Beruflich Dokumente

Kultur Dokumente

Tech Briefs - Chloride Stress Corrosion Cracking Resistance

Hochgeladen von

Eddie SantillánCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tech Briefs - Chloride Stress Corrosion Cracking Resistance

Hochgeladen von

Eddie SantillánCopyright:

Verfügbare Formate

Chloride Stress Corrosion Cracking of High Performance Copper

Alloys

Stress Corrosion Cracking (SCC) is an environmentally assisted failure caused by exposure to a corrodant while under a

sustained tensile stress. SCC is most often rapid, unpredictable and catastrophic. Failure can occur in as little as a few

hours or take years to happen and is commonly observed in the absence of other forms of corrosion, such as general or

crevice corrosion.

Most alloys are susceptible to SCC in one or more

environments requiring careful consideration of alloy type in

component design. In oxygenated aqueous chloride

environments austenitic stainless steels and many nickel

based alloys are known to perform poorly. These alloys

demonstrate a rapid decrease in failure time with increasing

applied stress. Use of these alloys often requires additional

processing, such as shot peening, cathodic protection or

the application of protective coatings to prolong the

structure life. However, the additional processing

requirements add significantly to the cost of use.

strength and tested in solution. Copper beryllium alloy

C17200 was tested at three levels of strength to determine

the effect of aging on resistance to chloride SCC.

Numerous service conditions exist where high chloride

conditions are present. Aqueous chloride environments are

common in the Oil and Gas industry in both the downhole

and production situations. Highly concentrated hot brine or

potassium chloride are common in exploration drilling

requiring the use of chloride SCC resistant materials such

as high copper alloys. Seawater conditions are another

area where copper beryllium alloys, for example, have been

exceptionally successful for undersea electronic and fiber

optic housings.

The results shown in the graph indicate that the stainless

steel alloys are highly susceptible to chloride SCC, as are

some of the nickel-based alloys. These alloys fail by

cracking in times as short as several hours, even at a

fraction of their yield strength. The data also show that

several high performance copper-based alloys demonstrate

SCC resistance at strength levels equal to, or greater, than

several SCC resistant nickel alloys. Copper beryllium

C17200, for example, provides the greatest strength and

SCC resistance of the alloys evaluated. The excellent

corrosion resistance is independent of strength, shown at

0.2% yield strengths ranging from 100 ksi to 150 ksi (689

MPa to 1034 MPa). A lower strength, but higher

conductivity copper beryllium alloy, C17500, is also shown

to be resistant to chloride SCC. A new commercially

available spinodally hardened Cu-Ni-Sn alloy, Brush

ToughMet 3 AT, offers SCC resistance at a yield strength

of 110 ksi (758 MPa).

A method of commonly evaluating material susceptibility to

Chloride SCC is ASTM Standard Practice G36, Performing

Stress-Corrosion Cracking Tests in a Boiling Magnesium

Chloride Solution. This accelerated test method

incorporates C-ring specimens of various alloys of steel,

nickel and copper to determine the failure time as a function

of applied stress. The specimens evaluated were loaded to

an applied stress of 100% of the yield strength and

immersed into the solution as described by the standard

practice. If the specimens failed in less than 1000 hr,

additional specimens were loaded to 50% of the yield

When design considerations require a chloride SCC

resistant alloy, other material properties and attributes

should also be considered. For example, AT0024/0800

instrumentation for directional sensing during downhole oil

and gas exploration may require high strength and nonmagnetic behavior. Other downhole drilling situations

require bending of a drill string over a tight radius defining

the need for a low modulus alloy which reduces generated

stress levels. Wear and friction behavior may be necessary

for bushings and wear surfaces exposed to SCC inducing

environments. These design requirements eliminate the

Materion Brush Performance Alloys

6070 Parkland Boulevard

Mayfield Heights, OH 4414 USA

phone: 216.486.4200 fax: 216.383.4005

e: BrushAlloys-Info@Materion.com

TECHNICAL INQUIRIES

ph: 800.375.4205

MATERION CORPORATION

www.materion.com

AT0024/0311

2011 Materion Brush Inc.

high nickel alloys from the application because of their

ferromagnetic behavior, high elastic modulus and

propensity for galling and seizing. High strength copper

alloys, such as the copper beryllium and spinodal alloys,

are the engineering solution in many applications where the

material demands are high.

SAFE HANDLING OF COPPER BERYLLIUM

Handling copper beryllium in solid form poses no special

health risk. Like many industrial materials, berylliumcontaining materials may pose a health risk if

recommended safe handling practices are not followed.

Inhalation of airborne beryllium may cause a serious lung

disorder in susceptible individuals. The Occupational

Safety and Health Administration (OSHA) has set

mandatory limits on occupational respiratory exposures.

Read and follow the guidance in the Material Safety Data

Sheet (MSDS) before working with this material. For

additional information on safe handling practices or

technical data on copper beryllium, contact Materion Brush

Performance Alloys, Technical Service Department at 1800-375-4205.

ToughMet is a registered trademark of Materion Brush Inc.

Incoloy and Monel are registered trademarks of Special

Metals Corporation. Nitronic is a registered trademark or

Armco Inc. SCF 19 and Pyromet are registered

trademarks of Carpenter Technology Corporation.

C17200 - Materion Brush Performance Alloys 25 AT; Tube, PA 150 ksi YS; Forged UA, 110 and 100 ksi YS

S31600 - AISI 316 SS A, Tube, 40 ksi

S17400 - 17-4 PH, Bar, 127 ksi YS

S20910 - Nitronic 50, 103 ksi YS

N09925 - Incoloy 925, 106 ksi YS

SCF 19 - SCF-19 (Carpenter Technology), 120 ksi YS

C72900 - Materion Brush Performance Alloys ToughMet 3 AT110, 110 ksi YS

C17510 - Materion Brush Performance Alloys 3 AT Tube, 80 ksi YS

N05500 - Monel K500 (Huntington Alloys, Inc.), 112 ksi YS

N07031 - Pyromet 31 (Carpenter Technology), 106 ksi YS

Materion Brush Performance Alloys

6070 Parkland Boulevard

Mayfield Heights, OH 4414 USA

phone: 216.486.4200 fax: 216.383.4005

e: BrushAlloys-Info@Materion.com

TECHNICAL INQUIRIES

ph: 800.375.4205

MATERION CORPORATION

www.materion.com

AT0024/0311

2011 Materion Brush Inc.

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Ma&Gnie Etsc HD 2000 2Dokument6 SeitenMa&Gnie Etsc HD 2000 2Amir AbbaszadehNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Construction and Performance Evaluation of A Michell-Banki Turbine PrototypeDokument9 SeitenConstruction and Performance Evaluation of A Michell-Banki Turbine Prototypemichael1135Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Cross Flow Turbine DesignDokument3 SeitenCross Flow Turbine DesignEddie SantillánNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- S M S LT S FT Q: Velocidad Absoluta Del FluidoDokument3 SeitenS M S LT S FT Q: Velocidad Absoluta Del FluidoEddie SantillánNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Ejma DSDokument1 SeiteEjma DSEddie SantillánNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Coa48 TCDokument4 SeitenCoa48 TCEddie SantillánNoch keine Bewertungen

- Stainless Steel Needle Tubing: Standard Specification ForDokument2 SeitenStainless Steel Needle Tubing: Standard Specification ForEddie SantillánNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- PRV 2 Size Quick Start GuideDokument36 SeitenPRV 2 Size Quick Start GuideAlcides Llanque ChoqueNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- JMNMMDokument2 SeitenJMNMMEddie SantillánNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Proper Piping For Vacuum SystemsDokument5 SeitenProper Piping For Vacuum SystemsDowni Oader100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- FC Mag - Keys To Effective Valve Sizing & Selection PDFDokument4 SeitenFC Mag - Keys To Effective Valve Sizing & Selection PDFEddie SantillánNoch keine Bewertungen

- Coa48 TCDokument4 SeitenCoa48 TCEddie SantillánNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Control Valve Noise Control Manual - DresserDokument24 SeitenControl Valve Noise Control Manual - DresserTrevor KanodeNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Pump CoolingDokument1 SeitePump CoolingEddie SantillánNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Gap 2.5.2 PDFDokument13 SeitenGap 2.5.2 PDFRoberto MendozaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Section F Section F: WeldingDokument3 SeitenSection F Section F: WeldingEddie SantillánNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Station Equipment: Pump CoolingDokument3 SeitenStation Equipment: Pump CoolingEddie SantillánNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Compressed Air SystemDokument29 SeitenCompressed Air SystemPrathmesh GujaratiNoch keine Bewertungen

- 008 Choke ValveDokument3 Seiten008 Choke ValveEddie SantillánNoch keine Bewertungen

- TM PT501 Tank HeatDokument30 SeitenTM PT501 Tank HeataufacikNoch keine Bewertungen

- Up6s 30 125Dokument1 SeiteUp6s 30 125Eddie SantillánNoch keine Bewertungen

- IRITS-0617-034 HLA Heatless Desiccant Air DryerDokument2 SeitenIRITS-0617-034 HLA Heatless Desiccant Air DryerEddie SantillánNoch keine Bewertungen

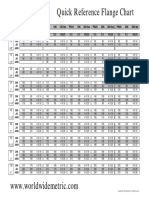

- Flange ChartDokument4 SeitenFlange ChartEddie SantillánNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Valve Testing StandardsDokument2 SeitenValve Testing StandardsPrashant Puri0% (1)

- Overpressure and Thermal ReliefDokument6 SeitenOverpressure and Thermal ReliefHamid Alilou100% (1)

- Reporte ValvulaDokument1 SeiteReporte ValvulaEddie SantillánNoch keine Bewertungen

- Models 180-LD 181-LDDokument2 SeitenModels 180-LD 181-LDEddie SantillánNoch keine Bewertungen

- Ver. 7.5.9.3.4, Build Date: Sep 14, 2010 Cashco Valve Sizing (CV Calculation) 12-Sep-17Dokument1 SeiteVer. 7.5.9.3.4, Build Date: Sep 14, 2010 Cashco Valve Sizing (CV Calculation) 12-Sep-17Eddie SantillánNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Epri - 25KW High Concentration Photovoltaic PDFDokument4 SeitenEpri - 25KW High Concentration Photovoltaic PDFEddie SantillánNoch keine Bewertungen

- WS 3Dokument9 SeitenWS 3Eddie SantillánNoch keine Bewertungen

- Rab Venturi Wet Scrubber 00Dokument2 SeitenRab Venturi Wet Scrubber 00rudiawanNoch keine Bewertungen

- Lec 14 MasonryDokument10 SeitenLec 14 Masonryamjad aliNoch keine Bewertungen

- Tripura Building Amendnent Rules 2019Dokument13 SeitenTripura Building Amendnent Rules 2019RupakDasNoch keine Bewertungen

- Tile Adhesives, Tile Grouts and Plastering SkimDokument30 SeitenTile Adhesives, Tile Grouts and Plastering SkimNykha Alenton100% (1)

- Schedule Q (Quality Requirements)Dokument86 SeitenSchedule Q (Quality Requirements)jeswinNoch keine Bewertungen

- Obo Commissioning 9Dokument75 SeitenObo Commissioning 998257002Noch keine Bewertungen

- Elevated Storage Reservoir DesignDokument8 SeitenElevated Storage Reservoir Designiqramoyale022Noch keine Bewertungen

- Pdvsa: Engineering Design ManualDokument6 SeitenPdvsa: Engineering Design Manual20jose12luisNoch keine Bewertungen

- Plastic LimitDokument9 SeitenPlastic LimitPoovan Rajaratnam100% (1)

- WMS For Pipe Supports ErectionDokument17 SeitenWMS For Pipe Supports ErectionRamaraju RNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Dokument15 SeitenDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- ECO AUDIT STEAM IRONDokument7 SeitenECO AUDIT STEAM IRONUlisses Heredia0% (1)

- Cmaa Education Training Flier WebDokument2 SeitenCmaa Education Training Flier WebRhytham SoniNoch keine Bewertungen

- Addis Ababa University (Eiabc) : Research ProposalDokument20 SeitenAddis Ababa University (Eiabc) : Research ProposalLemlem MamoNoch keine Bewertungen

- ECOBA Statistic 2004Dokument1 SeiteECOBA Statistic 2004dungnv2733Noch keine Bewertungen

- Aplus CompactorDokument8 SeitenAplus CompactorAlex ChewNoch keine Bewertungen

- Structural Calculation Design Criteria SummaryDokument2 SeitenStructural Calculation Design Criteria Summarykate denoyaNoch keine Bewertungen

- Fabrication EnquiryDokument180 SeitenFabrication Enquiryvinod23456100% (1)

- KD Nicholson Bench Lost Art PressDokument3 SeitenKD Nicholson Bench Lost Art PressIulian MihaiNoch keine Bewertungen

- STRENGTH OF MATERIALS REFRESHER SETDokument4 SeitenSTRENGTH OF MATERIALS REFRESHER SETGracielle Nebres67% (3)

- Subsea Pipeline Engineering (Indonesia) - ElisaDokument5 SeitenSubsea Pipeline Engineering (Indonesia) - ElisaMheErdiantoNoch keine Bewertungen

- RC Element Design Lesson PlanDokument3 SeitenRC Element Design Lesson Plandinesh11rNoch keine Bewertungen

- Single & 3-Way Decorator Wall Switch Set Up and Operating InstructionsDokument1 SeiteSingle & 3-Way Decorator Wall Switch Set Up and Operating InstructionsjrmsndrNoch keine Bewertungen

- Machine Design IgnouDokument181 SeitenMachine Design IgnouAnup ChoudharyNoch keine Bewertungen

- SECTION 16110 Residential Wiring Connections, Rev 0Dokument12 SeitenSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimNoch keine Bewertungen

- HLS Sleeve Anchor Technology ManualDokument5 SeitenHLS Sleeve Anchor Technology ManualHerli SiswoyoNoch keine Bewertungen

- ProkonDokument7 SeitenProkonTravel DiariesNoch keine Bewertungen

- Compressive Strength of Concrete - Cube Test Procedure ResultsDokument5 SeitenCompressive Strength of Concrete - Cube Test Procedure ResultsAriyan AriyanNoch keine Bewertungen

- Site Readiness Checksheet R1Dokument3 SeitenSite Readiness Checksheet R1Rahil TasawarNoch keine Bewertungen

- 04 Marl Chemical Park PDFDokument36 Seiten04 Marl Chemical Park PDFAnusha Rajagopalan100% (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableVon EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNoch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsVon EverandDesign for How People Think: Using Brain Science to Build Better ProductsBewertung: 4 von 5 Sternen4/5 (8)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)