Beruflich Dokumente

Kultur Dokumente

Borematch 148 Pib 001

Hochgeladen von

Jansen SaippaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Borematch 148 Pib 001

Hochgeladen von

Jansen SaippaCopyright:

Verfügbare Formate

PRODUCT INFORMATION

Product Bulletin No.: BoreMatch-148-PIB-001

Rev 01

HandlingTools

Date: October 10th, 2013

Subject:

Release of a new elevator/pipe selection tool BoreMatch.

Re-emphasize availability of Profile gauge.

Product:

BoreMatch, part number 10710179-001.

Profile gauge part number 10146201-001 (or legacy part number

59001005).

Objective:

Driven by dropped object occurrences, NOV provides tools that help

customers to reduce dropped pipe incidents caused by wrong diametrical

pipe versus elevator combinations and/or caused by wrong, inadequate

elevator bore versus Tool Joint (TJ) contour.

Issue:

Based on customer info a high percentage of all dropped pipe incidents

is related to selecting the wrong pipe-elevator bore combination and/or

worn or not matching elevator bore versus TJ contour.

Solution:

To reduce the risk of wrong ID and OD combinations, NOV has

developed a measuring tool that allows easy, fast and reliable

verification of pipe body and TJ OD, versus the elevator and TJ bore

ID, up to 9 (229 mm).

For verifying elevator bore and TJ contour combination NOV reemphasizes the use of the Profile gauge.

Both tools can be ordered from your nearest NOV facility.

Operators should also refer to previous NOV Product Information Bulletins and Safety

Alerts at http://www.nov.com/drilling for additional information regarding safe operation,

maintenance, and inspection criteria.

Failure to follow the recommendations and/or guidance in NOV Product Bulletins

may result in death, bodily injury or property damage.

Please contact your local National Oilwell Varco (NOV) Service Center if you have any

questions regarding this Product Information Bulletin.

2013 National Oilwell Varco

th

October 10 2013

Rev 01

Page 1 of 3

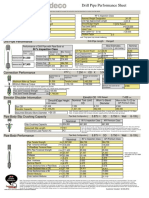

BoreMatch description;

2013 National Oilwell Varco

th

October 10 2013

Rev 01

Page 2 of 3

Profile gauge description;

The Profile gauge is used to verify the elevator bore contour versus the tool joint contour.

Figure 1, taking the TJ contour.

Figure 2, Match/verify contour in Elevator bore.

Based on measured (actual) diameters using the Borematch and bore contour versus pipe TJ contour

maximum allowed loads can be calculated. All wear data can be found in the elevator manual 50000815

latest rev. The below graph is part of this wear data. This graph is based on yield strength of 110.000psi.

When using any lower grade pipe then a 110 grade will require a correction by multiplying allowed load

taken from the graph with a factor of pipe grade/110.000.

Disclaimer: Both instruments are intended for reference purposes only. Do not use for absolute

measurements. NOV will not be held liable for errors in this material or errors arising from misuse

of this material.

2013 National Oilwell Varco

th

October 10 2013

Rev 01

Page 3 of 3

Das könnte Ihnen auch gefallen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Pad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesDokument3 SeitenPad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesAnirudh S. Goel83% (6)

- 5 7/8" VM-165 R2 Pipe SpecsDokument2 Seiten5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- Inspection of Turnouts/Diamonds - Procedure RAP 5134: Engineering Practices Manual Civil EngineeringDokument11 SeitenInspection of Turnouts/Diamonds - Procedure RAP 5134: Engineering Practices Manual Civil EngineeringShipra MishraNoch keine Bewertungen

- Bolt Load MeterDokument12 SeitenBolt Load MeterrzepedacNoch keine Bewertungen

- Nozzle InstallationDokument6 SeitenNozzle InstallationlmjustinianoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Webco ABS Sensor TestsDokument4 SeitenWebco ABS Sensor TestsДмитрий Пупкин0% (1)

- FQP - Fuel Handling SystemDokument21 SeitenFQP - Fuel Handling SystemAvijit DeyNoch keine Bewertungen

- Drill Pipe Performance Sheet 5.875 XT57 G105Dokument3 SeitenDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- Ambit PF Series Hydrant Tester InstructionsDokument5 SeitenAmbit PF Series Hydrant Tester InstructionsPremfeb27Noch keine Bewertungen

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Dokument3 SeitenDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNoch keine Bewertungen

- Fci - ST50Dokument25 SeitenFci - ST50Carlos Alfredo Rebolledo GodoyNoch keine Bewertungen

- GRIWrap Metric Manual 032205Dokument21 SeitenGRIWrap Metric Manual 032205kpinstNoch keine Bewertungen

- Paldex Seminar-2 - Stress AnalysisDokument75 SeitenPaldex Seminar-2 - Stress AnalysisCROSSFIELD ENGINEERING ENERGYNoch keine Bewertungen

- Autolite Generator and Starter Technical ManualDokument62 SeitenAutolite Generator and Starter Technical Manualjuliansimon67% (3)

- SA 02 TDS 11 Carriage InterferenceDokument4 SeitenSA 02 TDS 11 Carriage InterferenceHayLenLeeNoch keine Bewertungen

- c20547 PDFDokument34 Seitenc20547 PDFGuillermo Andrés CoupeNoch keine Bewertungen

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDokument3 SeitenDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DNV GL CertificateDokument3 SeitenDNV GL CertificatemikeNoch keine Bewertungen

- E551 Dead Line AnchorDokument12 SeitenE551 Dead Line AnchorHoward Berisford88% (8)

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- API Gaging Practice: PMC Lone Star Technical Brief Doc. 100 Rev. BDokument9 SeitenAPI Gaging Practice: PMC Lone Star Technical Brief Doc. 100 Rev. BMorez BarikaniNoch keine Bewertungen

- Smi 207Dokument3 SeitenSmi 207Greshy FieldNoch keine Bewertungen

- Boost Solenoid - TSB Title - 122807 08 - 01 - 2011 Engine - Failsafe - Codes FC 3100 - FC 30FE - FC 30FF StoredDokument8 SeitenBoost Solenoid - TSB Title - 122807 08 - 01 - 2011 Engine - Failsafe - Codes FC 3100 - FC 30FE - FC 30FF StoredBAO ANH LÊNoch keine Bewertungen

- 803353.000 E Accessory Pressure and PathmeasurementDokument20 Seiten803353.000 E Accessory Pressure and PathmeasurementsandeepbhallaNoch keine Bewertungen

- 1010-632-001-00 Pressure GaugesDokument1 Seite1010-632-001-00 Pressure GaugesMr ElEcTrOnNoch keine Bewertungen

- 0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsDokument29 Seiten0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsmohdnazirNoch keine Bewertungen

- PVElite Q&ADokument12 SeitenPVElite Q&Amsraja77Noch keine Bewertungen

- Rosemount 1195 Integral Orifice Primary Element: Quick Installation GuideDokument16 SeitenRosemount 1195 Integral Orifice Primary Element: Quick Installation GuideJosé Carlos Batista SilvaNoch keine Bewertungen

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- ACOBRIDokument153 SeitenACOBRISima ViorelNoch keine Bewertungen

- Brodie PD Flow MeterDokument26 SeitenBrodie PD Flow Meterahmedhassankhan50% (2)

- Feedwater Heaters Inspection ProcedureDokument2 SeitenFeedwater Heaters Inspection ProcedureAlmario SagunNoch keine Bewertungen

- Tank Provers: CapacitiesDokument7 SeitenTank Provers: CapacitiesSatit hunsaNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance Sheetjinyuan74Noch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- SERVICE TOOL CATALOG Carrier TransicoldDokument98 SeitenSERVICE TOOL CATALOG Carrier Transicoldgamagg100% (3)

- PQMP-ITP-001 Rev 0Dokument27 SeitenPQMP-ITP-001 Rev 0asexyguyNoch keine Bewertungen

- Drill Pipe Configuration: 95 % Inspection ClassDokument3 SeitenDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNoch keine Bewertungen

- Assembly and Tensioning of High Strength Bolts andDokument14 SeitenAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNoch keine Bewertungen

- Calculating CC10P6inCC17cupDokument12 SeitenCalculating CC10P6inCC17cupdsargoarnowoNoch keine Bewertungen

- Nuflo Turbine Meter Manual PDFDokument16 SeitenNuflo Turbine Meter Manual PDFfatsfinderNoch keine Bewertungen

- Section 28 - Deadweight TesterDokument22 SeitenSection 28 - Deadweight TesterhammamiNoch keine Bewertungen

- Bronze Commissioning Valves: SectionDokument15 SeitenBronze Commissioning Valves: SectionblindjaxxNoch keine Bewertungen

- Brookfield Dial ViscometerDokument35 SeitenBrookfield Dial ViscometerSheila Martinez0% (1)

- How To Determine The Gage Sizes of A GageDokument2 SeitenHow To Determine The Gage Sizes of A GageRahul VermaNoch keine Bewertungen

- Magnaflux Crack Comparators Assist in Measuring The Size of LPI IndicationsDokument3 SeitenMagnaflux Crack Comparators Assist in Measuring The Size of LPI IndicationsEngr Arfan Ali DhamrahoNoch keine Bewertungen

- Section 26 - Oilgear PV Liquid MeterDokument18 SeitenSection 26 - Oilgear PV Liquid MeterhammamiNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Von EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Noch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Automotive Sensor Testing and Waveform AnalysisVon EverandAutomotive Sensor Testing and Waveform AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Wireshark Developer's Guide - Version 2.9.0Dokument259 SeitenWireshark Developer's Guide - Version 2.9.0ind.sudhirNoch keine Bewertungen

- 08 - Memory ManagementDokument36 Seiten08 - Memory ManagementShunyi LiuNoch keine Bewertungen

- Tim Paterson Microsoft 1981 1994 GUI WindowsDokument9 SeitenTim Paterson Microsoft 1981 1994 GUI WindowspoonamNoch keine Bewertungen

- Competitive Comparisons POWER8 Versus Intel x86Dokument23 SeitenCompetitive Comparisons POWER8 Versus Intel x86jegansolaiNoch keine Bewertungen

- How Reservation Done in Hotels Process For ReservationDokument43 SeitenHow Reservation Done in Hotels Process For ReservationThefoodieswayNoch keine Bewertungen

- My Learning Journey ReflectionDokument2 SeitenMy Learning Journey Reflectionapi-486217715Noch keine Bewertungen

- StudioLiveSoftware ReferenceManual EN PDFDokument150 SeitenStudioLiveSoftware ReferenceManual EN PDFYennifer AliocNoch keine Bewertungen

- IT1T1Dokument2 SeitenIT1T1Vyshnavi ThottempudiNoch keine Bewertungen

- Activar Office 365Dokument1 SeiteActivar Office 365V MejicanoNoch keine Bewertungen

- Fuel Tender XML Implementation GuideDokument35 SeitenFuel Tender XML Implementation GuideJorgeMunizNoch keine Bewertungen

- A Framework For Halal Products Checking Interactive Application With OCR and AR Technologies PDFDokument6 SeitenA Framework For Halal Products Checking Interactive Application With OCR and AR Technologies PDFNila SuriaNoch keine Bewertungen

- Volte Drive TestDokument10 SeitenVolte Drive TestAli AliNoch keine Bewertungen

- EFY-Top100 Oct09 PDFDokument15 SeitenEFY-Top100 Oct09 PDFEnoch L SNoch keine Bewertungen

- FDOTRoadwayDesignand3DModeling MasterDokument343 SeitenFDOTRoadwayDesignand3DModeling MasterDoughnut Chilli PiNoch keine Bewertungen

- D D D D D: DescriptionDokument87 SeitenD D D D D: DescriptionahireprashNoch keine Bewertungen

- SAP ABAP Question and AnswerDokument49 SeitenSAP ABAP Question and Answerkalicharan13Noch keine Bewertungen

- AViCAD UserManual PDFDokument690 SeitenAViCAD UserManual PDFbrutuseczekNoch keine Bewertungen

- Datasheet-Top Enhancements Creo Parametric 4-EnDokument4 SeitenDatasheet-Top Enhancements Creo Parametric 4-EnDejan AntanasijevicNoch keine Bewertungen

- Manual IQ Plus 355Dokument54 SeitenManual IQ Plus 355willycifuentesNoch keine Bewertungen

- SDTDokument670 SeitenSDTSou HirrNoch keine Bewertungen

- Skill 6Dokument8 SeitenSkill 6Anggraini VionitaNoch keine Bewertungen

- Docker Swarm vs. Mesos vs. KubernetesDokument1 SeiteDocker Swarm vs. Mesos vs. KubernetesEjaz AlamNoch keine Bewertungen

- What Is R ProgrammingDokument7 SeitenWhat Is R Programmingravi kiranNoch keine Bewertungen

- IT 220: Computer Organization: Part I-C: Computer Hardware ComponentsDokument10 SeitenIT 220: Computer Organization: Part I-C: Computer Hardware ComponentsLouie Jay Gitgitin SalvañaNoch keine Bewertungen

- UT Dallas Syllabus For cs7301.002.07s Taught by Kevin Hamlen (kxh060100)Dokument11 SeitenUT Dallas Syllabus For cs7301.002.07s Taught by Kevin Hamlen (kxh060100)UT Dallas Provost's Technology GroupNoch keine Bewertungen

- Lesson 11Dokument9 SeitenLesson 11Alan ZhouNoch keine Bewertungen

- Bizhub c281 c221 c221s Catalog en PDFDokument4 SeitenBizhub c281 c221 c221s Catalog en PDFJuan LissandrelloNoch keine Bewertungen

- Brother PT-1650 PDFDokument152 SeitenBrother PT-1650 PDFbongio2007Noch keine Bewertungen

- Geethanjali College of Engineering and TechnologyDokument89 SeitenGeethanjali College of Engineering and TechnologyBhaskar NaiduNoch keine Bewertungen