Beruflich Dokumente

Kultur Dokumente

Groover Fundamentos Manual Soluciones

Hochgeladen von

CADTDDCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Groover Fundamentos Manual Soluciones

Hochgeladen von

CADTDDCopyright:

Verfügbare Formate

Solutions for Fundamentals of Modern Manufacturing, 3/e (published by Wiley)

MPGroover 2007

42 MANUFACTURING ENGINEERING

Review Questions

42.1

Define manufacturing engineering.

Answer. Manufacturing engineering is a technical staff department responsible for planning the

manufacturing processes for a product and its components.

42.2

What are the principal activities in manufacturing engineering?

Answer. Principal activities of manufacturing engineering are (1) process planning, (2) technical

problem solving and continuous improvement, and (3) advising the product designers in design for

manufacturability.

42.3

Identify some of the details and decisions that are included within the scope of process planning.

Answer. Table 42.1 lists the following details and decisions in process planning: (1) the processes

required and the sequence in which they are performed; (2) equipment selection; (3) tools, dies,

molds, fixtures, and gages that will be needed; (4) cutting tools and cutting conditions for

machining operations; (5) methods for manual operations (e.g., assembly) and manual portions of

machine cycles (e.g., loading and unloading a production machine); (6) time standards for each

operation; (7) estimates of production costs; (8) moving materials and work-in-progress in the

factory; and (9) plant layout and facilities design. Not all of these details and decisions are the

exclusive responsibility of the manufacturing engineering department.

42.4

What is a route sheet?

Answer. A route sheet is a listing of the production operations and their sequence required to make

a given part. It also lists the equipment and special tooling that is required.

42.5

What is the difference between a basic process and a secondary process?

Answer. A basic process establishes the starting geometry of the work material; e.g., casting, rolled

sheet metal, drawn metal bar. Secondary processes are used to refine the starting geometry and

transform the material into final shape and size; machining and sheet metal pressworking are

common secondary processes.

42.6

What is a precedence constraint in process planning?

Answer. A precedence constraint is a limitation on the order in which processing or assembly

operations can be performed on a given workpart; for example, a hole must be drilled before it can

be tapped.

42.7

In the make or buy decision, why is it that purchasing a component from a vendor may cost more

than producing the component internally, even though the quoted price from the vendor is lower

than the internal price?

Answer. Because purchasing the component may cause idle equipment and staff in the factory that

the company must still pay for.

42.8

Identify some of the important factors that should enter into the make or buy decision.

Answer. The factors in the make or buy decision include (1) cost, (2) whether the process is

available internally, (3) production quantity, (4) Product life, (5) whether or not the component is a

standard commercially available hardware item, (6) supplier reliability, and (7) possible need for

alternative sources.

Excerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional purposes only to

students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of this work beyond that permitted

by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the copyright owner is unlawful.

21

Solutions for Fundamentals of Modern Manufacturing, 3/e (published by Wiley)

42.9

MPGroover 2007

Name three of the general principles and guidelines in design for manufacturability?

Answer. Table 42.5 lists the following DFM principles and guidelines: (1) Minimize number of

components. (2) Use standard commercially available components. (3) Use common parts across

product lines. (4) Design for ease of part fabrication. (5) Design parts with tolerances that are within

process capability. (6) Design the product to be foolproof during assembly. (7) Minimize flexible

components. (8) Design for ease of assembly. (9) Use modular design. (10) Shape parts and

products for ease of packaging. (11) Eliminate or reduce adjustment required.

42.10

What is concurrent engineering and what are its important components?

Answer. Concurrent engineering is an approach used by companies to reduce the time to bring a

new product to market. It includes (1) design for manufacturability, (2) design for quality, (3) design

for life cycle, and (4) design for cost. It also includes certain organizational changes that attempt to

bring different functions in the company together during product design to consider all possible

aspects of the product.

42.11

Identify some of the enabling technologies for concurrent engineering?

Answer. Enabling technologies mentioned in the text are CAD/CAM, electronic mail, the Internet,

and rapid prototyping.

42.12

What is meant by the term design for life cycle?

Answer. Design for life cycle means that factors relating to the product after it has been

manufactured should be taken into consideration in design. These factors include ease of

installation, reliability, maintainability, serviceability, upgradeability, and disposability.

Multiple Choice Quiz

There is a total of 19 correct answers in the following multiple-choice questions (some questions have

multiple answers that are correct). To attain a perfect score on the quiz, all correct answers must be given.

Each correct answer is worth 1 point. Each omitted answer or wrong answer reduces the score by 1 point,

and each additional answer beyond the correct number of answers reduces the score by 1 point. Percentage

score on the quiz is based on the total number of correct answers.

42.1

The manufacturing engineering department in an organization is best described as which one of the

following: (a) branch of the sales department, (b) concurrent engineers, (c) management, (d)

product designers, (e) production supervisors, or (f) technical staff function?

Answer. (f).

42.2

Which of the following are the usual responsibilities of the manufacturing engineering department

(four best answers): (a) advising on design for manufacturability, (b) facilities planning, (c)

marketing the product, (d) plant management, (e) process improvement, (f) process planning, (g)

product design, (h) solving technical problems in the production departments, and (i) supervision of

production workers?

Answer. (a), (e), (f), and (h).

42.3

Which of the following are considered basic processes, as opposed to secondary processes (four

correct answers): (a) annealing, (b) anodizing, (c) drilling, (d) electroplating, (e) forward hot

extrusion to produce aluminum bar stock, (f) impression die forging, (g) rolling of sheet steel, (h)

sand casting, (i) sheet metal stamping, (j) spot welding, (k) surface grinding of hardened steel, (l)

tempering of martensitic steel, and (m) turning?

Answer. (e), (f), (g), and (h).

Excerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional purposes only to

students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of this work beyond that permitted

by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the copyright owner is unlawful.

22

Solutions for Fundamentals of Modern Manufacturing, 3/e (published by Wiley)

42.4

MPGroover 2007

Which of the following would be considered secondary processes, as opposed to basic processes

(four correct answers): (a) annealing, (b) arc welding, (c) drilling, (d) electroplating, (e) extrusion to

produce steel automotive components, (f) impression die forging, (g) painting, (h) plastic injection

molding, (i) rolling of sheet steel, (j) sand casting, (k) sheet metal stamping, (l) sintering of pressed

ceramic powders, and (m) ultrasonic machining?

Answer. (c), (e), (k), and (m).

42.5

Which of the following are operations to enhance physical properties (three correct answers): (a)

annealing, (b) anodizing, (c) die casting, (d) drilling, (e) electroplating, (f) rolling of nickel alloys,

(g) sheet metal drawing, (h) sintering of pressed ceramic powders, (i) surface grinding of hardened

steel, (j) tempering of martensitic steel, (k) turning, and (l) ultrasonic cleaning?

Answer. (a), (h), and (j).

42.6

A route sheet is a document whose principal function is which of the following (one best answer):

(a) continuous improvement, (b) design for manufacturability, (c) provides authorization for

material handlers to move the part, (d) quality inspection procedure, (e) specifies the process plan,

or (f) specifies the detailed method for a given operation?

Answer. (e).

42.7

In a make-or-buy situation, the decision should always be to purchase the component if the vendors

quoted price is less than the in-house estimated cost of the component: (a) true or (b) false?

Answer. (b).

42.8

Which one of the following types of computer-aided process planning relies on parts classification

and coding in group technology: (a) generative CAPP, (b) retrieval CAPP, (c) traditional process

planning, or (d) none of the preceding?

Answer. (b).

Excerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional purposes only to

students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of this work beyond that permitted

by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the copyright owner is unlawful.

23

Das könnte Ihnen auch gefallen

- XXXX Inj MOld Cost EstimationDokument23 SeitenXXXX Inj MOld Cost EstimationAmitava DattaNoch keine Bewertungen

- REMOS GX Pilot Operating Handbook r02 2009Dokument111 SeitenREMOS GX Pilot Operating Handbook r02 2009REMOS Aircraft86% (7)

- Craftsman ChainsawDokument21 SeitenCraftsman Chainsawgwrace1Noch keine Bewertungen

- Fixture DesignDokument14 SeitenFixture DesignnetiftkharNoch keine Bewertungen

- Internal Audit Checklist PRODUCTIONDokument6 SeitenInternal Audit Checklist PRODUCTIONRavi Baghel100% (3)

- ECSS-E-HB-32-20 - Part-2A - Structural Materials Handbook - Design Calculation MethodsDokument434 SeitenECSS-E-HB-32-20 - Part-2A - Structural Materials Handbook - Design Calculation Methodsdkleeman4444Noch keine Bewertungen

- Computer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - inDokument12 SeitenComputer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - indamonlanglois100% (1)

- Facility Layout TestDokument25 SeitenFacility Layout TestTesfaye Belaye100% (1)

- KIL3012 - WEEK 1 - 10.9.19 (Student Copy)Dokument61 SeitenKIL3012 - WEEK 1 - 10.9.19 (Student Copy)Ed100% (1)

- CH 22Dokument16 SeitenCH 22onlydlonly100% (1)

- Plant Design CHEN 451Dokument42 SeitenPlant Design CHEN 451lalitNoch keine Bewertungen

- Plant Design 2Dokument42 SeitenPlant Design 2Jaymee Delfinado100% (2)

- Design For Manufacturability SeminarDokument43 SeitenDesign For Manufacturability Seminarnithink100Noch keine Bewertungen

- Reverse Engineering NotesDokument4 SeitenReverse Engineering Notesapi-379303652100% (2)

- Engineering Applications: A Project Resource BookVon EverandEngineering Applications: A Project Resource BookBewertung: 2.5 von 5 Sternen2.5/5 (1)

- CIDEON ECTR Interface To SolidWorks Configuration Manual PDFDokument102 SeitenCIDEON ECTR Interface To SolidWorks Configuration Manual PDFCADTDDNoch keine Bewertungen

- c7-30 Road AncillariesDokument17 Seitenc7-30 Road AncillariesJacky TiongNoch keine Bewertungen

- Beckhoff and TwinCAT GuideDokument17 SeitenBeckhoff and TwinCAT Guidevoltus88Noch keine Bewertungen

- Advanced Manufacturing Technology MECH4012 Module#3 Tutorial#9 Manufacturing EngineeringDokument3 SeitenAdvanced Manufacturing Technology MECH4012 Module#3 Tutorial#9 Manufacturing EngineeringahmedNoch keine Bewertungen

- CH 01Dokument3 SeitenCH 01satyendrashuklaNoch keine Bewertungen

- Preguntas Cap 4 Manufactura ModernaDokument13 SeitenPreguntas Cap 4 Manufactura ModernaJavierNoch keine Bewertungen

- ME 473 Unit 6ADokument19 SeitenME 473 Unit 6AAma Serwaa YeboahNoch keine Bewertungen

- CH 39Dokument3 SeitenCH 39onlydlonlyNoch keine Bewertungen

- Chapter 21 Sol GrooverDokument12 SeitenChapter 21 Sol GrooverKASHIFNoch keine Bewertungen

- Fundamentals of Design & Manufacturing - An 201/ad 301: Postal Test Paper - 1 MARKS:100 DURATION:3 HoursDokument1 SeiteFundamentals of Design & Manufacturing - An 201/ad 301: Postal Test Paper - 1 MARKS:100 DURATION:3 Hoursmpcd07Noch keine Bewertungen

- Cutting Tool Technology: Review QuestionsDokument17 SeitenCutting Tool Technology: Review QuestionsKhaled ShaabanNoch keine Bewertungen

- Theory of Metal Machining: Review QuestionsDokument14 SeitenTheory of Metal Machining: Review QuestionsKhaled ShaabanNoch keine Bewertungen

- Chapter3 - Concurrent Engineering PDFDokument15 SeitenChapter3 - Concurrent Engineering PDFSandeep GogadiNoch keine Bewertungen

- Mid Term Questions ADC 604Dokument7 SeitenMid Term Questions ADC 604fazNoch keine Bewertungen

- OM Sample QPDokument8 SeitenOM Sample QPChandra ShekarNoch keine Bewertungen

- Chapter 1 INTRODUCTION AND OVERVIEW OF MANUFACTURINGDokument2 SeitenChapter 1 INTRODUCTION AND OVERVIEW OF MANUFACTURINGLinwoodNoch keine Bewertungen

- Ch.11. Questions - V1 - For FULL ChaptersDokument7 SeitenCh.11. Questions - V1 - For FULL ChaptersBENITA ROYNoch keine Bewertungen

- DFM Course IntroductionDokument21 SeitenDFM Course IntroductionNitheeshNoch keine Bewertungen

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Dokument8 SeitenDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNoch keine Bewertungen

- Operations MGMT Notes AMUDokument5 SeitenOperations MGMT Notes AMUBilal Mustafa KhanNoch keine Bewertungen

- QUIZ # 02 MGT 613 Productions & Operations Management: InstructionsDokument5 SeitenQUIZ # 02 MGT 613 Productions & Operations Management: InstructionsMuzammil QamarNoch keine Bewertungen

- Mtech. Design For Manufacturing and AssemblyDokument5 SeitenMtech. Design For Manufacturing and AssemblysimalaraviNoch keine Bewertungen

- IE 447 CIM Lecture Notes - Chapter 5: Concurrent Engineering - 44Dokument7 SeitenIE 447 CIM Lecture Notes - Chapter 5: Concurrent Engineering - 44Santhosh Buddenahalli SNoch keine Bewertungen

- Design ProcessDokument12 SeitenDesign Processramms_73Noch keine Bewertungen

- Process EngineeringDokument12 SeitenProcess EngineeringSaksham SarkarNoch keine Bewertungen

- ISQS Ch04 TB PracticeDokument21 SeitenISQS Ch04 TB PracticeManish GuptaNoch keine Bewertungen

- Early Cost Estimation of Injection Molds 315: Glossary Index 365 369Dokument6 SeitenEarly Cost Estimation of Injection Molds 315: Glossary Index 365 369omardzstNoch keine Bewertungen

- Quiz I-OM-IDokument4 SeitenQuiz I-OM-ImoonmoonNoch keine Bewertungen

- MMECM 105-4 Design For Manufacturing and Assembly-IDokument2 SeitenMMECM 105-4 Design For Manufacturing and Assembly-IRajeshNoch keine Bewertungen

- Om 6th Edition Collier Test BankDokument9 SeitenOm 6th Edition Collier Test Bankrobertadelatkmu100% (21)

- State of Cold Forging Technology in Global Competition - Net Shape PDFDokument20 SeitenState of Cold Forging Technology in Global Competition - Net Shape PDFMustafa Mert SAMLINoch keine Bewertungen

- Turning Fixtures 5 PDFDokument12 SeitenTurning Fixtures 5 PDFgsudhanta1604100% (2)

- Practice MCQ 4Dokument5 SeitenPractice MCQ 4business docNoch keine Bewertungen

- Practice MCQ 5Dokument5 SeitenPractice MCQ 5business docNoch keine Bewertungen

- Design For CastingDokument6 SeitenDesign For CastingJosue Cruz NavarroNoch keine Bewertungen

- Jntuworld: Design For ManufacturingDokument1 SeiteJntuworld: Design For ManufacturingcomputerstudentNoch keine Bewertungen

- Unit 8 Engineering DesignDokument14 SeitenUnit 8 Engineering Designsiamanwar893Noch keine Bewertungen

- A Holistic Approach To Zero Defect CastingsDokument10 SeitenA Holistic Approach To Zero Defect CastingsMiguel BrionesNoch keine Bewertungen

- DSP PracticeQuestions 2009Dokument15 SeitenDSP PracticeQuestions 2009sruthihriday100% (1)

- Process Engineering - Introduction5Dokument16 SeitenProcess Engineering - Introduction5Saravanan MuthukrishnanNoch keine Bewertungen

- NLL ANXDokument1 SeiteNLL ANXraviteja tankalaNoch keine Bewertungen

- Cad-Cam-Cim Lab Manual Me804Dokument49 SeitenCad-Cam-Cim Lab Manual Me804Vivek Patil100% (1)

- Minimize The Number of ComponentsDokument20 SeitenMinimize The Number of ComponentsJohnNoch keine Bewertungen

- Forming Simulation and Die Design in Sheet Metal FormingDokument8 SeitenForming Simulation and Die Design in Sheet Metal FormingALBERTUS DENoch keine Bewertungen

- Chapter-8 Engineering Failure AnalysisDokument12 SeitenChapter-8 Engineering Failure Analysissafeer ahmadNoch keine Bewertungen

- PME681Dokument1 SeitePME681janani2004Noch keine Bewertungen

- Dfa Analysis On Water PurifierDokument24 SeitenDfa Analysis On Water PurifierNshnthNoch keine Bewertungen

- Introduction To Machine DesignDokument36 SeitenIntroduction To Machine DesignHamza RaoNoch keine Bewertungen

- Chapter 5Dokument24 SeitenChapter 5maherkamelNoch keine Bewertungen

- Design Problem Solving: Knowledge Structures and Control StrategiesVon EverandDesign Problem Solving: Knowledge Structures and Control StrategiesNoch keine Bewertungen

- CS3844Dokument1 SeiteCS3844CADTDDNoch keine Bewertungen

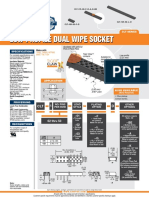

- PRODUCT NUMBER: 8579-0-15-80-21-84-10-0: Data SheetDokument3 SeitenPRODUCT NUMBER: 8579-0-15-80-21-84-10-0: Data SheetCADTDDNoch keine Bewertungen

- SMR-TS-1.7-1.6-3.6GRE Draft Spec Sheet - 200416Dokument1 SeiteSMR-TS-1.7-1.6-3.6GRE Draft Spec Sheet - 200416CADTDDNoch keine Bewertungen

- 12628108.GORE SMT EMI Gasket Supersoft Data SheetDokument2 Seiten12628108.GORE SMT EMI Gasket Supersoft Data SheetCADTDDNoch keine Bewertungen

- Produktflyer BADAMID PA9T ENDokument2 SeitenProduktflyer BADAMID PA9T ENCADTDDNoch keine Bewertungen

- TR Fastenings TR - KF2Dokument1 SeiteTR Fastenings TR - KF2CADTDDNoch keine Bewertungen

- IAQG KPI ExamplesDokument4 SeitenIAQG KPI ExamplesCADTDDNoch keine Bewertungen

- Section A-A SCALE 10: 1Dokument1 SeiteSection A-A SCALE 10: 1CADTDDNoch keine Bewertungen

- Samtec CLT-104-02-F-D-BEDokument1 SeiteSamtec CLT-104-02-F-D-BECADTDDNoch keine Bewertungen

- PRODUCT NUMBER: 0327-0-15-80-34-80-10-0: Data SheetDokument3 SeitenPRODUCT NUMBER: 0327-0-15-80-34-80-10-0: Data SheetCADTDDNoch keine Bewertungen

- Emi Catalog LR 1 1 - Compressed 1Dokument40 SeitenEmi Catalog LR 1 1 - Compressed 1CADTDDNoch keine Bewertungen

- Hi Temp 1Dokument1 SeiteHi Temp 1CADTDDNoch keine Bewertungen

- T-Top800 T-Top800 Top81Dokument1 SeiteT-Top800 T-Top800 Top81CADTDDNoch keine Bewertungen

- 3" Core Matte Electrostatic Dissipative 1 Mil Polyimide Circuit Board LabelsDokument5 Seiten3" Core Matte Electrostatic Dissipative 1 Mil Polyimide Circuit Board LabelsCADTDDNoch keine Bewertungen

- PRODUCT NUMBER: 0415-0-15-80-16-80-10-0: Data SheetDokument3 SeitenPRODUCT NUMBER: 0415-0-15-80-16-80-10-0: Data SheetCADTDDNoch keine Bewertungen

- Edition X Color Should Get Might Get Gcmi ShadeDokument2 SeitenEdition X Color Should Get Might Get Gcmi ShadeCADTDDNoch keine Bewertungen

- LVD Oj 2019-11-27 PDFDokument11 SeitenLVD Oj 2019-11-27 PDFCADTDDNoch keine Bewertungen

- Keystone Spacer 892Dokument1 SeiteKeystone Spacer 892CADTDDNoch keine Bewertungen

- Miss MendozaDokument34 SeitenMiss MendozaCADTDDNoch keine Bewertungen

- Unit 4Dokument40 SeitenUnit 4CADTDDNoch keine Bewertungen

- Guide 1670 En-Macbook ProDokument7 SeitenGuide 1670 En-Macbook ProCADTDD100% (1)

- Rhinoceros2 PDFDokument184 SeitenRhinoceros2 PDFwolf72007Noch keine Bewertungen

- Miss MendozaDokument31 SeitenMiss MendozaCADTDDNoch keine Bewertungen

- S-532 - UlineDokument1 SeiteS-532 - UlineCADTDDNoch keine Bewertungen

- Uline Static BagDokument1 SeiteUline Static BagCADTDDNoch keine Bewertungen

- Polyimide Label Roll: Enter Search Term or Part # All Product CategoriesDokument2 SeitenPolyimide Label Roll: Enter Search Term or Part # All Product CategoriesCADTDDNoch keine Bewertungen

- Polyimide Label Roll: Enter Search Term or Part # All Product CategoriesDokument2 SeitenPolyimide Label Roll: Enter Search Term or Part # All Product CategoriesCADTDDNoch keine Bewertungen

- Thermlfilm Select 21940Dokument2 SeitenThermlfilm Select 21940CADTDDNoch keine Bewertungen

- BVD2034GBDokument4 SeitenBVD2034GBSamehibrahemNoch keine Bewertungen

- 1.1 Industry Profile: Indian Valves Market OutlookDokument41 Seiten1.1 Industry Profile: Indian Valves Market OutlookKathir SNoch keine Bewertungen

- Asme A112.3.1-2007Dokument11 SeitenAsme A112.3.1-2007Jaime ColmenaresNoch keine Bewertungen

- Integrated Controls ManagementDokument22 SeitenIntegrated Controls ManagementPaulNoch keine Bewertungen

- Cisco UCS Administration Guide PDFDokument154 SeitenCisco UCS Administration Guide PDFSambath KumarNoch keine Bewertungen

- Ashok LeylandDokument7 SeitenAshok LeylandNicholas ReillyNoch keine Bewertungen

- Library ManagementDokument36 SeitenLibrary Managementkarthik gunjaNoch keine Bewertungen

- Surrealism Photomontage RubricDokument1 SeiteSurrealism Photomontage Rubricapi-236080651Noch keine Bewertungen

- Indian Ergonomics Standards - Existing and Needs: Production and General Engineering DepartmentDokument2 SeitenIndian Ergonomics Standards - Existing and Needs: Production and General Engineering Departmentnarendar.1Noch keine Bewertungen

- Dräger Babytherm 8000 LDR - User ManualDokument50 SeitenDräger Babytherm 8000 LDR - User ManualsangNoch keine Bewertungen

- Binomial DistributionDokument14 SeitenBinomial DistributionbulletproofsouljaNoch keine Bewertungen

- Iso 7 1 Pipe ThreadsDokument11 SeitenIso 7 1 Pipe ThreadsSintha AidroosNoch keine Bewertungen

- Skirt and Dust Control BrochureDokument8 SeitenSkirt and Dust Control BrochureJacob MelendezNoch keine Bewertungen

- DTA Manual UsuarioDokument12 SeitenDTA Manual Usuario99lea99Noch keine Bewertungen

- RCDLABDokument71 SeitenRCDLABMary MarieNoch keine Bewertungen

- Collapse of Hyatt RegencyDokument11 SeitenCollapse of Hyatt RegencyjokotsNoch keine Bewertungen

- GE Fanuc Automation: CIMPLICITY HMI Plant Edition Trend and XY ChartDokument228 SeitenGE Fanuc Automation: CIMPLICITY HMI Plant Edition Trend and XY ChartCowdrey IlanNoch keine Bewertungen

- Inclinimetro Boom RDSR3 BA 09 - BrochDokument3 SeitenInclinimetro Boom RDSR3 BA 09 - BrochedgarlimasNoch keine Bewertungen

- Technical Specification of Short Span 33 K.V OHLDokument46 SeitenTechnical Specification of Short Span 33 K.V OHLHassanien Alkhafaji100% (2)

- IntroductionDokument67 SeitenIntroductionCollins AparejadoNoch keine Bewertungen

- Ds 1110 CatalogueDokument4 SeitenDs 1110 CatalogueAmyt SrivastavNoch keine Bewertungen

- C++ Programming: From Problem Analysis To Program Design: Chapter 3: Input/OutputDokument50 SeitenC++ Programming: From Problem Analysis To Program Design: Chapter 3: Input/OutputAlmira SolimanNoch keine Bewertungen

- Types of PapersDokument2 SeitenTypes of Paperssaketh pedagandhamNoch keine Bewertungen

- Steering Column: Section 6EDokument16 SeitenSteering Column: Section 6Efrancisca19Noch keine Bewertungen