Beruflich Dokumente

Kultur Dokumente

Work Method Statement FOR HSS PQT

Hochgeladen von

enels77Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Work Method Statement FOR HSS PQT

Hochgeladen von

enels77Copyright:

Verfügbare Formate

DOCUMENT NUMBER :

Generic Code

Organisation

Code

Doc Type Code

Department / Discipline Code

Numeric Sequence Number

1404505

METHOD STATEMENT FOR PQT OF HEAT SHRINKABLE

SLEEVE

B

Rev

14/03/2015

Date

IFR

Prepared By

Reviewed By

Approved By

Description

METHOD STATEMENT FOR PQT Originator:

Date:

OF HEAT SHRINKABLE SLEEVE

Page:

Doc No:

Rev:

14/03/2015

3 of 12

B

TABLE OF CONTENTS

PURPOSE--------------------------------------------------------------------------------------------------------------------------3

REFERNCES,

STANDARD

SPECIFICATION-----------------------------------------------------------------------------3

AND

DEFINITION

AND

ABBREVIATION---------------------------------------------------------------------------------------------3

PROCEDURE

FOR

QUALIFCATION

SLEEVE-----------------------------------------------------3-4

OF

HEAT

SHRINKABLE

ATTACHEMENT-------------------------------------------------------------------------------------------------------------------5

METHOD STATEMENT FOR PQT Originator:

Date:

OF HEAT SHRINKABLE SLEEVE

Page:

Doc No:

1.0

2.0

3.0

4.0

Rev:

14/03/2015

3 of 12

B

PURPOSE

The purpose of this work method statement is to describe and document

qualification of Heat shrinkage sleeve application for field coating

REFERENCES, STANDARD AND SPECIFICATION

o Contracts document

o Shrink sleeve manufacturers installation guide (HTLP 80) for application

of HSS

o Project construction procedure

o ST 3 (Surface Preparation)

DEFINISION AND ABBREVIATION

HSS: Heat Shrinkable Sleeve

PROCEDURE FOR QUALIFICATION OF HEAT SHRINKABLE SLEEVE

4.1

In line with contract document, field joint coating, the heat shrinkable

sleeve (HSS) application method shall be qualified for use on the project

by the performance of a HSS procedure Qualification Test.

4.2

Inspection and test equipment shall be listed in HSS procedure

qualification Test Report attached).

4.3

Material for HSS procedure qualification Test shall be listed in HSS

procedure qualification Test (attached)

4.4

HSS shall be applied to a welded joint in project material in accordance

with project construction procedure.

1

Surface preparation: Visual inspection and surface profile. The

surface preparation of the field joint shall be deemed acceptable when it

has the characteristics listed below.

The substrate is visually clean and free from any evidence of

contamination, Weld spatter/mill scale or other foreign matters

and corrosion

2

Pre-Heat Temperature

Preheat the joint minimum 800c maximum 900, if ambient temperature

is <20 but if ambient temperature is >20 preheat is minimum 700c

maximum 800 using a propane torch. Check temperature with a contact

thermometer. The sleeve should overlap in the 10 to 2 Oclock position

and over the overlap of the sleeve onto itself should be at least 100mm.

3

Visual Inspection after Installation.

Full contact with steel joint

METHOD STATEMENT FOR PQT Originator:

Date:

OF HEAT SHRINKABLE SLEEVE

Page:

Doc No:

Rev:

14/03/2015

3 of 12

B

Adhesive flows beyond both sleeve

No cracks or hole in sleeve backing

No scorch marks

Holiday Detection Testing

The result of a holiday detecting test of the field joint shall be deemed

acceptable when it is carried out within 16.3-18.2Kv.

4.4

5.0

On successful completion of the specified tests of the HSS procedure

shall deemed qualified, see HSS procedure qualification Test Report.

(Attached)

Attachment

5.1

Shrink Sleeve manufacturers installation guide for application of HSS

5.2

HSS procedure Qualification Test Report

METHOD STATEMENT FOR PQT Originator:

Date:

OF HEAT SHRINKABLE SLEEVE

Page:

Doc No:

14/03/2015

3 of 12

Rev:

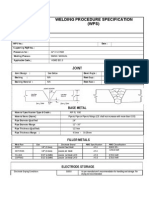

PROJECT

CLIENT

WELD No

CONSUMABLE DETAILS

HSS

Epoxy Resin

Hardener

HTLP 80

Epoxy primer

INSPECTION AND TEST EQUIPMENT ETAILS

Equipment

model

Measuring Range

Thermometer

~500C~ 13000C

Holiday Detector

5Kv~ 35Kv

N

o

1

Description of

inspection

Surface profile

Required value

Pre-Heat Temperature

900C + 50C

Visual Inspection after

installation

Full contact with

the steel joint

Measured

Value

Accuracy

10C

0.1Kv

Result

ST 3

Adhesive flows

beyond both

sleeve

No crack or holes

in sleeve backing

4

Holiday detection

testing

SIGN:

16.3 Kv ~ 18.2

Kv

SIGN:

Remarks

METHOD STATEMENT FOR PQT Originator:

Date:

OF HEAT SHRINKABLE SLEEVE

Page:

Doc No:

14/03/2015

3 of 12

Rev:

______________________

________________

NAME:

NAME:

DATE:

DATE:

Das könnte Ihnen auch gefallen

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDokument3 SeitenBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNoch keine Bewertungen

- Welding Material Control ProcedureDokument12 SeitenWelding Material Control ProcedureWalter RuedaNoch keine Bewertungen

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDokument6 SeitenProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123Noch keine Bewertungen

- QAP For Conical StrainerDokument2 SeitenQAP For Conical StrainersatishchidrewarNoch keine Bewertungen

- Method Statement Installation Os Static Equipment and InternalsDokument24 SeitenMethod Statement Installation Os Static Equipment and InternalsAjin SNoch keine Bewertungen

- Vessel Cleaning ProcedureDokument6 SeitenVessel Cleaning ProcedureZool HilmiNoch keine Bewertungen

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDokument2 SeitenDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNoch keine Bewertungen

- Painting ReportDokument1 SeitePainting Reportbaidu1980Noch keine Bewertungen

- PQT Heat Treatment Tms 1Dokument96 SeitenPQT Heat Treatment Tms 1nur wahyu dewi kusrini100% (1)

- Blasting Painting ProcedureDokument4 SeitenBlasting Painting ProcedureRyanNoch keine Bewertungen

- Radiation Safety Distance DiagramDokument3 SeitenRadiation Safety Distance DiagramEswaranNoch keine Bewertungen

- 800D SeriesDokument3 Seiten800D Seriesvkeie0206Noch keine Bewertungen

- Heat Shrink ProcedureDokument7 SeitenHeat Shrink ProcedureBabar Manzoor GhauriNoch keine Bewertungen

- F 941 - 99 - RJK0MQ - PDFDokument3 SeitenF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezNoch keine Bewertungen

- 36 - Painting Procedure - Rev0Dokument21 Seiten36 - Painting Procedure - Rev0Duc ThinNoch keine Bewertungen

- Paint Coating Stainless SteelsDokument2 SeitenPaint Coating Stainless SteelsSilva NumaNoch keine Bewertungen

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDokument2 SeitenExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNoch keine Bewertungen

- 001 Itp For Painting Rev 0Dokument7 Seiten001 Itp For Painting Rev 0Alif Rahmat FebriantoNoch keine Bewertungen

- Contractor IOT Infrastructure & Energy Services LTDDokument38 SeitenContractor IOT Infrastructure & Energy Services LTDNaveen KurupNoch keine Bewertungen

- Welder and Welder Operator Qualification Record FormDokument1 SeiteWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohNoch keine Bewertungen

- Fenomastic Hygiene Emulsion SilkDokument4 SeitenFenomastic Hygiene Emulsion Silkمحمد عزتNoch keine Bewertungen

- Painting ReportDokument2 SeitenPainting ReporthikmahNoch keine Bewertungen

- Prorox WM 960 Sa PDFDokument1 SeiteProrox WM 960 Sa PDFr afriantoNoch keine Bewertungen

- MS For Fabrication of Above-Ground Storage TankDokument8 SeitenMS For Fabrication of Above-Ground Storage Tankdadz mingiNoch keine Bewertungen

- CPVC ChecklistDokument1 SeiteCPVC Checklistchakravarthi kanugulaNoch keine Bewertungen

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDokument10 SeitenQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- Method Statement For Blasting and PaintingDokument11 SeitenMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Coke Crusher - Lubrication Pumps Run in TestDokument26 SeitenCoke Crusher - Lubrication Pumps Run in TestsayedNoch keine Bewertungen

- 8474l-000-Jsd-2310-001-2-Protective CoatingDokument31 Seiten8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Spark Testing FormDokument1 SeiteSpark Testing FormMark Kevin Bechayda100% (1)

- Certificate of Origin Form F For China-Chile FTADokument2 SeitenCertificate of Origin Form F For China-Chile FTAinspectormetNoch keine Bewertungen

- Inspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyDokument6 SeitenInspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyAhmad DagamsehNoch keine Bewertungen

- MNT - QC - BP - 001 Blasting & Painting ReportDokument1 SeiteMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNoch keine Bewertungen

- Cover Electrical & Tellemunication - RevisiDokument12 SeitenCover Electrical & Tellemunication - RevisiGhazi LuthfiNoch keine Bewertungen

- Pttep Painitng of Offshore FacilitiesDokument66 SeitenPttep Painitng of Offshore FacilitiesSufianNoch keine Bewertungen

- Itp Internal CoatingDokument4 SeitenItp Internal CoatingkamlNoch keine Bewertungen

- Standard Specification FOR Pipeline Internal CoatingDokument2 SeitenStandard Specification FOR Pipeline Internal CoatingRanjan KumarNoch keine Bewertungen

- Hydro Test ReportDokument2 SeitenHydro Test ReportAnonymous a8oga83Noch keine Bewertungen

- ITP For Mild Steel Pipe WorksDokument4 SeitenITP For Mild Steel Pipe WorksKumar AbhishekNoch keine Bewertungen

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerDokument2 SeitenPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebNoch keine Bewertungen

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDokument17 SeitenInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- 3500-00 Simathane Gloss (Finish Coat)Dokument3 Seiten3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNoch keine Bewertungen

- Prosedur Penetran TestingDokument11 SeitenProsedur Penetran TestingIkhsan DalimuntheNoch keine Bewertungen

- Audit Checklist Blasting PaintingDokument4 SeitenAudit Checklist Blasting PaintingEyoh EffiongNoch keine Bewertungen

- 8 JSA Holyday TestDokument3 Seiten8 JSA Holyday TestYosua SitumorangNoch keine Bewertungen

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Dokument7 Seiten13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- GS-09 (Painting) PDFDokument22 SeitenGS-09 (Painting) PDFSarbendu PaulNoch keine Bewertungen

- Grouting Format Report (Electrical Panel)Dokument1 SeiteGrouting Format Report (Electrical Panel)Anas PratamaNoch keine Bewertungen

- MSDS Bostik 2402 PDFDokument6 SeitenMSDS Bostik 2402 PDFJunior Gabriel Cusi HuillcaNoch keine Bewertungen

- Blasting & Painting ProcedureDokument10 SeitenBlasting & Painting ProcedurepraksahNoch keine Bewertungen

- Leak Test Procedure of Atmospheric VesselDokument9 SeitenLeak Test Procedure of Atmospheric VesselRicardo NapitupuluNoch keine Bewertungen

- Attachment D (SAEP 316)Dokument1 SeiteAttachment D (SAEP 316)imtiazNoch keine Bewertungen

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDokument31 Seiten8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Painting SpecificationDokument19 SeitenPainting SpecificationArunkumar Rackan0% (1)

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDokument4 SeitenProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNoch keine Bewertungen

- ITP PKS PaintingDokument3 SeitenITP PKS PaintingMuthu SaravananNoch keine Bewertungen

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDokument4 SeitenDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNoch keine Bewertungen

- Anubar SpecDokument8 SeitenAnubar SpecSHIVAJI CHOUDHURYNoch keine Bewertungen

- Elm 1950001 MR Q03 1001 R6Dokument137 SeitenElm 1950001 MR Q03 1001 R6Marwa Koubaies100% (1)

- Gal 6:1, 2 Matt 22:36-40 John 13:34,35 15:12 1Jn 3:15-18 1pet 4:8-10Dokument2 SeitenGal 6:1, 2 Matt 22:36-40 John 13:34,35 15:12 1Jn 3:15-18 1pet 4:8-10enels77Noch keine Bewertungen

- Golden WeldDokument4 SeitenGolden Weldenels77Noch keine Bewertungen

- 13cr Martensitic Stainless Steel PQR and Wps ReviewDokument1 Seite13cr Martensitic Stainless Steel PQR and Wps Reviewenels77Noch keine Bewertungen

- Character Reference Check ListDokument1 SeiteCharacter Reference Check Listenels77Noch keine Bewertungen

- Mechanical Fatigue Is Caused by What Material Does Not Have An Endurance Limit?Dokument1 SeiteMechanical Fatigue Is Caused by What Material Does Not Have An Endurance Limit?enels77Noch keine Bewertungen

- Welding Procedure Specification For 24'' PipeDokument2 SeitenWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Pipe GradeDokument1 SeitePipe Gradeenels77Noch keine Bewertungen

- Welding PositionDokument6 SeitenWelding Positionenels77Noch keine Bewertungen

- Itp TemplateDokument8 SeitenItp Templateenels77100% (1)

- Welding Procedure Specification For 24'' PipeDokument2 SeitenWelding Procedure Specification For 24'' Pipeenels77100% (1)

- NDTDokument80 SeitenNDTsungkang92% (12)

- 40 Inches Pipeline IsometricDokument1 Seite40 Inches Pipeline Isometricenels77Noch keine Bewertungen

- Cswip Questions and AnswerDokument4 SeitenCswip Questions and Answerenels770% (2)

- Welding PositionDokument6 SeitenWelding Positionenels77Noch keine Bewertungen

- Cqe Insert 2010Dokument5 SeitenCqe Insert 2010enels77Noch keine Bewertungen

- Piping Welding Daily Quality Control and Inspection Report FormDokument1 SeitePiping Welding Daily Quality Control and Inspection Report Formenels77100% (5)

- Piping Welding Daily Quality Control and Inspection Report FormDokument1 SeitePiping Welding Daily Quality Control and Inspection Report Formenels77100% (5)

- CswipDokument74 SeitenCswipMohammed Amjad AliNoch keine Bewertungen

- Cqe Insert 2010Dokument5 SeitenCqe Insert 2010enels77Noch keine Bewertungen

- Maintenance of Mechanical and Electrical Equipment at C4ISR Facilities Recommended Maintenance PracticesDokument261 SeitenMaintenance of Mechanical and Electrical Equipment at C4ISR Facilities Recommended Maintenance Practicesenels77Noch keine Bewertungen

- Example Slide of User Functions: Time Guide The Slide Should Be Finished byDokument70 SeitenExample Slide of User Functions: Time Guide The Slide Should Be Finished byHskumarReddy KarriNoch keine Bewertungen

- Twi - Welding Inspection - SteelsDokument209 SeitenTwi - Welding Inspection - Steelsenels77Noch keine Bewertungen

- Maryland Metrics - Thread Data ChartsDokument4 SeitenMaryland Metrics - Thread Data ChartsAnonymous VC68Xndnu9Noch keine Bewertungen

- Largest Steel Producers Since 1980Dokument38 SeitenLargest Steel Producers Since 1980Binod Kumar PadhiNoch keine Bewertungen

- Stripper Bolt, Coil Spring, Dowel PinDokument3 SeitenStripper Bolt, Coil Spring, Dowel Pinmuhamad laaliNoch keine Bewertungen

- Lecture 9 Life Cycle AssessmentDokument18 SeitenLecture 9 Life Cycle AssessmentAmmar SafwtNoch keine Bewertungen

- Snamprogetti Saipem Urea Process AmmoniaDokument23 SeitenSnamprogetti Saipem Urea Process AmmoniaTu Hai50% (2)

- AHTN2022 CHAPTER39 wNOTESDokument17 SeitenAHTN2022 CHAPTER39 wNOTESdoookaNoch keine Bewertungen

- Gke10 Spirax SarcoDokument2 SeitenGke10 Spirax SarcoEMANoch keine Bewertungen

- Depolymerization of Tire and Natural Rubber Using Supercritical FluidsflaDokument8 SeitenDepolymerization of Tire and Natural Rubber Using Supercritical FluidsflaAli DueNoch keine Bewertungen

- A Presentation BY Mbah Chinedu Drilling Engineer Segofs Energy Services LimitedDokument16 SeitenA Presentation BY Mbah Chinedu Drilling Engineer Segofs Energy Services LimitedAwani KesterNoch keine Bewertungen

- Hl500pin ManualDokument1 SeiteHl500pin ManualMarious NavNoch keine Bewertungen

- Abhitech Prasad RaoDokument44 SeitenAbhitech Prasad RaoSubhasish mukherjeeNoch keine Bewertungen

- Monitor m8-m9 User ManualDokument242 SeitenMonitor m8-m9 User Manualcarlos6696Noch keine Bewertungen

- CD-M Series 2 Manual - 2cDokument45 SeitenCD-M Series 2 Manual - 2cpaulgtswNoch keine Bewertungen

- Gas Turbine Blade Failures - Causes, Avoidance and Troubleshooting PDFDokument48 SeitenGas Turbine Blade Failures - Causes, Avoidance and Troubleshooting PDFTabiquera Guadalupe Victoria Texcoco De Mora100% (2)

- Nitotile Ep GroutDokument2 SeitenNitotile Ep GroutBalasubramanian AnanthNoch keine Bewertungen

- Instruction Manual: RA 0025 F, RA 0040 F, RA 0063 F, RA 0100 FDokument24 SeitenInstruction Manual: RA 0025 F, RA 0040 F, RA 0063 F, RA 0100 FAlexandru SavuNoch keine Bewertungen

- Magpul Industries M-Lok Information BookletDokument10 SeitenMagpul Industries M-Lok Information BookletTwobirds Flying PublicationsNoch keine Bewertungen

- Hermes-Pjt Training Manual: RSJ1/RSH1Dokument152 SeitenHermes-Pjt Training Manual: RSJ1/RSH1Cesar Calderon Gr100% (2)

- Septic TanksDokument6 SeitenSeptic TanksJustin MusopoleNoch keine Bewertungen

- Yvoh8 18HP SM 0114 (En) PDFDokument224 SeitenYvoh8 18HP SM 0114 (En) PDFTirta Noegraha100% (4)

- NX Nastran Advanced Nonlinear - Solution 601-701Dokument3 SeitenNX Nastran Advanced Nonlinear - Solution 601-701Rubén GabrielNoch keine Bewertungen

- 150 66-RP4Dokument92 Seiten150 66-RP4MJZENoch keine Bewertungen

- Cbse Class 10 Science Chapter 1 McqsDokument5 SeitenCbse Class 10 Science Chapter 1 Mcqsleena_louisNoch keine Bewertungen

- MRTS70Dokument42 SeitenMRTS70Indika2323Noch keine Bewertungen

- Feb IssueDokument40 SeitenFeb Issuesppram100% (1)

- Simulation Studies On GAX Absorption Compression CoolerDokument7 SeitenSimulation Studies On GAX Absorption Compression CooleralmadhagiNoch keine Bewertungen

- HardnessDokument3 SeitenHardnessHaider FiazNoch keine Bewertungen

- Project GuitarDokument11 SeitenProject GuitarMns100% (2)

- AFS, KanpurDokument5 SeitenAFS, Kanpurdipmoip2210Noch keine Bewertungen

- GlulamDokument7 SeitenGlulamvergopiNoch keine Bewertungen