Beruflich Dokumente

Kultur Dokumente

Engr6301 A1 RTO Summer14

Hochgeladen von

Vamsi KrishnaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Engr6301 A1 RTO Summer14

Hochgeladen von

Vamsi KrishnaCopyright:

Verfügbare Formate

Lamar University

ENGR 6301-A1 Real Time Optimization

Summer I 2014

MTWR 3:35-5:30 Lucas Rm 110

General Course Information

Instructor:

Office:

Office Hours:

Phone:

E-mail:

Textbook:

Dr. Peyton C. Richmond, Chemical Engineering

108 Lucas Building

2:00 3:00 p.m. Monday, Wednesday, or by appointment

880-2147

peyton.richmond@lamar.edu

Edgar, T.F., Himmelblau, D.M., and Lasdon, L.S., Optimization

of Chemical Processes, Second Edition, McGraw-Hill, New

York (2001)

Additional Material: Presentation Slides supplemented by Literature references

Course Objectives

This course introduces students to Real Time Optimization (RTO) as practiced by the

chemical and refining industry.

Student Learning Outcomes

At the successful conclusion of this course students will be able to:

1. Identify where an industrial real time optimization (RTO) application fits into the

corporate decision making hierarchy

2. Discuss the steps to solve optimization problems as well as some of the obstacles

to successful optimization;

3. Describe how equation oriented (EO) process simulation is used for RTO and why

it is more suitable than sequential modular (SM) process simulation;

4. By way of a class project, demonstrate the ability to formulate and solve a modest

RTO problem using AspenPlus EO software.

Web Site

Supplementary information for this course including class notes, PowerPoint slides, class

announcements, the course syllabus, test dates, and other information will be posted on

the Web. Further instructions will be provided when the information is posted.

All students are requested to obtain an e-mail account. If you have any questions about

the course or need assistance, please contact me in person or by telephone during office

hours; or by e-mail at any time. E-mail lab or homework submissions should be

submitted as an attachment in Microsoft Word format.

This course complies with university policies on disabilities, accommodations, and academic dishonesty as

printed in the Lamar University Student Handbook and Faculty Handbook

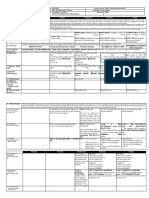

Grading and Evaluation Criteria

Homework and lab assignments are due on the assigned day before class starts.

Late homework and lab assignments (no more than one week after the due date)

will receive a maximum of 50% credit.

The final grading curve is subject to the discretion of the instructor

Point distribution:

50% of the grade is based on examinations (exam 1 25%, exam 2 25%).

Examinations are not cumulative and are given in a multiple choice format. An inclass review will be held prior to each examination.

25% of the grade is based on student projects.

25% of the grade is based on lab assignments.

Preliminary Syllabus

Week#

1

Date

Jun 4

Jun 9

Jun 16

Jun 23

Jun 30

Jul 9

Subject

Overview Plant Optimization Hierarchy

Flow sheeting analysis (SM/EO)

EO Nomenclature (Deethanizer/Depropanizer) Class

EO Nomenclature (Deethanizer/Depropanizer) Lab1

Control Structure and Simulation

EO Modes and Variables (Deethanizer/Depropanizer) Class

EO Modes and Variables (Deethanizer/Depropanizer) Lab2

EO Modes and Variables (Deethanizer/Depropanizer) Lab2

Specification Groups (Deethanizer/Depropanizer) Class

Specification Groups (Deethanizer/Depropanizer) Lab3

Review (student test questions due)

Exam 1

Infeasible Path Optimization (HW1)

Optimization (Light Hydrocarbon Refrigeration) Class

Optimization (Light Hydrocarbon Refrigeration) Lab4

Gross Error Detection & Data Reconciliation (HW2)

Distillation Optimization (Ethylene Tower) Class

Distillation Optimization (Ethylene Tower) Lab5

Scripting Language and Automation

Student Project Rubric Review

Measurement Models (Ethylene Tower) Class

Measurement Models (Ethylene Tower) Lab6

Review (student test questions due)

Project Due

Exam 2

This course complies with university policies on disabilities, accommodations, and academic dishonesty as

printed in the Lamar University Student Handbook and Faculty Handbook

Das könnte Ihnen auch gefallen

- Analysis of 2D-Anisotropic Plate With Elliptical Hole: ENGR 6310 Design ProjectDokument18 SeitenAnalysis of 2D-Anisotropic Plate With Elliptical Hole: ENGR 6310 Design ProjectVamsi KrishnaNoch keine Bewertungen

- Adsorption Thermodynamics of Cobalt Ions Onto AttapulgiteDokument5 SeitenAdsorption Thermodynamics of Cobalt Ions Onto AttapulgiteVamsi KrishnaNoch keine Bewertungen

- Gas Chromatography: Essential Hardware and OperationsDokument32 SeitenGas Chromatography: Essential Hardware and OperationsVamsi KrishnaNoch keine Bewertungen

- Ion Chromatography:: Separation of Polar and Ionic CompoundsDokument20 SeitenIon Chromatography:: Separation of Polar and Ionic CompoundsVamsi KrishnaNoch keine Bewertungen

- Real Time Optimization LAB #2 - Aspen EO Modes and VariablesDokument2 SeitenReal Time Optimization LAB #2 - Aspen EO Modes and VariablesVamsi KrishnaNoch keine Bewertungen

- Shipping Request Form 7 - 12Dokument1 SeiteShipping Request Form 7 - 12Vamsi KrishnaNoch keine Bewertungen

- Tofel ConfirmationDokument2 SeitenTofel ConfirmationVamsi KrishnaNoch keine Bewertungen

- Vamsi SopDokument3 SeitenVamsi SopVamsi KrishnaNoch keine Bewertungen

- Simulation Project Spring 2014Dokument19 SeitenSimulation Project Spring 2014Vamsi KrishnaNoch keine Bewertungen

- Aspen DMC Plus: Dynamic ModelingDokument41 SeitenAspen DMC Plus: Dynamic ModelingVamsi KrishnaNoch keine Bewertungen

- I901 Payment Confirmation 03132019 PDFDokument1 SeiteI901 Payment Confirmation 03132019 PDFSyllaNoch keine Bewertungen

- Project Report SimulationDokument17 SeitenProject Report SimulationVamsi KrishnaNoch keine Bewertungen

- Workshop 11Dokument30 SeitenWorkshop 11Vamsi KrishnaNoch keine Bewertungen

- DMC C2009Dokument27 SeitenDMC C2009Vamsi Krishna100% (1)

- DRW 0002Dokument1 SeiteDRW 0002Vamsi KrishnaNoch keine Bewertungen

- Control C 031714Dokument115 SeitenControl C 031714Vamsi KrishnaNoch keine Bewertungen

- Baba JobsDokument1 SeiteBaba JobsVamsi KrishnaNoch keine Bewertungen

- Cfa ResultDokument1 SeiteCfa ResultVamsi KrishnaNoch keine Bewertungen

- Project Full PaperDokument36 SeitenProject Full PaperVamsi KrishnaNoch keine Bewertungen

- Statistical Intervals.: INEN 5320 Statistical Decision Making Dr. Alberto Marquez Lamar UniversityDokument20 SeitenStatistical Intervals.: INEN 5320 Statistical Decision Making Dr. Alberto Marquez Lamar UniversityVamsi KrishnaNoch keine Bewertungen

- DRW 0001Dokument1 SeiteDRW 0001Vamsi KrishnaNoch keine Bewertungen

- Project Full PaperDokument36 SeitenProject Full PaperVamsi KrishnaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Michael Ruggiero ResumeDokument1 SeiteMichael Ruggiero ResumeMNoch keine Bewertungen

- Bauhaus-Universität Weimar - Doctoral Degree (PH.D.) - DR - Phil.Dokument2 SeitenBauhaus-Universität Weimar - Doctoral Degree (PH.D.) - DR - Phil.IoetRoqNoch keine Bewertungen

- Case Study Reflection3Dokument3 SeitenCase Study Reflection3api-321364197Noch keine Bewertungen

- Math7 2 Student MaterialsDokument122 SeitenMath7 2 Student Materialsapi-264794990Noch keine Bewertungen

- Welcome To Londiwe Londie MavusoDokument7 SeitenWelcome To Londiwe Londie MavusoLondiweNoch keine Bewertungen

- Elements Components of Curriculum - XXXDokument47 SeitenElements Components of Curriculum - XXXanir89% (18)

- What Is A Professional Learning CommunityDokument13 SeitenWhat Is A Professional Learning Communityrida74100% (1)

- 4 DecDokument2 Seiten4 DecNlm NaulakNoch keine Bewertungen

- Lesson Plan and Reflection With Annotations 2Dokument3 SeitenLesson Plan and Reflection With Annotations 2api-254905239Noch keine Bewertungen

- Elementary Graduation SpeechDokument3 SeitenElementary Graduation SpeechRob Closas100% (1)

- Thesis On Inservice Teacher TrainingDokument7 SeitenThesis On Inservice Teacher Trainingh0nuvad1sif2100% (2)

- St. Mary's College of Catbalogan: Impact Analysis and Risk AssessmentDokument4 SeitenSt. Mary's College of Catbalogan: Impact Analysis and Risk AssessmentDodoy Leandro Frincillo CrebelloNoch keine Bewertungen

- Kathryn Schulte Resume 2017Dokument2 SeitenKathryn Schulte Resume 2017api-367182338Noch keine Bewertungen

- Science Lower Secondary 2013Dokument39 SeitenScience Lower Secondary 2013tanNoch keine Bewertungen

- Maritime Labour Convention CourseDokument2 SeitenMaritime Labour Convention Courseidhur61Noch keine Bewertungen

- UBD Lesson Plan For WebQuestsDokument7 SeitenUBD Lesson Plan For WebQuestshazepascuaNoch keine Bewertungen

- Article Reviewed: Rasinski, T. V. (2000) - Speed Does Matter in Reading. The Reading Teacher, 146-151Dokument3 SeitenArticle Reviewed: Rasinski, T. V. (2000) - Speed Does Matter in Reading. The Reading Teacher, 146-151Rubinidevi VelooNoch keine Bewertungen

- Research ProjectDokument9 SeitenResearch ProjectkalaiselvanNoch keine Bewertungen

- FINAL RPMS T1 3 SY 2022 2023 IgotDokument37 SeitenFINAL RPMS T1 3 SY 2022 2023 IgotRamir Becoy100% (3)

- Daily Lesson LogDokument5 SeitenDaily Lesson LogJoscelle Joyce RiveraNoch keine Bewertungen

- Elaine Halle Reflexive PronounsDokument3 SeitenElaine Halle Reflexive PronounshuntclubNoch keine Bewertungen

- Part 1 BookDokument22 SeitenPart 1 BookPamela Alvarez BumatayNoch keine Bewertungen

- How Emotions Affect LearningDokument2 SeitenHow Emotions Affect Learningveralex100% (1)

- Utrecht Excellence ScholarshipsDokument3 SeitenUtrecht Excellence ScholarshipsAlex CandraNoch keine Bewertungen

- Kabul University Appreciation Letter From Dr. Maria BeebeDokument2 SeitenKabul University Appreciation Letter From Dr. Maria BeebeInayet Hadi100% (1)

- UT Dallas Syllabus For Comd6307.001 05s Taught by Ariela Jokel (Ariela)Dokument2 SeitenUT Dallas Syllabus For Comd6307.001 05s Taught by Ariela Jokel (Ariela)UT Dallas Provost's Technology GroupNoch keine Bewertungen

- Undergraduate LO RubricsDokument5 SeitenUndergraduate LO RubricsSafaruddin Al AfganiNoch keine Bewertungen

- Epse 432 - Reflection PaperDokument5 SeitenEpse 432 - Reflection Paperapi-260661724Noch keine Bewertungen

- August 14-16, 2017Dokument7 SeitenAugust 14-16, 2017Dotecho Jzo EyNoch keine Bewertungen

- National Reading PanelDokument20 SeitenNational Reading PanelTanya MartinNoch keine Bewertungen