Beruflich Dokumente

Kultur Dokumente

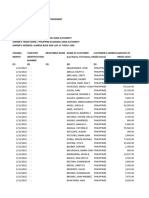

WM T Code List

Hochgeladen von

manutalwarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WM T Code List

Hochgeladen von

manutalwarCopyright:

Verfügbare Formate

Sr. No.

T Code

Description

LB01

Create Transfer Requirement

LB02

Change transfer requirement

LB03

Display Transfer Requirement

LB10

TRs for Storage Type

LB11

TRs for Material

LB12

TRs and Posting Change for MLEat.Doc.

LB13

TRs for Requirement

LD10

Clear decentralized inventory difference

LD11

Clear differences for decentral.sys.

10

.LI01

Create System Inventory Record

11

.LI02

Change System Inventory Record

12

.LI03

Display System Inventory Record

13

.LI04

Print System Inventory Record

14

.LI05

Inventory History for Storage Bin

15

.LI06

Block Storage types for annual invent.

16

.LI11

Enter Inventory Count

17

.LI12

Change inventory count

18

.LI13

Display Inventory Count

19

.LI14

Start Inventory Recount

20

.LI20

Clear Inventory Differences WM

21

.LI21

Clear Inventory Differences in MM-IM

22

.LL01

Warehouse Activity Monitor

23

.LLVS

WM Menu

24

.LN01

Number Ranges for Transfer Requirement

25

.LN02

Number Ranges for Transfer Orders

26

.LN03

Number Ranges for Quants

27

.LN04

Number Ranges for Posting Changes

28

.LN05

Number Ranges for Inventory

29

.LN06

Number Ranges for Reference Number

30

.LN08

Number Range Maintenance: LVS_LENUM

31

.LP10

Direct picking for PO

32

.LP11

WM staging of crate parts WM

33

.LP12

Staging release order parts (WM-PP)

34

.LP21

WM replenishment for fixed bins WM

35

.LP22

Replenishment Planning for Fixed Bins

36

.LQ01

Transfer Posting in Invent. Mgmt

37

.LQ02

Transfer Posting in Invent. Mgmt

38

.LS01

Create Warehouse Master Record

39

.LS02

Change Warehouse Master Record

40

.LS03

Display Warehouse Master Record

41

.LS04

Display Empty Storage Bins

42

.LS05

Generate Storage Bins

43

.LS06

Block Storage Bins

44

.LS07

Block Quants

45

.LS08

Block Storage Bins per Aisle

46

.LS09

Display Material Data for Storage Type

47

.LS11

Change storage bins (multiple proc.)

48

.LS12

Block Storage type

49

.LS22

Change Quants

50

.LS23

Display Quants

51

.LS24

Display Quants for Material

52

.LS25

Display Quants per Storage Bin

53

.LS26

Stock of Material

54

.LS27

Display Quants for storage unit

55

.LS28

Display storage units / bin

56

.LS32

Change storage unit

57

.LS33

Display storage unit

58

.LS41

List of control cycles for WIP loc

59

.LT01

Create Transfer Order

60

.LT02

Create TO for Inventory Difference

61

.LT03

Create TO from Delivery Note

62

.LT04

Create TO from TR

63

.LT05

Process Posting Change Notice

64

.LT06

Create TO for Material Document

65

.LT07

Create TO for mixed storage unit

66

.LT08

Manual addition to storage unit

67

.LT09

ID point function for storage units

68

.LT0A

Pre-plan storage units

69

.LT0B

Stock Placement of Shipping Units

70

.LT0C

Stock Removal of Shipping Units

71

.LT0D

Stock Transfer of Shipping Units

72

.LT0E

Create Removal TO for 2-Step Picking

73

.LT10

Create Transfer Order from List

74

.LT11

Confirm Transfer Order Item

75

.LT12

Confirm Transfer Order

76

.LT13

Confirm TO for storage unit

77

.LT14

Confirm preplanned TO item

78

.LT15

Canceling transfer order

79

.LT16

Canceling TO for storage unit

80

.LT17

Single Entry of Actual Data

81

.LT1A

Change Transfer Order

82

.LT21

Display Transfer Order

83

.LT22

Display Transfer Order / Storage Type

84

.LT23

Display Transfer Orders by Numbers

85

.LT24

Display Transfer Order / Material

86

.LT25

Display Transfer Order / Reference

87

.LT26

Transfer orders for storage bin

88

.LT27

Transfer order for storage unit

89

.LT28

Display Transfer Order / Reference

90

.LT31

Print TO Manually

91

.LT32

Print transfer order for storageunit

92

.LT41

Prepare TRs for Multiple Processing

93

.LT42

Create TOs by Multiple Processing

94

.LT43

Forming groups for deliveries

95

.LT44

Release for Multiple Processing

96

.LT45

Evaluation of reference numbers

97

.LT51

Maintain Missing Stock

98

.LT63

Control: Single Entry of Actual Data

99

.LT64

Single Entry of Actual Data

10

0.LT72

- Determine 2-step relevance

10

1.LT73

- Display 2-step

10

2.LU01

- Create Posting Change Notice

10

3.LU02

- Change Posting Change Notice

10

4.LU03

- Display Posting Change Notice

10

5.LU04

- Selection of Posting Change Notices

10

6.LX01

- List of Empty Storage Bins

10

7.LX02

- Inventory List

10

8.LX03

- Bin Status Report

10

9.LX04

- Capacity Used

11

0.LX05

- Block Bins in Bl.Storage w .Time Limt

11

1.LX06

- Inventory List for Fire Department

11

2.LX07

- Check storage

11

3.LX08

- Accident Regulations List

11

4.LX09

- Overview of All Transfer Requirements

11

5.LX10

- Activities per Storage Type

11

6.LX11

- Overview of Documents

11

7.LX12

- Document Overview: Landscape Format

11

8.LX13

- Analysis of Differences

11

9.LX14

- Analysis of Material Transfers

12

0.LX15

- Selection of Bins for Annual Inventory

12

1.LX16

- Selection of Bins for Continuous Inventory

12

2.LX17

- List of Inventory Differences

12

3.LX18

- Statistics of Inventory Differences

12

4.LX19

- Inventory Data Takeover by Batch Inp.

12

5.LX20

- Generate interim storage bins

12

6.LX21

- Pick List for Several Transfer Order

12

7.LX22

- Process Inventory from Overview

12

8.LX23

- Stock comparison IM - WM

12

9.LX24

- Display of Hazardous Material numbers

13

0.LX25

- Inventory Status

13

1.LX26

- Inventory in WM via cycle counting

13

2.LX27

- Stock levels by shelf life expiry date

13

3.LX28

- Relevant TO item for ext.system

13

4.LX29

- Fixed bin supervision

13

5.LX30

- Overview of WM messages ext.system

13

6.LX31

- Analysis of print control tables

13

7.LX32

- Archived transfer orders

13

8.LX33

- Archived transfer requirements

13

9.LX34

- Archived posting change notices

14

0.LX35

- Archived system inventory records

14

1.LX36

- Archived inventory histories

14

2.LX37

- Linked objects

14

3.LX38

- Check Report Customizing Strategy K

14

4.LX39

- Evaluation Reference No. for 2-S.Pck

14

5.LX40

- Material Situation Prod. Storage Bin

14

6.LX41

- Bin Status Report WM/PP Interface

14

7.LX42

- Evaluation PP Order from WM View

14

8.LX43

- Consistency Check for Control Cycles MCL9

WM: Material Plcmt/Removal:Selection

14

9.MCLD

: Material flow - Selection

15

0.MCLH

: Movement types - selection -

15

1.OL01

- Display / change LDK34 (bins)

15

2.OL02

- Display / change RLPLA (bins)

15

3.OL03

- Display / change LDK33 (stock)

15

4.OL04

- Display / change RLBES (stock)

15

5.OL05

- Display / change LDK30 (mat.whse)

15

6.OL06

- Display / change LDK31 (mat.type)

15

7.OL07

- Data transfer stor.bins LDK34->RLPLA

15

8.OL08

- Data transfer stor.bins RLPLA->B.I.

15

9.OL09

- Data transfer stor.bins LDK34->LAGP

16

0.OL10

- Test storage bin data transfer

16

1.OL11

- Data transfer stock LDK33->RLBES

16

2.OL12

- Data transfer stock RLBES-> B.I.

16

3.OL13

- Data transfer stock LDK33->LQUA

16

4.OL14

- Test stock data transfer

16

5.OL15

- Data transfer material whse no.view

16

6.OL16

- Test mat.master data transfer (MLGN)

16

7.OL17

- Data transfer material storage type

16

8.OL18

- Test mat.master data transfer (MLGT)

16

9.OLVS

C SD Menu for Master Data

17

0.VM01

- Create Hazardous Material

17

1.VM02

- Change Hazardous Material

17

2.VM03

- Display Hazardous Material

Sr.No.

T Code

Description

LS10

Generate Storage Bins

OLML

IMG structure Warehouse Management

OMK0

Link to PP interface

OMK1

Batch search method for Whse Mgmt

OMK2

Customer exits for strategies

OMK7

Batch WM..... (will be deleted)

OMKW

Stock removal strategy "SLEDu201D

OMKX

Automatic Transfer Orders

OMKY

Link to External System via ALE

10

.OMKZ

Automatic Transfer Orders

11

.OML0

MM: User Profile for Whse Mgmt MM:

12

.OML1

Overview of Critical Whse Monitor Obj

13

.OML2

Var. Report RLLL01SE: TOs

14

.OML3

Var. Report RLLL02SE: TR Items

15

.OML4

Var. Report RLLL03SE: Post.Chge Doc.

16

.OML5

Var. Report RLLL04SE: Deliveries

17

.OML6

Var. Report RLLL05SE: Negative Stock

18

.OML7

Var. Report RLLL06SE: Interim Stock

19

.OML8

Var. Report RLLL07SE: Stock Product.

20

.OMLA

Putaway Near Picking Bin

21

.OMLB

MObj.01: Critical TOs:

22

.OMLC

MObj.02: Critical TRs

23

.OMLD

MObj.03: Critical Post. Chge Notices:

24

.OMLE

M.Obj.04: Critical Deliveries

25

.OMLF

M.Obj.05: Negative Stocks

26

.OMLG

M.Obj.06: Stocks Interim Stor.Bins

27

.OMLH

M.Obj.07: Critical Stocks in Prod.

28

.OMLI

Report Variant: Single Entry ActData

29

.OMLJ

Movement Types for Whse Management

30

.OMLK

Default Values for Inventory

31

.OMLL

WM Movement Type: Clear Invent.Diff.

32

.OMLM

Definition Empty Bin Index

33

.OMLN

Warehouse Control Link

34

.OMLO

Sectioning of Storage Bins

35

.OMLP

Plan Jobs for Whse Activity Monitor

36

.OMLQ

Stock Removal Strategy FIFO

37

.OMLR

WM Interface to Inventory Management

38

.OMLS

Stock Removal Strategy LIFO

39

.OMLT

Stock Removal Strat. Partial Qty

40

.OMLU

Stock Placement Strategy Empty Bin

41

.OMLV

Print Control for Whse Management

42

.OMLW

Number Ranges for Whse Management

43

.OMLX

Confirmation

44

.OMLY

Storage Type Search

45

.OMLZ

Storage Section Search

46

.OMM0

MM: User Profile for Whse Management MM:

47

.OMM1

Storage Bin Type Search

48

.OMM2

Haz.Material Stock Placement

49

.OMM3

Stock Placement Strat.for Pallets

50

.OMM4

Stock Placement Strat. Bulk Storage

51

.OMM5

Storage Type Definition

52

.OMM6

Storage Type Definition

53

.OMM7

Storage Type Maintenance

54

.OMM8

Stock Removal Strat. Stringent FIFO

55

.OMM9

Stock Removal Strat. Large/Small

56

.OMMA

Print Assignment per Storage Type

57

.OMMB

Inventory No.Ranges for Whse Mgmt

58

.OMMC

Printer Assignment per WM Mov.Type

59

.OMMD

Confirmation Ctrl per Storage Type

60

.OMME

Confirmation Ctrl per Movement Type

61

.OMMF

Number Ranges per Warehouse

62

.OMMG

Number Ranges for Inventory

63

.OMMH

Type Search per Movement

64

.OMMI

Section Check per Storage Type

65

.OMMJ

Storage Unit Check per Storage Type

66

.OMMK

Stock Placement Strategies

67

.OMML

Hazardous Materials Storage Type

68

.OMMM

Storage Type Maintenance

69

.OMMN

Stringent FIFO Storage Type

70

.OMMO

Consistency Check for MM-WM Tables

71

.OMMP

Decentralized Warehouse Management

72

.OMMQ

Pre-Allocated Stock

73

.OMMR

Reference Numbers

74

.OMMS

Reference Number Documents

75

.OMMT

Reference Number Documents 2

76

.OMMU

Link to Decentralized Unit

77

.OMMV

Accumulation Decentralized

78

.OMMW

Error Recovery Decentralized

79

.OMMX

Printer Search

80

.OMMY

Print Code

81

.OMMZ

Spool Parameters for WM Print Ctrl

82

.OMN0

Control of Transaction Codes (MM-WM)

83

.OMN1

Print Reference Number

84

.OMN2

Stor.Type Control, Block Storage

85

.OMN3

Storage Classes Allowed

86

.OMN4

Storage Section Search

87

.OMN5

Storage Units Allowed

88

.OMN6

Storage Bin Type Search

89

.OMN7

Storage Type Search

90

.OMN8

Difference Indicators

91

.OMN9

Block Sectioning

92

.OMNA

Assignment for Bin Sectioning

93

.OMNB

Assignment PF Status

94

.OMNC

Control of Subsequent Screen

95

.OMND

Field Selection for Whse Mgmt

96

.OMNE

Control of Transactions in MM-WM

97

.OMNF

Requirement Types for Whse Mgmt

98

.OMNG

Queues Warehouse Management System

99

.OMNH

APPC Interface per Warehouse Number

10

0.OMN

Print Program per Warehouse Number

10

1.OMN

Link to Warehouse Control Unit

10

2.OMN

Inventory Control per Storage Type

10

3.OMN

Warehouse Number Maint./Inventory

10

4.OMN

Define Mail Recipient

10

5.OMN

Conversion Exit SU Number

10

6.OMN

Define Mail Recipient

10

7.OMN

Authorizations in MM-WM

10

8.OMN

Special Movement Indicators

10

9.OMN

TO Print Control with SU Management

11

0.OMN

Print Code for TOs with SU Mgmt

11

1.OMN

Printer Pool for SU Management

11

2.OMN

Print Control with SU Management

11

3.OMN

Number Range Intervals for Whse Mgmt

11

4.OMN

System Parameters for Dec.Whse Mgmt WM

11

5.OMN

Block Storage Indicators

11

6.OMN

Access Strategy for Stor.Type Search

11

7.OMN

Parameters for Activity in WM

11

8.WAP

Appointments worklist

11

9.WAP

Maintain goods receipt appointment

12

0.WAP

Display goods receipt appointment

12

1.WAP

Appointment, arrival

12

2.WAP

Appointment, departure

12

3.WAP

Maintain individual appointment

12

4.WAP

App., planned/actual comparison

Das könnte Ihnen auch gefallen

- Gift - Cards - Method - NOV - 2023 DN ModsDokument9 SeitenGift - Cards - Method - NOV - 2023 DN ModskaalmohamedaymenNoch keine Bewertungen

- Clarity Inquiry #9ehb78p6wbDokument17 SeitenClarity Inquiry #9ehb78p6wbPatricia CarvajalNoch keine Bewertungen

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyVon EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyBewertung: 4 von 5 Sternen4/5 (6)

- SAP WM QuestionsDokument62 SeitenSAP WM QuestionsSudhakar Karnan100% (2)

- SAP+WM TopicsDokument3 SeitenSAP+WM Topicsnithinb_kumar65Noch keine Bewertungen

- BUSS1030 MSE 2018 Sem 1 Sample PaperDokument11 SeitenBUSS1030 MSE 2018 Sem 1 Sample PaperDharniNoch keine Bewertungen

- SAP Electronic Bank Statement - Basic Process and Overview - TechloreanDokument6 SeitenSAP Electronic Bank Statement - Basic Process and Overview - TechloreaniuriiNoch keine Bewertungen

- WM ConfigDokument3 SeitenWM ConfigasadshoaibNoch keine Bewertungen

- SAP WM Vs eWMDokument6 SeitenSAP WM Vs eWMBIROJI VENKAT RAMANANoch keine Bewertungen

- SAPSTROOM White Paper WM-Vs-EWM - Receiving-PutawayDokument16 SeitenSAPSTROOM White Paper WM-Vs-EWM - Receiving-PutawayVenkat ChilukuriNoch keine Bewertungen

- WM ScenariosDokument6 SeitenWM ScenariosVishnu Kumar SNoch keine Bewertungen

- Blue Yonder Airlines: "Off We Go!"Dokument8 SeitenBlue Yonder Airlines: "Off We Go!"axl roseNoch keine Bewertungen

- HDFC LifeDokument66 SeitenHDFC LifeChetan PahwaNoch keine Bewertungen

- 5243 XXXX XX 319267 - 17 03 2019 - 000128Dokument8 Seiten5243 XXXX XX 319267 - 17 03 2019 - 000128Venu GopalNoch keine Bewertungen

- SAP WMS ConfigDokument11 SeitenSAP WMS ConfigVishal SatheNoch keine Bewertungen

- EWM WhseDokument26 SeitenEWM WhseShaik Khwaja Nawaz SharifNoch keine Bewertungen

- WM Interview 1Dokument5 SeitenWM Interview 1DeepakNoch keine Bewertungen

- Sap WM TcodesDokument7 SeitenSap WM TcodesVenkat Ram Reddy UppulaNoch keine Bewertungen

- SAP WM Tcode and Tables DetailsDokument11 SeitenSAP WM Tcode and Tables DetailsShailendra SInghNoch keine Bewertungen

- SAP IS-Retail Interview Questions, Answers, and ExplanationsVon EverandSAP IS-Retail Interview Questions, Answers, and ExplanationsBewertung: 3 von 5 Sternen3/5 (11)

- SAP IM Vs WM, How To Choose Use and OptimizeDokument56 SeitenSAP IM Vs WM, How To Choose Use and Optimizehalwanv100% (1)

- Replenishment CustomizingDokument6 SeitenReplenishment CustomizingAli MessaoudNoch keine Bewertungen

- Some Important T-Codes in WM: ReportsDokument6 SeitenSome Important T-Codes in WM: ReportsP RajendraNoch keine Bewertungen

- SAP WM T Codes TablesDokument4 SeitenSAP WM T Codes Tablesbal6918100% (1)

- WM OverviewDokument38 SeitenWM OverviewRahul KumarNoch keine Bewertungen

- Inventory ManagementDokument18 SeitenInventory ManagementAmolnanavareNoch keine Bewertungen

- WM Interview 2Dokument7 SeitenWM Interview 2DeepakNoch keine Bewertungen

- Chapter 1Dokument22 SeitenChapter 1Low Joey100% (1)

- Comparison Between SAP IM - WM - Lean WM - DWM - EWMDokument4 SeitenComparison Between SAP IM - WM - Lean WM - DWM - EWMSebastian BravoNoch keine Bewertungen

- WM-PP Interface For Pick Parts Material StagingDokument2 SeitenWM-PP Interface For Pick Parts Material StagingmohannaiduramNoch keine Bewertungen

- Capacity Check Control in SAP WMDokument11 SeitenCapacity Check Control in SAP WMsumitjain_250% (2)

- Automatic Replenishment - Warehouse Management (WM) in SAPDokument3 SeitenAutomatic Replenishment - Warehouse Management (WM) in SAPnikNoch keine Bewertungen

- SAP+MM End To End Implementation SquenceDokument73 SeitenSAP+MM End To End Implementation SquenceVasanth VarunNoch keine Bewertungen

- WM Transaction Codes PDFDokument5 SeitenWM Transaction Codes PDFmurali036100% (1)

- T-Code Lists in WM, Reports For Other ModulesDokument12 SeitenT-Code Lists in WM, Reports For Other ModulesArun RaviNoch keine Bewertungen

- SAP WM - Transaction CodesDokument3 SeitenSAP WM - Transaction CodesHarish KumarNoch keine Bewertungen

- WM Tcodes For Operational Reports: Following Is A List of Commonly Used WM TcodesDokument6 SeitenWM Tcodes For Operational Reports: Following Is A List of Commonly Used WM Tcodesshailja mishraNoch keine Bewertungen

- SAP WM Transaction For Transfer RequirementDokument9 SeitenSAP WM Transaction For Transfer Requirementpraveen kumarNoch keine Bewertungen

- Purchasing of A Material Packed To Nested Handling Units Using SAP EWMDokument3 SeitenPurchasing of A Material Packed To Nested Handling Units Using SAP EWMVenkat RamanaNoch keine Bewertungen

- WM Configuration Document - Step by StepDokument71 SeitenWM Configuration Document - Step by StepSubhasis Sikdar100% (1)

- SAP EWM Inbound ProcessDokument24 SeitenSAP EWM Inbound Processakss maneNoch keine Bewertungen

- Replenishment Control in SAP WMDokument11 SeitenReplenishment Control in SAP WMsumitjain_25Noch keine Bewertungen

- Interview Questions With Answers in SAP WMDokument3 SeitenInterview Questions With Answers in SAP WMmaheshtabmNoch keine Bewertungen

- SAP Stock Transport Order and Stock Transfer Process - SAP MM TrainingDokument13 SeitenSAP Stock Transport Order and Stock Transfer Process - SAP MM TrainingShayne229Noch keine Bewertungen

- Warehouse Management Transaction CodesDokument5 SeitenWarehouse Management Transaction Codesmaheshtabm100% (1)

- SAP WM NotesDokument9 SeitenSAP WM NotesLucas DantasNoch keine Bewertungen

- SAP S/4HANA Retail: Processes, Functions, CustomisingVon EverandSAP S/4HANA Retail: Processes, Functions, CustomisingBewertung: 5 von 5 Sternen5/5 (1)

- SCM 601 - Theoretical ContentDokument6 SeitenSCM 601 - Theoretical ContentroccatNoch keine Bewertungen

- Two Steps Picking Process in SAPDokument15 SeitenTwo Steps Picking Process in SAPSubhojit BanerjeeNoch keine Bewertungen

- Storage Type Indicators in SAP WMDokument13 SeitenStorage Type Indicators in SAP WMMohammed Savad0% (1)

- SAP WM SyllabusDokument7 SeitenSAP WM Syllabuskurrysuchit50% (2)

- WM - Transaction CodesDokument6 SeitenWM - Transaction CodesshyamsateeshNoch keine Bewertungen

- Handling Unit (HU) Is The Combination of Material and Packaging MaterialDokument22 SeitenHandling Unit (HU) Is The Combination of Material and Packaging MaterialDeepakNoch keine Bewertungen

- TO in SAP WMDokument3 SeitenTO in SAP WMmbraghumb9019Noch keine Bewertungen

- Fixed Bin Replenishment in SAPDokument5 SeitenFixed Bin Replenishment in SAPMohan NaiduNoch keine Bewertungen

- SAP WM - Uploading Opening Balances To Storage BinDokument3 SeitenSAP WM - Uploading Opening Balances To Storage BinIlmoyeteNoch keine Bewertungen

- WM Interface To Inventory ManagementDokument5 SeitenWM Interface To Inventory ManagementPhilip BurrowNoch keine Bewertungen

- Replenishment of Fixed Bins in SAP WM - Aroop's NotepadDokument3 SeitenReplenishment of Fixed Bins in SAP WM - Aroop's NotepadnikNoch keine Bewertungen

- WM Storage Location ControlDokument4 SeitenWM Storage Location ControlPradeep Kumar Reddy NaraNoch keine Bewertungen

- Sap WM User Manual: Published by Team of SAP Consultants at SaptopjobsDokument6 SeitenSap WM User Manual: Published by Team of SAP Consultants at SaptopjobsDISHIMUKH YADAVNoch keine Bewertungen

- FS - EWM - Gate Pass Details To Vendor PortalDokument10 SeitenFS - EWM - Gate Pass Details To Vendor PortalSUBHOJIT BANERJEENoch keine Bewertungen

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesVon EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNoch keine Bewertungen

- Warehouse Management Systems A Complete Guide - 2019 EditionVon EverandWarehouse Management Systems A Complete Guide - 2019 EditionNoch keine Bewertungen

- OptiX RTN 900 V1R3 Product IntroductionDokument24 SeitenOptiX RTN 900 V1R3 Product IntroductionRafael LessaNoch keine Bewertungen

- Lecture 3 WorkGroup Computing, EDI and IntranetDokument51 SeitenLecture 3 WorkGroup Computing, EDI and IntranetMichael AttehNoch keine Bewertungen

- PDFDokument4 SeitenPDFJunel King VillarNoch keine Bewertungen

- Principles of Accounting Chapter 1 QuestionsDokument45 SeitenPrinciples of Accounting Chapter 1 Questionsahmed156039Noch keine Bewertungen

- Factoring Forfaiting TheoryDokument39 SeitenFactoring Forfaiting TheoryCharu AroraNoch keine Bewertungen

- N MPR BINWw 8 K N2 SCDokument5 SeitenN MPR BINWw 8 K N2 SCNallagulla prasad100% (1)

- Intermediate Group I Test Papers FOR 2014 DECDokument88 SeitenIntermediate Group I Test Papers FOR 2014 DECwaterloveNoch keine Bewertungen

- Shivajirao Kadam Institute of Technology and Management: An Internship Report ONDokument11 SeitenShivajirao Kadam Institute of Technology and Management: An Internship Report ONYash KhuranaNoch keine Bewertungen

- Claim Form NewDokument4 SeitenClaim Form NewVicky GautamNoch keine Bewertungen

- Solution Manual For Intermediate Accounting 19th Edition by Stice PDFDokument18 SeitenSolution Manual For Intermediate Accounting 19th Edition by Stice PDFADNoch keine Bewertungen

- GST Tax InvoiceDokument1 SeiteGST Tax InvoiceSunnyNoch keine Bewertungen

- Questions Chapter 8Dokument19 SeitenQuestions Chapter 8SA 10Noch keine Bewertungen

- System-Generated Excel File For January 2022 SalesDokument120 SeitenSystem-Generated Excel File For January 2022 SalesGiomar BasalNoch keine Bewertungen

- Fortinet Wireless Product MatrixDokument10 SeitenFortinet Wireless Product MatrixViktor MahdalNoch keine Bewertungen

- Personal Loan PDFDokument3 SeitenPersonal Loan PDFbusiness loanNoch keine Bewertungen

- IPG UserGuide VirtualTerminal v2023-2Dokument47 SeitenIPG UserGuide VirtualTerminal v2023-2thiago_potroNoch keine Bewertungen

- Gr11 ACC P2 (ENG) June 2022 Answer BookDokument10 SeitenGr11 ACC P2 (ENG) June 2022 Answer Bookora mashaNoch keine Bewertungen

- How To Use KEATDokument5 SeitenHow To Use KEATAamir KhanNoch keine Bewertungen

- Air Waybill: Chgs CodeDokument3 SeitenAir Waybill: Chgs Codetioline art100% (1)

- iGW Brochure 2021Dokument4 SeiteniGW Brochure 2021Lâm Trần HữuNoch keine Bewertungen

- General Routing Encapsulation (GRE) Protocol 1Dokument2 SeitenGeneral Routing Encapsulation (GRE) Protocol 1Habet MoshmoshNoch keine Bewertungen

- Neeta Mod Copy2 DistributionDokument28 SeitenNeeta Mod Copy2 Distributionraina singhiNoch keine Bewertungen