Beruflich Dokumente

Kultur Dokumente

Tipseec PDF

Hochgeladen von

Kevin StrongOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tipseec PDF

Hochgeladen von

Kevin StrongCopyright:

Verfügbare Formate

1st Quarter 2000.

ENGINE CONTROLS AND FUEL SYSTEMS

The air flow sensor contains a switch

READER INPUT

REQUESTED

We try our best to make sure that our

tech tips remain interesting to you, and, we

would like to keep it that way. One way of

doing that is to get some input from you. If

there are any subjects that you would like to

see discussed in future articles, please give

us your suggestions. Just mail your request to

Nick Rinaldi-Technical Service Manager,

box G-14,

c/o Standard Motor Products,

37-18 Northern Boulevard.

L.I.C., N.Y. 11101.

FORDS W/ EEC IV

SYSTEM- CAR RUNS

POORLY, SCANNER

DISPLAY IS BLANK

The vehicle symptoms include: poor

running, Check Engine light illuminated, and

the scanner display becomes blank when it is

connected. Its no secret that all power and

ground circuit integrity is critical for a

computer controlled vehicle to operate

properly, and Fords are no exception. A

large number of sensors ( such as: the

Throttle Position sensor, Manifold Absolute

Pressure sensor, Coolant Temperature

sensor, and the Manifold Air Temperature

sensor) are grounded at pin # 46 of the

ECM. Even one of the terminals of the

diagnostic connector is grounded at pin # 46

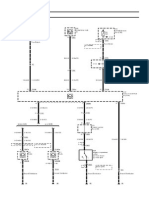

( see diagram #1). This ground circuit is

controlled through the ECM. The only time

the ground is provided is when the ignition

key is in the On position. When this

ground circuit has a large enough voltage

drop ( thats over .050volts, or 50 millivolts),

the voltage signals provided by certain

sensors, which the ECM is using to control

which grounds the windings of the circuit

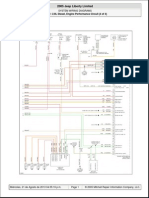

opening relay (or fuel pump relay). If you

unplug the airflow sensor and the pump

stops running, youre on the right track (see

diagram # 2). The only time the airflow

sensor grounds the relay is when the sensor

plate is open. If the fuel pump runs

constantly when the key is on, and the

engine is not running, then this indicates that

the flap in the sensor is stuck open. Carefully

Diagram #1

inspect the sensor for binding. This would

also explain the rich running condition. The

fuel delivery and spark advance, will be

incorrect, creating driveability problems and

scanner communication problems. In

addition to checking pin # 46 its important

to check the other grounds as well when

diagnosing intermittent driveability

problems. These grounds are also located at

pin #s: 16, 20, 40, 49, and 60.

Scott Milch- Standard Plus Technician

air flow sensor, being out of position, is

misleading the ECM into thinking that the

engine is under load, which would cause the

ECM to add fuel unnecessarily, resulting in

an over rich condition. Outside of cleaning,

no other repair is recommended other than

replacement of the sensor.

Pat Sugar- Top GunTechnician

RICH

RUNNING

TOYOTAS

If you come across a

Toyota with a vane type

airflow sensor and the

customer is complaining

of black smoke out of

the tail pipe and poor

fuel economy, check for

a binding airflow sensor

plate. A lead into

solving this problem

would be that the fuel

pump is running

constantly when the

ignition key is in the

On position.

Diagram #2

Standard Motor Products, Inc., Long Island City, NY 11101

GM VEHICLES CODE 43ELECTRONIC SPARK

CONTROL SYSTEM

This tip concerns itself with those

systems that do not use an external spark

control module. Unlike the ESC systems

that use an external module, this system

can set a code 43 immediately after starting

the engine.

In order for the ECM to detect engine

detonation, it must be connected to a knock

sensor. In order to verify knock sensor

circuit integrity, the ECM supplies a 5 volt

reference signal. The knock sensor has an

internal resistance range of 3.8K ohms to

4.8K ohms. This resistance will lower the

5 volt reference signal to approximately 2.5

volts. If the DC voltage drops lower than

1.25 volts or rises higher than 3.75 volts, a

voltage comparator in the ECM causes a

code 43 to set.

Failure mode includes: no ignition

timing retard when the engine detonates,

and less spark advance timing during light

throttle loads. It is possible to install the

incorrect sensor since they look the same. If

you install a sensor with a higher resistance,

it will change the voltage reading to be out of

specification, and cause code 43. Also, make

sure the sensor is properly torqued to

14 ft-lbs. If the sensor is not properly

tightened, its sensitivity will be affected.

Jeff Auerbach-Domestic Specialist

MAZDA 626-1988 TO

1992 W/ 2.2L ENG.- NO

START, HARD START,

STALLING, &/ OR

SURGING

These symptoms are created as a

result of a lean condition. Normally, air

flows through the Air Flow meter, then

through the Air Induction tube to the

throttle body. If you examine the bottom of

the air tube, you will see a short section of

tube leading into a large plastic box called

a Resonance Chamber (see diagram # 3).

The purpose of this chamber is to dampen

the pulses generated by the four cylinder

intake, so the Air Flow meter has a smooth

signal. Old age usually takes its toll on

plastics. Also, if the engine should backfire,

Diagram #3

this chamber may rupture or crack. The

size of the crack determines the severity of

the driveability problem. What usually

happens is that the Resonance Chamber

splits along the seam, which makes it

difficult to notice. Taping or using epoxy to

repair the crack usually solves the problem

temporarily. The only recommended fix is

to replace it.

DODGE DAKOTA

1991-95 - NO START,

INTERMITTENT

STALLING

The problem may be a no start, or an

intermittent stall with a hard start. This

symptom is caused due to no power to the

ECMs memory circuit and to the ASD and

fuel pump relays.

The power to the ASD and fuel pump

relays are supplied by the 30 amp maxi fuse

D, which is located in the engine compartment power distribution center. Power to

the ECM is then routed through a splice

(designated as S115-see diagram #4) ,

Which is located in the main computer

harness which is on the drivers side inner

fender well. Checking the integrity of this

splice first could be a time saver. The

plastic which covers this splice has a

tendency to collect moisture, salt, etc.

(Continued on next page)

Kerry Jonsson-Asian Specialist

SUBARU-1989 TO 1993 W/1.8L ENG.- NO START

If you are working on an 89 -93 Subaru L series or Loyale with a 1.8L single

or multi-point fuel injection system thats a no start, has spark and fuel injector

pulse, but no fuel pressure, heres something to keep in mind. Before investigating

the fuel pump circuit, please be aware that most wiring diagrams for these

vehicles indicate that the blue and black wire from the fuel pump relay coil is

grounded by the ECM. That would be at pin #47 for the single point injection

system, and pin #6 for the multi port system. This is true for vehicles that do not

have automatic shoulder belts.

For models equipped with automatic shoulder belts, the fuel pump relays

winding is grounded by a Revolution Sensor or fuel cut unit. This unit is similar

in operation to the fuel pump relay used on many European models (for example,

Volkswagon). When this unit receives a tach signal from the ignition coil negative

terminal, it grounds the blue and black wire, thus energizing the relay. The

Revolution Sensor is usually located just above the hood release cable handle.

Refer to the chart for proper operating voltages.

Peter McArdle- Aisian Specialist

IGNITION KEY POSITION

WIRE

COLOR

KEY ON

(ENGINE OFF)

BLUE/BLACK battery voltage

GREEN/WHITE battery voltage

BLACK/WHITE 0 volts

BLACK

less than .050 volts

(this is a constant ground)

ENGINE

RUNNING

ENGINE

CRANKING

grounded

battery voltage

0 volts

less than .050 volts

grounded

battery voltage

battery voltage

less than .050 volts

YELLOW - tach signal from ignition coil negative.

(Continued from page 2)

which leads to corrosion of this splice,

cutting power to the ECM. This splice is a

problem which needs to be repaired and

protected to prevent another failure.

Phil Austin-Chrysler Specialist

This problem may be seen in carbureted or

fuel injected vehicles. Although the

problem seems confusing at first, the fix is

quite simple both in diagnosis and repair.

The only tool required is a vacuum gauge

with a tee fitting.

Diagram #4

HONDA VEHICLESENGINE SURGE AT

STEADY SPEEDS

A common Honda owner complaint is

an engine surge that occurs while the

vehicle is at a steady speed, while being

non-existent at idle and when under load.

Honda feedback carburetor systems

control their fuel mixture by creating

different amounts of vacuum leaks. The

larger the leak, the leaner the mixture. The

reverse is also true. The smaller the leak,

the richer the mixture. This is accomplished

by the operation of vacuum diaphragms

called air control valves with pulsed

vacuum control signals. These vacuum

signals are produced by electric vacuum

solenoids called frequency solenoid valves,

which are controlled by the ECM based on

oxygen sensor readings. Honda realized

early that load conditions affected manifold

vacuum directly. This being the case, it

makes it difficult to control a system with

vacuum if the vacuum supply is constantly

changing. In order to solve this problem,

Honda uses a vacuum regulator which it

calls a constant vacuum valve, or, a

constant vacuum control valve. In using

this, Honda was able to control their

feedback systems under various load

conditions. Similar strategy is used on the

fuel injected models for EGR control.

If a constant vacuum valve fails where

the vacuum control valves are exposed to

full manifold vacuum, surge conditions can

arise when the vacuum signal changes too

quickly. If the valve fails where the control

valves see no vacuum at all, few

driveability problems would result,

however, emissions and fuel economy will

change for the worse.

Diagnosis can be accomplished by

installing a vacuum gauge between the

constant vacuum valve and the control

solenoid it supplies. Carbureted vehicles

should have a regulated vacuum range of

3. 9 to 7. 9 inches, while fuel injected

vehicles should measure about 8 inches.

Regardless of the system you are checking,

the vacuum reading should be steady. If

you have determined that the vacuum

readings are out of specification, then

replacement of the valve is necessary.

These units are normally located in the

emissions control box which is in the

engine compartment (see diagram # 5).

James DAnna- Top GunTechnician

GM- FULL SIZE

TRUCKS- 1996 AND

LATER- CHECK ENGINE

LIGHT

You may encounter a late model GM

truck with constant Check Engine light.

Diagnostics reveal a rather long list of

codes which include: P0102 (MAF low),

Diagram #5

P0135, P0141, P0147 (Heated O2 sensor),

P0340 (Cam Sensor circuit). In fact, you

may find any number of EGR, Heated O2

sensor, EVAP system, or MAF codes

stored. Before doing any diagnostics,

record any codes and freeze frame info.

Next, clear the ECM memory. If code

P0102 returns immediately when you turn

the key on, check for a blown ENG. 1 fuse

in the under hood electrical center. This

fuse supplies battery power to the: oxygen

sensor heaters, EGR valve, cam position

sensor, EVAP solenoid, MAF sensor, as

well as the ECM. Oddly enough, even

though this fuse supplies power to the

ECM, if this fuse is blown, it will not

prevent the vehicle from starting.

Code P0102 (MAF low) is the only code

that will reset immediately because it is the

only circuit that is monitored in the key

on position. What usually causes this fuse

to blow is a failure of one of the heated O2

sensor connectors which allows moisture

and/or corrosion to cause a short.

customers may not think its important to

tell you, or, they just completely forgot

about it.That is something that you dont

have control over. What you do have

control over is to make it imperative to

mark EVERY connector that you

disconnect when working on a vehicle so

that there is no mistake. Its also advisable

to make a list of all of the connectors, with

its location, that have been disconnected.

This way, when its time to put the vehicle

back together, you eliminate the

possibility of an unnecessary comeback.

Some may say Well, it takes too much

time! Try timing yourself. It shouldnt

take more than a few minutes. As opposed

to spending hours on a comeback. You

wouldnt believe how many times weve

seen this problem.

John Rogers- Domestic Specialist

MITSUBISHI-1995

ECLIPSE W/ 2.0L ENG.TIMING BELT TIP

Use caution when servicing the

camshaft sprockets or timing belt on the

95 Eclipse with the 2.0L non-turbo

engines. Some of these engines have two

timing marks on each cam sprocket. When

installing the timing belt, set the crankshaft

sprocket to TDC by aligning the mark on

the sprocket with the arrow on the oil pump

housing. Next, set the camshafts timing

marks together by aligning the marks on

the sprockets. Make sure to use the mark

that is closest to the 609 designation on

the gear. DO NOT use the mark that is

closest to the 2.0 L front designation.

Engine damage may result if the cams are

incorrectly set.

Richard Mooers- Aisian Specialist

Joe Dantuono- GM Specialist

CROSSED CONNECTORSALL VEHICLES

We have seen this scenario all too

often, where a vehicle is brought in with a

driveability problem where every thing

seems to be OK. Well, if everything was

OK there would not be a problem. Testing

of the basics usually leads to nowhere. All

we know is that the vehicle is not running

correctly. What usually happens after

spending much time investigating, is that

we discover that two connectors that look

similar have been crossed. Which means

that the two devices that they are connected

to are not functioning correctly. This is

usually the result of someone doing some

work to the vehicle before you get it. It is

helpful to ask the customer if any work has

been done to the vehicle prior to the

problem appearing. Its amazing what you

could find out if you ask, because

Diagram #6

4

ST8752-1Q00

Das könnte Ihnen auch gefallen

- Scripts de Formularios 01Dokument4 SeitenScripts de Formularios 01Kevin StrongNoch keine Bewertungen

- Chapter 18 Working With ChartsDokument2 SeitenChapter 18 Working With ChartsKevin StrongNoch keine Bewertungen

- Excel Arrives Excel Sort of Evolved From MultiPlanDokument1 SeiteExcel Arrives Excel Sort of Evolved From MultiPlanKevin StrongNoch keine Bewertungen

- Displaying A Data FormDokument2 SeitenDisplaying A Data FormKevin StrongNoch keine Bewertungen

- Customizing The ToolboxDokument2 SeitenCustomizing The ToolboxKevin StrongNoch keine Bewertungen

- Excel® 2010 Power Programming With VBA: Contents at A GlanceDokument2 SeitenExcel® 2010 Power Programming With VBA: Contents at A GlanceKevin StrongNoch keine Bewertungen

- A Function That Returns An Error ValueDokument2 SeitenA Function That Returns An Error ValueKevin StrongNoch keine Bewertungen

- AntitheftDokument11 SeitenAntitheftKevin StrongNoch keine Bewertungen

- Printing From OnDemand5 4Dokument1 SeitePrinting From OnDemand5 4Kevin StrongNoch keine Bewertungen

- UserForm Code ReferenceDokument4 SeitenUserForm Code ReferenceKevin StrongNoch keine Bewertungen

- Electronic Circuit Inspection Procedure: Introduction - How To Troubleshoot Ecu Controlled SystemsDokument5 SeitenElectronic Circuit Inspection Procedure: Introduction - How To Troubleshoot Ecu Controlled SystemsKevin StrongNoch keine Bewertungen

- Table of Contents (1) : TitleDokument42 SeitenTable of Contents (1) : TitleKevin StrongNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- On-Vehicle Inspection (4A-Fe) : Spark TestDokument4 SeitenOn-Vehicle Inspection (4A-Fe) : Spark TestNathaly MarcanoNoch keine Bewertungen

- SeaDoo 3D DI 2006 Manual PDFDokument320 SeitenSeaDoo 3D DI 2006 Manual PDFRicardo Vilhena100% (3)

- Fuse Application Chart For PEUGEOT 306 From DAM 7147 TO 7447Dokument3 SeitenFuse Application Chart For PEUGEOT 306 From DAM 7147 TO 7447dedi kurniawanNoch keine Bewertungen

- Mazda6FL Training Manual PDFDokument274 SeitenMazda6FL Training Manual PDFtomislavlkmNoch keine Bewertungen

- MZ34 35 Manual PDFDokument26 SeitenMZ34 35 Manual PDFSukhi SinghNoch keine Bewertungen

- Harley Davidson 2013 Sportster Electrical Diagnostic ManualDokument346 SeitenHarley Davidson 2013 Sportster Electrical Diagnostic ManualYael Rodriguez100% (4)

- Datasheet PDF Search Site.: Multi-Spark Cdi CircuitDokument27 SeitenDatasheet PDF Search Site.: Multi-Spark Cdi CircuitMuriel MatheusNoch keine Bewertungen

- Alt I Installation GuideDokument10 SeitenAlt I Installation GuidegustavoespinosamNoch keine Bewertungen

- IP22 MY11 Connector Library 20110728Dokument335 SeitenIP22 MY11 Connector Library 20110728Abel OviedoNoch keine Bewertungen

- Honda Invicta 150 PDFDokument338 SeitenHonda Invicta 150 PDFSandino JoseNoch keine Bewertungen

- Fuel TrimsDokument6 SeitenFuel TrimsahmedNoch keine Bewertungen

- Altronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)Dokument36 SeitenAltronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)francis_mouille_iiNoch keine Bewertungen

- Micro XXVDokument16 SeitenMicro XXVHarold FornessNoch keine Bewertungen

- Vortec 4.3L Teoria - OperacionDokument78 SeitenVortec 4.3L Teoria - OperacionJosé Luis Castro100% (3)

- Accent Engine Control SystemDokument35 SeitenAccent Engine Control Systemflash_24014910Noch keine Bewertungen

- Manual Sparker Dccdip4 en PDFDokument7 SeitenManual Sparker Dccdip4 en PDFRockley Lock SafeNoch keine Bewertungen

- Catalogo VdoDokument29 SeitenCatalogo VdoNuno Pires100% (1)

- Vident V301 User ManualDokument10 SeitenVident V301 User ManualZhang LynnNoch keine Bewertungen

- Service Manual EY35 EY40 RobinDokument51 SeitenService Manual EY35 EY40 RobinAgus YulfizarNoch keine Bewertungen

- Golf - Jetta IV Relay ListDokument2 SeitenGolf - Jetta IV Relay ListfsijestNoch keine Bewertungen

- 3502073-Manual-Mercedes Benz CR1 IMMO EmulatorDokument29 Seiten3502073-Manual-Mercedes Benz CR1 IMMO EmulatorMauro Castilho100% (1)

- HHM1 Drawing NotesDokument14 SeitenHHM1 Drawing Notespawoe3064Noch keine Bewertungen

- Ford Fiesta Endura - Diagnostico Inyeccion EEC VDokument7 SeitenFord Fiesta Endura - Diagnostico Inyeccion EEC VPol Illa100% (1)

- TrimLite™ UT20706 HomeliteDokument7 SeitenTrimLite™ UT20706 HomeliteBKVNoch keine Bewertungen

- Fd30t3 ServiceDokument150 SeitenFd30t3 ServicePyae Phyoe Aung100% (1)

- Motec M4 - M48 - M8 - Manual - A5Dokument63 SeitenMotec M4 - M48 - M8 - Manual - A5Melissa TanNoch keine Bewertungen

- Must-On Board Diagnostics II PCED PDFDokument19 SeitenMust-On Board Diagnostics II PCED PDFRopama BraNoch keine Bewertungen

- LD - 2012 - CK Truck Electrical 112911 PDFDokument831 SeitenLD - 2012 - CK Truck Electrical 112911 PDFНаталья ЛаубенштайнNoch keine Bewertungen

- TK 860g 862g SVC Man PDFDokument67 SeitenTK 860g 862g SVC Man PDFMariano Javier Martinez VilaNoch keine Bewertungen

- Cessna 152 POHDokument21 SeitenCessna 152 POHVighnesh VNoch keine Bewertungen