Beruflich Dokumente

Kultur Dokumente

Research and Development For Ethylbenezene Production

Hochgeladen von

JonesHutaurukOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Research and Development For Ethylbenezene Production

Hochgeladen von

JonesHutaurukCopyright:

Verfügbare Formate

New Technologies and Alternative Feedstocks in Petrochemistry and Refining

DGMK Conference October 9 11, 2013, Dresden, Germany

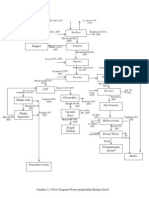

Research and Development for Ethylbenezene Production

Mingwei Xue, Hongmin Sun, Zhenhao Shen, Bin Zhang, Mingyao Huan, Weimin Yang

SINOPEC Shanghai Research Institute of Petrochemical Technology, Shanghai, China

Abstract

Ethylbenezene (EB) is mainly used for the production of styrene. The ethylbenezene is

mainly produced by alkylation of benzene with ethylene. The current commercially-used

processes mainly include the Mobile/Badger vapor phase process, EB-One liquid phase

process, EB-Max liquid phase process and CDTECH catalysis distillation process.

Shanghai Research Institute of Petrochemical Technology (SRIPT) began to research

the catalysts for the production of ethylbenezene in 1993. Now, with near 20 years work,

three series of catalysts for the alkylation of benzene with pure ethylene, dilute ethylene (dry

gas) and ethanol are in commerical use in China, respectively.

The AB-96, AB-97 catalysts for the alkylation of benzene with pure ethylene and the AB97-T catalyst for the transklation of benzene with diethylbenzene in vapor phase were

developed by SRIPT from 1994 to 1997. Base on the high activity catalysts, SRIPT

developed the technology for the alkylation of benzene with pure ethylene in vapor phase.

With this technology, the purity of ethylbenzene in product is over 99.7% and the xylene in

product is lower than 800 ppm. The service life of the catalyst is over 3 years and the

regeneration cycle is over 21 month. Now, the catalysts and technology are commercially

applied in four plants in China.

The off-gas of catalytic cracking (dry gas) contains some ethylene, which can be used to

produce ethylbenezene. The cost of raw material is greatly decreased with this method. In

2008, the SEB-08 catalyst was developed by SRIPT, which showed high catalytic ability for

the alkyation of benzene with dilute ethylene (dry gas) and high resistence to impurity of dry

gas. The industrial catalyst performance showed that the life of the catalyst is over 2 years

and the regeneration cycle is over 12 month. SRIPTand its parter cooperated to develop the

technology for the alkylation of benzene with dilute ethylene using SEB-08 and AEB-1

catalysts. With this technology, the purity of ethylbenzene in product is over 99.8% and the

xylene is lower than 800 ppm. Now, the SEB-08 catalyst is commercialized in 4 plants and is

to be used in 7 plants in the next 2 years in China.

Ethylbenezene can also be produced by alkylation of benzene with ethanol. With this

method, the source of raw material is increased. DF-AS catalyst with high hydrothermal

stability was developed by SRIPT in 2007, which displayed high catalytic ability for the

alkylation of benzene with biomass ethanol. The catalyst was commercialied in the industrial

plant with capacity of 200, 000 t/y. The conversion of ethanol is about 99.99% and the ethyl

selectivity is over 99.7% as well as the first cycle of the catalys is over 12 month. The purity

of ethylbenzene in product is over 99.7% and the xylene is lower than 900 ppm.

Das könnte Ihnen auch gefallen

- Operating Cost Ethylbenzene 1Dokument1 SeiteOperating Cost Ethylbenzene 1JonesHutaurukNoch keine Bewertungen

- Operating Cost EthylbenzeneDokument2 SeitenOperating Cost EthylbenzeneJonesHutaurukNoch keine Bewertungen

- Operating Cost EthylbenzeneDokument2 SeitenOperating Cost EthylbenzeneJonesHutaurukNoch keine Bewertungen

- Product Profile of AromaticsDokument1 SeiteProduct Profile of AromaticsJonesHutaurukNoch keine Bewertungen

- ZSM-5 (Mfi)Dokument2 SeitenZSM-5 (Mfi)JonesHutaurukNoch keine Bewertungen

- Ethilbenzen CostDokument2 SeitenEthilbenzen CostJonesHutaurukNoch keine Bewertungen

- ITS Undergraduate BibliographyDokument6 SeitenITS Undergraduate BibliographyJonesHutaurukNoch keine Bewertungen

- Vent GasDokument2 SeitenVent GasJonesHutaurukNoch keine Bewertungen

- Introduction Gas ScrubbersDokument2 SeitenIntroduction Gas ScrubbersJonesHutaurukNoch keine Bewertungen

- Typical Equipment Capacity Delivered Capital Cost Correlations.Dokument1 SeiteTypical Equipment Capacity Delivered Capital Cost Correlations.JonesHutaurukNoch keine Bewertungen

- ZSM-5 (Mfi)Dokument2 SeitenZSM-5 (Mfi)JonesHutaurukNoch keine Bewertungen

- Product Profile of AromaticsDokument1 SeiteProduct Profile of AromaticsJonesHutaurukNoch keine Bewertungen

- Problem 2.17 DQ KernDokument1 SeiteProblem 2.17 DQ KernJonesHutaurukNoch keine Bewertungen

- AppendixDokument349 SeitenAppendixLufya AdellaNoch keine Bewertungen

- Research and Development For Ethylbenezene ProductionDokument1 SeiteResearch and Development For Ethylbenezene ProductionJonesHutaurukNoch keine Bewertungen

- File Industri SemenDokument18 SeitenFile Industri SemenJonesHutaurukNoch keine Bewertungen

- Us 2495071 ADokument5 SeitenUs 2495071 AJonesHutaurukNoch keine Bewertungen

- AppendixDokument139 SeitenAppendixItonamyRitongaNoch keine Bewertungen

- Comparative Study of Adsorptive Removal of Congo Red and Brilliant Green Dyes From Water Using Peanut ShellDokument5 SeitenComparative Study of Adsorptive Removal of Congo Red and Brilliant Green Dyes From Water Using Peanut ShellJonesHutaurukNoch keine Bewertungen

- Luther and Calvin: Ralph HancockDokument37 SeitenLuther and Calvin: Ralph HancockhjjvrNoch keine Bewertungen

- Steady-state heat conduction through an axisymmetric shapeDokument2 SeitenSteady-state heat conduction through an axisymmetric shapeJonesHutauruk100% (1)

- John Calvin and The Reformation in GenevaDokument15 SeitenJohn Calvin and The Reformation in GenevaJonesHutaurukNoch keine Bewertungen

- Solution Manual 1.45-1.46 KernDokument2 SeitenSolution Manual 1.45-1.46 KernJonesHutaurukNoch keine Bewertungen

- Daftar Pustaka: Universitas Sumatera UtaraDokument3 SeitenDaftar Pustaka: Universitas Sumatera UtaraJonesHutaurukNoch keine Bewertungen

- Data TermodinamikaDokument1 SeiteData TermodinamikaJonesHutaurukNoch keine Bewertungen

- Acetone CPDokument6 SeitenAcetone CPJonesHutaurukNoch keine Bewertungen

- 4 Description of Chemical ProcessesDokument45 Seiten4 Description of Chemical Processesishhh12Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Downstream Oil Industry Deregulation Act of 1998.Dokument24 SeitenDownstream Oil Industry Deregulation Act of 1998.Kriz MartinezNoch keine Bewertungen

- HDM4 Vehicle Fleet Export FormatDokument8 SeitenHDM4 Vehicle Fleet Export FormatAnonymous 5exSer0% (1)

- Aerodynamics and Aerodynamic Research in Formula 1Dokument26 SeitenAerodynamics and Aerodynamic Research in Formula 1nignog100% (1)

- FJR 1300 AdDokument662 SeitenFJR 1300 AdFelipe SafadiNoch keine Bewertungen

- Template ST 2019Dokument1 SeiteTemplate ST 2019Reza RamadhanNoch keine Bewertungen

- Design and Fabrication of A Tadpole Hybrid TrikeDokument6 SeitenDesign and Fabrication of A Tadpole Hybrid TrikeSP CreationsNoch keine Bewertungen

- T250 6902724 enUS SM 06-12Dokument1.066 SeitenT250 6902724 enUS SM 06-12mohanad abdullahNoch keine Bewertungen

- 70ft Luxury Traditional NarrowboatDokument2 Seiten70ft Luxury Traditional NarrowboatDominic MilesNoch keine Bewertungen

- SC13003-0000-49D1-0020 - Nitrogen Purge System Process Flow Diagram-Rev.03Dokument1 SeiteSC13003-0000-49D1-0020 - Nitrogen Purge System Process Flow Diagram-Rev.03Dwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Physical and Thermal Properties of Crude Oil and Its ProductsDokument22 SeitenPhysical and Thermal Properties of Crude Oil and Its ProductsAbdullah N TahaNoch keine Bewertungen

- Clark TCM 75A Parts Manual PDFDokument119 SeitenClark TCM 75A Parts Manual PDFW Morales100% (3)

- 1204E-ELE Perkins PDFDokument254 Seiten1204E-ELE Perkins PDFHenry Huayhua100% (6)

- 966H-972H - Serv1815 - TXTDokument233 Seiten966H-972H - Serv1815 - TXTBrahim Rabia100% (7)

- Diethyl EtherDokument10 SeitenDiethyl EtherDiana Lee Navarro100% (1)

- 21 SOP For Vacuum PumpDokument6 Seiten21 SOP For Vacuum PumpAmit Biswas100% (1)

- 1104A-44TG1 ElectropaK PN1783Dokument2 Seiten1104A-44TG1 ElectropaK PN1783Francisco Martinez OrtizNoch keine Bewertungen

- 010 Tank Condition 03-05-20Dokument22 Seiten010 Tank Condition 03-05-20Nur SahirohNoch keine Bewertungen

- Calado Árbol de Levas VW t4Dokument4 SeitenCalado Árbol de Levas VW t4Radulf PugnusNoch keine Bewertungen

- Diesel GensetDokument4 SeitenDiesel GensetErwin GunawanNoch keine Bewertungen

- 2016 nmax125 서비스메뉴얼 2DS-F8197-E0 (20권)Dokument444 Seiten2016 nmax125 서비스메뉴얼 2DS-F8197-E0 (20권)DonNoch keine Bewertungen

- D300K 33 Operators Manual NEWDokument34 SeitenD300K 33 Operators Manual NEWvitrolaNoch keine Bewertungen

- Engine Jaa AtplDokument5 SeitenEngine Jaa AtplMukesh Singh MehtaNoch keine Bewertungen

- Characteristics of Integrated Micro Packed Bed Reactor-Heat OkDokument9 SeitenCharacteristics of Integrated Micro Packed Bed Reactor-Heat OkAngelloVargasNoch keine Bewertungen

- Om Ysd490zlDokument51 SeitenOm Ysd490zlValeriyNoch keine Bewertungen

- Same Engines Spare PartsDokument98 SeitenSame Engines Spare PartsAdrian Macaya100% (1)

- BMW Models and German Abbreviations Used On ALL CarsDokument14 SeitenBMW Models and German Abbreviations Used On ALL CarsDOMINO66100% (2)

- Crj200.amm (62) .Amm49 31 03 04Dokument6 SeitenCrj200.amm (62) .Amm49 31 03 04CHIMONoch keine Bewertungen

- ISOBUTANOL - A RENEWABLE SOLUTION For THE TRANSPORTATION FUELS VALUE CHAINDokument16 SeitenISOBUTANOL - A RENEWABLE SOLUTION For THE TRANSPORTATION FUELS VALUE CHAINc7oplayNoch keine Bewertungen

- Total Rubia Fleet HD 200 15W40 20W50 PDFDokument2 SeitenTotal Rubia Fleet HD 200 15W40 20W50 PDFdnoaisapsNoch keine Bewertungen

- Parts Book Hd785-7 Lepbh78703 J30001-UpDokument674 SeitenParts Book Hd785-7 Lepbh78703 J30001-UpMc MuklisNoch keine Bewertungen