Beruflich Dokumente

Kultur Dokumente

CSTR

Hochgeladen von

hishamCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CSTR

Hochgeladen von

hishamCopyright:

Verfügbare Formate

1.

0 PROCEDURE

1.1 General Start Up Procedure

1. The following solutions are prepared :

a. 20L of Sodium Hydroxide, NaOH (0.1M)

b. 20L of Ethyl Acetate, Et (Ac) (0.1M)

c. 1L of Hydrochloric Acid, HCl (0.25M) for quenching

2. All valves are initially ensured closed.

3. The feed tanks are changed as follows :

a. The charge port caps for tank T1 and T2 are opened.

b. NaOH solution is carefully poured into vessel T2 and Et(Ac) solution is poured

into vessel T1.

c. The charge port caps for both tanks are closed.

4. The power for the control panel is turned on.

5. The heater is not switched on unless it is fully submerged in the liquid. The liquid

level is always maintained above the height of the heater to avoid damage to the

heater.

6. The stirrer assembly is made sure secured properly to avoid damage to the mechanical

seal.

7. All tubings are inspected periodically for leakage and worn out. Leakage might cause

damage to the equipments by corrosive reactants.

8. The unit is then ready for experiment.

1.2 Experimental Procedure

1. The general start up procedures are set up.

2. The overflow tube is adjusted to give a working volume of 2.5L.

3. Pump P1 is switched on and 1.25L of Ethyl Acetate is pumped from the feed pump

into the reactor. Then pump P2 is switched on and 1.25L of 0.1 NaOH into the reactor.

When the reactants volume reached 2.5L, pump P2 is switched off and the timer is

started immediately.

4. At the same time, 10ml of 0.25M HCl is prepared into a flask to quench with the

sample.

5. The sample is titrated with 0.1M Sodium Hydroxide, NaOH in the hood chamber to

determine the amount of unreacted HCl in the sample. 3 drops of phenolphthalein is

added to see the changes of solution colour.

6. Step 4 and 5 is repeated for reaction times 1,5,10,15,20 and 25 minutes.

7. All swith are switched of after the experiment done.

1.3 General Shut Down Procedure

1. Both pumps P1 and P2 are switched off. Stirrer also switched off.

2. The power for the control panel is turned off.

3. All apparatus and reactor are made sure cleaned properly after the experiment.

RECOMMENDATION

Throughout the experiment, in order to reduce the potential of inaccuracy in obtaining

measured data, a few recommendations and precautions must be considered during

performing the experiment.

First of all, for each experiment we must do the start up and start down procedure in

order to make sure there is no left over in the chamber and no leakage at the equipment.

Next, during the experiment, the titration should be repeated at least two times to get

accurate values and then take the average to make comparisons. This can minimize the error.

Thirdly, to improve the reading and get the better results, the positions of the eyes

must be parallel to the meniscus. Next, we should rinse all the apparatus before we use it and

again we must rinse the apparatus for the next solution. This is to ensure that all the beakers,

or burette is clean so that any chemical that we put into these apparatus does not react with

with the left over chemicals and hence do not disturb the reading.

Fourth, the titration should carefully conducted. Add the NaOH drop by drop using the

burette slowly. Titration should be immediately stopped when the indicator turned pink. This

to because a lot of error comes from titration. For a safety, do the titration only in the fume

chamber while wearing gloves. This is to ensure students safety.

Fifth, we should divide into two groups which is the first team in charge of the CSTR

machine while another group run the back titration procedures after the sample collected.

Last but not least, the stopper must immediately start up when the reactants volume

reach accurately 2.5L.

REFERENCES

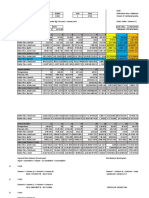

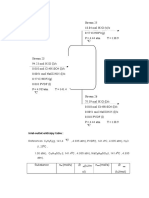

APPENDIX

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Mass & Energy BalanceDokument4 SeitenMass & Energy BalancehishamNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Photo BioreactorDokument4 SeitenPhoto BioreactorhishamNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Profitibilty AnalysisDokument2 SeitenProfitibilty AnalysishishamNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Mass Balance and Mole BalanceDokument5 SeitenMass Balance and Mole BalancehishamNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Full Report Ip Sem 4Dokument75 SeitenFull Report Ip Sem 4hishamNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- CP For Pinch (E-101 and E-102) ..Dokument2 SeitenCP For Pinch (E-101 and E-102) ..hishamNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Heuristics For Heat ExchangerDokument3 SeitenHeuristics For Heat ExchangerhishamNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- E-102 LatestDokument13 SeitenE-102 LatesthishamNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- E-101 LatestDokument12 SeitenE-101 LatesthishamNoch keine Bewertungen

- Draft For Mini Project (Plant Design)Dokument1 SeiteDraft For Mini Project (Plant Design)hishamNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Name of Lecturer: DR Jagan Group: EH 220 5B Case Study: Production of MethanolDokument7 SeitenName of Lecturer: DR Jagan Group: EH 220 5B Case Study: Production of MethanolhishamNoch keine Bewertungen

- Kmspico Install EditionDokument2 SeitenKmspico Install EditionYohanes BongNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Cash FlowDokument4 SeitenCash FlowhishamNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Cash FlowDokument1 SeiteCash FlowhishamNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Cp composition hot stream counter flow heat exchangerDokument2 SeitenCp composition hot stream counter flow heat exchangerhishamNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Faculty of Chemical Engineering: AssignmentDokument1 SeiteFaculty of Chemical Engineering: AssignmenthishamNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Energy Balance On SeparatorDokument8 SeitenEnergy Balance On SeparatorhishamNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Certificates SubDokument4 SeitenCertificates SubhishamNoch keine Bewertungen

- Reactor Design Guide1Dokument27 SeitenReactor Design Guide1Chau MaiNoch keine Bewertungen

- Assignment For EnvDokument3 SeitenAssignment For EnvhishamNoch keine Bewertungen

- Full Report - Production - of - MethanolDokument67 SeitenFull Report - Production - of - Methanolhisham100% (4)

- Chapter 5 - Chemical DesignDokument104 SeitenChapter 5 - Chemical DesignhishamNoch keine Bewertungen

- Final CHE625 Dec 2014Dokument4 SeitenFinal CHE625 Dec 2014hishamNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- List of Previous Internship PlacementsDokument78 SeitenList of Previous Internship PlacementsZaidi ZakariaNoch keine Bewertungen

- CascadeDokument11 SeitenCascadehishamNoch keine Bewertungen

- CSTR Series Experiment Determines Concentration ResponseDokument2 SeitenCSTR Series Experiment Determines Concentration ResponsehishamNoch keine Bewertungen

- EXP6 TubularDokument19 SeitenEXP6 TubularhishamNoch keine Bewertungen

- CSTR 40LDokument16 SeitenCSTR 40LhishamNoch keine Bewertungen

- Flowmeter DemonstrationDokument21 SeitenFlowmeter DemonstrationhishamNoch keine Bewertungen

- BB Cream Water in SiliconDokument6 SeitenBB Cream Water in SiliconSari RamadhaniNoch keine Bewertungen

- Discover the functions and properties of lipids through experimentsDokument8 SeitenDiscover the functions and properties of lipids through experimentsJasper Ian Tan JumalaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Phase Equilibria in Ceramic SystemsDokument43 SeitenPhase Equilibria in Ceramic SystemsAlexNoch keine Bewertungen

- Mitzi 2001Dokument12 SeitenMitzi 2001Reena BalharaNoch keine Bewertungen

- Battery AdvancementsDokument7 SeitenBattery Advancementsabhishek gowdaNoch keine Bewertungen

- Chapter 1: The Human OrganismDokument9 SeitenChapter 1: The Human OrganismMidnight Rosenfield100% (1)

- Top metals used in construction including steel, aluminum and moreDokument203 SeitenTop metals used in construction including steel, aluminum and moreGopalakrishnan KuppuswamyNoch keine Bewertungen

- Aromatic Compounds: NamingDokument13 SeitenAromatic Compounds: NamingTanzimNoch keine Bewertungen

- Alum CrystalsDokument5 SeitenAlum CrystalsAJ BragadoNoch keine Bewertungen

- Nucleic AcidDokument28 SeitenNucleic AcidStellar OutputsNoch keine Bewertungen

- G.O.C. Iws-1Dokument50 SeitenG.O.C. Iws-1Lakshya ChandakNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fluorescent Organic Nanoparticles New Generation Materials With Diverse Analytical and Biomedical ApplicationsDokument72 SeitenFluorescent Organic Nanoparticles New Generation Materials With Diverse Analytical and Biomedical ApplicationsAhmed AbadyNoch keine Bewertungen

- United States Patent (10) Patent No.: US 9,096,564 B2Dokument6 SeitenUnited States Patent (10) Patent No.: US 9,096,564 B2Ahmad InterestaNoch keine Bewertungen

- Arihant 41 Years Chemistry (Crackjee - Xyz)Dokument497 SeitenArihant 41 Years Chemistry (Crackjee - Xyz)KaushikNoch keine Bewertungen

- January 2015 (IAL) QP - Unit 4 Edexcel Chemistry A-Level PDFDokument28 SeitenJanuary 2015 (IAL) QP - Unit 4 Edexcel Chemistry A-Level PDFMaria KolokasiNoch keine Bewertungen

- Weerdt, 2011Dokument39 SeitenWeerdt, 2011Fernando SchmidtNoch keine Bewertungen

- Protein Synthesis Paper Lab InstructionsDokument11 SeitenProtein Synthesis Paper Lab Instructionsapi-292473508Noch keine Bewertungen

- Determination of Total Sulfur in Fertilizers by High Temperature CombustionDokument1 SeiteDetermination of Total Sulfur in Fertilizers by High Temperature CombustionJa Phe TiNoch keine Bewertungen

- Microbial Physiology and Genetics Part 1Dokument43 SeitenMicrobial Physiology and Genetics Part 1Carl Elexer Cuyugan Ano100% (7)

- DNA ReplicationDokument13 SeitenDNA ReplicationJoanne NgauNoch keine Bewertungen

- Redken Color HandbookDokument40 SeitenRedken Color HandbookVane Vane100% (3)

- Materials For Roads and Pavements: Standard Terminology Relating ToDokument4 SeitenMaterials For Roads and Pavements: Standard Terminology Relating ToOscar VillaNoch keine Bewertungen

- CONTINUOUS DistillationDokument5 SeitenCONTINUOUS DistillationNaseer SattarNoch keine Bewertungen

- Ammonia (EHC 54, 1986)Dokument153 SeitenAmmonia (EHC 54, 1986)newuserNoch keine Bewertungen

- Rocol Flawfinder InstructionsDokument2 SeitenRocol Flawfinder InstructionsDD H1Noch keine Bewertungen

- Master Thesis Jeroen Brenkman RepositoryDokument130 SeitenMaster Thesis Jeroen Brenkman RepositoryguittonNoch keine Bewertungen

- Synthesis of Bactericidal Microfiltration Ceramic MembranesDokument14 SeitenSynthesis of Bactericidal Microfiltration Ceramic MembranesGlobal Research and Development ServicesNoch keine Bewertungen

- Cell The Unit of LifeDokument5 SeitenCell The Unit of LifeeloelNoch keine Bewertungen

- BS - Traffigard Optimize 0Dokument6 SeitenBS - Traffigard Optimize 0TungNoch keine Bewertungen

- Sheet Metal Gauge Size Chart-Stainless SteelDokument2 SeitenSheet Metal Gauge Size Chart-Stainless Steellorenzinho290Noch keine Bewertungen

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaVon EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNoch keine Bewertungen

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (50)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (57)

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationVon EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationBewertung: 4.5 von 5 Sternen4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (241)

- Pale Blue Dot: A Vision of the Human Future in SpaceVon EverandPale Blue Dot: A Vision of the Human Future in SpaceBewertung: 4.5 von 5 Sternen4.5/5 (586)

- Highest Duty: My Search for What Really MattersVon EverandHighest Duty: My Search for What Really MattersNoch keine Bewertungen

- The Weather Machine: A Journey Inside the ForecastVon EverandThe Weather Machine: A Journey Inside the ForecastBewertung: 3.5 von 5 Sternen3.5/5 (31)