Beruflich Dokumente

Kultur Dokumente

FORTRON® 1120L4 - PPS - Specialty: Description

Hochgeladen von

Adam GordonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FORTRON® 1120L4 - PPS - Specialty: Description

Hochgeladen von

Adam GordonCopyright:

Verfügbare Formate

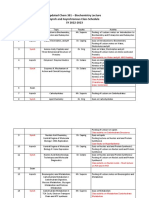

FORTRON 1120L4 | PPS | Specialty

Description

Fortron 1120L4 is a 20% glass fiber reinforced injection molding grade exhibiting excellent heat and chemical resistance,

inherent flame retardancy, high hardness and stiffness at elevated temperatures.

Physical properties

Value

Unit

Test Standard

Density

Water absorption (23C-sat)

1480

0.02

kg/m

%

ISO 1183

ISO 62

Mechanical properties

Value

Unit

Test Standard

Tensile stress at break (5mm/min)

Tensile strain at break (5mm/min)

Flexural modulus (23C)

Flexural strength (23C)

Unnotched impact str (Izod) @ 23C

Notched impact strength (Izod) @ 23C

Rockwell hardness

120

1.5

8000

170

35

7.0

100

MPa

%

MPa

MPa

kJ/m

kJ/m

M-Scale

ISO 527-2/1A

ISO 527-2/1A

ISO 178

ISO 178

ISO 180/1U

ISO 180/1A

ISO 2039-2

Thermal properties

Value

Unit

Test Standard

DTUL @ 1.8 MPa

Flammability @1.6mm nom. thickn.

255

V-0

C

class

ISO 75-1/-2

UL94

Contact Information

Americas

Europe

Ticona

Product Information Service

8040 Dixie Highway

Florence, KY 41042

USA

Tel.: +1-800-833-4882

Tel.: +1-859-372-3244

email: prodinfo@ticona.com

Ticona on the web: www.ticona.com

Ticona GmbH

Information Service

Tel.: +49 (0) 180-5842662 (Germany)*

+49 (0) 69-30516299 (Europe)

Fax: +49 (0) 180-2021202 (Germany & Europe)**

email: infoservice@ticona.de

Internet: www.ticona.com

*starting 01.01.2007 0,14/minute + local landline rates

**0,06/Call + local landline rates

Customer Service

Tel.: +1-800-526-4960

Tel.: +1-859-372-3214

Fax: +1-859-372-3125

Printed: 18. January 2008

Page: 1

Ticona - A business of Celanese

FORTRON 1120L4 | PPS | Specialty

General Disclaimer

NOTICE TO USERS: Values shown are based on testing of laboratory test specimens and represent data that fall within the standard range

of properties for natural material. These values alone do not represent a sufficient basis for any part design and are not intended for use in

establishing maximum, minimum, or ranges of values for specification purposes. Colorants or other additives may cause significant variations

in data values.

Properties of molded parts can be influenced by a wide variety of factors including, but not limited to, material selection, additives, part

design, processing conditions and environmental exposure. Any determination of the suitability of a particular material and part design for any

use contemplated by the users and the manner of such use is the sole responsibility of the users, who must assure themselves that the

material as subsequently processed meets the needs of their particular product or use.

To the best of our knowledge, the information contained in this publication is accurate; however, we do not assume any liability whatsoever for

the accuracy and completeness of such information. The information contained in this publication should not be construed as a promise or

guarantee of specific properties of our products. It is the sole responsibility of the users to investigate whether any existing patents are

infringed by the use of the materials mentioned in this publication.

Moreover, there is a need to reduce human exposure to many materials to the lowest practical limits in view of possible adverse effects. To

the extent that any hazards may have been mentioned in this publication, we neither suggest nor guarantee that such hazards are the only

ones that exist. We recommend that persons intending to rely on any recommendation or to use any equipment, processing technique or

material mentioned in this publication should satisfy themselves that they can meet all applicable safety and health standards.

We strongly recommend that users seek and adhere to the manufacturers current instructions for handling each material they use, and

entrust the handling of such material to adequately trained personnel only. Please call the telephone numbers listed (+49 (0) 69 30516299 for

Europe and +1 859-372-3244 for the Americas) for additional technical information. Call Customer Services for the appropriate Materials

Safety Data Sheets (MSDS) before attempting to process our products.

The products mentioned herein are not intended for use in medical or dental implants.

Copyright 2007, Ticona, all rights reserved. (Pub. 26-Dec-2007)

Printed: 18. January 2008

Page: 2

Ticona - A business of Celanese

Das könnte Ihnen auch gefallen

- Standard For Wood Containers 2012Dokument51 SeitenStandard For Wood Containers 2012Cristina Garcia100% (1)

- Atom WorksheetsDokument4 SeitenAtom Worksheetsapi-271960049Noch keine Bewertungen

- EHS Guidelines Offshore Oil and Gas June2015Dokument42 SeitenEHS Guidelines Offshore Oil and Gas June2015IFC Sustainability100% (3)

- B.3.4 Design Calculations For Snap-Fit Joints, FarbigDokument18 SeitenB.3.4 Design Calculations For Snap-Fit Joints, FarbigpchannagoudarNoch keine Bewertungen

- Sae j429 Vs Astm A354 BDDokument2 SeitenSae j429 Vs Astm A354 BDAdam GordonNoch keine Bewertungen

- Soudure Plastique Ultra Son PDFDokument30 SeitenSoudure Plastique Ultra Son PDFamr_akram_2Noch keine Bewertungen

- IDENTIFYING CAP SCREW GRADESDokument2 SeitenIDENTIFYING CAP SCREW GRADESAdam GordonNoch keine Bewertungen

- Genie: Hot Water Driven Vapor Absorption MachineDokument39 SeitenGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyNoch keine Bewertungen

- Palm Based Non Hydrogenated Creamer PDFDokument4 SeitenPalm Based Non Hydrogenated Creamer PDFbellesuperNoch keine Bewertungen

- Top Steel Companies in IndiaDokument3 SeitenTop Steel Companies in Indiazukmos67% (3)

- Din 580Dokument1 SeiteDin 580safaozhanNoch keine Bewertungen

- Norris Maximum Torque Values For PCP ApplicationsDokument2 SeitenNorris Maximum Torque Values For PCP ApplicationsJorgeArraizNoch keine Bewertungen

- 2628Dokument3 Seiten2628renebbNoch keine Bewertungen

- Celcon CE67 Data SheetDokument2 SeitenCelcon CE67 Data SheetRT Sport SNoch keine Bewertungen

- ISO Datasheet UE-71D10 Preliminary BMSTDokument1 SeiteISO Datasheet UE-71D10 Preliminary BMSTNamtien UsNoch keine Bewertungen

- Ara 2012Dokument5 SeitenAra 2012pavan_03Noch keine Bewertungen

- Intercare 123Dokument4 SeitenIntercare 123Trịnh Minh KhoaNoch keine Bewertungen

- Engage 8200Dokument2 SeitenEngage 8200Vladimir VanyukovNoch keine Bewertungen

- 3 100e Unersal Silicone Tds enDokument1 Seite3 100e Unersal Silicone Tds enJames MurrayNoch keine Bewertungen

- 1049D CERABOND 2000 Rev (1409)Dokument2 Seiten1049D CERABOND 2000 Rev (1409)Trịnh Minh KhoaNoch keine Bewertungen

- Delrin 100 AFDokument2 SeitenDelrin 100 AFom12315Noch keine Bewertungen

- P840J Feb, 09Dokument2 SeitenP840J Feb, 09Tan Chen TatNoch keine Bewertungen

- P740JDokument2 SeitenP740JTan Chen TatNoch keine Bewertungen

- Zytel 103HSL BKB080Dokument3 SeitenZytel 103HSL BKB080Parag NambiarNoch keine Bewertungen

- HZ Tecaflon Ptfe Natural in de 201501Dokument1 SeiteHZ Tecaflon Ptfe Natural in de 201501Jonathan CruzNoch keine Bewertungen

- Desmodur N 3300Dokument4 SeitenDesmodur N 3300Cesar Martinez50% (2)

- Ryton QC160N and QC160P: Polyphenylene Sulfide AlloysDokument2 SeitenRyton QC160N and QC160P: Polyphenylene Sulfide AlloysJustin HendrixNoch keine Bewertungen

- EL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingDokument2 SeitenEL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingTan Chen TatNoch keine Bewertungen

- CERABEST Grey Heat Resistant Paint Technical Data SheetDokument2 SeitenCERABEST Grey Heat Resistant Paint Technical Data SheetTrịnh Minh KhoaNoch keine Bewertungen

- 100 PDFDokument4 Seiten100 PDFebercueNoch keine Bewertungen

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Dokument2 SeitenPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaNoch keine Bewertungen

- P640JDokument2 SeitenP640JTan Chen TatNoch keine Bewertungen

- Polycarbonate Film Makrofol LM228 160005 CurbellDokument4 SeitenPolycarbonate Film Makrofol LM228 160005 CurbellVinaya Almane DattathreyaNoch keine Bewertungen

- Pearlthane 11T93Dokument2 SeitenPearlthane 11T93Gabriel SalomonNoch keine Bewertungen

- Dow 3504Dokument2 SeitenDow 3504khantoNoch keine Bewertungen

- Desmopan 487 injection molding grade TPUDokument2 SeitenDesmopan 487 injection molding grade TPUMohammad Doost MohammadiNoch keine Bewertungen

- PVDF31508 - 0003 Data SheetDokument2 SeitenPVDF31508 - 0003 Data SheetsoumsarkarNoch keine Bewertungen

- Acothane Twin Pack: Product DescriptionDokument3 SeitenAcothane Twin Pack: Product DescriptionpazhanivelmuruganNoch keine Bewertungen

- Formulation: StartingDokument4 SeitenFormulation: StartingA MahmoodNoch keine Bewertungen

- Delrin500pnc010 PDFDokument4 SeitenDelrin500pnc010 PDFtushar7000Noch keine Bewertungen

- Zytel 80G33HS1L BK104Dokument3 SeitenZytel 80G33HS1L BK104nimonhNoch keine Bewertungen

- PR143 TDSDokument2 SeitenPR143 TDSAero GuyNoch keine Bewertungen

- Desmopan 192 ISODokument2 SeitenDesmopan 192 ISOaakashlakhanpal9830Noch keine Bewertungen

- Interclene 5012Dokument4 SeitenInterclene 5012Trịnh Minh KhoaNoch keine Bewertungen

- Lotrène FE8000 2014 04 16 PDFDokument2 SeitenLotrène FE8000 2014 04 16 PDFHameer SattarNoch keine Bewertungen

- Amplify Io 3701Dokument2 SeitenAmplify Io 3701Julio GarcíaNoch keine Bewertungen

- 3M 9731RWDokument4 Seiten3M 9731RWcbol91311Noch keine Bewertungen

- Data SheetDokument3 SeitenData Sheetashv1972Noch keine Bewertungen

- Polypropylene Product Technical InfoDokument2 SeitenPolypropylene Product Technical InforcnexyNoch keine Bewertungen

- Desmophen 650 MPA enDokument3 SeitenDesmophen 650 MPA enCesar MartinezNoch keine Bewertungen

- Properties Data Sheet: HDPE - 5220BNDokument1 SeiteProperties Data Sheet: HDPE - 5220BNSergio Rubens Oliveira SantosNoch keine Bewertungen

- Bond Breaker Tape TDS PDFDokument2 SeitenBond Breaker Tape TDS PDFengsam777Noch keine Bewertungen

- 8250 Rust Inhibitive Oil CK Rev (1409)Dokument2 Seiten8250 Rust Inhibitive Oil CK Rev (1409)Trịnh Minh KhoaNoch keine Bewertungen

- Magnum 960 301-01438Dokument2 SeitenMagnum 960 301-01438Yen Sebastian SantosNoch keine Bewertungen

- Pinnacle PP 4220HDokument4 SeitenPinnacle PP 4220Hbrandon_809656159Noch keine Bewertungen

- 5083 BANNOH 2000 QD Rev (1409)Dokument2 Seiten5083 BANNOH 2000 QD Rev (1409)Trịnh Minh KhoaNoch keine Bewertungen

- Safety Data Sheet: 3M™ Unitek™ Transbond™ XT Light Cure Adhesive Kit (712-030, 712-035)Dokument21 SeitenSafety Data Sheet: 3M™ Unitek™ Transbond™ XT Light Cure Adhesive Kit (712-030, 712-035)謎超人Noch keine Bewertungen

- 5409 Epicon Marine CH Rev (1409)Dokument2 Seiten5409 Epicon Marine CH Rev (1409)Trịnh Minh KhoaNoch keine Bewertungen

- Datasheet PA66 TT6600-5001 EC GreyDokument2 SeitenDatasheet PA66 TT6600-5001 EC GreySeahawk76Noch keine Bewertungen

- 226N Data Sheet - FBE CoatingDokument2 Seiten226N Data Sheet - FBE Coatingbello imamNoch keine Bewertungen

- Conductive Mastic 8004Dokument0 SeitenConductive Mastic 8004LaplaceFourierNoch keine Bewertungen

- Amcel KP20Dokument1 SeiteAmcel KP20Marcos KuriharaNoch keine Bewertungen

- MATERIAL SAFETY DATA SHEET FOR DPF CLEANER AGENTDokument5 SeitenMATERIAL SAFETY DATA SHEET FOR DPF CLEANER AGENTJorge SepulvedaNoch keine Bewertungen

- Elastomeric Polyurethane Desmocoll 540 Product InformationDokument2 SeitenElastomeric Polyurethane Desmocoll 540 Product Informationlobocerna100% (3)

- Dupont Zytel: Zytel 73G15Hsl Bk363Dokument2 SeitenDupont Zytel: Zytel 73G15Hsl Bk363Roberto HernandezNoch keine Bewertungen

- HysolDokument2 SeitenHysoljorgequijanoNoch keine Bewertungen

- 5084 Bannoh 1500 (1409)Dokument2 Seiten5084 Bannoh 1500 (1409)Trịnh Minh KhoaNoch keine Bewertungen

- Cadenas RR-C-271F PDFDokument45 SeitenCadenas RR-C-271F PDFAdam GordonNoch keine Bewertungen

- Gems LS1900 PN35676 FLOTANTEDokument1 SeiteGems LS1900 PN35676 FLOTANTEAdam GordonNoch keine Bewertungen

- Sae J1397-1992 PDFDokument11 SeitenSae J1397-1992 PDFAdam GordonNoch keine Bewertungen

- Steam Calculators - Steam Turbine Calculator2Dokument2 SeitenSteam Calculators - Steam Turbine Calculator2Adam GordonNoch keine Bewertungen

- Ansi Icwm 2012Dokument65 SeitenAnsi Icwm 2012Adam GordonNoch keine Bewertungen

- FORTRON® 1140L4 - PPS - Glass Reinforced: DescriptionDokument7 SeitenFORTRON® 1140L4 - PPS - Glass Reinforced: DescriptionAdam GordonNoch keine Bewertungen

- ONE-WAY CLUTCH BEARINGS—CSK SeriesDokument3 SeitenONE-WAY CLUTCH BEARINGS—CSK SeriesAdam GordonNoch keine Bewertungen

- Tabale de ParafusoDokument54 SeitenTabale de ParafusoSilas MendesNoch keine Bewertungen

- Ansi C3752Dokument17 SeitenAnsi C3752Adam GordonNoch keine Bewertungen

- Cadenas RR-C-271F PDFDokument45 SeitenCadenas RR-C-271F PDFAdam GordonNoch keine Bewertungen

- Dimensiones y Acotaciones PDFDokument34 SeitenDimensiones y Acotaciones PDFAdam GordonNoch keine Bewertungen

- Polymer LectureDokument12 SeitenPolymer LectureAdam GordonNoch keine Bewertungen

- Naca Report 1368Dokument86 SeitenNaca Report 1368Adam GordonNoch keine Bewertungen

- Curva 4HF 70LDokument1 SeiteCurva 4HF 70LAdam GordonNoch keine Bewertungen

- Industrial rivets according to DIN standardsDokument10 SeitenIndustrial rivets according to DIN standards'Verness'NotoBudyoNoch keine Bewertungen

- Parker O-Ring Handbook: Approximate Service Temperature Ranges For Commonly Used Basic Polymer TypesDokument53 SeitenParker O-Ring Handbook: Approximate Service Temperature Ranges For Commonly Used Basic Polymer Typesvadim.isheevNoch keine Bewertungen

- Steel PipesDokument16 SeitenSteel PipesAdam GordonNoch keine Bewertungen

- API - 6D - Plant 3 - 2015Dokument1 SeiteAPI - 6D - Plant 3 - 2015Adam GordonNoch keine Bewertungen

- GlossaryDokument17 SeitenGlossaryPRASAD326100% (1)

- SW11Dokument6 SeitenSW11Adam GordonNoch keine Bewertungen

- Chtmultiregionfoam4regiontutorial 140818030511 Phpapp01Dokument24 SeitenChtmultiregionfoam4regiontutorial 140818030511 Phpapp01Adam GordonNoch keine Bewertungen

- CSK..P, CSK..PP CSK..P-2RS: Combined Bearing/FreewheelDokument2 SeitenCSK..P, CSK..PP CSK..P-2RS: Combined Bearing/FreewheelAdam GordonNoch keine Bewertungen

- CFD with OpenSource softwareDokument31 SeitenCFD with OpenSource softwareAdam GordonNoch keine Bewertungen

- Reedswitch HYR-2003Dokument2 SeitenReedswitch HYR-2003Adam GordonNoch keine Bewertungen

- Contracción ElastomerosDokument2 SeitenContracción ElastomerosAdam GordonNoch keine Bewertungen

- Specific Energy Curve Lab ReportDokument8 SeitenSpecific Energy Curve Lab ReportEngr Muhammad TariqNoch keine Bewertungen

- Molecules: Blumea Balsamifera-A Phytochemical andDokument25 SeitenMolecules: Blumea Balsamifera-A Phytochemical andAlyssa Leah Veloso EvangelistaNoch keine Bewertungen

- Wastewater treatment and sludge digestion process explainedDokument17 SeitenWastewater treatment and sludge digestion process explainedParas KathvadiyaNoch keine Bewertungen

- Canadian Coast Guard Welding SpecificationDokument39 SeitenCanadian Coast Guard Welding Specificationalvin dueyNoch keine Bewertungen

- Corrosion Prevention and ControlDokument19 SeitenCorrosion Prevention and ControlJosa FatyNoch keine Bewertungen

- Evolution of Atomic Structure PDFDokument1 SeiteEvolution of Atomic Structure PDFAnonymous VI4gZ25FbaNoch keine Bewertungen

- BooCax Disinfection Solution For Beijing 2022 Winter OlympicsDokument21 SeitenBooCax Disinfection Solution For Beijing 2022 Winter OlympicsRobotics BoocaxNoch keine Bewertungen

- Marshall Tufflex: GRP Cable Management SystemsDokument18 SeitenMarshall Tufflex: GRP Cable Management SystemsGabriel BroascaNoch keine Bewertungen

- Experiment 2: Brinell Hardness TestDokument5 SeitenExperiment 2: Brinell Hardness TestseifNoch keine Bewertungen

- 6 Emission AbsorptionDokument6 Seiten6 Emission AbsorptionArya RaoNoch keine Bewertungen

- RTS PS 2024ref2023ftsDokument3 SeitenRTS PS 2024ref2023ftsmohitabochare2039Noch keine Bewertungen

- Content of The Dossier For Chemical Purity and Microbiological QualityDokument23 SeitenContent of The Dossier For Chemical Purity and Microbiological QualityjdemelloNoch keine Bewertungen

- Ekatalog 2023 Sulsel RajawaliDokument50 SeitenEkatalog 2023 Sulsel RajawaliSafria HamzaNoch keine Bewertungen

- Effect of Acids and Bases On The Browning of ApplesDokument2 SeitenEffect of Acids and Bases On The Browning of ApplesAnkur Agarwall0% (1)

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDokument2 SeitenDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNoch keine Bewertungen

- Line Sizing CriteriaDokument5 SeitenLine Sizing CriteriaBILAL ILYASNoch keine Bewertungen

- Du Et Al 2020Dokument12 SeitenDu Et Al 2020Deise Dalazen CastagnaraNoch keine Bewertungen

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchDokument3 SeitenSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANANoch keine Bewertungen

- GATE-Architecture Sample QuestionsDokument6 SeitenGATE-Architecture Sample QuestionsCharan ReddyNoch keine Bewertungen

- Springwire Xinhua 2006Dokument10 SeitenSpringwire Xinhua 2006teban09Noch keine Bewertungen

- Niton XRF V Fire Assay App NoteDokument2 SeitenNiton XRF V Fire Assay App Notedarioharloc2272Noch keine Bewertungen

- Activity Coefficients of The Tetramethyl Compounds of Group 14 Elements in N-Alkane Solutions From g.1.c. MeasurementsDokument7 SeitenActivity Coefficients of The Tetramethyl Compounds of Group 14 Elements in N-Alkane Solutions From g.1.c. Measurementsm_adnane_dz3184Noch keine Bewertungen

- PhysicsBowl 2002Dokument14 SeitenPhysicsBowl 2002satishirish3938Noch keine Bewertungen

- Special Fiber Optic PDFDokument18 SeitenSpecial Fiber Optic PDFtarluzNoch keine Bewertungen

- Plastics: Name: Taaha Muzaffar Imam ROLL NO.: 19011AA002 Sem/Sec: Ii/A Branch: B.Arch College: Spa' JnafauDokument5 SeitenPlastics: Name: Taaha Muzaffar Imam ROLL NO.: 19011AA002 Sem/Sec: Ii/A Branch: B.Arch College: Spa' JnafauTaaha Muzaffar ImamNoch keine Bewertungen