Beruflich Dokumente

Kultur Dokumente

Cram

Hochgeladen von

jabo_briCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cram

Hochgeladen von

jabo_briCopyright:

Verfügbare Formate

clrcmical &z~inrcrhg

Science. Vol.

Printed in Great Britain.

47. No.

13/14. pp. 3557-3564.

1992.

oam-2509i92

01992klpunon

HYDRODYNAMICS

AND MASS TRANSFER

CHARACl-ERISTICS

REACTOR

WITH A DOWNFLOW

LIQUID

JET

P.H.M.R.

Cramers.

Department

DSM

A.A.C.M.

Beenackers

and

L.L.

of Chemical

Engineering,

University

Netherlands

9747 AG Groningen,

Research,

PO Box

18, 6160 MD

Geleen.

ss.oo+o.oo

PressLd

OF A LOOP-VENTURI

EJECTOR

van

of

Dierendonck

Groningen

Netherlands

ABSTRACT

The hydrodynamics

and mass

transfer

characteristics

of a loop-venturi

reactor

have

been investigated

using

a downflow

liquid

jet

ejector.

The specific

interfacial

area

of the ejector

and the main holding

vessel

were

determined

separately.

The cobalt

catalyzed

sulfite

oxidation

was used as a model system.

T@e measured

values of the

interfacial

area were in the range of 40.000 to 70.000 m*/m

in the ejector

and 500 to

2500 in the total system.

From this it can be concluded

that the Loop-venturi

reactor

is particularly

suitable

for

very

fast

reactions,

in which

the

liquid

phase

mass

transfer

is the reaction

limiting

step

of the process.

Further

it was

demonstrated

that

the flow

regime

in the ejector

has a huge

influence

on the .mass transfer

characteristics

of

the total

system.

From

the results

it is concluded

that

for

a

proper

design

of

a loop-venturi

reactor,

the ejector

and

the main

holding

vessel

should be considered

as two reactors

in series. which require

individual modeling.

KEYWORDS

Ejector,

venturi,

jet,

mass

transfer,

flow

regime,

modeling.

INTRODUCTION

In many chemical

processes,

the overall

production

rate

is often

limited by gas-liquid

mass

transfer.

Recently

gas-liquid

contactors

with

ejector-type

of

gas

distributors

have been recommended

for chemical

processes

if the interfacial

mass transfer

is the

rate-controlling

step

of the process.

Ejectors

are

devices

which

utilize

the kinetic

energy of a high velocity liquid jet in order to entrain and disperse

the gas phase.

transfer

of

loop-venturi

reactors

Investigations

on the hydrodynamics

and the mass

(LVR1 with liquid driven ejectors

have been reported

by several

authors

{Zahradnik

et

al.

(19821, Dutta

et al.

(19871 and van Dierendonck

et al.

(19881). Comparison

of

these

literature

data

is difficult,

since

different

ejector

configurations

and ranges

Until

now only one author

studied

the mass

of gas-liquid

flow

ratios

were

applied.

transfer

rates

of the ejector

and the vessel

separately

[Dirix

and van de Wiele.

19901. They demonstrated

that the mass transfer

of both the ejector

and vessel

are

From this it can be concluded that there

influenced

by the .flow regime

in the ejector.

is a need

to study

the

local

hydrodynamics

in ejectors,

rather

than

lumping

its

properties

with those of the reactor

volume.

The present

work

presents

an experimental

study on the influence

of the gas/liquid

flow

ratio

on the hydrodynamics

and the mass transfer

characteristics

of both the

the influence

of the initial

liquid

ejector

and the main holding

vessel.

Besides

that,

volume in the vessel was studied on the overall reactor

performance.

THEORETICAL

CONSIDERATIONS:

BASIC PRINCIPLES

OF TURBULENT

The

structural

cts 47:13/14-z

element

through

which

the

DISPERSION

initial

3557

dispersion

of

the

gas

takes

PlaCe

iS

Characteristicsof loop-venturireactor

Cl0

3559

The mass transfer

rates

in the loop-venturi

reactor

were studied by using the cobalt

catalyzed

sulfite

oxidation

as a model system.

Applying

air at ambient

pressure

and

sulfite

concentrations

higher

than its critical

value,

the reaction

orders

of oxygen,

sulfite

and cobalt

concentration

0 and

1 respectively

(Linek et al.,

1981).

are 2.

it is not

Since the reaction

rate constant

is very sensitive

to traces

of impurities,

Therefore

the reaction

rate

allowed

to adopt

kinetic

constants

from

the literature.

constant

(kr)

was

determined

for

each

charge

of

sulfite

solution

used

in

the

experiments_

The oxidation

rate of the sulfite

solution

was measured

with a standard

flat interface

stirred cell reactor.

Experimentally

it was verified

that all interfacial

area measurements

In

under

the

conditions

of

so-called

fast

reaction

(Ha

> 2).

interfacial

area can be calculated

with Eqs. (3) and (4)

Further,

the gas flow

both through

the ejector

and

assumed to be plug flow.

A more detailed

description

and procedures used, is given by Cramers (1993).

EXPERIMENTAL

RESULTS

in

of

the

the

were carried

this

regime,

out

the

main holding

vessel

iS

experimental

techniques

& DISCUSSION

regimes in the eiector

different

flow

regimes

have been

observed

in the ejector

depending

on the

If the gas

phase

dispersion

gas-liquid

flow

ratio,

i.e.

bubble

flow

and jet

flow.

occurs

in the mixing

tube of the ejector,

bubble flow

occurs.

If on the other hand

dispersion

takes place in the diffuser

or draft tube jet flow is observed.

Bubble flow

This flow

regime

is characterized

appears

if Iow gas-liquid

flow

ratios

are applied.

by the formation

of very small bubbles in a continuous

liquid phase (Fig. 3aI. Under

of the holding vessel

is relatively

small.

these flow

conditions

the dispersed

section

from

bubble to jet flow.

In the jet

At higher gas flow

rates

there is a transition

straightly

through

the mixing

flow

regime

the gas and the liquid phase are ejected

tube

into

the diffuser

(Fig.

3b)

or draft

tube,

depending

on the gas-liquid

flow

ratio. Visual observations

showed that in case the ejector

entrains the maximum amount

of gas, the mixing zone is located near the outlet of the ejector.

In this flow regime

the dispersed section in the column is large.

by the liquid

velocity

through

The transition

from

bubble to jet

flow

is influenced

transition

the nozzle

as shown in figure

4. It is seen that the flow

ratio

at the

This corresponds

well with the data

point decreases

by using higher liquid flow rates.

of Dirix and van de Wiele (1990).

TWO

DisDersion behavior in the main holding vessel

i.e. the dispersed

Fig. 2 shows that the holding vessel can be divided into two zones,

in the column are given

and the clear liquid zone. In Fig. 5 the clear liquid heights

that

the clear

the gas-liquid

flow

ratios.

Experimantally

it has been verified

vs.

liquid heig-ths in the column . It shows that the clear liquid height at the bottom of

This

is caused

by the

the column

decreases

with

increasing

liquid flow

velocities.

from the ejector.

For a

increasing

momentum of the faster

two phase jet discharging

nearly

constant

up to a

constant

liquid flow

rate,

the clear

liquid height

remains

certain

gas

flow

rate,

where

after

the clear

liquid

level

rapidly

decreases.

This

These

sudden change is also caused

by the change in flow

regime

in the ejector.

observations

prove that the flow regime in the ejector

has a significant

effect

on the

hydrodynamics

in the main holding vessel.

loop-venturi

total

area

and

eas

hold-un

of

Overall

averaeed

snecif ic

interfacial

reactor system

6

shows

the

the

influence

of

the

gas

flow

rate

on

the

overall

specific

Fig.

of the liquid

interfacial

area and gas hold-up

of the system

as a whole as function

increases

with both the gas flow

rate and the liquid

flow rate.

It is seen that a

flow rate. At the lower

are almost

proportional

gas gow

rates the

to the superficial

gas

gas

hold-ups

velocity.

and specific

interfacial

areas

For the higher

liquid flow

Cl0

P. H. M. R. CRAM~RSet al.

3560

rates

this linear dependency

vanishes

rather

regime as mentioned in the previous sections.

Further

it is seen

influence

systematic

from

Fig.

on either

abruptly,

caused

by

the

change

in

flow

6 that

the initial

diplength

the overall

gas

hold-up

and

of

the

ejector

has no

Visual

observations

a

ov

indicated

the

the

bubbles

discharging

from

the

ejector

vessel

did not

the

into

coalescence

(the

sulfite

solution

is a coalescence

inhibited

system 1. The

gas

and

liquid formed

a stable

dispersion;

a swarm

of

spherical

bubbles

of a steady

size.

Therefore

it can be concluded that the bubble swarm velocity

remains

nearly constant.

The latter

suggest

that under the homogeneous

bubble flow

conditions

the gas hold-up

the

dispersed

in

section

is

proportional

to

independently

of

the

cis .swarm;

dispersion height (as will be shown in the next sections).

Svecif ic interfacial

a

h m

e iector

The variation

of the specific

interfacial

area

in the ejector

with

the jet

velocity

and the gas-liquid

flow ratio

is shown in Fig. 7. In this, the total ejector

volume is

used as reactor

volume.

Since very small bubbles

are formed

in the ejector

(in the

range of 25-60

~1,

it is permissible

to disregard

the slip between

both phases,

so

that the gas hold-up can be calculated

from the gas and liquid throughputs.

Fig. 7 shows that extreme

high specific

interfacial

areas

are created

in the ejector

section.

Further is seen that both the jet velocity

and the change in flow regime have

a significant

effect

on the specific

interfacial

area of the ejector.

In the region of

lower gas flow

rates,

an increase

in gas flow

rate

results

in a larger

number of

bubbles

without

appreciably

Increasing

the

bubble

diameter,

thereby

proportionally

increasing

the interfacial

area.

In the region of higher gas flow

rates,

however,

due

to the

formation

of

larger

bubbles

and bubble

coalescence,

increase

of

the

the

specific

contact

area with gas flow rate decreases

and eventually

the specific

contact

area even starts

to decrease

with increasing

Q,.

The latter

effect

however

is caused

by a decrease

in reactor

volume (change in flow regime).

In fact

in this regime the

actual reactor

volume becomes

smaller

than the ejector

volume,

causing

the dramatic

decrease

of the total

interfacial

area

in the ejector

and thus is the specific

area

which is based on the total ejector volume.

Fig. 8 shows that Eq. (21 correlates

the experimental

data within

10 7. accuracy

for

C=19500.

It is seen that the theoretical

value of 0.4

indeed can be used as exponent

for

the energy

dissipation

rate,

is locally

indicating

that

the flow

in the ejector

isotropic.

This is also in agreement

with the results

of Nagel (19761. who studied the

two-phase

pipe flow

nozzle

which

is also

an ejector-type

of

digtri$utog.

Further.

Nagel (19761 measured

also mass transfer

areas of the order of 10

using the

m /m

sulfite oxidation as a model system.

Soecific

interfacial

area in the main holding vessel

The gas hold-up

and specific

interfacial

area of the dispersed

section

of the holding

vessel are shown in Fig. 9. It is seen that the power

supplied by the two-phase

jet

discharging

from

the ejector

has no effect

on either

Ed and adIs. This

implies that

the mass transfer

in this section

is only influenced

by the gas

that this section behaves like a bubbIe column, were the ejector

gas distributor.

Further

it follows

that

1 relative

to

areas (a

dls

flow rate,

confirming

is used as a special

the dispersed

section

of the LVR has much higher

interfaciai

conventional

bubble columns

in which gas distributors

such aS

of the ejector

sparger

rings and perforated

plates

are used. Therefore

the benefits

in the ejector

section,

but it

are not restricted

to a larger

rate of mass transfer

particularly

for

non-coalescing

also generates

smaller

bubbles

in the holding

vessel,

systems.

The specific

interfacial

area

on the

clear

liquid

volume.

of the column

As

mentioned,

(including

the clear

liquid zone) depends

liquid

level

decreases

using

the

clear

Characteristicsof loop-venturireactor

Cl0

higher

liquid

flow

rates,

resulting

in

higher

acol

3561

values.

The

decrease

of

the

clear

liquid level is attributed

to the higher two-phase

jet momentum

with increasing

liquid

circulation

rate,

causing

the bubbles

to penetrate

deeper

into the column.

For free

submerged

turbulent

jets

it

is known

that

the

penetration

depth

of

the

jet

is

proportional

to ,,t&e discharging

velocity

(Davies.

19721.

For

liquid

jets

this

length

is equal to (P

* .

,.a

Our data

empirically

a

which

is shown

P

More

co1

let

existing

=(P

correlate

as

1

Jet

in Fig.

(51

10. The two-phase

jet

power

is defined

as

= x/8*oL*(1-e

correlations

for

and

co

contain

the

energy

dissipation

per

unit

time

and per unit reactor

volume (kW/rn?.

Our results

however

indicate

that this approach

is unsuccessful

here,

since

the

column

characteristics

are

not

influenced

by the

volume

of

the holding

vessel.

Changing

the

reactor

volume

by varying

the

vessel

diameter

was studied

by Dutta et al. (19871. He noted that the mass transfer

of a

larger tank is more localized

near the ejector

than in a smatler

tank, indicating

that

the mass

transfer

rates

of the column

will

be influenced

by the vessel

geometry.

Further,

in the

literature

on looo-venturi

reactors

with

the

down-f low

ejectors,

penetration

depth

of

the

bubble

-dispersion

in the

main

holding

vessel

is never

mentioned,

though this is a very important

design and scale-up

parameter.

Therefore,

additional

research

on

vessel

the

bubble

ejector

to

depth

and

on

penetration

geometries

is required

to learn its influence

on the mass transfer

characteristics

of

the column section.

Effective

eiector

contribution

to the overall interfacial

area

Fig. 11 gives an impression

of the magnitude

of the effective

ejector

contribution

to

the overall

specific

interfacia1

area created

in the LVR. From this figure

it is seen

that in the bubble flow

regime

a large part of the overall

gas-liquid

mass transfer

takes place in the ejector.

Therefore,

in this flow

regime

it should be considered

as

a separate

reactor.

i.e. the loop-venturi

reactor

should be modeled as two reactors

in

series.

CONCLUSIONS

-.

In ejectors

extreme

high specific

contact

areas

are

created

and

in case

of

fast

reactions

the

ejector

should

be considered

as two

reactors

in

and holding

vessel

series,

which require separate

modeling.

Further it was shown that the flow regime in

the ejector

strongly

influences

the mass transfer

characteristics

of both the ejector

transfer

capacity

of the

and dispersed

section

of the holding vessel.

The high mass

Loop-venturi

reactor

makes

this

reactor

particularly

suitable

for

fast

reactions,

in

which the liquid phase mass transfer

is the reaction

limiting

step of the process.

In

case of downflow

ejectors,

the clear

liquid height

in the holding

vessel

is a very

important design parameter.

ACKNOWLEDGEMENTS

The

authors

gratefully

acknowledge

the

technical

and

Research

(Geleen.

Netheriands)

and Buss

AC

(Pratteln,

without

the contributions

would

not have

been possible

Hartholt and C. van de Hek.

financial

support

from

DSM

Switzerland).

This

research

students

G.

of

graduating

REFERENCES

Dirix

C.A.M.C.

and

K.

van

der

Wiele

(19901,

Mass

tranfer

in

jet

loop

reactors,

Chem.

P. H. M. R. CRAMERS

3562

Cl0

er ol.

Eng.

Ski.. 45(8), pp. 2333-2340

Dierendonck

van

L-L..

G.W.

Meindersma

and

and

G.

Leuteritz

(19881,

Scale

up

of

Gas-Liquid

reactions

made

simple

with

loop

reactors,

6th

European

Conference

on

Mixing,

287-295

Dutta

N-N.

and K-V.

Raghavan

(19871,

Mass Transfer

and Hydrodynamic

Characteristics

of

Loop Reactors

with Downflow

Liquid

Jet Ejector,

Chem.

Eng.

J., 36,

Pp. 111-121

Evans

(19911,

PhD

thesis,

A

study

of

a

Plunging

Jet

Bubble

Column,

University

of

Newcastle,

N.S. W.

Henzler

H. J.

Stoffsystem:

Das

fiir

das

Sogverhalten

von

Strahlsaugern

(1981).

flilssig-gasfbrmig.

Vt-Verfahrenstechnik,

lS(lO),

738-749

Hesketh

R-P.,

Russel

(19871,

Bubble

Size

in

Horizontal

A. W.

Etchells

and

T.W.F.

Pipelines,

AIChE Journal,

a.

663-667

Levich

V. G., Physicochemical

Hydrodynamics

(1962).

Prentice

Hail.

New York

Linek

V.

and

V.Vacek

(19811.

Chemical

Engineering

use

of

Catalyzed

Sulfite

Oxidation

Kinetics,

Chem.

Eng. Scl.,

36, pp.1746

Rylek

M.

and

J.

Zahradnik

(19871:

Chisa,

9th

International

Congress

of

Chemical

Engineering,

Praha,

August

31-September

4

Jets,,

water

Sande

van

de

E.

PhD

thesis,

Plunging

Air

entrainment

by

(1976).

University

of

Delft,

Netherlands

Mech.,

36(41,

pp. 639-655

Witte

J.H. (19691,

Mixing

Shocks

in two-phase

flow,

J. fluid

Hedrodynamic

Zahradnik

J..

F.

Kastanek,

J.

Kratochvil

and

M.

Rylek

[19821.

Characteristics

of

Gas-Liquid

beds

in Contactors

with

Ejector

type

Gas

Distributors,

Coil.

Czech,

Chem.

COmrfL, 47. pp.1939-1949

NOMENCLATURE

Ii

cat

C

d

D

E

J

kr

:

[I

V

We

E

P

Q

specific

interfacial

area

interfacial

area

concentration

concentration

at interface

diameter

diffusion

coefficient

power-input

per unit volume

molar

flux

reaction

rate

constant

power

volumetric

flow

rate

velocity

volume

Weber-number

hold-up

density

surface

tension

-3

m%.m

m

kmol.mm3

kmol.mm3

m

2 -1

m .s

W.mv3

kmol.m-2.s-1

m3. kmol-. s-l

w

-1

m3.s

-1

mb

m

kg. m3

N.m-

Subscriots:

A

b,j

:

co1

d

D

ej

G

jet

L

max

N

S

tot

oxygen

two-phase

jet

continuous

phase

critical

column

dispersed

phase

draft

tube

ejector

gas phase

liquid

jet

liquid

phase

maximum

nozzle

sauter

total

Cl0

Fig.

3563

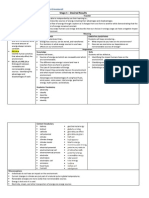

Characteristics of loop-venturi reactor

Scheme of the hydrodynamics and

pressure distribution across the

ejector.

(a) nozzle; (b) gas

suction chamber; (cl mixing tube;

(d) diffuser;

(e) draft tube.

Fig.

Schematic

set-up.

dia&am

ot experlmental

2.o

I

1.6 *

Jet

flow

Bubble

0.0

1.

Fig. 3

2

QL

(b)

(a)

Flow regimes

in the ejector:

(1) liquid jet;

(2) mixing

zone;

(3) bubbly flow.

Fig.

flow

(ml/h)

Transition

from

bubble

flow

regime

in ejector.

100000

~~~~

to

jet

&

80000

20000

0.0

0.3

Qe,=4

oU=s

0.9

1.2

area

in the

0.6

QGQ,

Fig.

Clear liquid heights

vessel.

in holding

Fig.

Specific

ejector.

interfacial

1.5

P. H. M. R. CRAMIW

kxrk/s)

Fig.

Cl0

et al.

Effect

of the liquid flow rate,

gas flow

rate and initial

liquid

the overall

specific

interfacial

area of the total

system;

(0: gashold-up:

o: VL= 62.4 1; .VZ V = 70 1.; A: VL= 80 1.).

volume

on

01

0.0

aFig.

1500

(m-7

Predicted

a-values

mental

a-values.

vs.

the

0.5

Fig.

2.5

0.0

01

0.00

0.02

0.04

0.05

01

0.06

lb

1.5 2.0

Specific

interfacial

area

and

gas

hold-up

in the dispersed

section

of the column.

500

Fig.

caw-4

kmk.)

experi-

1.0

Specific

interfacial

are of the

total column section

(including

the clear

liquid section).

Fig.

11

bnLs)

Effective

ejector

contributio

to

the

overall

interfacial

area

based

on total

system

volume

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Koyo Oil SealDokument119 SeitenKoyo Oil Sealvicksgeorge100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- IBA Test Prep MaterialDokument3 SeitenIBA Test Prep MaterialAmmar Hassan67% (9)

- c1 - Intermolecular ForcesDokument69 Seitenc1 - Intermolecular ForcesNabilah MustafaNoch keine Bewertungen

- Experiment 6 (Calibration of Temperature Measuring Devices - A4)Dokument16 SeitenExperiment 6 (Calibration of Temperature Measuring Devices - A4)Jamiel CatapangNoch keine Bewertungen

- Science 8 ExamDokument5 SeitenScience 8 Examangge21100% (1)

- Lets Rock ItDokument17 SeitenLets Rock Itapi-312503373Noch keine Bewertungen

- A Computational Fluid Dynamics Model of Algal Growth Development and ValidationDokument11 SeitenA Computational Fluid Dynamics Model of Algal Growth Development and ValidationsuyyinNoch keine Bewertungen

- UBD Physics Unit 2 - Energy and The EnviornmentDokument5 SeitenUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaNoch keine Bewertungen

- WP Correct Weight-Handling enDokument4 SeitenWP Correct Weight-Handling enbertan dağıstanlıNoch keine Bewertungen

- CSL361 Programming Assignment 2:: March 9, 2014Dokument2 SeitenCSL361 Programming Assignment 2:: March 9, 2014Jam SinghNoch keine Bewertungen

- STAD Balancing ValvesDokument10 SeitenSTAD Balancing ValvesNestramiNoch keine Bewertungen

- Physcis Unit Test 3Dokument5 SeitenPhyscis Unit Test 3Yuta NeyaNoch keine Bewertungen

- Prilling TowerDokument29 SeitenPrilling TowerMuhammad Saleem SukheraNoch keine Bewertungen

- Zdorovye - The Means To PrepareDokument4 SeitenZdorovye - The Means To PrepareBrett DrinkwaterNoch keine Bewertungen

- GNSS Based Synchronisation Solutions: Rakon AdvantagesDokument2 SeitenGNSS Based Synchronisation Solutions: Rakon AdvantagesullascsNoch keine Bewertungen

- IB Lab - 07 Loaded Metre Rule (DCP)Dokument3 SeitenIB Lab - 07 Loaded Metre Rule (DCP)ringo_tigerNoch keine Bewertungen

- Iec 60794-1-22Dokument80 SeitenIec 60794-1-22Pablo DaitaNoch keine Bewertungen

- Purga Fondo BBV 980 A PDFDokument2 SeitenPurga Fondo BBV 980 A PDFaugusto7777Noch keine Bewertungen

- Arc - Wleding Final Exam PDFDokument13 SeitenArc - Wleding Final Exam PDFronaldo de guzmanNoch keine Bewertungen

- Refratometro LSC 1022Dokument51 SeitenRefratometro LSC 1022Letícia HaukNoch keine Bewertungen

- Kinetic Theory of Gases 2018Dokument23 SeitenKinetic Theory of Gases 2018PalomaNoch keine Bewertungen

- Class 7 - 9 State Space Representation To Transfer Function and Vice VersaDokument13 SeitenClass 7 - 9 State Space Representation To Transfer Function and Vice Versaapi-26676616Noch keine Bewertungen

- Ation Words That Best Completes The SentenceDokument8 SeitenAtion Words That Best Completes The SentenceMG's Fhya Part II0% (1)

- Catalog PlasfabDokument8 SeitenCatalog PlasfabDeep ZaveriNoch keine Bewertungen

- TCRT 1000Dokument7 SeitenTCRT 1000Costel MirzacNoch keine Bewertungen

- Derrick Scott Van Heerden - Mathemagical Music Scales, 2013Dokument54 SeitenDerrick Scott Van Heerden - Mathemagical Music Scales, 2013Tiago Ramos100% (1)

- Duraturf Product Group Harver Magnetic Induction: Harver Induction InfoDokument8 SeitenDuraturf Product Group Harver Magnetic Induction: Harver Induction Infoadrianajones4Noch keine Bewertungen

- Electrostatics FormulaDokument2 SeitenElectrostatics FormulaAbdul AhadNoch keine Bewertungen

- Borzone Et Al 1996Dokument13 SeitenBorzone Et Al 1996Daiane Evangelista AvizNoch keine Bewertungen

- 13chapter STEEL-CONCRETE COMPOSITE STRUCTURAL MEMBERSDokument23 Seiten13chapter STEEL-CONCRETE COMPOSITE STRUCTURAL MEMBERSTarif Aziz MarufNoch keine Bewertungen