Beruflich Dokumente

Kultur Dokumente

1 s2.0 S096386950300046X Main

Hochgeladen von

Gabriel Vazquez VegaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 S096386950300046X Main

Hochgeladen von

Gabriel Vazquez VegaCopyright:

Verfügbare Formate

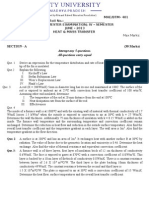

NDT&E International 37 (2004) 917

www.elsevier.com/locate/ndteint

The evaluation of surface residual stress in aeronautic bearings

using the Barkhausen noise effect

S. Desvauxa,b, M. Duquennoya,*, J. Gualandrib, M. Ouraka

a

IEMN, Departement OAE (UMR CNRS 8520), Universite de Valenciennes et du Hainaut Cambresis, B.P. 311,

Valenciennes cedex 9, 59313, France

b

SNFA, Z.I. n82 Batterie 900 Rouvignies, Valenciennes 59309, France

Received 2 December 2002; revised 4 March 2003; accepted 17 March 2003

Abstract

Bearings in aeronautic engines are subject to heavy mechanical demands. The bearing raceways withstand levels of mechanical stress

capable of causing metal fatigue that can lead to bearing malfunction, which in turn may cause engine failure mid-flight. For this reason,

regular verifications of engine bearings to gauge the degree of metal fatigue are essential. Such verifications require knowledge of the prestress state of the bearing raceways through use of surface residual stress (SRS) estimates. In this paper, we present a non-destructive method

for estimating SRS, based on the Barkhausen noise (BN) effect. This method was validated on several different batches of bearings. Our

investigations have shown this method to be rapid, well suited to industrial imperatives connected to on-line measurement and easily adapted

to the circular geometries of the bearings rings. In addition, we have shown the efficiency of the BN effect for estimating the SRS of bearing

raceways after engine operation, in order to perform necessary bearing maintenance.

q 2004 Elsevier Ltd. All rights reserved.

Keywords: Residual stress; The Barkhausen noise effect; Bearings

1. Introduction

Bearings in aeronautic engines are subject to extremely

severe running conditions. The contact areas between the

balls or rollers and the raceways (both the inner and outer

rings) sustain mechanical stress leading to a hertzien

fatigue process. As a result of this fatigue, micro-cracks

may appear on the contact area. Without intervention,

these cracks can develop until they cause bearing

malfunction, which may lead to engine failure. It is

therefore indispensable to ensure that the contact areas of

aeronautic engine bearings are in optimal condition,

paying particular attention to the metallurgical aspect of

the metal (evidence of grinding abuse, for instance) and to

the metals stress level for any bearing-loading zone by

targeting compressive residual stress. Both the validation

of a method capable to introduce residual stresses and the

development of a non-destructive method that can ensure

* Corresponding author. Fax: 33-03-27-51-11-89.

E-mail address: marc.duquennoy@univ-valenciennes.fr

Duquennoy).

(M.

0963-8695/03/$ - see front matter q 2004 Elsevier Ltd. All rights reserved.

doi:10.1016/S0963-8695(03)00046-X

the follow-up of associated residual stresses has become a

necessity. This paper presents a non-destructive method

for identifying the surface stress of the contact areas

between the balls or rollers and their raceways. This

method is based on the phenomenon of Barkhausen noise

(BN), and is adapted to industrial imperatives connected

to on-line measurement. It is rapid, requires no direct

contact and is suitable for the circular geometry of the

bearing rings. Using X-ray diffraction as our method of

reference, we have shown the efficiency of BN in

estimating the surface residual stress (SRS) of raceways

following grinding operations, specific pre-stress treatments and engine operation. Given the success of our

current research, we have begun to consider the possibility

of transferring this method to an industrial environment.

2. Barkhausen effect

BN, as it is often called, was discovered in 1919 by

H. Barkhausen. He put the first in evidence the brutal and

discontinuous character of the movement of magnetic

10

S. Desvaux et al. / NDT&E International 37 (2004) 917

Fig. 1. Barkhausen noise and the associated hysteresis loop.

domain walls. The discontinuous character of magnetic

domain wall movement can be explained if one considers

the crystal in the scale of the wall and takes into account

the number of surface imperfections (precipitate, vacancy,

dislocations, grain boundaries) which can mark the

perfection of its crystalline network. Confronted with a

defect, the domain wall movement stops abruptly,

remaining blocked at this point until the field reaches a

certain value. If the value of the applied field continues to

increase, the domain wall movement suddenly resumes,

moving on to another defect. The blocking capacity of the

crystalline defects depends on the interaction energy

existing between the defect and the domain wall. An

abrupt domain wall movement provokes an elementary

Barkhausen event; the sum of these events constitutes BN.

Since Weiss domain walls are blocked by defects in the

material, BN allows the measurement of any modifications in the magnetic microstructure and consequently

any modifications in the metallurgic microstructure. Fig. 1

shows the evolution of BN during a hysteresis loop. In

addition to the electromagnetic disruption, some types of

domain wall movement will provoke a magnetostriction

phenomenon. This change in dimension generates an

elastic wave, called acoustic BN or Broadcast

magnetoacoustics.

The works of Tiitto [1] in 1977 are the principal

starting point for research concerning the use of BN as a

method of non-destructive control of the metallurgic

states, particularly stress. Under the influence of an

applied magnetic field, domains whose magnetization

parallels that of the magnetic field increase, and domains

whose magnetization is perpendicular to the field decrease

until they finally disappear. Similarly, when a material

undergoes tensile stress, the domains whose magnetization

parallels the direction of the tensile stress increase at the

expense of the other domains, gradually taking over the

total available volume. On the other hand, domains whose

magnetization is perpendicular to the direction of

compressive stress increase and eventually cancel out

the other domains. Thus, as Tiitto showed, the level of the

BN is influenced both by stress and by applied magnetic

fields. If the stress and the magnetic field generate the

same type of change in domain configurations,

the cumulative effect causes elevated levels of BN. On

the other hand, if the stress and the magnetic field cause

conflicting effects on wall movement, the level of BN is

reduced. This phenomena of BN and the influence of

stress on the latter have been well described by many

authors [1,2].

3. Use of Barkhausen noise to estimate stress

Many authors [3 6] have shown that it is possible to

use BN to characterize traction or compression stress.

Pasley [7] was one of the first to use BN to quantify stress

measurements. He studied the evolution of the BN

amplitudes as a function of to the level of stress on a

test tube that was being bent. For a traction load, Pasley

observed an increase in the BN amplitude in the elastic

domain, followed by a zone of saturation when moving

into the plastic domain. For a compression load, he

detected the reduction of the BN amplitude in the elastic

domain, followed once again by noise saturation as the

domain changes to plastic. Langman [8] studied the

influence of stress on the shape of the hysteresis loop on

annealed condition mild steel. He showed that the

hysteresis loop narrows when the measurement of

S. Desvaux et al. / NDT&E International 37 (2004) 917

the field parallels the applied stress, and becomes larger,

though with a smaller amplitude, when the measurement

of the field is perpendicular to the stress. Gilbert et al. [9]

tried to link the applied stress level to the shape of the BN

signal envelope. He applied uniaxial pressure to two of

the magnetically soft steels (with a significant density in

pure iron) used in electric motors. The author noted the

temporal Barkhausen signal, transverse to the uniaxial

pressure, as indicated by the envelope for three loads 200,

400 and 600 MPa, and he noticed an increase in the

Barkhausen signal in terms of the applied stress. However,

the most prevalent representations give the maximum

Barkhausen signal envelope versus the applied stress [4,6,

9 12] or applied strain [13].

Other studies have been done to determine stress using

the BN level of pieces tempered at different temperatures

and having different degrees of hardness [14], or on

materials with different micro-structures [15]. Overall

results are highly diverse, as could be expected given the

variety of microstructures present in the samples and the

sensitivity of BN to a wide selection of metal properties.

For example, different BN levels have been observed for

pieces with the same level of stress but different

metallurgic microstructures [6]. In addition, whatever of

the initial metallurgic microstructure of the material,

magnetically soft steels and low stress levels due to

traction or compression (2 500 and 1000 MPa) produce

sharp noise level variations that are nearly linear. On the

other hand, sensitivity to stress appears to decrease at high

stress levels, and a phenomenon of saturation has been

observed [6].

The evaluation of SRS has been the object of several

publications. The research of Moorty and Nierlich [16,17]

concerning carburising steels EN36 and high bearing steel

100Cr6, has shown that the BN level allows the quantification of SRS. Evaluation of SRS using BN has also proved

very useful for the testing pipes where some defects due to

tensile surface stress can appear either on the pipe surface or

on the welds. Tonshoff and Lindgren [18,19] have shown

that comparing BN parameters to X-ray diffraction

measurements, make it possible to control SRS levels

using BN on soft steel for stress values situated between

2 400 and 400 MPa.

Different parameters were exploited to establish a

linear relation between SRS and the BN. Tonshoff

considered the amplitude, the positions of the amplitude

of the temporal signal and the maximal height of the BN

impulse height distribution [20]. Theiner, on the other

hand, used the amplitude of the Barkhausen signal and the

value of the coercive field [21]. Studies have indicated

that 2D mapping of SRS using BN could limit defects

during the shaping of steel plate [22,23]. For stress

between 2 150 and 300 MPa, the mapping is done by

measuring the BN level versus the micro-deformations in

the longitudinal and transversal directions.

11

4. Determination of surface residual stress using

Barkhausen noise

In 1957, Biorci and Pescetti [24] proposed a very simple

mathematical formulation for modelling a Barkhausen

impulse in pure iron. He verified that this formulation was

well adapted by verifying that the sum of impulses

permitted the original shape of the BN to be reconstituted.

In 1997, Saquet [25] reactualised this study, representing an

elementary Barkhausen event in temporal terms and from a

Fourier transformation in terms of frequency. Several

authors [26,27] have mentioned the attenuation phenomenon resulting when an electromagnetic field is propagated

in matter, as well as its consequences on the representation

of the BN frequency spectrum.

Because the elementary impulse, and therefore the BN, is

attenuated both by frequency and by the depth of the

elementary impulse (i.e. the distance between the surface

where the receiving wire has been placed and the domain

wall that moves), we can use this attenuation phenomenon

to obtain information about surface stress. Given that the

high-frequency components of the Barkhausen signal are

rapidly attenuated as the wave progresses through the

material, by choosing to analyse the components with

the highest frequency, we are able to study the part of the

Barkhausen signal that is typical of the matters surface

state, leading in turn to information about the surface stress.

In order to establish the relationship between BN and

surface stress, it was first necessary to establish reference

samples. For this purpose, we used several M50 steel

samples, each with a different level of SRS. These samples

were characterized using X-ray diffraction. For each of

these samples, we determined the BN and calculated its

corresponding spectrum. Among the different spectrum

analysis parameters, we chose the area under the section

being analysed.

BN covers a large frequency bandwidth, from about

100 Hz to several MHz. Two filtering procedures are

necessary: a low-pass filter to eliminate high-frequency

interferences and a high-pass filter to free from the slow

variations in the magnetic flux through the section of the

coil of the probe. Our frequency analysis of the BN signal

limited the frequency range between 20 kHz and 1 MHz.

This bandwidth corresponds to that of the receiving coil

used in this study, and in addition to limiting interference, it

allows calculation times to be reduced. Within the 20 kHz

1 MHz bandwidth, we had to select the frequency analysis

band characteristic of the SRS in order to obtain the

relationship between the BN spectrum of each reference

sample and the levels of surface stress as determined by the

X-ray diffraction method.

Since high frequency components were used, the upper

bound of the section is determined by the bandwidth of the

receiving wire: 1 MHz. Then, the lower bound of the

analysis section had to be determined. With this in mind,

we first took 10 BN measurements for each sample. Then,

12

S. Desvaux et al. / NDT&E International 37 (2004) 917

Fig. 2. Parameters of Barkhausen noise versus the residual surface stress where R2 is the correlation coefficient.

a frequency band was chosen for the high-frequency

analysis [F1;F2] where F2 was equal to 1 MHz. The area

was then calculated for the 10 spectrum measurements. We

averaged these area calculations for each sample, and

connected them to their level of residual surface stress.

Then, we looked for the best regression curve (linear,

exponential) that would allow us to characterize the

evolution of the BN parameter (area) as a function of

the surface stress. Finally, we shifted the lower bound of the

analysis frequency range, and we repeated all these steps

until we obtained the optimum correlation coefficient. A

computerized search using an appropriate frequency range

allowed us to demonstrate a linear relationship between the

SRS and the BN parameter. For reasons of confidentiality,

we cannot specify the value of lower bound F1. Generally,

increasing compression stress causes a reduction of the area

under the amplitude spectrum (Fig. 2). The error margin for

measurements of the area under the amplitude spectrum in

the frequency range [F1, F2] was a maximum of 5%. This is

represented by the vertical bars in Fig. 2. The horizontal

bars show the corresponding error margin for stress

measurements using X-ray diffraction.

Table 1

Micrograph and the mechanical properties of bearings

5. Validation of the method

In order to validate the method, we used BN to estimate

the different levels of SRS on five bearing rings that had

undergone a variety of shot peening operations. These five

rings, respectively, B1, B2, B3, B4 and B5, were made of

M50 steel, whose characteristic structure is a tempering

martensitic matrix composed of ferrites and carbides. The

mechanical properties of M50 steel are primarily determined by thermal treatments, and the principal chemical

constituents are summarized in Table 1.

Given that the estimation of the SRS is obtained from a

parameter of the BN spectrum, it is essential to calibrate before

trying to estimate the stress itself. This calibration consists of

creating a table giving the stress versus the value of area under

the section being analysed (analysis frequency range [F1,

F2]). Because BN is influenced by many material characteristics and properties, a table had to be created for each type of

bearing, taking into consideration every slight difference in

material and every manufacturing process (i.e. heat treatments, chemical treatments and mechanical treatments). For

our study, we created a table using four reference samples.

S. Desvaux et al. / NDT&E International 37 (2004) 917

13

Fig. 3. Surface residual stress measured by X-ray diffraction versus surface residual stress estimated by Barkhausen noise.

Once the calibration phase is achieved, we estimated the

SRS on five rings, B1, B2, B3, B4 and B5, first using BN and

then using X-ray diffraction. In Fig. 3, we have presented

the SRS measured by X-ray diffraction versus those

estimated using BN. The stress error measured by X-ray

diffraction was obtained by moving the diffraction peak,

which is a function of the metallurgical and geometrical

characteristics of the sample. The stress error estimated by

BN was obtained statistically with a confidence limit of

95%. These experimental results show a clear parallel

between the measurements of SRS using X-ray diffraction

and those estimated using BN; the correlation coefficient of

the linear regression is 99.28%. Given that the X-ray

diffraction method is the calibrated method of reference, the

systematic concurrence of the stress estimates of the two

methods confirms the pertinence and the reliability of the

Barkhausen method for the evaluation of SRS of any given

material.

6. Estimation of surface residual stress on bearings,

following engine operation

This study aims to test the material fatigue of bearings

after engine use, by studying the stress level of the bearings.

The estimation of the SRS after engine operation using BN

is a question of enormous importance for the aircraft

industry of the future. Indeed, the cost of plane maintenance

operations, particularly engine maintenance, continues to

climb due to the longer life expectancy of the planes and the

increasingly stricter safety requirements. For this reason,

some companies plan to do systematic bearing overhauls

following engine operation. These overhauls would include

a visual examination of the components, followed by the regrinding or super finishing of the bearing raceways. This

new approach to engine maintenance will require

taking material fatigue into account. Depending on

the programmed flight plan, the engine bearings and

materials will sustain supplementary fatigue, which will

lead again to modifications of both the materials microstructure and its level of stress. These overhauls will be

limited to those bearings exhibiting a fatigue level under

pre-defined limits, since it would obviously be too

dangerous to repair bearings whose raceways have already

sustained heavy material fatigue.

The level of the material fatigue is currently characterized by measuring the materials residual internal stress.

Doing so requires a non-destructive testing method whose

stress estimates are reliable enough to clearly reject all the

parts, which should not be repaired without eliminating

parts that are still in satisfactory condition. But this method

has to be cheap enough to keep the cost of controlling and

overhauling under the cost of simply replacing the parts.

Both of these conditions are respected by the magnetic

method using BN presented in this article. The SRS

measurements obtained with this method have been

validated by comparison with those measurements obtained

by X-ray diffraction, and if we verify the levels of

compressive residual stress on the total surface of the

bearing rings after engine operation, the cost is 40 times less

than that of the X-ray diffraction method. In addition, the

mapping of 200 measurement points is 60 times as fast. The

measurements of surface stress were made on a batch of 20

bearings with the same reference. The inner rings of these

bearings are made of 52,100 steel, a material characterized

by a compound spheroid structure of ferrites and carbides.

The mechanical properties of 52,100 steel are summarized

in Table 2.

After creating the table which allows the estimation of

surface stress on these inner rings using BN, we estimated

the SRS on all 20 rings and compared the estimations using

BN with the measurements obtained with the X-ray

diffraction method. The results, shown on Fig. 4, indicate

a clear parallel between the estimations using BN and

14

S. Desvaux et al. / NDT&E International 37 (2004) 917

Table 2

Micrograph and the mechanical properties of bearings

Fig. 4. Surface residual stress estimations using Barkhausen noise on 20 inner rings of 52,100 steel compared to the X-ray diffraction measurements.

the measurements using X-ray diffraction, with the exception of two inner rings (90,343 and A244). To understand

why the X-ray diffraction measurements and BN estimations of the SRS differed for both rings 90,343 and A244,

we verified the homogeneity of the stress over the width of

the raceway. The difference in the results obtained with

these two methods could be explained by the fact that the

volumes inspected were not the same for both methods (Fig.

5(a) and (b)). For the X-ray diffraction, the measurement

was localized only a few mm3 were irradiated and X-rays

were focused in the middle of raceway. For the BN method,

on the other hand, the volume of material contributing to

measurement is several mm3. Therefore, of the stress

evolves along the transversal direction of the raceway

(following the direction z in Fig. 6), the estimated SRS were

different for the two methods.

In order to control the homogeneity of the stress over

the width of the raceway, we did several mappings using

BN on the load zones of three inner rings, one ring where

the X-ray and Barkhausen measurements concurred (ring

A79) and two others, the rings 90,343 and A244. These

mappings were obtained by moving the position of

Fig. 5. Bulk inspected (a) by X-rays diffraction and (b) by Barkhausen

noise.

S. Desvaux et al. / NDT&E International 37 (2004) 917

15

Fig. 6. Mapping of surface loading zone inspected using Barkhausen noise.

the magnetic sensor along the raceway in the transversal

direction, at the same time causing the ring to rotate on its

axis (Fig. 6). These mappings correspond in the end to

those developed for the stress levels of the bearing

raceways, similar to the C-scan of ultrasonic methods.

Obtaining the same kind of mapping with the X-ray

diffraction method would require approximately 200

measurements, which explains the higher cost and the

longer time needed for this method, as opposed to the BN

method.

The three mappings discussed above are presented in

Figs. 7 9. For reasons of confidentiality, BN levels versus

the spatial position on the raceway are given rather than

the stress levels. Despite this presentation, the homogeneities and the heterogeneities of the stress appear

clearly, given that the BN levels are directly proportional

to the levels of SRS.

Fig. 7 represents the mapping of raceway A79. Clearly,

the level of BN is homogeneous and uniform throughout the

raceway. The observed stress level is the result of the initial

stress (prior to engine operation) and of the stress introduced

by the loads appearing between the loading zones of the

inner ring and the rolling elements. This homogeneity

means that both the pre-stress treatments prior to engine

operation and the load distribution on the inner ring during

engine operation were homogeneous.

Figs. 8 and 9 represent the mappings of inner rings

90,343 and A244 ,respectively. The level of BN, and

consequently the stress level, is neither homogeneous nor

uniform in the transverse direction of the raceways of these

Fig. 7. Mapping of the Barkhausen noise level on the loading zones of A79

bearing inner rings after engine operation.

Fig. 8. Mapping of the Barkhausen noise level on the loading zones of

90,343 bearing inner rings after engine operation.

16

S. Desvaux et al. / NDT&E International 37 (2004) 917

cycle (i.e. during renovation), but also encourage a review

of the conditions which led to these poorly distributed loads.

Finally, this magnetic BN method has the advantages of

being rapid, suitable for the circular geometry of the rings,

and requiring no direct contact. Given the progress of our

research, we hope in the near future to move this method out

of the laboratory and into the industrial environment.

References

Fig. 9. Mapping of the Barkhausen noise level on the loading zones of A244

bearing inner rings after engine operation.

two rings. This lack of homogeneity and uniformity

probably comes from a heterogeneous distribution of the

loads on these inner rings during engine operation. On

mapping in Fig. 8, the load must have been located

essentially at the top of raceway, between 10 and 13 mm,

whereas mapping in Fig. 9 shows the load situated between

2 and 5 mm. This second load, however, must have been

less important than the previous one, given that the

Barkhausen level is higher. Clearly, the loads on the ring

introduce compressive stress, which has the effect of

reducing the level of BN.

These mappings allowed us to discover a significant

asymmetry in the surface stress distribution of the loading

zone, which explains the difference between the localized

X-ray diffraction measurements and the Barkhausen

estimations presented in Fig. 4. In addition, these mappings

highlight the importance of producing complete maps of

raceway stress distribution, because incomplete mappings

can hide possible asymmetries in the stress field.

7. Conclusion

In this article, we have presented a non-destructive

method based on the phenomenon of BN to identify SRS in

the contact zones between ball or roller bearings and their

raceways. Using X-ray diffraction as the method of

reference, we have shown the efficiency of BN for

estimating the fields of SRS on raceways after specific

pre-stress treatments and after engine operation. Some

mappings of the loading zones were created using BN.

These mappings show an uncentered load on the raceway of

the inner ring after engine operation. This observation is

especially important since it will not only allow the rejection

of a certain number of bearings during the maintenance

[1] Tiitto S. On the influence of microstructure on magnetization

transitions in steel. Acta Polytechnica Scandinavica. Appl Phys

Series 1977;119:080.

[2] Cullity BD. Introduction to magnetic materials. London: AddisonWesley; 1972.

[3] Barton JR, Kusenberger FN. Residual stresses in gas turbine engine

components from Barkhausen noise analysis. J Engng Power, Trans

ASME 1974;34957.

[4] Tiitto K. Use of Barkhausen effect in testing for residual stresses and

material defects. Residual stress in design process and material

selection. Cincinnati, OH: AMS; 1987. p. 27 9.

[5] Catty J. Etude des relations entre la microstructure, letat de contrainte

dune part, les proprietes magnetiques and magnetostrictives dautre

part, dans le fer pur et des alliages a` bas carbone. The`se: INSA de

Lyon; 1995. p. 0245.

[6] Shaw BA, Hyde TR, Evans JT. Detection of grinding damage in

hardened gear steels using Barkhausen noise analysis. Conference

Proceedings of Barkhausen Noise and Micromagnetic Testing-I,

ICBM 1, Hannover, Germany 1998; 12: 187196.

[7] Pasley RL. Barkhausen effectan indication of stress. 29th National

Fall Conference of the American Society for Non-destructive Testing,

Philadelphia; 1969. p. 1316.

[8] Langman R. Some comparisons between the measurement of stress in

mild steel by means Barkhausen noise and rotation of magnetization.

NDT Int 1987;20(2):93 9.

[9] Gilbert IP, Bull SJ, Evans JT, Moorthy V, Shaw BA. Barkhausen

noise study of soft magnetic composites, Conference Proceedings of

Barkhausen Noise and Micromagnetic Testing-III, ICBM 3, Tampere,

Finlande 2001; 2 3: 168 173.

[10] Kwun H. Investigation of the dependence of Barkhausen noise on

stress and angle between the stress and magnetization directions.

J Magn Magn Mater 1985;49:235 40.

[11] Tiitto K, Karvonen I. Evaluating heat treat defects, grinding burns and

stress in steels by Barkhausen noise method. 4th European Conference

on Non-destructive Testing, London, September; 1987. p. 14 18.

[12] Tiitto K, Fix R. Evaluation of residual stresses, grinding burns and

heat treat defects through chrome plating. 24th Annual Aerospace/

Airline, Plating and Metal Finishing, Forum and Exposition, Phoenix,

Arizona; 1988. p. 4 7.

[13] Tiitto S. Magnetoelastic testing of uniaxial and biaxial stresses,

International conference residual stresses. Soc Francaise de metallurgie, Nancy; 1988.

[14] Shaw BA, Benson M, Hofmann DA. Calibration of the Barkhausen

noise method as a tool for assessing the surface integrity of gear

steels. Conference Proceedings of Barkhausen Noise and Micromagnetic Testing-II, ICBM 2, Newcastle, United Kingdom 1999;

25 26: 129 140.

[15] Tiitto K. Solving internal stress measurement problems by a new

magnetoelastic method non-destructive methods for materials property determination. ASM 1984;10514.

[16] Moorty V, Shaw BA, Brimble K, Atkins I. Evaluation of Heat

treatment and deformation induced changes in material properties in

gears steels using magnetic Barkhausen noise analysis. Conference

S. Desvaux et al. / NDT&E International 37 (2004) 917

[17]

[18]

[19]

[20]

[21]

Proceedings of Barkhausen Noise and Micromagnetic Testing-III,

ICBM 3, Tampere, Finlande 2001; 2 3: 63 83.

Nierlich W. Investigations on ground parts using Barkhausen noise,

XRD and metallographic methods. Conference Proceedings of

Barkhausen Noise and Micromagnetic Testing-I, ICBM 1, Hannover,

Germany 1998; 12: 125139.

Tonshoff HK, Karpuschewski B. Residual stress determination of

ferromagnetic sheets. Conference Proceedings of Barkhausen Noise

and Micromagnetic Testing-I, ICBM 1, Hannover, Germany 1998; 1

2: 141 154.

Lindgren M, Lepisto T. Residual stress evaluation in welded steel

tubes using Barkhausen noise. Conference Proceedings of Barkhausen

Noise and Micromagnetic Testing-II, ICBM 2, Newcastle, United

Kingdom 1999; 2526: 91100.

Tonshoff HK, Oberbeck-Spintig I, Seegers H. Micromagnetic quality

assurance of metal sheets. Conference Proceedings of Barkhausen

Noise and Micromagnetic Testing-II, ICBM 2, Newcastle, United

Kingdom 1999; 2526: 115 127.

Theiner WA. Physical basis of micromagnetic methods and sensor

systems and their application areas. Conference Proceedings of

Barkhausen Noise and Micromagnetic Testing-I, ICBM 1, Hannover,

Germany, September 1998; 1 2: 197 218.

17

[22] Augustyniak B, Chmielewski M, Siecinski J. Evaluation of residual

stress distribution maps in shipyard sheets with Barkhausen effect

non-contact probe. Conference Proceedings of Barkhausen Noise and

Micromagnetic Testing-II, ICBM 2, Newcastle, United Kingdom

1999; 2526: 2736.

[23] Kielczynski W, Augustyniak B, Chmielewski M. Residual stress full

state evaluation at welded Plate using Barkhausen effect: modelling

and experiment. Conference Proceedings of Barkhausen Noise and

Micromagnetic Testing-III, ICBM 3, Tampere, Finlande 2001; 23:

113123.

[24] Biorci G, Pescetti T. Frequency spectrum of the barkhausen noise.

J Appl Phys 1957;28:77780.

[25] Saquet O. Caracterisation des aciers par bruit Barkhausen (Interaction

microstructure cristalline/microstructure magnetique). Optimisation

de la mise en uvre pour un developpement industriel. Application au

controle des traitements thermiques, The`se: INSA de Lyon; 1997. p.

0214.

[26] Tiitto S, Saynajakangas S. Spectral damping in Barkhausen noise.

IEEE Trans Magn 1975;11(6):166675.

[27] Francino K, Tiitto K. Evaluation of surface and subsurface stresses

with Barkhausen noise: a numerical approach. AMS conference,

Indianapolis; 1991. p. 1517.

Das könnte Ihnen auch gefallen

- Diederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During TunnelingDokument28 SeitenDiederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During Tunnelingfatihkaya_16Noch keine Bewertungen

- Estimation and Costing: Unit 2 6Dokument40 SeitenEstimation and Costing: Unit 2 6Funny VinesNoch keine Bewertungen

- UTG-2 (1987) Structural Design of Segmental Block PavementsDokument55 SeitenUTG-2 (1987) Structural Design of Segmental Block PavementsATHOLSCHWARZNoch keine Bewertungen

- Lecture Notes on Reinforced Concrete DesignVon EverandLecture Notes on Reinforced Concrete DesignNoch keine Bewertungen

- Residual Stress Analysis of Pipeline Girth Weld JointsDokument289 SeitenResidual Stress Analysis of Pipeline Girth Weld JointsGabriel Vazquez Vega100% (1)

- English Pre-Intermediate Reading Comprehension Test 001 - 2Dokument3 SeitenEnglish Pre-Intermediate Reading Comprehension Test 001 - 2Gabriel Vazquez VegaNoch keine Bewertungen

- Tunnel Blasting TechniquesDokument25 SeitenTunnel Blasting TechniquesBaga Yoice100% (1)

- Design Aspects of Concrete Lined Vertical Shafts For Hydropower ConstructionDokument12 SeitenDesign Aspects of Concrete Lined Vertical Shafts For Hydropower ConstructionHatef SardariNoch keine Bewertungen

- Handbook of Residual Stress and DeformationDokument478 SeitenHandbook of Residual Stress and DeformationSneha KriNoch keine Bewertungen

- Strain Concentrations in Pipelines With Concrete CoatingDokument7 SeitenStrain Concentrations in Pipelines With Concrete CoatingAslan AlpNoch keine Bewertungen

- Elastic Stresses in Single Mitred BendsDokument22 SeitenElastic Stresses in Single Mitred BendsWang Kin HuiNoch keine Bewertungen

- TunnelDokument12 SeitenTunnelMasihullah EbadiNoch keine Bewertungen

- Design Aspects For Concrete Lined Vertic PDFDokument11 SeitenDesign Aspects For Concrete Lined Vertic PDFCamilo A PhillipsNoch keine Bewertungen

- SECTION 2900 FinalDokument10 SeitenSECTION 2900 Finalkartick adhikaryNoch keine Bewertungen

- The Bending Moment Changes of Tunnel Lining Due To KarstificationDokument4 SeitenThe Bending Moment Changes of Tunnel Lining Due To Karstificationblisscutest beagleNoch keine Bewertungen

- Design of Underground Structures Under Seismic Conditions: A Long Deep Tunnel and A Metro TunnelDokument37 SeitenDesign of Underground Structures Under Seismic Conditions: A Long Deep Tunnel and A Metro TunnelClinton DameNoch keine Bewertungen

- 13) 2008 The Effect of Changing Loads Affecting The Martensite Steel On Itsstructure and The Barkhausen Noise LevelDokument7 Seiten13) 2008 The Effect of Changing Loads Affecting The Martensite Steel On Itsstructure and The Barkhausen Noise LevelGabriela TarazonaNoch keine Bewertungen

- The Effect of Microstructure and Applied Stress On Magnetic Barkhausen Emission in Induction Hardened SteelDokument8 SeitenThe Effect of Microstructure and Applied Stress On Magnetic Barkhausen Emission in Induction Hardened Steelbrandt.nickNoch keine Bewertungen

- Experimental Analysis On Friction Materials For Supplemental Damping DevicesDokument33 SeitenExperimental Analysis On Friction Materials For Supplemental Damping DevicesVincenzo PilusoNoch keine Bewertungen

- Intechopen 90740Dokument25 SeitenIntechopen 90740brandt.nickNoch keine Bewertungen

- Measuring The Permeability of Stressed Steel by The Magnetomotive-Force - Vane Method With Magnetization Perpendicular To The SurfaceDokument12 SeitenMeasuring The Permeability of Stressed Steel by The Magnetomotive-Force - Vane Method With Magnetization Perpendicular To The SurfaceLeandro AriasNoch keine Bewertungen

- Scaling Phenomena Due To Fractal Contact in Concrete and Rock FracturesDokument18 SeitenScaling Phenomena Due To Fractal Contact in Concrete and Rock FracturessonalisarayNoch keine Bewertungen

- 3MA Academia NDTDokument17 Seiten3MA Academia NDTBhavani PrasadNoch keine Bewertungen

- 1 s2.0 S0304885307005975 MainDokument9 Seiten1 s2.0 S0304885307005975 MainMd Nurul AbsarNoch keine Bewertungen

- Eigenspannung SchweißnahtDokument5 SeitenEigenspannung Schweißnahtbrandt.nickNoch keine Bewertungen

- Nes Luan 2017Dokument44 SeitenNes Luan 2017Henrique Scheidt KleinNoch keine Bewertungen

- Damage Assessment of Boiler Tubes Subjected To Erosion and Corrosion Failures by Non-Invasive TechniqueDokument4 SeitenDamage Assessment of Boiler Tubes Subjected To Erosion and Corrosion Failures by Non-Invasive TechniqueSebastián MoraNoch keine Bewertungen

- 82 Some Aspects Design Surface Tunnel PDFDokument10 Seiten82 Some Aspects Design Surface Tunnel PDFAjay SinghNoch keine Bewertungen

- Magnetostriction, Barkhausen Noise and Magnetization Processes in Non-Electrical Steels PDFDokument9 SeitenMagnetostriction, Barkhausen Noise and Magnetization Processes in Non-Electrical Steels PDFallanromarioNoch keine Bewertungen

- Tachi e 2004Dokument12 SeitenTachi e 2004Ahsan Habib TanimNoch keine Bewertungen

- Fracture Mechanical Properties of CO2 Corrosion Product Scales and Their Relation To Localized CorrosionDokument8 SeitenFracture Mechanical Properties of CO2 Corrosion Product Scales and Their Relation To Localized CorrosionspottedkelpieNoch keine Bewertungen

- Tunnel-Ground Interaction Analysis: Discrete Beam-Spring vs. Continuous Fe ModelDokument9 SeitenTunnel-Ground Interaction Analysis: Discrete Beam-Spring vs. Continuous Fe ModelNguyen Thanh Duc BKNoch keine Bewertungen

- Composite Structures: S.A. Niaki, J.R. Mianroodi, M. Sadeghi, R. NaghdabadiDokument8 SeitenComposite Structures: S.A. Niaki, J.R. Mianroodi, M. Sadeghi, R. NaghdabadiJohn VatistasNoch keine Bewertungen

- Concrete Pavement Slab Under Blast Loads: Bibiana Marı A Luccioni, Mariela LuegeDokument19 SeitenConcrete Pavement Slab Under Blast Loads: Bibiana Marı A Luccioni, Mariela LuegeFABIAN FIENGONoch keine Bewertungen

- Validation Blast JATCDokument18 SeitenValidation Blast JATCPrasannaNoch keine Bewertungen

- Strain Rate Effect On The Response of Blast Loaded Reinforced Concrete SlabsDokument10 SeitenStrain Rate Effect On The Response of Blast Loaded Reinforced Concrete Slabsmahmoud elkhedrNoch keine Bewertungen

- Dynamic Stress Field Around A Blast Hole - A Laboratory StudyDokument9 SeitenDynamic Stress Field Around A Blast Hole - A Laboratory StudyJherson NietoNoch keine Bewertungen

- Bond Behaviour of Structural Lightweight Concrete: January 2018Dokument10 SeitenBond Behaviour of Structural Lightweight Concrete: January 2018SameerKareeeemNoch keine Bewertungen

- Intro-Rcd NotesDokument6 SeitenIntro-Rcd NotesRam CaniculaNoch keine Bewertungen

- J Engfracmech 2016 08 014Dokument43 SeitenJ Engfracmech 2016 08 014Ali ANoch keine Bewertungen

- Effects of Seismicity On Rock Support in Tunnels oDokument12 SeitenEffects of Seismicity On Rock Support in Tunnels otrinitrocainaNoch keine Bewertungen

- Modelling The Flexural Tensile Strength of MasonryDokument10 SeitenModelling The Flexural Tensile Strength of MasonryRameshNayakaNoch keine Bewertungen

- San Andres FaultsDokument12 SeitenSan Andres FaultsHelardQuispePaucarNoch keine Bewertungen

- 02 - Barkhausen Noise As A Magnetic Nondestructive Testing TechniqueDokument22 Seiten02 - Barkhausen Noise As A Magnetic Nondestructive Testing TechniquesolisiusNoch keine Bewertungen

- Tunnel Blasting TechniquesDokument24 SeitenTunnel Blasting TechniquesAbhishek MajiNoch keine Bewertungen

- Blasting Waves On ConcreteDokument9 SeitenBlasting Waves On ConcretemelseNoch keine Bewertungen

- 1 s2.0 S0734743X08000778 MainDokument11 Seiten1 s2.0 S0734743X08000778 Mainfa.jamshidiNoch keine Bewertungen

- Rebar Buckling Model GOpazoDokument10 SeitenRebar Buckling Model GOpazoD Toño ToroNoch keine Bewertungen

- On Static and Dynamic Behavior of Noise Barriers Structures Using FEADokument6 SeitenOn Static and Dynamic Behavior of Noise Barriers Structures Using FEADomnica StanciuNoch keine Bewertungen

- Hazan 2021Dokument9 SeitenHazan 2021rxx1218Noch keine Bewertungen

- Kaloper - Zivalj - Medic - Experimental and Numerical Assessment of Reinforced Concrete Column Under Cyclic Loading - CroCEEDokument8 SeitenKaloper - Zivalj - Medic - Experimental and Numerical Assessment of Reinforced Concrete Column Under Cyclic Loading - CroCEEsenad medicNoch keine Bewertungen

- Microstructural and Residuals Stress Analysis of Friction Stir Welding of X80 Pipeline Steel Plates Using Magnetic Barkhausen NoiseDokument9 SeitenMicrostructural and Residuals Stress Analysis of Friction Stir Welding of X80 Pipeline Steel Plates Using Magnetic Barkhausen NoiseAgus WidyiantoNoch keine Bewertungen

- The Analysis of The Transient Dynamic Response of Elastic Thin-Walled Beams of Open Section Via The Ray MethodDokument13 SeitenThe Analysis of The Transient Dynamic Response of Elastic Thin-Walled Beams of Open Section Via The Ray MethodPasc Oana JianinaNoch keine Bewertungen

- Finite Element Simulation of Explosive WeldingDokument14 SeitenFinite Element Simulation of Explosive WeldingWahyu Lailil FaisNoch keine Bewertungen

- 2012 Eurock Shafts PDFDokument12 Seiten2012 Eurock Shafts PDFsafinasal7432Noch keine Bewertungen

- Vazouras-Karamanos2017 Article StructuralBehaviorOfBuriedPipeDokument26 SeitenVazouras-Karamanos2017 Article StructuralBehaviorOfBuriedPipeBalaji NaikNoch keine Bewertungen

- Mehreganian 等。 - 2018 - Inelastic dynamic response of square membranes subDokument18 SeitenMehreganian 等。 - 2018 - Inelastic dynamic response of square membranes subhuangyifan350Noch keine Bewertungen

- Extended AbstractDokument10 SeitenExtended AbstractRohan ReddyNoch keine Bewertungen

- Chapter Outline: Failure Fracture: How Do Materials Break?Dokument9 SeitenChapter Outline: Failure Fracture: How Do Materials Break?Anonymous T02GVGzBNoch keine Bewertungen

- Influence of Mandrel's Surface and Material On The Mechanical Properties of Joints Electromagnetic Compression PDFDokument10 SeitenInfluence of Mandrel's Surface and Material On The Mechanical Properties of Joints Electromagnetic Compression PDFmohamad zareNoch keine Bewertungen

- Krylov NOVEM 2005Dokument13 SeitenKrylov NOVEM 2005Lokesh GorantlaNoch keine Bewertungen

- Tunnel RoughnessDokument13 SeitenTunnel Roughnessvpamatya100% (1)

- Domenic D'Ambrosio and Roberto Marsilio - Shock-Induced Separated Structures in Symmetric Corner FlowsDokument31 SeitenDomenic D'Ambrosio and Roberto Marsilio - Shock-Induced Separated Structures in Symmetric Corner FlowsWhiteLighteNoch keine Bewertungen

- Festkörper Probleme: Plenary Lectures of the Divisions Semiconductor Physics, Surface Physics, Low Temperature Physics, High Polymers, Thermodynamics and Statistical Mechanics, of the German Physical Society, Münster, March 19–24, 1973Von EverandFestkörper Probleme: Plenary Lectures of the Divisions Semiconductor Physics, Surface Physics, Low Temperature Physics, High Polymers, Thermodynamics and Statistical Mechanics, of the German Physical Society, Münster, March 19–24, 1973Noch keine Bewertungen

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceVon EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNoch keine Bewertungen

- A Study On The Variation of Forces and Temperature in A Friction Stir Welding Process A Finite Element ApproachDokument9 SeitenA Study On The Variation of Forces and Temperature in A Friction Stir Welding Process A Finite Element ApproachGabriel Vazquez VegaNoch keine Bewertungen

- Vacuum TechnologyDokument58 SeitenVacuum TechnologyGabriel Vazquez Vega100% (1)

- The Mechanism Governing Cutting of Polycrystalline Cubic Boron NiDokument76 SeitenThe Mechanism Governing Cutting of Polycrystalline Cubic Boron NiGabriel Vazquez VegaNoch keine Bewertungen

- 1 s2.0 S0040609009015570 MainDokument4 Seiten1 s2.0 S0040609009015570 MainGabriel Vazquez VegaNoch keine Bewertungen

- Thermal Modelling and Effect of Process Parameters in Friction Stir Welding PDFDokument10 SeitenThermal Modelling and Effect of Process Parameters in Friction Stir Welding PDFGabriel Vazquez VegaNoch keine Bewertungen

- Surface & Coatings TechnologyDokument11 SeitenSurface & Coatings TechnologyGabriel Vazquez VegaNoch keine Bewertungen

- English Pre-Intermediate Reading Comprehension Test 001 - 1Dokument3 SeitenEnglish Pre-Intermediate Reading Comprehension Test 001 - 1Gabriel Vazquez VegaNoch keine Bewertungen

- Transient Model of Heat Transfer and Material Flow at Different Stages of Friction Stir Welding ProcessDokument17 SeitenTransient Model of Heat Transfer and Material Flow at Different Stages of Friction Stir Welding ProcessGabriel Vazquez VegaNoch keine Bewertungen

- Thermal Modelling and Effect of Process Parameters in Friction Stir Welding PDFDokument10 SeitenThermal Modelling and Effect of Process Parameters in Friction Stir Welding PDFGabriel Vazquez VegaNoch keine Bewertungen

- English Intermediate Reading Comprehension Test 002 - 1Dokument4 SeitenEnglish Intermediate Reading Comprehension Test 002 - 1Gabriel Vazquez VegaNoch keine Bewertungen

- Numerical Analysis of Friction Stir Welding ProcessDokument14 SeitenNumerical Analysis of Friction Stir Welding ProcessGabriel Vazquez VegaNoch keine Bewertungen

- Ansys Heatxfer 1 v5p6Dokument14 SeitenAnsys Heatxfer 1 v5p6seventhhemanthNoch keine Bewertungen

- Thermal Modelling and Effect of Process Parameters in Friction Stir Welding PDFDokument10 SeitenThermal Modelling and Effect of Process Parameters in Friction Stir Welding PDFGabriel Vazquez VegaNoch keine Bewertungen

- Airbus Crisis Over - Reading Comprehension Exercise - UsingEnglishDokument3 SeitenAirbus Crisis Over - Reading Comprehension Exercise - UsingEnglishGabriel Vazquez Vega100% (1)

- 10 Battle of Chancellorsville Free Sample PDFDokument8 Seiten10 Battle of Chancellorsville Free Sample PDFGabriel Vazquez VegaNoch keine Bewertungen

- 9 Summer Rain Free SampleDokument6 Seiten9 Summer Rain Free SampleorriolsbasconesNoch keine Bewertungen

- 6 The Rio Grande Free SampleDokument5 Seiten6 The Rio Grande Free SampleMas Jaja100% (1)

- 8 Tools of Persuasion Free SampleDokument5 Seiten8 Tools of Persuasion Free SampleAura García-Junco MorenoNoch keine Bewertungen

- Streetcar Named Desire Free SampleDokument5 SeitenStreetcar Named Desire Free SampleMarwan DeyaaNoch keine Bewertungen

- TN-701-1 PhotoelasticityDokument6 SeitenTN-701-1 PhotoelasticityGabriel Vazquez VegaNoch keine Bewertungen

- Ose OgbeDokument13 SeitenOse OgbeGabriel Vazquez Vega33% (3)

- masterCAM X Tutorial 5 Thru 7Dokument74 SeitenmasterCAM X Tutorial 5 Thru 7Sandra MartinezNoch keine Bewertungen

- 11 Chronic Traumatic Encephalopathy Free SampleDokument7 Seiten11 Chronic Traumatic Encephalopathy Free SampleNisha Agarwal 3Noch keine Bewertungen

- 1 Carlys Family Free SampleDokument3 Seiten1 Carlys Family Free SampleDiego UrbanoNoch keine Bewertungen

- 4059 12994 1 PB - CCMDokument5 Seiten4059 12994 1 PB - CCMGabriel Vazquez VegaNoch keine Bewertungen

- Tc128b PropertiesDokument11 SeitenTc128b PropertiesGabriel Vazquez VegaNoch keine Bewertungen

- HMT Question PaperDokument1 SeiteHMT Question PaperSanjay GomastaNoch keine Bewertungen

- BPSC AE Paper 5 (Civil) 2022 (English)Dokument9 SeitenBPSC AE Paper 5 (Civil) 2022 (English)धीरज कुमारNoch keine Bewertungen

- E3-11 Preparation of Metallographic Specimens PDFDokument12 SeitenE3-11 Preparation of Metallographic Specimens PDFevelyn50% (2)

- CaissonDokument12 SeitenCaissonBrian OndigoNoch keine Bewertungen

- 04-06-2022 444 East Alexander Palm RD, Boca Raton, Fl. ALUM. PEDESTRIAN GATESDokument2 Seiten04-06-2022 444 East Alexander Palm RD, Boca Raton, Fl. ALUM. PEDESTRIAN GATESdianaNoch keine Bewertungen

- Selection of Heat Exchanger (Size and Weight, Type)Dokument3 SeitenSelection of Heat Exchanger (Size and Weight, Type)Zati TarhiziNoch keine Bewertungen

- 2 Determination of Dynamic Modulus of Elasticity of Concrete by Impact Hammer PDFDokument4 Seiten2 Determination of Dynamic Modulus of Elasticity of Concrete by Impact Hammer PDFGana C RoverNoch keine Bewertungen

- Asme IxDokument98 SeitenAsme IxNam KhansomboonNoch keine Bewertungen

- Conbextra EP: T T T T T TDokument4 SeitenConbextra EP: T T T T T TFeri Oktara IrawanNoch keine Bewertungen

- Cesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingDokument7 SeitenCesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingJadeNoch keine Bewertungen

- Katalog 3Dokument8 SeitenKatalog 3Kenny YjwNoch keine Bewertungen

- IPPL BrochureDokument8 SeitenIPPL BrochuretoharshaNoch keine Bewertungen

- Compressive Strength of Self-Compacting Concrete During High-Temperature ExposureDokument7 SeitenCompressive Strength of Self-Compacting Concrete During High-Temperature ExposureDonaldo CVNoch keine Bewertungen

- Lakshmi Narayana V KDokument10 SeitenLakshmi Narayana V KBhargav KNoch keine Bewertungen

- 11 Bearing CapacityDokument14 Seiten11 Bearing CapacityVincze RobertNoch keine Bewertungen

- Pyrometric ConesDokument1 SeitePyrometric Coneslhoffman3Noch keine Bewertungen

- Appendix AbsorberDokument20 SeitenAppendix Absorbermitikeshav_935105731Noch keine Bewertungen

- Application of Fluid Machinery: Piping Design and Pump SelectionDokument16 SeitenApplication of Fluid Machinery: Piping Design and Pump SelectionLeslie CatindigNoch keine Bewertungen

- LPI Conventional Lightning ProtectionDokument16 SeitenLPI Conventional Lightning ProtectionLathif CCYRINoch keine Bewertungen

- SS 557 2010 Preview PDFDokument9 SeitenSS 557 2010 Preview PDFdhruvNoch keine Bewertungen

- Bio FiberDokument2 SeitenBio FiberGelina HernandezNoch keine Bewertungen

- Prestressed Concrete - Wikipedia, The Free EncyclopediaDokument6 SeitenPrestressed Concrete - Wikipedia, The Free EncyclopediaBaguma Grace GariyoNoch keine Bewertungen

- Thermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterDokument12 SeitenThermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterTJPRC PublicationsNoch keine Bewertungen

- Analisis Kekuatan Nominal Balok Lentur Baja DenganDokument6 SeitenAnalisis Kekuatan Nominal Balok Lentur Baja DenganZel Cys CivilEngineeringNoch keine Bewertungen

- All Slab - LSDokument15 SeitenAll Slab - LSTechnical OriliteNoch keine Bewertungen

- Pitot TubeDokument8 SeitenPitot TubeFarhad MalikNoch keine Bewertungen

- Galvanic Sacrificial Anodes InstallationDokument7 SeitenGalvanic Sacrificial Anodes InstallationReda AbdelhayNoch keine Bewertungen