Beruflich Dokumente

Kultur Dokumente

NT Big Breakthrough

Hochgeladen von

Tudor RatiuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

NT Big Breakthrough

Hochgeladen von

Tudor RatiuCopyright:

Verfügbare Formate

www.racetechmag.

com

ENGINE TECHNOLOGY NANOTECH ADVANCES

TINY TECHNOLOGY:

BIG BREAKTHROUGH

Despite its extra expense, nanotechnology is poised

to make major inroads into motorsport lubricants.

John Coxon investigates some rave reviews

HE CUT and thrust of touring car racing

isnt the first place you would look for

new and innovative technologies. But within

the paint-swapping action of the tin-top

boys a quiet revolution is currently taking

place. And if early results are anything to go

by, these latest developments could lead to

a major shift in technology for motorsport

lubes and, in the longer term, perhaps even

automotive oils in general.

Much of this early work is being done in

the specialised world of gearbox lubricants.

But given impressive results so far in the

British Touring Car Championship, already

plans are being developed to transfer the

technology onto engine developments. As

you read this, the first of the Millers

nanotechnology competition engine oils will

be pounding around the British circuits.

A staunch advocate of solid lubricants in

some types of transmission oils since the

advent of Black Moly in earlier

formulations, Martyn Mann, technical

director at Millers Oils in West Yorkshire,

was all too aware of the weaknesses and

problems associated with conventional

lubricants. Conventional lubricants are

traditionally sensitive to heat and their

ability to take heavy or shock loading in

gearboxes, particularly as temperatures

increase, can be of major concern. This

heat not only reduces the viscosity of the

oil but can have the secondary effect of

acting as an initiator for oxidation, he

claims. In engines as well, boundary and

mixed lubrication regimes are typically

observed in the piston ring at top and

bottom dead centre as well as in the valve

train and on gear flanks. While the wedge

of lubricant separates components under

hydrodynamic lubrication, in those zones

typified by boundary and mixed regimes

the presence of another entity is

necessary to prevent excessive wear.

EXTREME PRESSURE ADDITIVES

In engines this other entity is the antiwear component introduced to cling to

the metal parts when the wedge of oil

disappears. Until recently it has been the

province of ZDDP additives. In gearboxes,

particularly those characterised as API GL4

and GL5, the use of these EP or Extreme

Pressure additives is not always desirable

and so other less active sulphur-phosphorus

compounds are more generally used.

But conventional lubricants also have

other weaknesses. For instance, they do

not provide suitable solutions to high load

LEFT Exceptional transmission lube

performance is spearheading the

introduction of nanotechnology into the

engine crankcase lube in the BTCC

RIGHT The science coming to a race

championship near you ! Fullerenes

act like ball bearings to keep surfaces

apart under high load

00

www.racetechmag.com

July 09

www.racetechmag.com

ENGINE TECHNOLOGY

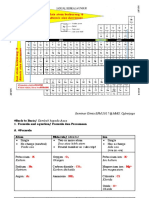

GEAR TOOTH LUBRICATION

At low speeds wear will take place near the tip of the gear tooth

whereas at higher speed this is transferred lower down the flank

Subscribe +44 (0) 208 446 2100

July 09

www.racetechmag.com

00

www.racetechmag.com

ENGINE TECHNOLOGY NANOTECH ADVANCES

ABOVE This football-shaped fullerene is

made entirely from carbon but now scientists

believe that fullerenes can be made from

many organic or inorganic substrates

cycling conditions when cavities formed on

or just underneath the metal surface can

cause fatigue wear. Neither do they afford

sufficient protection under low amplitude

oscillating conditions when the lubricant

can be expelled from the friction zone. A

perfect example of the latter is the

meshing between two gears in a gearbox

where the very high loads on the gears can

have the effect of squeezing out the oil. If

the movement is slow, the oil has sufficient

time to flow away and so thicker, more

viscous base oils tend to be used. At high

meshing speeds, full film lubrication will

take place on the gear flanks with mixed

conditions towards the tip of the gears. At

slow speeds the tips of the gears will

experience wear-inducing boundary layer

conditions unless some form of anti-wear

or EP additive is used.

small fissures from propagating in the

surface. On the formulation side, solid

lubricants can be readily dispersed into the

oil and incorporated into the finished

lubricant as either a complementary

additive or, if necessary, as a substitute for

any conventional anti-wear/extreme

pressure compounds.

However, when you consider solid

lubricants, thoughts of graphite and

molybdenum disulphide immediately spring

to mind. These dry powder lubricants are

perhaps more usually found in speciality

greases and some engine oils, but as well as

settling inside engine oil filters, graphite has

been linked to corrosion of some aluminium

A new and exciting concept was adopted:

nanotechnology and inorganic fullerenes

engine parts in the presence of water; as

such, it is not really suitable for engine oils.

On the other hand, molybdenum disulphide

has been successfully used in Millers high

shock transmission oils as late as last year (in

the form of Black Moly). But issues

associated with its manufacture its intense

blackness made it unpopular in the

blending plant. So when the opportunity

arose to redesign Millers complete range of

competition gearbox lubes, a new and

exciting concept was adopted:

nanotechnology and inorganic fullerenes, or

IF to those in the know.

Discovered in 1985 by Messrs Curl, Kroto

and Smalley at the University of Sussex

PHYSICAL BARRIER

Research at Millers Oils, which is associated

with no fewer than six teams in this

seasons BTCC, suggested that solid

lubricants could be the solution to these

limitations. To start off with, they are more

resistant to high temperatures and pressure

and form a physical barrier between the

mating surfaces themselves, says Mann.

This covering capacity is very high and

effectively fills in the surface asperities and

any surface cracks, presenting a much

smoother external surface to the lubricant.

By evening out the load across the surface,

solid lubricants can therefore interfere with

the mechanisms producing surface pitting,

galling or fretting as well as preventing

00

www.racetechmag.com

July 09

and Rice University, fullerenes are a family

of carbon allotropes molecules

composed entirely of carbon in the form

of hollow spheres, ellipsoids, tubes or

planes. When spherical in shape, they can

often be referred to as Buckyballs after

Richard Buckminster Fuller whose

particular type of shell or lattice structure

(geodesic dome) it resembles.

Fullerenes are similar in structure to

graphite, which is composed of stacked

sheets of linked hexagonal rings, but will

also contain a mixture of pentagonal or

heptagonal rings that would prevent a sheet

from being planar. Interestingly, the shape

of the association football is based on the

RIGHT In traditional solid

lubrication graphite

plates slide easily over

each other because of

the existence of weak

Van de Waals bonds

C60 fullerene, more precisely referred to as

the Buckminsterfullerene.

So significant was the discovery in the

scientific world, that in 1996 the trio were

awarded the Nobel Prize for Chemistry. In

1992, however, it was realised that graphite

was not the only element in the periodic

table that could form fullerenes or

nanotubes. In fact, any compound

exhibiting a layered structure is highly likely

to display this property. Thus molybdenum

disulphide or similar lattice structures could

all form closed polyhedra or nanotubes of

some type or another and, when in a multilayer nested form, could indeed be the

most stable of all.

www.racetechmag.com

ENGINE TECHNOLOGY NANOTECH ADVANCES

These fullerenes behave totally differently

as a solid lubricant to the more

conventional materials. Graphite, for

instance, relies on the different layers of the

lattice sliding over each other to reduce the

friction. Fullerenes, however, act more like

ball bearings between two surfaces and

under high load or shock can distort and

unravel to retain separation.

While conventional solid lubes work at the

molecular level, fullerenes work at the nano

level, which is considerably bigger. Sized

somewhere around 60 to 100 nanometres

(10-9 metres), these multi-layered spherical

and nested structures look very much like

onions under the microscope. The covalent

bonds link the metal and sulphide atoms

together within the same layer, which can

wrap around on itself to form a tube or

sphere. Between the layers, much weaker

Van-der-Waal interactions exist which assist

the layers to move relative to each other,

changing the shape of the structure

depending on the loads upon it. Because of

this, IFs are far more resistant to the physical

constraints and dont shear as easily as the

corresponding lamellar products.

If that were not enough, the lack of free

GEARBOX OILS

TRANSMISSION oils, although similar to

engine crankshaft oils in make-up, have totally

different demands. Like engine oils they need

excellent viscosity-temperature characteristics

but it is important to note that the viscosity

grades of gearbox oils are very different to

those of engine crankcase lubricants.

Not too viscous at low temperature, the

viscosity needs to be adequate at high

temperature to protect the highly loaded

gears. The oil is therefore said to need a

high viscosity index (VI). In engine oils

viscosity index can be increased by the

addition of modifiers, which cause the oil to

thicken as the temperature increases. This

means that thinner oils can be used to

combat the low temperature viscosity and

are quite normal in engine crankcase oil.

sulphide atoms makes them much more

chemically unreactive, perhaps even inert,

and therefore highly resistant to oxidation.

While important in gear oils, this is even

more so in crankcase lubricants.

In other forms of anti-wear, the additives

are generally drawn to the surfaces to be

However, unlike engine oils, gear oils

undergo a substantial amount of shearing in

operation and so oils need to be highly

shear-stable. Any VM long chain polymers

added to the mix would therefore get

chopped by the incessant action of the gears

and would rapidly become ineffective such

that the lubricant would become too thin

after a short while. For this reason the best

gearbox oils are high quality, high VI oils.

In addition to all the other additives required

(dispersants/detergents, anti-corrosion additives,

anti-oxidants, anti-foam etc), wear protection will

be needed according to the type of gears,

speed and loadings experienced. Thus different

grades and formulations may be specified

depending upon the running temperature of the

gearbox and the type of gears used.

protected by polar attraction. Although

having no overall electrical charge, either

positive or negative, the molecule has an

electrical dipole which gives it an affinity for

metallic surfaces. This can often compete

with other surface-active additives, for

instance the detergents, and is why it is

BELOW TH Motorsport reports a

much reduced spend on replacement

gearbox parts after using the new oil

in its Honda Integra

00

www.racetechmag.com

July 09

www.racetechmag.com

ENGINE TECHNOLOGY NANOTECH ADVANCES

unwise to add other compounds to engine

or gearbox oils when the surface activity of

one component may overpower that of

another to the detriment of the total. As EP

anti-wear components, fullerenes are not

surface active at all and so can be used

alongside other anti-wear or surface-active

components should that be necessary. This

therefore reduces the cost and complexity of

product testing in the early stages.

You may have the most exciting and

innovative product around but, as anyone

currently only financially viable with

specialised products like those of the Millers

range of competition gearbox oils. It is a

case of you only get what you pay for, if

ever there was one.

Among the teams in the BTCC using the

oil, there is nothing but enthusiasm for the

product. According to Trevor Humphrey of

TH Motorsport, which runs John George in

a Honda Integra, It seems to cope with

the heat much better than any other oil

and retains its viscosity far longer. The oil

seems to stick

to the gears

and dog rings

much better;

approaching

the halfway

point in the

season, we had

spent about only half of what we spent last

year on replacement gearbox parts.

Sequential gearboxes take some quite

brutal loads and the extra EP protection

during the shock loading seems to be

visibly noticeable. Humphrey also mentions

that the oil seems to be better at picking

up any fragments of metal and depositing

them into the filter. No doubt this is a

benefit of the reduced surface activity of

the anti-wear system allowing the

detergent/dispersant package to be more

effective. For teams paying their own bills,

such benefits would suggest that this is

becoming a must-have technology.

Indeed, the response to the performance

of the oil is such that plans are being

drawn up much earlier than originally

SYNTHETIC OIL Ball on plate rig test

The presence of nanotechnology reduces

friction slightly but gives a much cleaner

signal, indicating the reduced amount of

wear taking place

Fullerenes can distort and unravel under

high load or shock to retain separation

who deals with any form of chemicals in

the workplace will know, it is simply a nonstarter unless it passes all manner of health

and safety regulations. Since lubricants

consist of a cocktail of any number of

individual chemicals, each one having to be

individually approved, the matter is far

from straightforward. Fortunately, the

unreactive characteristic of the structure is

that same characteristic that makes the

fullerenes both non-toxic and

dermatologically safe. The product

therefore passes all current health and

safety standards.

The downside, almost inevitably, is the

cost. Bought in from a separate supplier

and carefully blended into the revised

formulations of the new range of oils, it is

anticipated to introduce inorganic fullerene

technology into the engine crankcase. To

date the new-for-2009 Team AON has

adopted a conservative strategy to its

crankcase oils, using a 5W-40 competition

oil classed as full synthetic with a surfaceactive triple ester formulation. This is as

you might expect for a team needing

absolute reliability as it progressively

extracts more power from the two-litre

engine. Based on its experience with the IF

oil in its gearboxes, though, the team is

now looking to transfer this

nanotechnology into the engine oil.

ENGINE OIL TRIALS

LUBE MECHANISM

The onion ring-like fullerene particles distort under load,

acting similar to ball bearings. They can also unravel

under shear forces to keep metal surfaces apart

00

www.racetechmag.com

July 09

We shall do some development work on

the dyno and examine the components

before committing ourselves, says Dick

Langford of Team AON engine supplier

Langford Performance Engineering

which, incidentally has already run a 0W20 formulation. The technology has been

very successful in the gearbox and we are

looking to transfer some of its advantages

into the engine oil.

Taking the conservative route, the engine

is to be dyno-tested on a 5W-40 nanotech

oil similar to that currently used in order to

provide benchmarking data. Assuming it is

successful, the viscosity will then be

reduced in the chase for reduced friction

and extra engine performance. RT

Das könnte Ihnen auch gefallen

- Ads AdspDokument20 SeitenAds AdspTudor RatiuNoch keine Bewertungen

- Safety Data Sheet Heavy-Duty Synthetic Diesel Oil: Revision Date: 1/28/2019Dokument11 SeitenSafety Data Sheet Heavy-Duty Synthetic Diesel Oil: Revision Date: 1/28/2019Tudor RatiuNoch keine Bewertungen

- Safety Data Sheet Heavy-Duty Synthetic Diesel Oil: Revision Date: 1/28/2019Dokument11 SeitenSafety Data Sheet Heavy-Duty Synthetic Diesel Oil: Revision Date: 1/28/2019Tudor RatiuNoch keine Bewertungen

- Diesel Fuel Additive Safety Data SheetDokument13 SeitenDiesel Fuel Additive Safety Data SheetTudor RatiuNoch keine Bewertungen

- HP Z620 Workstation: +3Uhfrpphqgv:LqgrzvDokument2 SeitenHP Z620 Workstation: +3Uhfrpphqgv:LqgrzvFairPlay SerbanNoch keine Bewertungen

- Safety Data Sheet Heavy-Duty Synthetic Diesel Oil: Revision Date: 1/28/2019Dokument11 SeitenSafety Data Sheet Heavy-Duty Synthetic Diesel Oil: Revision Date: 1/28/2019Tudor RatiuNoch keine Bewertungen

- Section 1. Identification: Safety Data SheetDokument17 SeitenSection 1. Identification: Safety Data SheetTudor RatiuNoch keine Bewertungen

- Amsoil AdaDokument13 SeitenAmsoil AdaTudor RatiuNoch keine Bewertungen

- Amsoil AddDokument13 SeitenAmsoil AddTudor RatiuNoch keine Bewertungen

- Section 1. Identification: Safety Data SheetDokument12 SeitenSection 1. Identification: Safety Data SheetTudor RatiuNoch keine Bewertungen

- Revised Safety Data Sheet for Chain LubeDokument13 SeitenRevised Safety Data Sheet for Chain LubeTudor RatiuNoch keine Bewertungen

- Amsoil ACBDokument9 SeitenAmsoil ACBTudor RatiuNoch keine Bewertungen

- Limited Slip Additive 1Dokument1 SeiteLimited Slip Additive 1Tudor RatiuNoch keine Bewertungen

- Limslip AdditiveDokument1 SeiteLimslip AdditiveTudor RatiuNoch keine Bewertungen

- Slip Lock: Differential AdditiveDokument1 SeiteSlip Lock: Differential AdditiveTudor RatiuNoch keine Bewertungen

- 1F Mark Thomas Racing TestimonialDokument1 Seite1F Mark Thomas Racing TestimonialTudor RatiuNoch keine Bewertungen

- Mathcad Installation GuideDokument49 SeitenMathcad Installation GuideTudor RatiuNoch keine Bewertungen

- Axle Lubricants Quick Reference Chart - EnglishDokument2 SeitenAxle Lubricants Quick Reference Chart - EnglishTudor RatiuNoch keine Bewertungen

- Synthetic Engine Oil Technology GuideDokument12 SeitenSynthetic Engine Oil Technology GuideTudor RatiuNoch keine Bewertungen

- 2018 Ford Mustang Owners Manual Version 1 Om en US 09 2017 2Dokument496 Seiten2018 Ford Mustang Owners Manual Version 1 Om en US 09 2017 2Tudor RatiuNoch keine Bewertungen

- Sturaco 7098Dokument1 SeiteSturaco 7098Tudor RatiuNoch keine Bewertungen

- 2017 Ford Mustang GT350 Supplement Version 2 - Su EN US - 02 - 2017Dokument69 Seiten2017 Ford Mustang GT350 Supplement Version 2 - Su EN US - 02 - 2017Tudor RatiuNoch keine Bewertungen

- Workstation AEC ISV One Pager - AutoCADDokument2 SeitenWorkstation AEC ISV One Pager - AutoCADTudor RatiuNoch keine Bewertungen

- Octanium Unleaded EU SDSDokument15 SeitenOctanium Unleaded EU SDSTudor RatiuNoch keine Bewertungen

- Manual Transmissions, Double-Clutch Transmissions and Automatic Transmissions For Cars List of Lubricants TE-ML 11Dokument7 SeitenManual Transmissions, Double-Clutch Transmissions and Automatic Transmissions For Cars List of Lubricants TE-ML 11houssem houssemNoch keine Bewertungen

- Ravenol AWD-H Fluid CertificateDokument2 SeitenRavenol AWD-H Fluid CertificateTudor RatiuNoch keine Bewertungen

- Rolf Atf Iiig ZFDokument1 SeiteRolf Atf Iiig ZFTudor RatiuNoch keine Bewertungen

- Oil Analysis Awd-H FluidDokument11 SeitenOil Analysis Awd-H FluidTudor RatiuNoch keine Bewertungen

- Octanium EU SDSDokument13 SeitenOctanium EU SDSTudor RatiuNoch keine Bewertungen

- Renewable Lubricants, IncDokument2 SeitenRenewable Lubricants, IncTudor RatiuNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Invincible Southern Extension Modification EA - ...Dokument123 SeitenInvincible Southern Extension Modification EA - ...Nicolás Andrés Bastián MonarcaNoch keine Bewertungen

- Nickel-Cobalt Laterite Deposits on Maniang IslandDokument7 SeitenNickel-Cobalt Laterite Deposits on Maniang IslandAmira SiregarNoch keine Bewertungen

- Chapter 6Dokument13 SeitenChapter 6aregawi weleabezgiNoch keine Bewertungen

- HaloalkaneDokument20 SeitenHaloalkaneHediarta Widiana PutraNoch keine Bewertungen

- OK Flux 10.62 (Low-Alloyed Steels)Dokument4 SeitenOK Flux 10.62 (Low-Alloyed Steels)גרבר פליקסNoch keine Bewertungen

- Congo Red Dye PDFDokument6 SeitenCongo Red Dye PDFkiranpatil1014532Noch keine Bewertungen

- Marco Material Datasheet Z1216Dokument1 SeiteMarco Material Datasheet Z1216radziNoch keine Bewertungen

- Advanced Materials for Turbofan Engine Fan BladesDokument9 SeitenAdvanced Materials for Turbofan Engine Fan BladesAhmed KhasawnehNoch keine Bewertungen

- IGCC-BGC Qualified Welders ListDokument4 SeitenIGCC-BGC Qualified Welders ListAhmedNoch keine Bewertungen

- DPP3 Gaseous State BansalDokument2 SeitenDPP3 Gaseous State BansalBhushanNoch keine Bewertungen

- Solubility and Solubilization: Mahendrasingh Ajitsingh Chavan M.Pharm I ST Year (Pharmaceutics) S.P.C.P. NagpurDokument33 SeitenSolubility and Solubilization: Mahendrasingh Ajitsingh Chavan M.Pharm I ST Year (Pharmaceutics) S.P.C.P. NagpurBolli SandeepNoch keine Bewertungen

- SikaFiber PPM-12 (900gr) PDFDokument3 SeitenSikaFiber PPM-12 (900gr) PDFDo ThaiducNoch keine Bewertungen

- Honeywell Sensing Temperature Sensors Line Guide 0 1109480Dokument12 SeitenHoneywell Sensing Temperature Sensors Line Guide 0 1109480X'mix ĐreamerNoch keine Bewertungen

- DTW 1359Dokument35 SeitenDTW 1359GANESH GNoch keine Bewertungen

- Grade 10 ScienceDokument2 SeitenGrade 10 ScienceEric Artocillo100% (1)

- MINERALOGY Notes 2022Dokument60 SeitenMINERALOGY Notes 2022Kisaakye GraceNoch keine Bewertungen

- Seminar Kimia SPM Mmu 2017 CG Adura Jawapan Kertas 2 PDFDokument48 SeitenSeminar Kimia SPM Mmu 2017 CG Adura Jawapan Kertas 2 PDFNoorleha Mohd YusoffNoch keine Bewertungen

- Lab Manual IPCDokument21 SeitenLab Manual IPCVijay Kumar TilakNoch keine Bewertungen

- "Chemical Names and Formulas": Grade 9 Science 2 QuarterDokument60 Seiten"Chemical Names and Formulas": Grade 9 Science 2 QuarterJulius Memeg PanayoNoch keine Bewertungen

- Welding Journal 1959 8Dokument142 SeitenWelding Journal 1959 8AlexeyNoch keine Bewertungen

- Gunj Glass Works. LTD Visit ReportDokument26 SeitenGunj Glass Works. LTD Visit ReportHM Bhatti100% (1)

- Enclosure Mansonry Wall Systems WorldwideDokument229 SeitenEnclosure Mansonry Wall Systems Worldwidexxxxx8086Noch keine Bewertungen

- A Powerpoint Presentaion On Ready-Mix ConcreteDokument22 SeitenA Powerpoint Presentaion On Ready-Mix ConcreteGowriSenthilNoch keine Bewertungen

- Foundation Engineering-I Design of Shall PDFDokument44 SeitenFoundation Engineering-I Design of Shall PDFAhmed MohammedNoch keine Bewertungen

- Cumene: Process Features Process BenefitsDokument2 SeitenCumene: Process Features Process BenefitsGerman Arrieta ZapaNoch keine Bewertungen

- Resistance Wire: Properties of Major AlloysDokument2 SeitenResistance Wire: Properties of Major Alloysyasir127Noch keine Bewertungen

- CDH Product Catalogue 2018 19Dokument340 SeitenCDH Product Catalogue 2018 19Matriya NitinNoch keine Bewertungen

- Glass Fiber SpecsDokument4 SeitenGlass Fiber SpecsJanus AntonioNoch keine Bewertungen

- Victor Welding and Heating NozzleDokument6 SeitenVictor Welding and Heating Nozzleagniva datta100% (1)

- B31.3 QuestionsDokument17 SeitenB31.3 Questionsemaanazeem67% (6)