Beruflich Dokumente

Kultur Dokumente

Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Compression PDF

Hochgeladen von

Topaca PaecOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Compression PDF

Hochgeladen von

Topaca PaecCopyright:

Verfügbare Formate

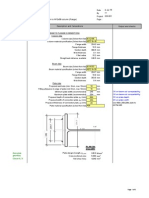

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

Example: Calculation of effective section

properties for a cold-formed lipped channel

section in compression

This example deals with the effective properties calculation of a coldformed lipped channel section subjected to compression.

For practical design of light gauge sections to EN1993, designers will normally use software

or refer to manufacturers data. This example is presented for illustrative purposes

Basic Data

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The dimensions of the cross-section and the material properties are:

Total height

h = 200 mm

Total width of upper flange

b1 = 74 mm

Total width of bottom flange

b2 = 66 mm

Total width of edge fold

c = 20,8 mm

Internal radius

r = 3 mm

Nominal thickness

tnom = 2 mm

Steel core thickness

t = 1,96 mm

Basic yield strength

f yb = 350 N mm2

Modulus of elasticity

E = 210000 N mm 2

Poissons ratio

= 0,3

Partial factor

M0 = 1,0

The dimensions of the section centre line are:

Web height

hp = h tnom = 200 2 = 198 mm

Width of upper flange

bp1 = b1 tnom = 74 2 = 72 mm

Width of bottom flange

bp2 = b2 tnom = 66 2 = 64 mm

Width of edge fold

cp = c tnom 2 = 20 ,8 2 2 = 19 ,8 mm

EN1993-1-3

3.2.4(3)

EN1993-1-3

2(3)

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

Checking of geometrical proportions

The design method of EN1993-1-3 can be applied if the following conditions EN1993-1-3

are satisfied:

5.2

b t 60

b1 t = 74 1,96 = 37,75 < 60 OK

c t 50

c t = 20,8 1,96 = 10,61 < 50 OK

h t 500

h t = 200 1,96 = 102,04 < 500 OK

In order to provide sufficient stiffness and to avoid primary buckling of the

stiffener itself, the size of stiffener should be within the following range:

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

0,2 c b 0,6

c b1 = 20,8 74 = 0,28

0,2 < 0,28 < 0,6 OK

c b2 = 20,8 66 = 0,32

0,2 < 0,32 < 0,6 OK

The influence of rounding of the corners is neglected if:

r t5

r t = 3 1,96 = 1,53 < 5 OK

r bp 0,10

r bp1 = 3 72 = 0,04 < 0,10 OK

EN1993-1-3

5.1(3)

r bp 2 = 3 64 = 0,05 < 0,10 OK

Gross section properties

Abr = t (2cp + bp1 + bp2 + hp ) = 1,96 (2 19,8 + 72 + 64 + 198) = 732 mm2

Position of the centroidal axis with regard to the upper flange:

z b1 =

[c (h

p

cp 2 ) + bp2 hp + hp2 2 + cp2 2 t

Abr

= 96,88 mm

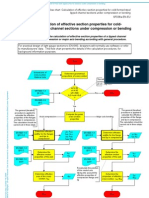

Effective section properties of the flanges and lips in compression

The general (iterative) procedure is applied to calculate the effective EN1993-1-3

properties of the compressed flange and the lip (plane element with edge 5.5.3.2

stiffener). The calculation should be carried out in three steps:

Step 1:

Obtain an initial effective cross-section for the stiffeners using effective

EN1993-1-3

widths of the flanges determined by assuming that the compressed flanges are 5.5.3.2 (3)

doubly supported, the stiffener gives full restraint ( K = ) and that design

strength is not reduced ( com,Ed = f yb / M 0 ).

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

Effective width of the compressed flanges

The stress ratio: = 1 (uniform compression), so the buckling factor is:

k = 4 for internal compression element.

EN1993-1-3

5.5.2 and

= 235 f yb

EN1993-1-5

4.4

For the upper flange:

The relative slenderness:

p,b1 =

bp1 t

28,4 k

72 1,96

= 0,789

28,4 235 350 4

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The width reduction factor is:

1 =

p,b1 0,055(3 + )

p,b1

0,789 0,055 (3 + 1)

= 0,914

0,789 2

The effective width is:

beff1 = 1bp1 = 0 ,914 72 = 65,8 mm

be11 = be12 = 0 ,5beff1 = 0 ,5 65,8 = 32 ,9 mm

For the bottom flange:

The relative slenderness:

p,b2 =

bp2 t

28,4 k

64 1,96

= 0,702

28,4 235 350 4

The width reduction factor is:

2 =

p,b2 0 ,055(3 + )

p,b2

0,702 0,055 (3 + 1)

= 0 ,978

0,702 2

The effective width is:

beff2 = 2 bp2 = 0 ,978 64 = 62 ,6 mm

be21 = be22 = 0,5beff2 = 0 ,5 62 ,6 = 31,3 mm

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

Effective width of the edge fold

EN1993-1-3

5.5.3.2(5a)

For the upper edge fold:

The buckling factor is:

if bp,c bp 0 ,35 :

k = 0,5

if 0 ,35 < bp,c bp 0 ,6 :

k = 0 ,5 + 0 ,83 3 (bp,c bp 0 ,35)

bp,c bp1 = 19 ,8 72 = 0 ,275 < 0 ,35

so

k 1 = 0 ,5

The relative slenderness:

p,c1 =

cp t

28,4 k 1

19,8 1,96

= 0,614

28,4 235 350 0,5

EN1993-1-5

4.4

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The width reduction factor is:

1 =

p,c1 0,188

p,c1

0,614 0,188

= 1,13 but 1 so 1 = 1

0,614 2

The effective width is:

EN1993-1-3

5.5.3.2(5a)

ceff1 = cp 1 = 19 ,8 1 = 19 ,8 mm

Effective area of the upper edge stiffener:

As1 = t (be12 + ceff1 ) = 1,96 (32 ,9 + 19 ,8) = 103,3 mm 2

5.5.3.2(6)

For the bottom edge fold:

EN1993-1-3

The buckling factor is:

5.5.3.2(5a)

bp,c bp2 = 19 ,8 64 = 0 ,309 < 0 ,35

so

k 2 = 0 ,5

The relative slenderness:

p,c2 =

cp t

28,4 k 2

19,8 1,96

= 0,614

28,4 235 350 0,5

The width reduction factor is:

2 =

p,c2 0,188

p,c2

0 ,614 0 ,188

= 1,13 but 1 so 2 = 1

0 ,614 2

EN1993-1-5

4.4

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

The effective width is:

ceff2 = cp 2 = 19 ,8 1 = 19 ,8 mm

Effective area of the bottom edge stiffener:

As2 = t (be22 + ceff2 ) = 1,96 (31,3 + 19 ,8) = 100 ,2 mm 2

EN1993-1-3

5.5.3.2(5a)

5.5.3.2(6)

EN1993-1-3

Use the initial effective cross-section of the stiffener to determine the 5.5.3.2(3)

reduction factor, allowing for the effects of the continuous spring restraint.

Step 2:

The elastic critical buckling stress for the edge stiffener is:

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

cr,s =

2 K E Is

As

EN1993-1-3

5.5.3.2(7)

where:

K is the spring stiffness per unit length,

Is is the effective second moment of area of the stiffener.

For the upper edge stiffener:

The spring stiffness is:

1

E t3

K1 =

2

3

2

4(1 ) b1 hp + b1 + 0,5 b1 b2 hp k f

with:

b1 distance from the web to the centre of the effective area of the stiffener in

compression (upper flange)

b1 = bp1

be12 t be12 2

32,9 1,96 32,9 2

= 72

= 61,73 mm

(be12 + ceff ) t

(32,9 + 19,8) 1,96

b2 distance from the web to the centre of the effective area of the stiffener

in compression (bottom flange)

b2 = bp2

be22 t be22 2

31,3 1,96 31,3 2

= 64

= 54,41 mm

(be22 + ceff2 ) t

(31,3 + 19,8) 1,96

EN1993-1-3

5.5.3.1(5)

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

kf =

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

As2 100 ,2

=

= 0 ,97 for a member in axial compression

As1 103,3

K1 = 0,331 N mm 2

The effective second moment of area:

2

2

3

2

ceff1

b t3 c t

ceff1

ceff1

I s1 = e12 + eff1 + be12 t

+

c

t

eff1

12

12

2(be12 + ceff1 )

2 2(be12 + ceff1 )

I s1 = 3663 mm 4

so, the elastic critical buckling stress for the upper edge stiffener is

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

cr,s1 =

2 0,331 210000 3663

= 309 N mm 2

103,3

For the bottom edge stiffener:

The spring stiffness is:

E t3

1

K2 =

2

,

3

2

4(1 ) b2 hp + b2 + 0,5 b1 b2 hp kf

K 2 = 0,406 N mm 2

The effective second moment of area:

2

3

2

2

ceff2

be22 t 3 ceff2 t

ceff2

ceff2

I s2 =

+

+ be22 t

+ ceff2 t

12

12

2(be22 + ceff2 )

2(be22 + ceff2 )

2

I s2 = 3618 mm 4

so, the elastic critical buckling stress for the bottom edge stiffener is

cr,s2 =

2 0,406 210000 3618

= 350,7 N mm 2

100,2

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

Thickness reduction factor d for the edge stiffener

For the upper edge stiffener:

f yb cr,s1 = 350 309 = 1,064

EN1993-1-3

5.5.3.1(7)

The reduction factor will be:

if d 0 ,65

d = 1,0

if 0 ,65 < d < 1,38

d = 1,47 0 ,723d

if d 1,38

d = 0 ,66 d

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

0 ,65 < d1 = 1,064 < 1,38

EN1993-1-3

5.5.3.2(3)

Figure 5.10d

The relative slenderness:

d1 =

so

EN1993-1-5

4.4(2)

d1 = 1,47 0,723 1,064 = 0,701

For the bottom edge stiffener:

The relative slenderness:

d2 =

f yb cr,s2 = 350 350 ,7 = 0 ,999

The reduction factor will be:

0 ,65 < d2 = 0 ,999 < 1,38

so

d2 = 1,47 0,723 0,999 = 0,748

Step 3:

As the reduction factor for buckling of the stiffener is d < 1, iterate to refine

the value of the reduction factor for buckling of the stiffener.

The iterations are carried out based on modified values of obtained using:

com,Ed,i = d f yb M0 and

p,red = p d

The iteration stops when the reduction factor converges.

For the upper edge stiffener:

Initial values (iteration 1):

Final values (iteration n):

d1 = 0,701

d1 = d1,n = 0 ,683

be12 = 32 ,9 mm

be12 = be12,n = 36 mm

ceff1 = 19,8 mm

ceff1 = ceff1,n = 19 ,8 mm

EN1993-1-3

5.5.3.2(3)

Figure 5.10e

EN1993-1-3

5.5.3.2 (10)

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

of

For the bottom edge stiffener:

Initial values (iteration 1):

Final values (iteration n):

d2 = 0,748

d2 = d2,n = 0 ,744

be22 = 31,3 mm

be22 = be22,n = 32 mm

ceff2 = 19 ,8 mm

ceff2 = ceff2,n = 19 ,8 mm

Final values of effective properties for flanges and lips in compression are:

For the upper flange and lip:

d1 = 0,683

be12 = 36 mm

ceff1 = 19 ,8 mm

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

and be11 = 32,9 mm

For the bottom flange and lip:

d2 = 0,744

be22 = 32 mm

ceff2 = 19 ,8 mm

and be 21 = 31,3 mm

t red,1 = t d1 = 1,96 0,683 = 1.34 mm

t red,2 = t d2 = 1,96 0,744 = 1,46 mm

EN1993-1-3

5.5.3.2(12)

Effective section properties of the web

The stress ratio: = 1 (uniform compression), so the buckling factor is:

k = 4 for internal compression element.

and

= 235 f yb

EN1993-1-5

4.4

The relative slenderness:

p,h =

hp t

28,4 k

198 1,96

= 2,171

28,4 235 350 4

The width reduction factor is:

p,h 0 ,055(3 + )

p,h

EN1993-1-3

5.5.2

2,171 0,055 (3 + 1)

= 0,414

2 ,1712

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref:

SX023a-EN-EU

Title

Example: Calculation of effective section properties for a

cold-formed lipped channel section in compression

Eurocode Ref

EN 1993-1-3

Made by

V. Ungureanu, A. Ruff

Date

Dec 2005

Checked by

D. Dubina

Date

Dec 2005

Sheet

The effective width of the web is:

heff = hp = 0 ,414 198 = 82 mm

he1 = he2 = 0,5heff = 0 ,5 82 = 41 mm

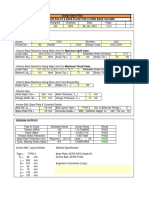

Effective section properties

Effective cross-section area:

Aeff = t [be11 + be21 + he1 + he2 + (be12 + ceff1 ) d1 + (be22 + ceff2 ) d2 ]

Aeff = 436,7 mm 2

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Position of the centroidal axis with regard to the upper flange:

z G1

2

2

ceff2

he2 he1

ceff1 d1

+

t ceff2 d2 hp

+ hp (be22 d2 + be21 ) + he2 hp

+

2

2

2

2

=

Aeff

z G1 = 98,44 mm

Position of the centroidal axis with regard to the bottom flange:

z G2 = hp z G1 = 198 98 ,44 = 99 ,56 mm

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

Example: Calculation of effective section properties for a cold-formed lipped

channel section in compression

SX023a-EN-EU.doc

Quality Record

RESOURCE TITLE

Example: Calculation of effective section properties for a cold-formed

lipped channel section in compression

Reference(s)

ORIGINAL DOCUMENT

Name

Company

Date

Created by

V. Ungureanu, A. Ruff

BRITT Ltd. Timisoara,

Romania

05/12/2005

Technical content checked by

D. Dubina

BRITT Ltd. Timisoara,

Romania

08/12/2005

1. UK

G W Owens

SCI

12/4/06

2. France

A Bureau

CTICM

12/4/06

3. Sweden

B Uppfeldt

SBI

11/4/06

4. Germany

C Mller

RWTH

11/4/06

5. Spain

J Chica

Labein

12/4/06

G W Owens

SCI

11/9/06

Editorial content checked by

Created on Friday, February 20, 2009

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Technical content endorsed by the

following STEEL Partners:

Resource approved by Technical

Coordinator

TRANSLATED DOCUMENT

This Translation made and checked by:

Translated resource approved by:

Page 10

Das könnte Ihnen auch gefallen

- Proracun - Example Cold Formed SteelDokument10 SeitenProracun - Example Cold Formed SteelpedjaNoch keine Bewertungen

- Example Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDokument10 SeitenExample Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Bendingcbler100% (10)

- Column Base Plate (Eurocode)Dokument4 SeitenColumn Base Plate (Eurocode)_at_to_Noch keine Bewertungen

- Example Composite Floor SlabDokument13 SeitenExample Composite Floor SlabZamfira Octavian100% (2)

- Example Calculation of Alpha-Cr PDFDokument9 SeitenExample Calculation of Alpha-Cr PDFHerdean RemusNoch keine Bewertungen

- Pad Foundation Design To Bs 81101997Dokument23 SeitenPad Foundation Design To Bs 81101997Anonymous 66uWhphVNoch keine Bewertungen

- Example Design of A Cold-Formed Steel Lipped Channel Wall Stud in CompressionDokument4 SeitenExample Design of A Cold-Formed Steel Lipped Channel Wall Stud in CompressionOprisor Costin100% (1)

- Composite SlabDokument13 SeitenComposite Slabkosithuag50% (2)

- Ec3 Kolon HesabıDokument5 SeitenEc3 Kolon HesabınaimalimliNoch keine Bewertungen

- Design of Cold Formed Steel Members 2003 LibroDokument246 SeitenDesign of Cold Formed Steel Members 2003 LibroFelipeNoch keine Bewertungen

- SX033b-En-EU-Example - Truss or Post End ConnectionDokument8 SeitenSX033b-En-EU-Example - Truss or Post End ConnectionWNoch keine Bewertungen

- Axially Loaded Columns - Base Plate DesignDokument2 SeitenAxially Loaded Columns - Base Plate DesignaomareltayebNoch keine Bewertungen

- BS and ECDokument9 SeitenBS and ECNGUYENNoch keine Bewertungen

- SX028a-EN-EU-Example - Design Resistance of A Screwed Connection of Cold-Formed Members PDFDokument4 SeitenSX028a-EN-EU-Example - Design Resistance of A Screwed Connection of Cold-Formed Members PDFWNoch keine Bewertungen

- Design of Column For Axial Loads and BendingDokument6 SeitenDesign of Column For Axial Loads and BendingGihan ChathurangaNoch keine Bewertungen

- Steel Joints According To Eurocode 3Dokument21 SeitenSteel Joints According To Eurocode 3alfonxxlNoch keine Bewertungen

- Beam-Column Connection To BS5950Dokument6 SeitenBeam-Column Connection To BS5950Mitra RampersadNoch keine Bewertungen

- BS 6399-1996 Loading For Building-Part3 Imposed Roof Loads PDFDokument31 SeitenBS 6399-1996 Loading For Building-Part3 Imposed Roof Loads PDFSenthooran MahendranNoch keine Bewertungen

- Eurocode Side BarsDokument6 SeitenEurocode Side BarsraymondNoch keine Bewertungen

- RCC51 Column Load Take-Down DesignDokument7 SeitenRCC51 Column Load Take-Down DesignBst PerchatNoch keine Bewertungen

- Access Steel - SF038 - Effective Section Properties of Lipped Steel ChannelsDokument3 SeitenAccess Steel - SF038 - Effective Section Properties of Lipped Steel Channelsgianniorlati1972Noch keine Bewertungen

- 115-Eurocode Design - Cantilever DeflectionDokument1 Seite115-Eurocode Design - Cantilever Deflectionrodriguez.gaytanNoch keine Bewertungen

- Advantages CFSTDokument14 SeitenAdvantages CFSTprajjwal patidarNoch keine Bewertungen

- 11 Continuous BeamsDokument55 Seiten11 Continuous BeamsMelinda GordonNoch keine Bewertungen

- BS 5950-2000 Example 001Dokument5 SeitenBS 5950-2000 Example 001Anitha Hassan KabeerNoch keine Bewertungen

- Bending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UDokument8 SeitenBending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UReef20Noch keine Bewertungen

- Composite Beam Design ExampleDokument7 SeitenComposite Beam Design ExampleAlphyl Balasabas100% (2)

- Fin Plate ConnectionDokument70 SeitenFin Plate Connectionfloi dNoch keine Bewertungen

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Dokument4 Seiten2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNoch keine Bewertungen

- Deflection Limits - EurocodeDokument1 SeiteDeflection Limits - EurocodeielleNoch keine Bewertungen

- Purlin DesignDokument28 SeitenPurlin DesignFatih Genc100% (2)

- Wind Load Bs 6399Dokument1 SeiteWind Load Bs 6399Kutty MansoorNoch keine Bewertungen

- Agricultural Buildings Designed To BS 5502-22Dokument3 SeitenAgricultural Buildings Designed To BS 5502-22fNoch keine Bewertungen

- Simply Supported Primary Composite BeamDokument17 SeitenSimply Supported Primary Composite BeamPaul Marceti100% (2)

- Standard Lighting Column FoundationsDokument2 SeitenStandard Lighting Column FoundationsEm MarNoch keine Bewertungen

- Shear KeyDokument14 SeitenShear KeyMbalekelwa MpembeNoch keine Bewertungen

- Common Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: OtherDokument8 SeitenCommon Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: Otherstarsplesh100% (1)

- Composite Beams & Columns To Eurocode 4Dokument155 SeitenComposite Beams & Columns To Eurocode 4dfdfdfasd324sad100% (2)

- BS 5268-6.2-2001 Structural Use of Timber PDFDokument24 SeitenBS 5268-6.2-2001 Structural Use of Timber PDFAlf Esparon100% (1)

- BRC Wire MeshDokument12 SeitenBRC Wire MeshDharnendra P BhavsarNoch keine Bewertungen

- Composite Slab ReportDokument10 SeitenComposite Slab ReportAhmed Moustafa AboelelaNoch keine Bewertungen

- Tying Resistance of A Fin Plate ConnectionDokument9 SeitenTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- LT Buckling Beam Design - Simple Method - 2upDokument5 SeitenLT Buckling Beam Design - Simple Method - 2upberto2008Noch keine Bewertungen

- Flitch BeamDokument4 SeitenFlitch BeamOlanrewaju OkunolaNoch keine Bewertungen

- Wind Loads UK Portal Frame WEDokument31 SeitenWind Loads UK Portal Frame WEmandregomes100% (1)

- Access Steel Data Sheets BindedDokument154 SeitenAccess Steel Data Sheets BindedblueswanNoch keine Bewertungen

- T3701a DFEDokument10 SeitenT3701a DFEAnca SimaNoch keine Bewertungen

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDokument10 SeitenExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranNoch keine Bewertungen

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDokument4 SeitenDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNoch keine Bewertungen

- Tedds RC Beam Design 2Dokument3 SeitenTedds RC Beam Design 2Hor Ka WaiNoch keine Bewertungen

- Cold Formed BendingDokument8 SeitenCold Formed BendinggeorgeispasoiuNoch keine Bewertungen

- Calculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorDokument8 SeitenCalculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorMoonzeNoch keine Bewertungen

- Mathcad - Baseplate Design - 8Dokument6 SeitenMathcad - Baseplate Design - 8Monotobo X MakinaNoch keine Bewertungen

- Simply Supported Secondary Composite BeamDokument11 SeitenSimply Supported Secondary Composite BeamgeorgeispasoiuNoch keine Bewertungen

- Beam UnrestrainedDokument9 SeitenBeam Unrestrainedgorgika papandNoch keine Bewertungen

- Mathcad - BASEPLATE DESIGN - 10 PDFDokument6 SeitenMathcad - BASEPLATE DESIGN - 10 PDFMonotobo X MakinaNoch keine Bewertungen

- Moment Connection - Flush End Plate-19.01.06Dokument48 SeitenMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- UK Afternoon WorkshopDokument50 SeitenUK Afternoon WorkshopanhkhoacgNoch keine Bewertungen

- EC2 Beam Section DesignDokument3 SeitenEC2 Beam Section Designikanyu79100% (1)

- Schwer - Florence - Axisymmetric Compression of A Mohr-Coulomb Medium Around A Circular HoleDokument13 SeitenSchwer - Florence - Axisymmetric Compression of A Mohr-Coulomb Medium Around A Circular Holegianniorlati1972Noch keine Bewertungen

- Compressed Air WorkDokument26 SeitenCompressed Air WorkSaminathan Munisamy0% (1)

- Units SlidesDokument18 SeitenUnits Slidesabegarza1Noch keine Bewertungen

- NCCI: Determination of Non-Dimensional Slenderness of I and H SectionsDokument11 SeitenNCCI: Determination of Non-Dimensional Slenderness of I and H SectionslingchenhNoch keine Bewertungen

- Bonini - Barla - FLAC Applications To The Analysis of Swelling Behaviour in TunnelsDokument5 SeitenBonini - Barla - FLAC Applications To The Analysis of Swelling Behaviour in Tunnelsgianniorlati1972Noch keine Bewertungen

- Access Steel - SF038 - Effective Section Properties of Lipped Steel ChannelsDokument3 SeitenAccess Steel - SF038 - Effective Section Properties of Lipped Steel Channelsgianniorlati1972Noch keine Bewertungen

- 05 - Example Sway StabilityDokument10 Seiten05 - Example Sway StabilityAlex TimocNoch keine Bewertungen

- Putzmeister - Concreting of Kops II Power Station - Distribution BoomDokument2 SeitenPutzmeister - Concreting of Kops II Power Station - Distribution Boomgianniorlati1972Noch keine Bewertungen

- AbstractDokument10 SeitenAbstractmarkNoch keine Bewertungen

- Electric Current in ConductorsDokument31 SeitenElectric Current in ConductorsthinkiitNoch keine Bewertungen

- Moving Coil Gavanometer - Classnotes (By Alakh Sir-Lakshya Batch)Dokument24 SeitenMoving Coil Gavanometer - Classnotes (By Alakh Sir-Lakshya Batch)sanjeev singhNoch keine Bewertungen

- Resnick Halliday Krane Vol 2Dokument695 SeitenResnick Halliday Krane Vol 241Kevin Thomas XI-B100% (1)

- A PM 07 Copper PillarsDokument7 SeitenA PM 07 Copper PillarsSieww GlenNoch keine Bewertungen

- LECTURE 2: Supplementary Notes Example: Comparison of Van Der Waals Forces For Pure SpeciesDokument14 SeitenLECTURE 2: Supplementary Notes Example: Comparison of Van Der Waals Forces For Pure SpeciesAnıl KahvecioğluNoch keine Bewertungen

- WST - Hydraulic Fracturing Part 1 - S12020 PDFDokument23 SeitenWST - Hydraulic Fracturing Part 1 - S12020 PDFShadishwaren ParameswaranNoch keine Bewertungen

- Analysis of Polymers by GPC SEC - AgilentDokument40 SeitenAnalysis of Polymers by GPC SEC - AgilentelenitabastosNoch keine Bewertungen

- Mass Proportional Damping in Nonlinear Time-History AnalysisDokument5 SeitenMass Proportional Damping in Nonlinear Time-History AnalysisEvgeny ShavelzonNoch keine Bewertungen

- (Always Learning) Jindal, U C - Strength of Materials, 1e-Pearson Education India (2012)Dokument880 Seiten(Always Learning) Jindal, U C - Strength of Materials, 1e-Pearson Education India (2012)googleNoch keine Bewertungen

- Dtic Ada097546Dokument34 SeitenDtic Ada097546Rodrigo GarciaNoch keine Bewertungen

- Neha Nylon 6,6Dokument16 SeitenNeha Nylon 6,6sakshi ranadeNoch keine Bewertungen

- Radiation Effects On Mosfets: Deepkumar R. ShahDokument5 SeitenRadiation Effects On Mosfets: Deepkumar R. Shahcarlos ricardo herrera castilloNoch keine Bewertungen

- Non Destructive TestDokument11 SeitenNon Destructive TestDms〆 FrïllèxNoch keine Bewertungen

- The Influence of Defects Theni2Pand0 of NioDokument6 SeitenThe Influence of Defects Theni2Pand0 of NioRodrigoEspinosa'fNoch keine Bewertungen

- Aws D17.2 - D17.2M-2013Dokument11 SeitenAws D17.2 - D17.2M-2013iwanNoch keine Bewertungen

- DME 2 Design of Spur GearDokument3 SeitenDME 2 Design of Spur Gearthe secret legendNoch keine Bewertungen

- And 1he ''Phii - Adelphia Expfriment': Negative TimeDokument94 SeitenAnd 1he ''Phii - Adelphia Expfriment': Negative TimegospodarmunjaNoch keine Bewertungen

- Post Tension Ing DesignDokument59 SeitenPost Tension Ing DesignFrank StephensNoch keine Bewertungen

- Hardness Conversion ChartDokument3 SeitenHardness Conversion ChartShikhar KhatriNoch keine Bewertungen

- 2507 Spec SheetDokument2 Seiten2507 Spec SheetlazaroccsNoch keine Bewertungen

- Fea Laboratory ManualDokument18 SeitenFea Laboratory Manualzoyarizvi11Noch keine Bewertungen

- A Review of Solar Cell Fundamentals andDokument13 SeitenA Review of Solar Cell Fundamentals andDonny TNoch keine Bewertungen

- HW 1Dokument12 SeitenHW 1peeyush_tapadiyaNoch keine Bewertungen

- Chapter 12 Powerpoint LDokument62 SeitenChapter 12 Powerpoint LSam H. SalehNoch keine Bewertungen

- 2016 Advances in Tool Wear in Turning ProcessDokument14 Seiten2016 Advances in Tool Wear in Turning ProcessorlandoduranNoch keine Bewertungen

- JNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESDokument1 SeiteJNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESConor StevensonNoch keine Bewertungen

- Dynamic Failure of Materials Theory, Experiments and NumericsDokument405 SeitenDynamic Failure of Materials Theory, Experiments and NumericsAbhilash R MNoch keine Bewertungen

- Q2 Chem 1 Molecular Geometry HandoutsDokument1 SeiteQ2 Chem 1 Molecular Geometry Handoutsmikomira21Noch keine Bewertungen