Beruflich Dokumente

Kultur Dokumente

Fabrication Scope for FRP Tanks

Hochgeladen von

Rajesh RamOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fabrication Scope for FRP Tanks

Hochgeladen von

Rajesh RamCopyright:

Verfügbare Formate

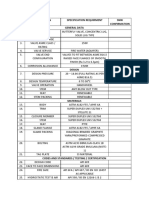

CLIENT : SOLVAY SPECIALITIES INDIA PVT. LTD.

Doc No.

PROJECT NO. : 44QS8700

Rev No.

Annexure-I of

44QS8700/ER.13/0030

/0A/A4

B

Date

26-Dec-14

PROJECT : PROJECT FLOURISH

Annexure-I: Scope Document for Fabrication of FRP Tanks

Vendor has to submit this document duly filled-in (stamped & signed) along with the offer. Without this document, offer will be treated as an incomplete &

liable for rejection.

FRP Tanks T-5511, T-5512

Sr

No.

Description

Vendor's Scope

Vendors scope include the design, engineering, procurement, manufacturing, inspection

and testing, primer painting, packing, forwarding and supply at site, providing mechanical

design, material and workmanship guarantee of FRP Tanks as per the requirements

specified in the attached MDS, standard specification.

Vendor's Reply with

Offer

Jacobs' Remarks

Accepted

Vendor to design FRP Tank's as per BS EN 13121-3 Ed.2008+A1:2010

The Vendor's scope of work/supply shall include, but is not limited to, the following:

FRP Tank Design Calculations

Platform, Ladder and all around Handrail per Jacobs's Std.IND-VSD-152

Vendor Data and Documentation as required by "SDR"

Calculations for lifting devices

Anchorage calculation

Spare Parts

o 10% Spare Bolting

o (3) Spare Gaskets for each blinded opening

All required testing per Code

Preparation for shipment and load-out of FRP Tanks to Panoli, Gujarat

All Flanges to be Blanked off with 12 thk. plywood or steel disc, each disc to be

secured with a minimum of 4 bolts.

Accepted

Painting:

Surface preparation and External/Internal Painting on CS parts at shop as mentioned

below:

A) Surface Preparation Blast cleaning to Swedish Specification

SIS-05-5900 with grade SA2-3

B) Priming Zinc rich epoxy primer DFT of 40 microns

(Zinc approx. 90% and more by weight)

3

Accepted

C) Intermediate Coat 2 pack epoxy with micaceous Iron - Oxide

DFT of 100 microns

D) Finish Coat Polyamide cured phenolic epoxy, DFT of 40 microns

Note:

Where surface preparation by blast cleaning is impracticable, mechanical cleaning is to

be carried out followed by epoxy zinc phosphate primer of 40 microns DFT instead

of zinc rich epoxy primer. Subsequent layers will remain unchanged.

Painting Colour Coding: Light Grey

Colour reference no. 631 as per I.S-5

Wind Code - IS875 - 1987 (Part-3)

Basic Wind Speed - 44m/s

Terrain Category - 2, Equipment class - 1

Risk Factor - 1

Topography Factor - 1

Percent Wind for Hydrotest - 33%

Seismic Code - IS1893 - 2005 (Part-4)

Importance Factor - 1.75

Earthquake Zone no.- 3

Earthquake Zone Factor - 0.16

Soil Type - Soft

Force Factor R - 3

Following documents to be furnished by vendor alongwith Bid as a minimum:

a) Unit price rate for nozzles for sizes 1 NB 150# SOFF thro to including

NB 150# SORF with or without blind flanges, gaskets and bolting.

b) Unit rate for any pipe support cleats Kg. Basis.

c) Sample Quality Plan

d) Sub-vendor List

e) Confirmation of compliance to Requisition.

Accepted

24

Accepted

Refer supplier document schedule attached along with enquiry.

Temporary Protection of FRP Tanks & Packings

For FRP equipment provide stoppers against rolling, providing blind covers but have

open vent provision storage, avoiding accidental fall on sharp pointed objects or on

solid ground. Providing strapping during transporting and any other protection

required during handling, transporting or erecting.

Vendor to furnish allowable nozzle Load for all process connections greater than 2" during

detail engineering stage.

All Tolerances will be as per Code.

Inspection and Test Plan as per Annexure II

Accepted

accepted

accepted

accepted

Page 1 of 1

Das könnte Ihnen auch gefallen

- Erp Packages PDFDokument2 SeitenErp Packages PDFAlexNoch keine Bewertungen

- Pressure Vacuum Breather ValvesDokument4 SeitenPressure Vacuum Breather ValvesAdhitya DarmadiNoch keine Bewertungen

- FiatechDokument19 SeitenFiatechJm AzanaNoch keine Bewertungen

- Anvil Pipe Hanger CatalogueDokument252 SeitenAnvil Pipe Hanger Cataloguezahra danNoch keine Bewertungen

- GTL technology converts natural gas to liquid fuelsDokument18 SeitenGTL technology converts natural gas to liquid fuelsShashwat VatsaNoch keine Bewertungen

- Cold Spring of Restrained Piping SystemDokument5 SeitenCold Spring of Restrained Piping Systemsateesh chandNoch keine Bewertungen

- Lecture - Solar Geometry - 2017Dokument79 SeitenLecture - Solar Geometry - 2017Xue AdamsNoch keine Bewertungen

- PV QCDokument1 SeitePV QCrameshqcNoch keine Bewertungen

- Cosasco Access FittingsDokument2 SeitenCosasco Access FittingsE_Rodriguez20Noch keine Bewertungen

- The Complete Guide to Telephone Interview Questions and AnswersVon EverandThe Complete Guide to Telephone Interview Questions and AnswersNoch keine Bewertungen

- Valves Shell Design StrengthDokument10 SeitenValves Shell Design Strengthمحمد عبدالدايمNoch keine Bewertungen

- MOUNDED BULLETS FOR LPG STORAGEDokument41 SeitenMOUNDED BULLETS FOR LPG STORAGEMarco Dos Santos NevesNoch keine Bewertungen

- Risk ManagementDokument33 SeitenRisk ManagementRukii EllinaNoch keine Bewertungen

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionVon EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNoch keine Bewertungen

- STS05120Dokument20 SeitenSTS05120JunaidAhmedNoch keine Bewertungen

- Stud Bolts 2hex Nuts Weight Imperial SizesDokument12 SeitenStud Bolts 2hex Nuts Weight Imperial SizesBryan Mauricio Diaz Avila100% (1)

- Piping Mat Specs Line Class Index Hb-202Dokument6 SeitenPiping Mat Specs Line Class Index Hb-202OswaldoDCBNoch keine Bewertungen

- PDO Material Receipt Document ChecklistDokument1 SeitePDO Material Receipt Document ChecklistJames KentNoch keine Bewertungen

- GU-611 - PDO Guide To Engineering Standards and ProceduresDokument1 SeiteGU-611 - PDO Guide To Engineering Standards and ProceduresDhamuNoch keine Bewertungen

- Steel Equal Angles PropDokument6 SeitenSteel Equal Angles PropRAMSINGH CHAUHANNoch keine Bewertungen

- Picom User Guide (1st Issue) - 28!11!07Dokument36 SeitenPicom User Guide (1st Issue) - 28!11!07hariharanoilgasNoch keine Bewertungen

- Bahador, A. Prediction of Bulk Modulus and Volumetric Expansion Coefficient of Water For Leat Tightness Test of Pipelines. 2009Dokument5 SeitenBahador, A. Prediction of Bulk Modulus and Volumetric Expansion Coefficient of Water For Leat Tightness Test of Pipelines. 2009IvanRodriguezNoch keine Bewertungen

- PDS Pipe Supports ModelerDokument412 SeitenPDS Pipe Supports ModelershanmugamNoch keine Bewertungen

- Mechanical Engineer Syed Zain Ali resumeDokument5 SeitenMechanical Engineer Syed Zain Ali resumeSyedZainAliNoch keine Bewertungen

- 77 06 650 506reballotDokument7 Seiten77 06 650 506reballotVinicius GobboNoch keine Bewertungen

- Profile of BSEDokument45 SeitenProfile of BSEprabhu_jay23Noch keine Bewertungen

- Steel Pipe PilesDokument12 SeitenSteel Pipe PilesSteven LiyantoNoch keine Bewertungen

- Format From EIL 5 2744 0212 F1 - REV2Dokument27 SeitenFormat From EIL 5 2744 0212 F1 - REV2sshastrimechNoch keine Bewertungen

- Certified Engineering Technologist A Complete Guide - 2020 EditionVon EverandCertified Engineering Technologist A Complete Guide - 2020 EditionNoch keine Bewertungen

- Material Selection GuideDokument5 SeitenMaterial Selection GuideAnil S ChaudharyNoch keine Bewertungen

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Dokument14 SeitenA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNoch keine Bewertungen

- Exxon IP 10-3-4 Axial Compressors For Air ServiceDokument7 SeitenExxon IP 10-3-4 Axial Compressors For Air ServiceGilvan SilvaNoch keine Bewertungen

- Vecom - Japanese BlackDokument2 SeitenVecom - Japanese Blackdiaccessltd_17172961Noch keine Bewertungen

- Pipeline Equipment and ConstructionDokument16 SeitenPipeline Equipment and ConstructionHansLopezNoch keine Bewertungen

- 66-165 - A804 - Fire Penetration Details (Version)Dokument1 Seite66-165 - A804 - Fire Penetration Details (Version)Parth DaxiniNoch keine Bewertungen

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDokument2 SeitenSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNoch keine Bewertungen

- Cost Esti Mate Classi FI Cati ON System - AS Appli ED I N MAI Ntenance Turnarounds FOR THE Process I Ndustri ESDokument5 SeitenCost Esti Mate Classi FI Cati ON System - AS Appli ED I N MAI Ntenance Turnarounds FOR THE Process I Ndustri ES이라크인비비Noch keine Bewertungen

- Thermoplastic TanksDokument8 SeitenThermoplastic TankssegomezpNoch keine Bewertungen

- Pip Adg001 Specification For Developing Practices: Work ProcessesDokument21 SeitenPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNoch keine Bewertungen

- Everything You Need to Know About Small Bore Piping SystemsDokument69 SeitenEverything You Need to Know About Small Bore Piping SystemsbashirNoch keine Bewertungen

- Valve & Flange Box FundamentalsDokument20 SeitenValve & Flange Box Fundamentalsautin3:16Noch keine Bewertungen

- Trim Chart API 600Dokument16 SeitenTrim Chart API 600Pradipta DwiNoch keine Bewertungen

- Sectional ValvesDokument107 SeitenSectional Valveswalk111Noch keine Bewertungen

- Double Wiper SealDokument1 SeiteDouble Wiper SealJoeNoch keine Bewertungen

- TDW Tapping Fittings: Sizes: 2" - 30"Dokument3 SeitenTDW Tapping Fittings: Sizes: 2" - 30"Gabriel OvillaNoch keine Bewertungen

- J95. Islamic Shariah Market Principles - QRFMDokument16 SeitenJ95. Islamic Shariah Market Principles - QRFMfahad100% (1)

- Emergency Vent Cover Installation ManualDokument16 SeitenEmergency Vent Cover Installation ManualandyNoch keine Bewertungen

- Datasheet For Butterfly ValveDokument3 SeitenDatasheet For Butterfly ValvevishnuvarthanNoch keine Bewertungen

- Asme Secc XDokument40 SeitenAsme Secc XAndres Felipe TorresNoch keine Bewertungen

- Sample UDS DocumentDokument14 SeitenSample UDS Documentnilesh_raykarNoch keine Bewertungen

- ACC FAC and Cycle Chemistry SessionDokument37 SeitenACC FAC and Cycle Chemistry Sessionchemicalchouhan9303Noch keine Bewertungen

- Profile of the International Pump Industry: Market Prospects to 2010Von EverandProfile of the International Pump Industry: Market Prospects to 2010Bewertung: 1 von 5 Sternen1/5 (1)

- Earthquake Code For TurkeyDokument161 SeitenEarthquake Code For Turkeywpchen2Noch keine Bewertungen

- Chapter 2-RRL BindersDokument4 SeitenChapter 2-RRL BindersAlfred Louie RimorinNoch keine Bewertungen

- Plant LayoutDokument8 SeitenPlant Layoutrsmallwood395895100% (1)

- Basalt Rock Fiber Seminar ReportDokument25 SeitenBasalt Rock Fiber Seminar Reportsaqib mujtabaNoch keine Bewertungen

- GP 09-04-01Dokument31 SeitenGP 09-04-01Anbarasan Perumal100% (1)

- Stack Wind CalculationsDokument5 SeitenStack Wind CalculationsJosé García100% (2)

- Industrial Engineer: Passbooks Study GuideVon EverandIndustrial Engineer: Passbooks Study GuideNoch keine Bewertungen

- Chemical Compatibility Chart - LDPE, HDPE, PP, Teflon ResistanceDokument1 SeiteChemical Compatibility Chart - LDPE, HDPE, PP, Teflon ResistanceRajesh RamNoch keine Bewertungen

- PipesDokument8 SeitenPipesRajesh RamNoch keine Bewertungen

- Sr. No. Id Od Thk. TPL DescriptionDokument18 SeitenSr. No. Id Od Thk. TPL DescriptionRajesh RamNoch keine Bewertungen

- Allowable Tensile Strength Allowableb Arcol Value Glass ContentDokument1 SeiteAllowable Tensile Strength Allowableb Arcol Value Glass ContentRajesh RamNoch keine Bewertungen

- Guidelines / Instructions To Vendor Documentation For Nirma ProjectDokument2 SeitenGuidelines / Instructions To Vendor Documentation For Nirma ProjectRajesh RamNoch keine Bewertungen

- 06 Annexure IIDokument2 Seiten06 Annexure IIRajesh RamNoch keine Bewertungen

- 06 Annexure IIDokument2 Seiten06 Annexure IIRajesh RamNoch keine Bewertungen

- JR Fibreglass Industries Pvt. LTDDokument2 SeitenJR Fibreglass Industries Pvt. LTDRajesh RamNoch keine Bewertungen

- ASME B16.5 Flanges PDFDokument50 SeitenASME B16.5 Flanges PDFPedro De Mesquita Soares CamposNoch keine Bewertungen

- Testing ProcedureDokument2 SeitenTesting ProcedureRajesh RamNoch keine Bewertungen

- AstmDokument5 SeitenAstmRajesh RamNoch keine Bewertungen

- Utus, Bond, Lap, PeelDokument15 SeitenUtus, Bond, Lap, PeelRajesh RamNoch keine Bewertungen

- Fans & Blowers-Calculation of PowerDokument20 SeitenFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- E Booklet Feeding The ChakrasDokument20 SeitenE Booklet Feeding The ChakrasVibrating PickleNoch keine Bewertungen

- Test For Cations, Anions and Gases (QA) NotesDokument10 SeitenTest For Cations, Anions and Gases (QA) Noteschong56100% (2)

- International Journal of Plasticity: Rolf Mahnken, Andreas Schneidt, Thomas AntretterDokument22 SeitenInternational Journal of Plasticity: Rolf Mahnken, Andreas Schneidt, Thomas AntretterKhouloud GharbiNoch keine Bewertungen

- Concrete Strength by Brick ChipsDokument10 SeitenConcrete Strength by Brick ChipsHamayet RaselNoch keine Bewertungen

- MScSYChem18 19Dokument40 SeitenMScSYChem18 19kumarNoch keine Bewertungen

- Magnaglo 14a Dry PowderDokument2 SeitenMagnaglo 14a Dry Powdermlowe680Noch keine Bewertungen

- Essco Product CatalogueDokument23 SeitenEssco Product CatalogueMohammedAasimUmairNoch keine Bewertungen

- 20b. Global S CycleDokument15 Seiten20b. Global S CyclerossydaNoch keine Bewertungen

- Against Water Hummer PDFDokument36 SeitenAgainst Water Hummer PDFDenstar Ricardo SilalahiNoch keine Bewertungen

- Cape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDokument5 SeitenCape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDestinee SullivanNoch keine Bewertungen

- Deltaweld 652Dokument26 SeitenDeltaweld 652Hugo RodriguezNoch keine Bewertungen

- Instruction and Technical Manual for CentrifugesDokument56 SeitenInstruction and Technical Manual for CentrifugesDiana RaieNoch keine Bewertungen

- P1501-TOS-70000-PP-RP-0002 - Revb0 Piping Stress Analysis Design BasisDokument49 SeitenP1501-TOS-70000-PP-RP-0002 - Revb0 Piping Stress Analysis Design BasisBharuk Mech50% (2)

- BOF1Dokument3 SeitenBOF1Skartini DayNoch keine Bewertungen

- General Characteristics of Bacteria and MollicutesDokument13 SeitenGeneral Characteristics of Bacteria and MollicutesPrincess Mehra0% (1)

- LCGC Europe 2001Dokument4 SeitenLCGC Europe 2001Jhonattan BaezNoch keine Bewertungen

- ESSO Shaft Sealing Systems SpecificationDokument13 SeitenESSO Shaft Sealing Systems SpecificationFlorin Daniel AnghelNoch keine Bewertungen

- 5 Steps Homemade BiogasDokument5 Seiten5 Steps Homemade BiogasJan Aguilar EstefaniNoch keine Bewertungen

- PERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Dokument10 SeitenPERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Angel Ombid100% (1)

- Spot WeldingDokument5 SeitenSpot WeldingRao MaazNoch keine Bewertungen

- Presentation1. AEC GeoTech LANDFILLDokument22 SeitenPresentation1. AEC GeoTech LANDFILLAyan BorgohainNoch keine Bewertungen

- Quality Assurance Plan Product Name: Stone Ware PipesDokument3 SeitenQuality Assurance Plan Product Name: Stone Ware PipesAnonymous ciKyr0tNoch keine Bewertungen

- 02 Heubach No 00181 ZPA RZ Epoxy Dispersion WDokument2 Seiten02 Heubach No 00181 ZPA RZ Epoxy Dispersion WnanoNoch keine Bewertungen

- Role of DSS in RefineryDokument24 SeitenRole of DSS in Refineryramadoss_alwar7307100% (1)

- ArcelorMittal Projects Steel Pipe ProductionDokument20 SeitenArcelorMittal Projects Steel Pipe Productionanil-kumar-singh-6674Noch keine Bewertungen

- 810-701 CRSeals Handbook PRESSURE Apr-2018Dokument4 Seiten810-701 CRSeals Handbook PRESSURE Apr-2018Anonymous VNu3ODGavNoch keine Bewertungen

- Land Deep Production Casings in Menengai Geothermal FieldDokument30 SeitenLand Deep Production Casings in Menengai Geothermal FieldShafeeq ChappuNoch keine Bewertungen

- SIP MeenakshDokument17 SeitenSIP MeenakshRati GuptaNoch keine Bewertungen

- Aldehyde, Ketones and Carboxylic AcidDokument18 SeitenAldehyde, Ketones and Carboxylic AcidPRADEEP CNoch keine Bewertungen

- RAC (ME 802) by Prof. Sangeev S. TomarDokument9 SeitenRAC (ME 802) by Prof. Sangeev S. Tomarapi-19832143Noch keine Bewertungen