresanaomNoch keine Bewertungen

- Komatsu Dump Truck Hm250 2 Shop Manual Sen04733 00Dokument20 SeitenKomatsu Dump Truck Hm250 2 Shop Manual Sen04733 00john100% (45)

- Performance Report: Caterpillar 325D L vs. Caterpillar 325C LDokument10 SeitenPerformance Report: Caterpillar 325D L vs. Caterpillar 325C LDANIEL VARGAS RODRIGUEZNoch keine Bewertungen

- Rollover Prevention GuideDokument28 SeitenRollover Prevention GuidelucasNoch keine Bewertungen

- Volvo DemolitionDokument16 SeitenVolvo DemolitionCarlosNoch keine Bewertungen

- A Critical Evaluation of Haul Truck Tyre Performance and Management System at Rössing Uranium MineDokument6 SeitenA Critical Evaluation of Haul Truck Tyre Performance and Management System at Rössing Uranium MineGustavoNoch keine Bewertungen

- TBTDokument6 SeitenTBTNimish MadananNoch keine Bewertungen

- Fuso FJ UaeDokument7 SeitenFuso FJ UaeSatria WibisonoNoch keine Bewertungen

- WPT 50 WPT 70 / WPT 95: Truck Mounted Concrete PumpDokument2 SeitenWPT 50 WPT 70 / WPT 95: Truck Mounted Concrete PumpIvan D. RiveraNoch keine Bewertungen

- Ready Mix ConcreteDokument14 SeitenReady Mix ConcreteYog Aiyappa100% (1)

- Diesel and LPG Forklift Trucks: 2 000 - 3 000 KG H2.0-3.0XTDokument5 SeitenDiesel and LPG Forklift Trucks: 2 000 - 3 000 KG H2.0-3.0XTAhmed Elbihy100% (1)

- Remote Operated Fork Lift Mechanism Work PDFDokument32 SeitenRemote Operated Fork Lift Mechanism Work PDFasdfrewNoch keine Bewertungen

- Volvo Fe Product Guide Euro3 5 en en PDFDokument16 SeitenVolvo Fe Product Guide Euro3 5 en en PDFYuber CcoaNoch keine Bewertungen

- Weichai CNG WP12NG EngineDokument2 SeitenWeichai CNG WP12NG EnginevikzefgNoch keine Bewertungen

- EDDR of Batching Plant Sialkot Pdf1Dokument33 SeitenEDDR of Batching Plant Sialkot Pdf1aqeelNoch keine Bewertungen

- SANY EU SY16-18C - v1-2 - ENDokument7 SeitenSANY EU SY16-18C - v1-2 - ENTan Yun WongNoch keine Bewertungen

- Byd Class 8 TruckDokument2 SeitenByd Class 8 TruckFred Lamert100% (1)