Beruflich Dokumente

Kultur Dokumente

Tin Coat

Hochgeladen von

pravi3434Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tin Coat

Hochgeladen von

pravi3434Copyright:

Verfügbare Formate

CMCI

THIN COAT

LATEX MODIFIED PATCH

KIT

THIN COAT is a latex modified cementitious

product designed for use as a concrete repair

mortar at thicknesses of up to 13 mm. It is

formulated to incorporate liquid latex technology,

which provides excellent durability under freezethaw cycling as well as protection against ingress

by water and de-icing salts. THIN COAT is easy to

work with at a high slump consistency and

provides a fast setting abrasion resistant repair.

PRIMARY APPLICATIONS

l Parking decks

l Docks

l Ramps

l Curbs and gutters

l Floors

l Marine structures

l Joints

l Pavements and walkways

TECHNICAL INFORMATION

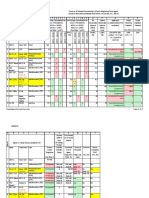

Typical Engineering Data

Compressive Strength

ASTM C-109 50 mm Cubes

Age

Strength

1 day

3 days

7 days

28 days

3,000 psi (21 MPa)

4,000 psi (28 MPa)

5,500 psi (38 MPa)

7,000 psi (48 MPa)

Flexural Strength ASTM C-78

28 days

1,600 psi (11 MPa)

Bond Strength ASTM C-1042

14 days

1,500 psi (10 MPa)

FEATURES / BENEFITS

l Provides a strong, wear resistant patch

l Excellent durability under freeze/thaw

cycling

l Resists penetration of water and de-icing

salts for good substrate protection

l Excellent bond to properly prepared sound

concrete

l Easy to use two part system

l Suitable for both indoor and outdoor use.

SPECIFICATIONS / COMPLIANCES

l THIN COAT attains a bond strength in

compliance with ASTM C 1059-86 Type II

systems.

l THIN COAT has been approved for use by

the Ohio EPA for contact with drinking water

supplies.

PACKAGING / YIELD

THIN COAT is a unit containing 20.0 kg of THIN

COAT POWDER and 3.8 liter of THIN COAT LIQUID

and yields 0.010 m3 of mixed material. One unit

of THIN COAT will cover approximately 1.9 m2

when placed at an average depth of 6 mm

thickness.

Up to 18 kg of pea gravel may be added per kit for

filling deep patches. Note : This product may require

a separately sold primer and curing compound.

DIRECTIONS FOR USE

Surface Preparation - New concrete must be a

minimum of 28 days old if an epoxy adhesive will

be used to bond the topping. If a slurry bond coat

is used, the concrete must be a minimum of 3

days old.

The concrete must be clean and rough. All oil,

dirt, debris, paint and unsound concrete must be

prepared mechanically using a scabbler,

bushhammer, shotblast or scarifier which will give

a surface profile of a minimum 3 mm and expose

the coarse aggregate, final step in-cleaning of the

concrete should be the complete removal of all

residue with a vacuum cleaner or by pressure

washing.

Acid etching is acceptable only when mechanical

preparation is impractical NOTE : Use of an epoxy

bonding agent is strongly recommended if acid

etching will be used to create the surface profile.

All concrete must possess and open surface

texture with all curing compounds and sealers

removed.

Joints and Edges - Edges should be sawcut to 6

mm deeper than the topping thickness and the

floor should be notched at the edge of the overlay

to provide a locked in, reinforced edge. Expansion

joints should be brought up through the repair by

sawcutting or with the use of a divider strip.

Bonding - After the surface has been prepared,

prime all areas with either a slurry coat of THIN

COAT or a bonding agent such as CORR-BOND

or EUCO #452 EPOXY.

The primer bonding agent must be ordered

separately.

Slurry Coat - Mix THIN COAT as instructed but

add an additional one 1 liter of water per unit to

the mix. Broom the slurry coat on to the prepared

and pre-dampended concrete. Apply the THIN

Quality Construction Chemicals

CONSTRUCTION MATERIAL CHEMICAL INDUSTRIES P.O. Box 7137, Dammam 31462, Saudi Arabia

Tel: 00966-3-8471450; Fax: 00966-3-8471575; Email: tech@cmci-sa.com Web: www.cmci-sa.com

COAT topping before the slurry coat has dried.

Epoxy Primer - Use EUCO #352 (LV or MV) epoxy

adhesive for exterior repairs. Use EUCO #452 (LV

or MV) epoxy adhesive for interior repairs.

Mixing - Small quantities of THIN COAT may be

mixed with a drill and jiffy mixer. Use a paddle

type mortar mixer for large jobs. Add the

appropriate amount of THIN COAT LIQUID for the

batch size and then add the dry product. Mixfor a

minimum of 3 minutes. The mixed product should

be quickly transported to the repair area and

placed immediately.

Placement - Discharge material from mixer and

place onto floor. For patching, spread with trowel,

come-a-long, or square tipped shovel to a

thickness that matches the surrounding concrete.

Finish by hand trowelling.

Finishing- Finish the repair material to the desired

texture. Do not add additional water to the surface

during the finishing operation. If additional liquid is

required, use THIN COAT LIQUID.

Curing and Sealing - To prevent surface cracking,

cure the repair with two coats of a high solids curing

compound, such as SUPER AQUA-CURE VOX

(Note : A solvent based curing compound should

not be used on this product.) In hot, windy or direct

sunlight situations, rewet the surface after the

curing compound has dried and cover with

polyethylene for a minimum of three (3) days.

If a curing compound is not desired, wet cure for a

minimum of three (3) days.

CLEAN-UP

Clean tools and equipment with water before the

material hardens.

PRECAUTIONS / LIMITATIONS

l Store in a dry place above freezing.

l Keep liquid and powder off of skin and out

of eyes.

l Wear protective clothing and eyewear

l May not be suitable as an overlay for

abusive traffic. Use THIN TOP SUPREME

or CONCRETE COAT SUPREME.

l No heavy traffic until the product has cured.

Quality Construction Chemicals

CONSTRUCTION MATERIAL CHEMICAL INDUSTRIES P.O. Box 7137, Dammam 31462, Saudi Arabia

Tel: 00966-3-8471450; Fax: 00966-3-8471575; Email: tech@cmci-sa.com Web: www.cmci-sa.com

CMCI

Das könnte Ihnen auch gefallen

- Flex ConDokument2 SeitenFlex Conpravi3434Noch keine Bewertungen

- Tin Top SupremeDokument2 SeitenTin Top Supremepravi3434Noch keine Bewertungen

- Tin TopDokument2 SeitenTin Toppravi3434Noch keine Bewertungen

- CemmixDokument2 SeitenCemmixpravi3434Noch keine Bewertungen

- EucocreteDokument2 SeitenEucocretepravi3434Noch keine Bewertungen

- Euco SpeedDokument2 SeitenEuco Speedpravi3434Noch keine Bewertungen

- High Strength Concrete Repair MortarDokument2 SeitenHigh Strength Concrete Repair Mortarpravi3434Noch keine Bewertungen

- Concrete Top SupremeDokument2 SeitenConcrete Top Supremepravi3434Noch keine Bewertungen

- Thin Top 100Dokument2 SeitenThin Top 100pravi3434Noch keine Bewertungen

- Thin Top 100Dokument2 SeitenThin Top 100pravi3434Noch keine Bewertungen

- CemfixDokument2 SeitenCemfixpravi3434100% (1)

- FlotopDokument2 SeitenFlotoppravi3434Noch keine Bewertungen

- FlotopDokument2 SeitenFlotoppravi3434Noch keine Bewertungen

- Cemkem 10Dokument2 SeitenCemkem 10pravi3434100% (1)

- Cem BondDokument1 SeiteCem Bondpravi3434Noch keine Bewertungen

- Euco WeldDokument2 SeitenEuco Weldpravi3434Noch keine Bewertungen

- Cmci Cmci: CEMTEC 227 P.UDokument2 SeitenCmci Cmci: CEMTEC 227 P.Upravi3434Noch keine Bewertungen

- CMCI EUCO 700 Flexible Industrial Floor Joint FillerDokument2 SeitenCMCI EUCO 700 Flexible Industrial Floor Joint Fillerpravi3434Noch keine Bewertungen

- High Strength Epoxy Mortar for Manhole RehabilitationDokument1 SeiteHigh Strength Epoxy Mortar for Manhole Rehabilitationpravi3434Noch keine Bewertungen

- CMCI CEMTEC P.U. PRIMER Joint Sealant PrimerDokument1 SeiteCMCI CEMTEC P.U. PRIMER Joint Sealant Primerpravi3434Noch keine Bewertungen

- Euco 495 HPDokument1 SeiteEuco 495 HPpravi3434Noch keine Bewertungen

- Epoxy Primer for Damp ConcreteDokument1 SeiteEpoxy Primer for Damp Concretepravi3434Noch keine Bewertungen

- Cmci Cmci: Cemtec 920Dokument2 SeitenCmci Cmci: Cemtec 920pravi3434Noch keine Bewertungen

- Eu Co 456 MortarDokument2 SeitenEu Co 456 Mortarpravi3434Noch keine Bewertungen

- Euco 495 HPDokument1 SeiteEuco 495 HPpravi3434Noch keine Bewertungen

- Jet Fuel Sealant CEMTEC 200Dokument2 SeitenJet Fuel Sealant CEMTEC 200pravi3434Noch keine Bewertungen

- CMCI CEMTEC P.U. PRIMER Joint Sealant PrimerDokument1 SeiteCMCI CEMTEC P.U. PRIMER Joint Sealant Primerpravi3434Noch keine Bewertungen

- Neo SealDokument2 SeitenNeo Sealpravi3434Noch keine Bewertungen

- Cmci Cmci: CEMTEC 227 P.SDokument2 SeitenCmci Cmci: CEMTEC 227 P.Spravi3434Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- IMT Ghaziabad PGDM Timetable Term II 2020Dokument22 SeitenIMT Ghaziabad PGDM Timetable Term II 2020Ved JhingranNoch keine Bewertungen

- Control SystemsDokument269 SeitenControl SystemsAntonis SiderisNoch keine Bewertungen

- GIS Arrester PDFDokument0 SeitenGIS Arrester PDFMrC03Noch keine Bewertungen

- Distinguish Between Tax and FeeDokument2 SeitenDistinguish Between Tax and FeeRishi Agarwal100% (1)

- Basf Masterseal 725hc TdsDokument2 SeitenBasf Masterseal 725hc TdsshashiNoch keine Bewertungen

- Insize Catalogue 2183,2392Dokument1 SeiteInsize Catalogue 2183,2392calidadcdokepNoch keine Bewertungen

- Individual Sports Prelim ExamDokument13 SeitenIndividual Sports Prelim ExamTommy MarcelinoNoch keine Bewertungen

- Radio Theory: Frequency or AmplitudeDokument11 SeitenRadio Theory: Frequency or AmplitudeMoslem GrimaldiNoch keine Bewertungen

- Reservoir Rock TypingDokument56 SeitenReservoir Rock TypingAffan HasanNoch keine Bewertungen

- Clean Agent ComparisonDokument9 SeitenClean Agent ComparisonJohn ANoch keine Bewertungen

- Translation EquivalenceDokument6 SeitenTranslation EquivalenceJamal Anwar TahaNoch keine Bewertungen

- BoQ East Park Apartment Buaran For ContractorDokument36 SeitenBoQ East Park Apartment Buaran For ContractorDhiangga JauharyNoch keine Bewertungen

- Huawei WCDMA Primary Scrambling Code PlanningDokument22 SeitenHuawei WCDMA Primary Scrambling Code PlanningZeljko Vrankovic90% (31)

- Emerson Park Master Plan 2015 DraftDokument93 SeitenEmerson Park Master Plan 2015 DraftRyan DeffenbaughNoch keine Bewertungen

- Scharlau Chemie: Material Safety Data Sheet - MsdsDokument4 SeitenScharlau Chemie: Material Safety Data Sheet - MsdsTapioriusNoch keine Bewertungen

- Socially Responsible CompaniesDokument2 SeitenSocially Responsible CompaniesItzman SánchezNoch keine Bewertungen

- 13 Fashion Studies Textbook XIDokument158 Seiten13 Fashion Studies Textbook XIMeeta GawriNoch keine Bewertungen

- Environmental Technology Syllabus-2019Dokument2 SeitenEnvironmental Technology Syllabus-2019Kxsns sjidNoch keine Bewertungen

- Suband Coding in MatlabDokument5 SeitenSuband Coding in MatlabZoro Roronoa0% (1)

- Impact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisDokument5 SeitenImpact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Urodynamics Griffiths ICS 2014Dokument198 SeitenUrodynamics Griffiths ICS 2014nadalNoch keine Bewertungen

- Laws of MotionDokument64 SeitenLaws of MotionArnel A. JulatonNoch keine Bewertungen

- Spsi RDokument2 SeitenSpsi RBrandy ANoch keine Bewertungen

- SEO Design ExamplesDokument10 SeitenSEO Design ExamplesAnonymous YDwBCtsNoch keine Bewertungen

- Unit 1 - Introduction To BankingDokument17 SeitenUnit 1 - Introduction To Bankingc08Noch keine Bewertungen

- Judge Vest Printable PatternDokument24 SeitenJudge Vest Printable PatternMomNoch keine Bewertungen

- S2 Retake Practice Exam PDFDokument3 SeitenS2 Retake Practice Exam PDFWinnie MeiNoch keine Bewertungen

- Course Tutorial ASP - Net TrainingDokument67 SeitenCourse Tutorial ASP - Net Traininglanka.rkNoch keine Bewertungen

- Impolitic Art Sparks Debate Over Societal ValuesDokument10 SeitenImpolitic Art Sparks Debate Over Societal ValuesCarine KmrNoch keine Bewertungen

- April 2017 Jacksonville ReviewDokument40 SeitenApril 2017 Jacksonville ReviewThe Jacksonville ReviewNoch keine Bewertungen