Beruflich Dokumente

Kultur Dokumente

Sop Iii-100 R00

Hochgeladen von

BepdjOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sop Iii-100 R00

Hochgeladen von

BepdjCopyright:

Verfügbare Formate

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 1 of 28

Visual and Dimensional Inspection

STANDARD OPERATING PROCEDURE

FOR

VISUAL AND DIMENSIONAL INSPECTION

NOTE: This document is considered COMPANY CONFIDENTIAL and is not to be distributed

in whole or in part outside the Company, without the express, written consent of the

undersigned authority.

PROCEDURE APPROVAL: ___________________________ DATE: _____________

Vice President Inspection & Coating Product Line

PROCEDURE APPROVAL: ___________________________ DATE: ______________

Director Quality & Technical Services

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 2 of 28

Visual and Dimensional Inspection

INTRODUCTION

This procedure establishes minimum requirements for the dimensional measurement of tool

joints on drill pipe and heavy weight drill pipe (HWDP). The purpose is for proper

classification of the tool joint in accordance with the parameters set forth in API RP 7G, DS1 or NS-2. This procedure also establishes minimum requirements for the dimensional

measurement of rotary shouldered connections on drill pipe, HWDP, drill collars and other

components of the Bottom Hole Assembly (BHA). Additionally, this procedure establishes

the minimum requirements for the visual inspection and O.D. gauging of the pipe body on

drill pipe.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 3 of 28

Visual and Dimensional Inspection

TABLE OF CONTENTS

1.0

2.0

3.0

4.0

5.0

Scope............................................................................................................................................ 5

1.2.1 Tool Joints ........................................................................................................5

1.2.3 BHA..................................................................................................................5

Personnel Requirements.............................................................................................................. 6

Equipment Requirements............................................................................................................. 6

3.7 Lead Gauge........................................................................................................................ 7

3.7.3 Lead Gauge Contact Points ................................................................................ 8

3.8 Visible Light Sources......................................................................................................... 8

3.9 Equipment Calibration........................................................................................................ 8

Surface Preparation...................................................................................................................... 8

Inspection Procedure.................................................................................................................... 8

5.3 Weight and Grade Verification.......................................................................................... 9

5.5 Visual Connection.............................................................................................................. 9

5.5.1 Shoulder (Face) .................................................................................................... 9

5.5.2 Thread Inspection ............................................................................................... 10

5.5.3 Bevel ................................................................................................................... 11

5.5.4 Box Outside Diameter Swell (Tool Joints only)................................................ 11

5.5.5 Box Diameter Swell (Drill Collars and BHA Components only) ...................... 11

5.5.6 Shoulder Flatness ..........................................................................................11

5.5.7 Thread Profile..................................................................................................... 11

5.5.8 Hard-banding .................................................................................................11

5.6 Tool Joint Dimensional Measurements .......................................................................... 12

5.6.1 Outside Diameter ............................................................................................... 12

5.6.2 Pin Inside Diameter........................................................................................12

5.6.3 Bevel Diameter...............................................................................................12

5.6.4 Tong Space ....................................................................................................12

5.6.5 Box Shoulder Width .......................................................................................13

5.6.6 Pin Neck Length.............................................................................................13

5.6.7 Box Seal Width...............................................................................................13

5.6.8 Box Counterbore Diameter (Swell) ................................................................13

5.6.9 Box Counterbore Depth .................................................................................13

5.6.10 Pin Lead .........................................................................................................13

5.7 Drill Collars and BHA Components .............................................................................14

5.7.1 Box Outside Diameter ....................................................................................14

5.7.2 Pin Inside Diameter........................................................................................14

5.7.3 Pin Length ......................................................................................................14

5.7.4 Pin Relief Groove Diameter ...........................................................................14

5.7.5 Pin Relief Groove Width.................................................................................14

5.7.6 Box Counterbore Diameter ............................................................................14

5.7.7 Boreback Diameter ........................................................................................14

5.7.8 Boreback Length ............................................................................................15

5.7.9 Box Counterbore Depth .................................................................................15

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 4 of 28

Visual and Dimensional Inspection

5.7.10 Boreback Thread Length................................................................................15

5.7.11 Pin Neck Length.............................................................................................15

5.7.12 Mid Tube Upset Diameter of HWDP ..............................................................15

5.7.13 Mid Tube Upset Height of HWDP ..................................................................15

5.8 Tube Body Inspections.................................................................................................... 16

5.8.1 Visual .............................................................................................................16

5.8.2 Straightness ....................................................................................................... 16

5.9 O.D. Gauging ................................................................................................................... 16

5.9.1 Surface Condition...........................................................................................16

5.9.2 Standardization ...............................................................................................16

5.9.6 Slip/Critical Area Gauging ...............................................................................18

5.9.7 Measuring Mechanical Damage......................................................................... 18

6.0 Field Refacing of Used Tool Joint Shoulders............................................................................. 18

6.1 Bench Mark...................................................................................................................... 18

6.4 Shoulder Face Bevel........................................................................................................ 19

6.5 Coating of Shoulder Face ................................................................................................ 20

7.0 Classification of Tool Joints and Rotary Shouldered Connections............................................ 20

7.1 Tool Joints ........................................................................................................................ 20

7.2 Drill Collars ....................................................................................................................... 20

7.3 HWDP............................................................................................................................... 20

7.4 Shoulders ......................................................................................................................... 20

8.0 Post Inspection Procedures ....................................................................................................... 21

Table 1.2 - Dimensional and Visual Inspection Attributes ................................................................... 22

Figure 1.2.a........................................................................................................................................... 23

Figure 1.2.b........................................................................................................................................... 24

Table 3.7.3 - Gauge Contact Point Diameter....................................................................................... 24

Figure 5.3.2-1 Old API Marking System for Drill Pipe....................................................................... 25

Figure 5.3.2-2 New API Marking System for Standard Wall Drill Pipe ............................................. 25

Figure 5.3.2-3 New API Marking System for Heavy Wall Drill Pipe ................................................. 26

Figure 5.3.2-4 New API Marking System for Thick Wall Drill Pipe ................................................... 26

Figure 5.3.2-5 New API Marking System for Standard Wall Drill Pipe ............................................. 27

Table 5.7.13 Heavy Weight Drill Pipe Center Upset Dimensions..................................................... 28

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

1.0

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 5 of 28

Visual and Dimensional Inspection

SCOPE

1.1

This procedure establishes minimum requirements for the dimensional

measurement of tool joints on drill pipe and heavy weight drill pipe (HWDP).

The purpose is for proper classification of the tool joint in accordance with the

parameters set forth in API RP 7G. This procedure also establishes minimum

requirements for the dimensional measurement of rotary shouldered

connections on drill pipe, HWDP, drill collars and other components of the

Bottom Hole Assembly (BHA). Additionally, this procedure establishes the

minimum requirements for the visual inspection and O.D. gauging of the pipe

body on drill pipe.

1.2

Specifically, this inspection covers those items indicated as Required and

Optional in API RP 7G. Additionally, this procedure covers the three (3)

Dimensional Inspections contained in DS-1. The customer should be consulted,

to determine the level of visual inspection service required. Refer to Table 1.2

and Figures 1.2 a. and 1.2 b. for a breakdown and diagram of the details.

1.2.1

Tool Joints. Unless specified otherwise by the customer, only the items

identified under API RP 7G - Required in Table 1.2 must be performed.

1.2.2

API RP 7G - Optional, Dimensional 1 and Dimensional 2 are invoked

only by customer request.

1.2.3

BHA. Includes Drill Collars, HWDP, Drilling Jars, Saver Subs,

MWD/LWD Tools, mud motors, turbines, Stabilizers, Under reamers,

Hole Openers, Roller Reamers, Casing Scrapers and Subs. For these

components, all items identified under Dimensional 3 shall be

performed.

1.2.4

Surface Safety Valves, Kelly Valves and Inside Blowout Preventers

(IBOPs). For these components, all items identified under Dimensional

2 shall be performed.

1.3

The measured dimensions obtained during the inspections described in this

SOP are not required to be documented on the Tuboscope Drill Pipe Inspection

Report, unless specified in the applicable section of this SOP or when specified by

the customer.

1.4

This Tuboscope document is the controlling document whenever any other like

kind prior-dated Tuboscope inspection procedures are in conflict.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

1.5

2.0

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 6 of 28

Visual and Dimensional Inspection

The latest revision of the following documents were used as references for

establishing this procedure:

1.5.1

API Specification 7 - Rotary Drill Stem Elements.

1.5.2

API Recommended Practice 7G - Drill Stem Design and Operating

Limits.

1.5.3

SOP III-001 - General Requirements.

1.5.4

SOP III-403 Manual Ultrasonic Thickness Gauging.

1.5.5

Applicable Tuboscope Division Operating Procedure for Straightening

Drill Pipe.

1.5.6

DS-1 - Drill Stem Design and Inspection.

1.5.7

NS-2 North Sea Drillstring Inspection Standard.

PERSONNEL REQUIREMENTS

Personnel performing the inspection techniques outlined in this procedure shall be

qualified in Used Drill Pipe Inspection (code 46) and Bottom Hole Assembly Inspection

(code 47) in accordance with 4.0 of SOP III-001.

3.0

EQUIPMENT REQUIREMENTS

3.1

A 12 inch steel rule with graduations in 1/64 inch (0,5 mm) units.

3.2

External (OD) spring calipers capable of expanding beyond the new diameter of

the tool joint.

3.3

Internal (ID) spring calipers capable of expanding beyond the maximum inside

diameter of the material being inspected.

3.3.1

3.4

Electronic, dial or vernier type calipers may also be used for measuring

purposes.

A small, flat, non-tinted mirror for observing the load flanks and roots of the

internal threads.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

3.5

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 7 of 28

Visual and Dimensional Inspection

Horse shoe shaped outside diameter gauge capable of measuring diameter

reductions in 1/32 inch increments. The gauge shall have a maximum spacing

of nominal diameter plus 1/32 inch if oversize gauging is required. In all other

instances the gauge shall be capable of measuring nominal pipe diameter minus

5/32 inches.

3.5.1

Check the faces of side wear blocks and center wear blocks for excessive

wear.

3.5.2

Check the movable plunger alignment.

a. No side play.

b. Free movement in the slot.

3.5.3

The appropriate setting standard for the specified pipe size is required

for gauge set up. The length of the gauge bar standard is 1/32 inch (0,79

mm) less than the specified OD of the pipe. This standard shall be

verified with a precision caliper or micrometer prior to use.

3.5.4

As an alternative, the gauge may be set up with a dial/vernier caliper or

inside micrometer.

3.5.5 As an alternative to a diameter gauge, an external spring caliper, set up

with an electronic, dial or vernier caliper may also be used to check for

diameter reductions.

3.6

The applicable API rotary shoulder connection (RSC) hardened and ground

profile gauge.

3.7

Lead Gauge

3.7.1

The gauge for measuring lead tolerance is equipped with two (2) contact

points and a balance dial type indicator. Several types of gauges are

available:

a. External-internal, RSC sizes 4-1/2 inch and larger.

b. Universal gauges are available for all RSC sizes.

3.7.2

A lead setting standard is also required. The setting standard shall be

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

3.7.3

5.0

SOP No.

III-100

Revision No. 0

Page No. 8 of 28

Visual and Dimensional Inspection

appropriate for the thread pitch and thread taper.

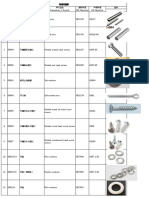

Lead Gauge Contact Points. The diameters of contact points shall meet

the requirements of Table 3.7.3. Ball type contact points shall be

visually examined for evidence of wear on the points of the ball which

contact the thread surface. Worn contacts points shall be replaced

regardless of actual diameter.

3.8

Visible Light Sources. Overhead lighting, hand held white light fixtures and light

meters shall meet the requirements in 9.0 of SOP III-001.

3.9

Equipment Calibration. Equipment calibration/verification shall be in accordance

with 9.1 of SOP III-001.

3.9.1

4.0

Effective Date

August 1, 2005

Calipers, micrometers, Lead gauge setting standards and Lead

gauges shall be calibrated after any repairs and at the frequency

specified in Table 9.1 in SOP III-001.

SURFACE PREPARATION

4.1

Thread protectors shall be removed and cleaned (if required) in accordance with

14.0 in SOP III-001. If the customer requires optional sandblasting prior to

inspection, thread protectors shall remain installed until the sandblasting

operation is completed.

4.2

Thread compound, grease and other hard foreign deposits, shall be removed

from surfaces to be inspected.

4.3

All excessive amounts of rust, dirt, grease, oil or applied coatings shall be

removed prior to O.D. gauging.

4.4

Scale should be evaluated in accordance with 10.1.1 in SOP III-001. Internal

coatings should be graded in accordance with DS-1, par. 3.4.4.f or NS-2,

Appendix 8.

INSPECTION PROCEDURE

5.1

Material identification shall be in accordance with 11.0 in SOP III-001.

5.2

The appropriate information shall be completed on the Drill Pipe Inspection Tally

sheet for applicable information and dimensions from this section.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

5.3

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 9 of 28

Visual and Dimensional Inspection

Weight and Grade Verification. The tool joint weld date and grade mark

inspection consists of a visual examination to determine pipe age, grade, weight,

and past tool joint rework.

5.3.1

The base of each pin must be cleaned as necessary to allow visual

inspection of the surface for the manufacturers markings. (These markings

are stamped on the base of the pins when the tool joints are welded onto

the pipe.)

5.3.2

Check each pin base (neck) or milled slot for the following markings as

illustrated in Figure 5.3.2-1 through 5.3.2-5

a. Manufacturers Symbol

b. Date of tool joining

c. Grade of Drill Pipe

d. Weight of Drill Pipe

NOTE: The absence of these markings indicates that the tool joints may have been

reworked. This should be noted on the inspection report.

5.4

Refer to Table 1.2 for the appropriate items from this section to be inspected.

5.5

Visual Connection

NOTE: Sections 5.5 and 5.6 are intended for API and Similar Non-proprietary

Connections. For GrantPrideco; Hi Torque, eXtreme Torque, Double Shoulder, XT-M,

OMSCO TuffTorq and Hydril Wedge Thread connections, refer to the applicable

manufacturers documentation, DS-1 or contact QTS for information on visual and

dimensional inspection of these connections.

5.5.1

Shoulder (Face). Visually inspect shoulder on both the pin and box

connections for damage that may prevent proper make-up or pressure

seal. The sealing shoulder must be relatively smooth to resist a leak path.

Inspect for galls, nicks, fins, washes or any other matter or deformation

which would affect the ability of the stability or pressure holding capacity

of the connection.

Classification of shoulder damage is subjective and requires a degree of

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 10 of 28

Visual and Dimensional Inspection

judgment, experience and, if possible, knowledge of the drill pipe strings

performance history. If the performance history, or visual examination

indicates a significant number of shoulder leaks and/or washes; it may be

possible that conditions other than shoulder damage could be contributing

to the leaks and washes. In that case, minor cuts, dents, scars or washes

which extend radically across the shoulder face should be viewed with

critical judgment. On the other hand, if performance history or visual

examination indicates very little or no leakage or washing, minor damage

may be viewed with less critical judgment. The inspector should be aware

that the presence of thread compound helps seal minor leak paths against

pressure, but also that shoulder face is the only seal against pressure in the

tool joint design.

If damage is present classify in accordance with Table 18.2.3 in SOP III001.

5.5.2

Thread Inspection. Visually inspect the entire thread surfaces of both the

pin and box connections for pitting, galling, lapped threads, rolled

pressure flanks, broken threads, washed shoulder, washed threads,

flank wear and other mechanical damage that may prevent proper makeup or pressure seal. Inspect the box threads using an inspection mirror.

Tool joint threads do not seal, therefore minor imperfections and damage

on the threads is not cause for rejection. On the other hand, some

protrusions on thread flanks can interfere with make-up and should be

rejected or repaired. The Inspector should exercise good judgment in

these matters.

a. Protrusions from thread crests or flanks are cause for rejection and

shall be marked as field repairable. When approved by the

customer, minor repair of thread crests and flanks threads may be

performed with caution. The pressure flanks are the most critical to

maintain a tight wobble-free connection. The inspection may be less

critical on the non-pressure (stabbing) flank.

b. Burrs and other protrusions on the pin chamfer and starting thread

may also be removed, when approved by the customer.

c. The starting thread and first two (2) full crested threads of the pin

and box are less critical than the other threads. Normal flank and

crest wear is allowable but there should not be any type of thread

form distortion that would cause thread damage during make-up.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 11 of 28

Visual and Dimensional Inspection

d. A thread profile gauge is a valuable tool for identifying an acceptable

thread form. If the entire length of the gauge will not seat snugly in

the threads, starting in the first full crested thread from the shoulder,

look for a high spot or protrusion (on one [1] or more thread

surfaces) or for pin stretch. If the gauge seats loosely on the

threads, flank wear or flank corrosion may be excessive. To ensure

proper repair, verify that the gauge seats correctly over the repair

area.

5.5.3

Bevel. Verify that there is an approximate 45 bevel from the shoulder to

the tool joint O.D. which has a minimum width of 1/32 inch (0,79 mm).

This bevel must extend the full 360 circumference of the tool joint on

both pin and box ends.

5.5.4

Box Outside Diameter Swell (Tool Joints only). Place a straight edge

(steel rule) along the longitudinal axis of the outside of the connection,

looking for a gap between the straight edge and the connection.

NOTE: This is not a requirement of API RP 7G, but may be used as a quick

visual check only. Acceptance shall be based on box counterbore diameter, see

5.6.8.

5.5.5

Box Diameter Swell (Drill Collars and BHA Components only. Place a

straight edge (steel rule) along the longitudinal axis of the box threads,

looking for rocking due to swelling of the box.

5.5.6

Shoulder Flatness. Place a straight edge across the diameter of the box

shoulder, rotating the straightedge through 180 look for any gaps

between the shoulder and straightedge. Repeat the process for the pin

by placing the straightedge across the largest chord of the pin possible.

Any gap noticed shall be cause for rejection or marked for shop repair or

refacing, if requested by the customer.

5.5.7

Thread Profile. Check the pin threads for stretch by placing the profile

gauge across the interval which includes the first full-depth thread

nearest the shoulder. Check in two (2) positions, 90 apart. Any

condition where the profile gauge will not sit squarely in the thread form

shall be evaluated with a lead gauge in accordance with 5.6.10.

5.5.8

Hard-banding. Check the condition of the hard-banding when present.

Broken and missing areas shall be reported to the customer. Hairline

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 12 of 28

Visual and Dimensional Inspection

cracks are permissible provided the cracks do not extend into the base

metal. Protruding carbide chips or beads shall be rejected, unless

permitted by the customer.

5.6

Tool Joint Dimensional Measurements (Refer to Figure 1.2 - a)

5.6.1

Outside Diameter (Item E).

a. Establish the acceptable tool joint wear in accordance with 7.1 or

customer specifications, as applicable.

b. Set the caliper to the minimum OD for tool joint size being calipered by

adjusting the caliper contacts using the steel rule.

c. Caliper each tool joint, approximately 1 inch (2,5 cm) from the

shoulder, 360 of the OD surface. If caliper goes over at any point, it is

not a premium tool joint, proceed to 5.6.1.d.

d. Locate minimum OD and set caliper to the reduced tool joint OD.

Take a measurement of caliper opening by placing one (1) of the

contacts at the end of the steel rule representing 0" and read to the

nearest 1/32 inch (0,8 mm), classify to the applicable criteria

referenced in 7.1.

e. Repeat 5.6.1.a for each tool joint.

5.6.2

Pin Inside Diameter (Item A). Using the internal spring caliper, measure

the internal diameter of the pin under the last thread nearest the

shoulder. Place one (1) of the contacts at the end of the steel rule

representing 0" and read the diameter to the nearest 1/32 inch (0,8

mm).

5.6.3

Bevel Diameter (Item B). Measure the bevel diameter of the box

connection with the steel rule to the nearest 1/64 inch. For the pin end,

adjust the external spring caliper to the bevel diameter, place one (1) of

the contacts at the end of the rule representing 0" and read the diameter

to the nearest 1/64 inch (0,5 mm).

5.6.4

Tong Space (Item C). Measure the available tong space on both pin and

box connections, excluding the bevel. Tong space measurements on

hard-banded boxes shall not include the length of the hard-banding. In

cases where the hard-banding has been worn flat (essentially the same

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 13 of 28

Visual and Dimensional Inspection

diameter as the tool joint), the hard-banded area may be included in the

tong space measurement, but shall be documented.

5.6.5

Box Shoulder Width (Item F). Using the steel rule, measure the width of

the shoulder, including bevels, at the narrowest point, to the nearest 1/64

inch (0,5 mm).

5.6.6

Pin Neck Length (Item I). Using the steel rule, measure the width of the

pin neck length, at the intersection of the flank of the first full depth

thread. Pin neck length shall not exceed 9/16 inch (14 mm).

5.6.7

Box Seal Width (Item G). Using the steel rule, measure the width of the

seal, at the narrowest point, to the nearest 1/64 inch (0,5 mm).

5.6.8

Box Counterbore Diameter (Swell) (Item H). Using a steel rule, dial or

vernier caliper, set the I.D. caliper 1/16 inch (1,5 mm) above the QC

dimension specified in Table 25 of API Spec 7. Check each box with the

calipers. If the calipers slip inside the box at any point, the counterbore

has exceeded the nominal diameter by more than 1/16 inch (1,5 mm) and

the tool joint must be identified as shop repairable or scrap.

5.6.9

Box Counterbore Depth (Item J). Measure the depth of the box

counterbore, to the nearest 1/64 inch (0,5 mm), from the make-up

shoulder to the intersection of the first point of thread taper inside the

box connection.

5.6.10 Pin Lead. Using the profile gauge, check for damaged thread form

throughout the connection which would interfere with proper make-up.

Ensure the lead gauge has the proper diameter contact points for the

thread form being inspected in accordance with 3.7.3.

a. Lead Gauge Standardization. The accuracy of the gauge is verified

by applying the gauge to the lead setting standard. With both

contacts in a setting standard groove, the gauge should be pivoted in

an arc about the fixed contact. Adjustment is necessary if the gauge

does not register zero. This adjustment is made by loosening the

lock screw on the arm adjusting the gauge to read zero by adjusting

the screw and then re-tightening the lock screw.

b. With the gauge set for a 2 inch interval measure the lead across the

last engaged thread. The gauge is pivoted on the fixed contact point

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 14 of 28

Visual and Dimensional Inspection

through a small arc. The reading from zero is the lead error. Two (2)

measurements 90 apart are required. If the reading exceeds 0.006

inches, the connection shall be marked for re-cut.

NOTE: Do not take measurement where thread flank damage exists.

5.7

Drill Collars and BHA Components (Refer to Figure 1.2 - b)

5.7.1

Box Outside Diameter (Item E). For drill collars and other components of

the BHA, measure the diameter of the box connection approximately 4

inches (10 cm) from the shoulder. Place one (1) of the contacts at the

end of the steel rule representing 0" and read the diameter to the

nearest 1/32 inch (0,8 mm). Two (2) measurements shall be made

approximately 90 apart.

5.7.2

Pin Inside Diameter (Item A). For the pin of drill collars or other

components of the BHA assembly, measure the internal diameter under

the last thread nearest the shoulder using the internal spring caliper.

Place one (1) of the contacts at the end of the steel rule representing 0"

and read the diameter to the nearest 1/32 inch (0,8 mm).

5.7.3

Pin Length (Item D). Measure the length of the pin to the nearest 1/64

inch (0,5 mm).

5.7.4

Pin Relief Groove Diameter (Item B). For those connections with the

relief groove feature on the pin end, the diameter of the groove shall be

measured to the nearest 1/64 inch (0,5 mm) at the mid point of the relief

groove using an external caliper.

5.7.5

Pin Relief Groove Width (Item C). For those pin connections with a

stress relief groove, use a steel rule and measure its width at the

intersection of the load flank and crest of the first full-depth thread from

the shoulder.

5.7.6

Box Counterbore Diameter (Swell) (Item G). Using a steel rule, dial or

vernier caliper, set the I.D. caliper 1/16 inch (1,5 mm) above the QC

dimension specified in Table 25 of API Spec 7. Check each box with the

calipers. If the calipers slip inside the box at any point, the counterbore

has exceeded the nominal diameter by more than 1/16 inch (1,5 mm) and

the tool joint must be identified as shop repairable or scrap.

5.7.7

Boreback Diameter (Item F). For those connections with a bore back

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 15 of 28

Visual and Dimensional Inspection

relief feature on the box end, the diameter of the cylinder shall be

measured to the nearest 1/64 inch (0,5 mm) at the mid point of the

cylinder using an internal caliper and steel rule.

5.7.8

Boreback Length (Item I). For those connections with a bore back relief

feature on the box end, the length of the boreback shall be measured

with a steel rule.

5.7.9

Box Counterbore Depth (Item J). Measure the depth of the box

counterbore to the nearest 1/64 inch (0,5 mm) measured from the makeup shoulder to the intersection of the first point of thread taper inside the

box connection.

5.7.10 Boreback Thread Length (Item K). For those connections with a bore

back relief feature on the box end, the length of the box threads shall be

measured with a steel rule measured from the make-up shoulder to the

last point of full thread depth.

5.7.11 Pin Neck Length (Item I, Figure 1.2 - a). For pin connection without

stress relief grooves, use a steel rule and measure the width of the pin

neck length, at the intersection of the flank of the first full depth thread.

Pin neck length shall not exceed the counterbore depth minus 1/16 inch

(1,5 mm).

5.7.12 Mid Tube Upset Diameter of HWDP. For HWDP with a mid tube upset,

the diameter of the upset shall be measured at the center. Using the

external caliper, adjust the caliper to the outside diameter of the midtube upset on HWDP. Use the steel rule to determine the diameter to

the nearest 1/64 inch (0,5 mm). Two (2) measurements are required,

approximately 90 apart.

NOTE: The measurements shall be taken adjacent to rather than over any

applied hard-banding.

5.7.13 Mid Tube Upset Height of HWDP. For HWDP with a mid tube upset, the

height of the upset in relation to the tube body shall also be measured.

The difference between the maximum height and the minimum height

shall be less than or equal to 1/8 inch (3 mm). The diameter of the upset

shall comply with the requirements in Table 5.7.13.

NOTE: Two (2) measurements on each connection are required, approximately

90 apart.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 16 of 28

Visual and Dimensional Inspection

5.7.14 In addition to the above, refer to applicable items from 5.6 for required

dimensional checks for BHA connections as specified by Table 1.2.

5.8

Tube Body Inspections

5.8.1

Visual. Visually examine both the inside and outside surfaces of the

pipe body for obvious damage. Particular attention shall be paid to the

critical and slip areas. The internal upset area shall also be carefully

examined for pitting using a light and mirror. The pipe shall be rotated

through a minimum of 1-1/4 revolutions to facilitate full inspection.

a. The internal surface of internally coated drill pipe shall be inspected

for signs of deterioration of the coating using a light and mirror. If

such conditions exist, the customer shall be notified.

5.8.2

5.9

Straightness. Rotate the pipe a minimum of two (2) complete revolutions

while observing straightness of the tube body. Lengths obviously

bowed, bent or corkscrewed shall be classified as rejects or straightened

in accordance with the Tuboscope Divisional Operating Procedures for

straightening.

O.D. Gauging. The tube body outside diameter shall be mechanically gauged from

upset to upset to determine abrasive wear and/or mechanical damage using an

OD gauge or spring caliper. The pipe is rolled as the OD gauge or caliper is

dragged or stabbed along the surface.

5.9.1

Surface Condition. The outside diameter of the tube must be free of

scale, mud, etc. Clean as necessary to adequately perform the OD

gauging.

5.9.2

Standardization.

a. Standardize the OD gauge by placing the setting standard between

the fixed and moveable contacts. Check and adjust the anvils, if

necessary, so the anvils are parallel and the setting standard fits

snug at both ends of the anvil and at an exact gauge bar distance

apart at each corner. Ensure that all screws are tight. Adjust the wire

indicator to point to the number 1 (for 1/32 inch).

b. Standardization Checks. Verify that the setting standard still fits as

described in 5.9.2.a at the following intervals. All pipe inspected

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 17 of 28

Visual and Dimensional Inspection

between an unacceptable check and the most recent acceptable

check shall be reinspected.

1. At the beginning and end of each inspection shift and after meal

break.

2. At least once every hour of continuous operation or every 25

pipe inspected.

3. Whenever there is a change in inspector.

4. When the OD gauge is subjected to abnormal mechanical shock.

5. Prior to resuming operation after repair or adjustments.

6. If any looseness of the movable face is detected.

7. Whenever in doubt of the accuracy of the gauge.

5.9.3

Each length of pipe shall be OD gauged full length (upset to upset). The

pipe is rolled a full 360. Ensure that the anvils of the OD gauge stay

tight during the job.

5.9.4

While the length is rolling on the pipe rack, push the gauge firmly against

the length and drag the gauge laterally along the entire length.

a. The gauge makes a continuous spiral track down the length. Distance

gauged during one (1) revolution is approximately one (1) foot.

b. Allow the length to roll as many complete revolutions as necessary to

gauge the pipe from upset to upset.

c. At any section where the length is worn more than 1/32 inch (0,79 mm),

the gauge will slip over the length completely.

5.9.5

Circle the pipe with chalk or marking crayon and calculate percent of OD

wear at point on the pipe where maximum wear was found during gauging.

Determine the minimum wall thickness in accordance with 6.2 in SOP III403.

NOTE: Calculated Wear = Maximum wear reading minus 1/2 the minimum wear

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 18 of 28

Visual and Dimensional Inspection

reading multiplied by the wall percent for pipe being inspected.

Example: 4- in., 0.337 in. wall thickness, 1/32 in. of specified wall =

9.3%, gauge readings: Max 2, Min 1

1/2 of 1 = 0.5, 2 - 0.5 = 1.5 X 9.3% = 14%

5.9.6

Slip/Critical Area Gauging

a. Place the gauge over the pipe in the slip/critical area with the center

wear block firmly against the pipe surface.

b. Read the gauge while rotating the length and moving the gauge

laterally through the slip/critical area.

c. If a reduction, as indicted by the gauge indicator, is close to downgrading as per the applicable Table 7.2.3 1 through 7.2.3 - 18 in SOP

III-002 or applicable customer specification or if mechanical damage is

evident, use OD calipers and measure exact OD to determine the

classification.

5.9.7

Measuring Mechanical Damage

a. Diameter Variations

1. Dents, Mashes, Stretch and Necking. Caliper and measure.

Record, in percentage, the OD reduction in the Percent OD Wear

column of the Drill Pipe Inspection Report.

2. String shot. Caliper and measure. Record, in percentage, the OD

increase in the Percent OD Wear column of the Drill Pipe

Inspection Report.

6.0

FIELD REFACING OF USED TOOL JOINT SHOULDERS

6.1

Bench Mark. A benchmark is used to aid in determining if shoulder face

damage should be repaired by field refacing. The bench marks may be in the

form of one (1) of the following:

6.1.1

6.1.2

A short transverse line or tangent at the base of a symbol stamped on

the base of the pin shoulder or on the box counterbore.

A transverse groove machined into the shoulder face of the pin.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

6.1.3

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 19 of 28

Visual and Dimensional Inspection

A transverse ridge machined on the base of the pin shoulder or the box

counterbore.

6.2

When the tool joint is new, the bench mark is placed a specific distance from the

shoulder face. Usually 1/8 inch, but will vary according to the tool joint

manufacturer.

6.3

During use and periodic refacing, the distance from the shoulder face to the

bench mark changes. When the original (manufacturer) distance is changed by

1/16 inch (1,5 mm)or less by field repair of the shoulder face, then the tool joint

is considered safe for use. If the original (manufacturer) distance to the face is

changed by more than 1/16 inch (1,5 mm), the tool joint cannot be refaced and

shall be painted red to be shop repaired (re-cut) or scrapped.

6.3.1

6.4

When refacing, a minimum amount of material should be removed and <

1/32 inch (0,8 mm) at any one (1) refacing. Cumulatively, # 1/16 inch

(1,5 mm).

Shoulder Face Bevel.

6.4.1

After or during the refacing operation, a 45 bevel diameter shall be cut

on the outer edge of the shoulder face. The bevel must extend the full

360 circumference. Never cut more than a 3/32 inch (2 mm) bevel.

6.4.2

For API RP7G inspections, never allow the shoulder width to be < the

value in Table 10 in API RP7G, for the type and class of tool joint being

beveled.

a. On worn tool joints, it may not be possible to cut the original bevel

diameter because of a lack of shoulder width. In this case, scrap the

connection.

NOTE: API RP7G and DS-1 define the term shoulder differently. See Figure 1.2a, items F and G.

6.4.3

For DS-1 inspections, never allow the seal width to be < the value in the

applicable Table 3.7.1, 3.7.9 or 3.9.1 in DS-1, for the type and class of

tool joint being beveled.

a. On worn tool joints, it may not be possible to cut the original bevel

diameter because of a lack of seal width. In this case, scrap the

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 20 of 28

Visual and Dimensional Inspection

connection.

6.4.4

6.5

7.0

On eccentric worn tool joints, it may not be possible to cut the original

bevel at the area of eccentric wear. In this case, scrap the connection.

Coating of Shoulder Face. After a shoulder seal has been refaced by

machining, a copper sulfate coating should be applied to the face, if specified by

the customer. This will prevent seizing and galling, during "break in" of the new

face, when the tool joint is "made up" and "broke out" on the rig floor.

6.5.1

The coating should be mixed up on a per job basis.

6.5.2

Mix three (3) tablespoons crushed (powdered) copper sulfate with three

(3) tablespoons sulfuric acid. Mix well.

6.5.3

Pour the above acid solution into one (1) quart of water, NEVER pour

water into acid! Mix well.

6.5.4

Once experience shows how many faces can be done per quart, larger

quantities can be mixed as the job size requires.

6.5.5

Apply the copper sulfate solution to the clean face of the tool joint with a

plastic bristled brush. Use rubber gloves when mixing and applying the

solution sulfuric acid will burn the skin.

CLASSIFICATION

CONNECTIONS

7.1

OF

TOOL

JOINTS

AND

ROTARY

SHOULDERED

Tool Joints. Tool joints shall be classified as Premium or Class 2 in accordance

with Table 10 of API RP 7G, Table 3.7.1 through 3.7.11 in DS-1, or Table 6, 6a,

6b or 6c in NS-2, as applicable.

7.1.1

For Dimensional 1 or 2 Acceptance Criteria not listed in Table 10 and

Section 12 of API RP 7G, refer to Table 3.7.1 through 3.7.7 in DS-1, as

applicable.

7.2

Drill Collars. For Drill Collar Acceptance Criteria refer to Table 3.8 in DS-1 or

Table 9 in NS-2, as applicable.

7.3

HWDP. For HWDP Acceptance Criteria refer to Table 3.9.1 through 3.9.6 in DS1 or Table 8 in NS-2, as applicable.

7.4

Shoulders. Shoulders shall be classified as follows:

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

8.0

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 21 of 28

Visual and Dimensional Inspection

7.4.1

Acceptable. No repair work is required.

7.4.2

Repairable. This applies to field or shop repairable.

7.4.3

Non-repairable. Scrap.

POST INSPECTION PROCEDURES

The applicable requirements of Sections 15.0 and 18.0 in SOP III-001 shall be

followed when the last inspection service is completed on each piece.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 22 of 28

Visual and Dimensional Inspection

Table 1.2 - Dimensional and Visual Inspection Attributes

API RP 7G

Dimensional / Visual Attribute

5.5.1 - Shoulder (Face)

5.5.2 - Visual Thread Inspection

5.5.3 Bevel Width/Angle

5.5.4 & 5.5.5 - Box Counterbore

Diameter (Swell) - Visual

5.5.6 - Shoulder Flatness

5.5.7 - Thread Profile

5.5.8 Hardbanding

5.6.1 & 5.7.1 - Outside Diameter

5.6.2 & 5.7.2 - Pin Inside Diameter

5.6.3 - Bevel Diameter

5.6.4 - Tong Space

5.6.5 - Box Shoulder Width

5.6.6 & 5.7.11 - Pin Neck Length (Pin

Flat)

5.6.7 - Box Seal Width

5.6.8 & 5.7.6 - Box Counterbore

Diameter (Swell) Measurement

5.6.9 & 5.7.9 - Box Counterbore Depth

5.6.10 - Pin Lead

5.7.3 - Pin Length

5.7.4 - Pin Relief Groove Diameter

5.7.5 - Pin Relief Groove Width

5.7.7 - Boreback Diameter

5.7.8 - Boreback Length

5.7.10 - Boreback Thread Length

5.7.12 - Center Upset Dia. on HWDP

5.7.13 - Center Upset Height on

HWDP

Required Optional

X

X

X

Dimensional Dimensional

1

2

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X1

X

X

X

X

X

X

X

X

Dimensional

3

X2

X

X2

X

X2

X

X

X

X

X

X

X

X

NOTE: When an API RP 7G Optional inspection is specified by the customer, all items listed under

Required and Optional must be performed.

1 - Not applicable to connections containing a stress relief groove.

2 Only required when the profile gauge indicates pin stretch.

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 23 of 28

Visual and Dimensional Inspection

LPC

D

A

PIN:

A - PIN INSIDE DIAMETER

B - BEVEL DIAMETER (BOTH PIN AND BOX)

C - TONG SPACE (BOTH PIN AND BOX)

D - BEVEL WIDTH

I - PIN NECK LENGTH (PIN FLAT)

E BH

G

J

F

LBT

BOX:

E - OUTSIDE DIAMETER (BOTH PIN AND BOX)

F - BOX SHOULDER WIDTH (DS-1)

G - BOX SEAL WIDTH (DS-1) (Box Shoulder Width per API RP7G)

H - BOX COUNTERBORE DIAMETER

J - BOX COUNTERBORE DEPTH

Figure 1.2-a

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 24 of 28

Visual and Dimensional Inspection

H

G

J

K

B

C

I

E

D

F

LEGEND:

PIN:

BOX:

A - PIN INSIDE DIAMETER

B - PIN RELIEF GROOVE DIAMETER

E - BOX OUTSIDE DIAMETER

C - PIN RELIEF GROOVE WIDTH

F - BOREBACK DIAMETER

G - BOX COUNTERBORE DIAMETER

D - PIN LENGTH

H - BEVEL DIAMETER (PIN AND BOX)

I - BOREBACK LENGTH

J - BOX COUNTERBORE DEPTH

K - BOREBACK THREAD LENGTH

Figure 1.2-b

Table 3.7.3 - Gauge Contact Point Diameter (Inches)

Thread

Connection

Diameter

Type

Number Style

V-0.038 R

NC

0.142 - 0.146

V-0.040 R

REG (2-3/8 to 4-1/2)

0.113 - 0.117

V-0.050

REG (5-1/2 to 8-5/8) and FH

0.142 - 0.146

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 25 of 28

Visual and Dimensional Inspection

Figure 5.3.2 1 - Old API Marking System for Drill Pipe

Figure 5.3.2 2 - New API Marking System for Standard Wall Drill Pipe

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 26 of 28

Visual and Dimensional Inspection

Figure 5.3.2 3 - New API Marking System for Heavy Wall Drill Pipe

Figure 5.3.2 4 - New API Marking System for Thick Wall Drill Pipe

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Pipe

Size (in.)

2-3/8

2-7/8

3-1/2

4

4-1/2

5

5-1/2

5-7/8

6-5/8

Weight

(lb./ft.)

4.85

6.65 Std

6.85

10.40 Std

9.50

13.30 Std

15.50

11.85

14.00 Std

15.70

13.75

16.60 Std

20.00

22.82

24.66

25.50

16.25

19.50 Std

25.60

19.20

21.90

24.70

23.40

26.30

25.20 Std

27.70

Weight

Code

1

2

1

2

1

2

3

1

2

3

1

2

3

4

5

6

1

2

3

1

2

3

2

3

2

3

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 27 of 28

Visual and Dimensional Inspection

Grade

Code

E75

E

X95

X

G105

G

S135

S

Z140

Z

V150

V

Mill/Processor

Symbol

Algoma

X

British Steel

B

Dalmine

D

Grant Prideco

GP

Kawasaki

H

Nippon

I

NKK

K

Mannesmann

M

Omsco

OMS

Reynolds Aluminum

RA

Sumitomo

S

Siderca

SD

Tamsa

T

US Steel

N

Vallorec

V

Grade

1 2 34

GP 401 N X

Example: Grant Prideco Tool Joint joined April, 2001 on US Steel

Grade X Drill Pipe

Figure 5.3.2 5 Weight/Grade Codes and API Pin Neck Marking System

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

VOLUME III USED DRILL PIPE

STANDARD OPERATING PROCEDURE

(Company Confidential)

Effective Date

August 1, 2005

SOP No.

III-100

Revision No. 0

Page No. 28 of 28

Visual and Dimensional Inspection

Table 5.7.13 - Heavy Weight Drill Pipe

Center Upset Dimensions

Pipe

Minimum Center Pad Diameter

Size

3-1/2

3-7/8

4

4-13/32

4-1/2

4-31/32

5

5-3/8

5-1/2

5-7/8

6-5/8

7

Copyright 2005 Tuboscope, P.O. Box 808, Houston, Texas 77001

Das könnte Ihnen auch gefallen

- Used Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TDokument44 SeitenUsed Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TIvan MauricioNoch keine Bewertungen

- Sop Iii-306 R00Dokument23 SeitenSop Iii-306 R00Bepdj100% (1)

- Bear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARDokument5 SeitenBear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARGabriel Ibarra100% (2)

- API Casing Color CodesDokument2 SeitenAPI Casing Color CodesRajmohan BabuNoch keine Bewertungen

- Running Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGDokument16 SeitenRunning Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGSumesh DethanNoch keine Bewertungen

- Sop Iii-001 R00Dokument27 SeitenSop Iii-001 R00BepdjNoch keine Bewertungen

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDFDokument3 SeitenField Inspection Procedure For Used GPDS Connections Revision 03 PDFJohn Dolan0% (1)

- Compressed Catalog 2Dokument95 SeitenCompressed Catalog 2ask101Noch keine Bewertungen

- 20-335 - Technical Manual For Teach PackerDokument41 Seiten20-335 - Technical Manual For Teach Packermahmod alrousanNoch keine Bewertungen

- Pipe Installation Us PDFDokument17 SeitenPipe Installation Us PDFTeguh Setiono100% (1)

- Prem ConnectionDokument2 SeitenPrem ConnectionJan Arild SkappelNoch keine Bewertungen

- Fox Public Fox-Tp-M-101 Field InspectionDokument5 SeitenFox Public Fox-Tp-M-101 Field InspectionJoseph MidouNoch keine Bewertungen

- X Over Wash Pipe FJWPDokument1 SeiteX Over Wash Pipe FJWPkhalilNoch keine Bewertungen

- DS-1 Vol. 3 Table 2.1-2.2 Fig. 2.7 To 2.12Dokument11 SeitenDS-1 Vol. 3 Table 2.1-2.2 Fig. 2.7 To 2.12Chandrasekhar Sonar100% (1)

- Pressure Test BOP 03.95Dokument4 SeitenPressure Test BOP 03.95Babi LakhdariNoch keine Bewertungen

- Arnco Hard Banding Specification Manual-Version 1Dokument53 SeitenArnco Hard Banding Specification Manual-Version 1junk059033% (3)

- DS1 Standards DP BHADokument3 SeitenDS1 Standards DP BHAGeotag100% (1)

- Handling ToolsDokument24 SeitenHandling ToolsGhinet Teodor-ioanNoch keine Bewertungen

- ADM 260 - Derrick Inspection - CAT III PDFDokument90 SeitenADM 260 - Derrick Inspection - CAT III PDFMohamed Ismail100% (1)

- HH SwivelDokument3 SeitenHH SwivelHoracio LafuenteNoch keine Bewertungen

- Slip Type Elevator PDFDokument22 SeitenSlip Type Elevator PDFسہۣۗفيہۣۗانشہۣۗينہۣۗوي100% (1)

- EMI Buggy Cal 5Dokument2 SeitenEMI Buggy Cal 5John DolanNoch keine Bewertungen

- BH-T2 Thread Inspection and Rework Procedure - All SizesDokument59 SeitenBH-T2 Thread Inspection and Rework Procedure - All SizesIvan Mauricio100% (2)

- Leopard General and in Stal Tion InformationDokument18 SeitenLeopard General and in Stal Tion InformationChandrasekhar SonarNoch keine Bewertungen

- Iso - Work - Instructions-For Rotary Shouldered Connection PDFDokument124 SeitenIso - Work - Instructions-For Rotary Shouldered Connection PDFAnonymous xhzy2K99Og100% (1)

- B+V ManuallyAir Operated - BVES 500-1 - 752000-Y-A-D Rev 003Dokument72 SeitenB+V ManuallyAir Operated - BVES 500-1 - 752000-Y-A-D Rev 003Daniel TostaNoch keine Bewertungen

- BOP Test FormDokument1 SeiteBOP Test FormKarwan Dilmany67% (3)

- QCP KOC-VME 1221006120-PART 1 Rev 2Dokument49 SeitenQCP KOC-VME 1221006120-PART 1 Rev 2Alireza GolpesarNoch keine Bewertungen

- Repair TrainingDokument35 SeitenRepair TraininguraliNoch keine Bewertungen

- Weatherford PDC Drillout ProceduresDokument2 SeitenWeatherford PDC Drillout ProceduresTriadi Herwasto AribowoNoch keine Bewertungen

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDokument3 Seiten4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (1)

- XLC-S Connector - Product SheetDokument1 SeiteXLC-S Connector - Product SheetulasNoch keine Bewertungen

- Stabilizer TypeDokument14 SeitenStabilizer TypeAdin PraviMoški PartAdisNoch keine Bewertungen

- ETI-CPW Packer Manual Spare PartDokument4 SeitenETI-CPW Packer Manual Spare PartDidin DelgadoNoch keine Bewertungen

- B+V Manual - Elevator Links PDFDokument10 SeitenB+V Manual - Elevator Links PDFYina UsecheNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- Slips Maintenance, Inspection, & Wear Data PDFDokument3 SeitenSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (1)

- DDZ Series Elevator Wear Data RutongDokument2 SeitenDDZ Series Elevator Wear Data RutongIsrael AyllonNoch keine Bewertungen

- Manual: CDQ (S) Sucker Rod ElevatorsDokument5 SeitenManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNoch keine Bewertungen

- Primarycementingproducts 121117203852 Phpapp01Dokument56 SeitenPrimarycementingproducts 121117203852 Phpapp01Shyamoly GhoshalNoch keine Bewertungen

- Section 1Dokument90 SeitenSection 1Doni KurniawanNoch keine Bewertungen

- International Limited International Limited: JC JCDokument5 SeitenInternational Limited International Limited: JC JCMichael OkwuwaNoch keine Bewertungen

- HP Hoses PDFDokument2 SeitenHP Hoses PDFKaleem UllahNoch keine Bewertungen

- Specialized Tools Catalog 2008Dokument60 SeitenSpecialized Tools Catalog 2008IMEDHAMMOUDANoch keine Bewertungen

- NS-1-90. Dimensional InspectionDokument9 SeitenNS-1-90. Dimensional InspectionWHWENNoch keine Bewertungen

- MS Tong MaintenanceDokument7 SeitenMS Tong MaintenanceBahman MatouriNoch keine Bewertungen

- Used Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TDokument44 SeitenUsed Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TIvan MauricioNoch keine Bewertungen

- TenarisHydril Wedge 563 RunningGuidelinesDokument16 SeitenTenarisHydril Wedge 563 RunningGuidelinesDario JaimesNoch keine Bewertungen

- Jsa TubularDokument2 SeitenJsa TubularRonniNoch keine Bewertungen

- Rutong DH 吊环使用说明书(ZY)2013 links - 1Dokument3 SeitenRutong DH 吊环使用说明书(ZY)2013 links - 1QAMAR ALI KHANNoch keine Bewertungen

- Packard CatalogDokument22 SeitenPackard Catalogcrni roko100% (1)

- 01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFDokument5 Seiten01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFKarla HernandezNoch keine Bewertungen

- RP Insp Rep 01Dokument8 SeitenRP Insp Rep 01advantage025Noch keine Bewertungen

- API 4G Qualified Drilling Structures InspectionDokument6 SeitenAPI 4G Qualified Drilling Structures InspectionranjitpandeyNoch keine Bewertungen

- Rotary Sub-Thread Checking Procedure-JSSbrochureDokument4 SeitenRotary Sub-Thread Checking Procedure-JSSbrochureMinakshi SawantNoch keine Bewertungen

- POF 300 Achieving Successful In-Line Inspection - Nov 2021Dokument33 SeitenPOF 300 Achieving Successful In-Line Inspection - Nov 2021Stephen MalobaNoch keine Bewertungen

- POF 310 Field Verification For in Line Inspection 1707929297Dokument34 SeitenPOF 310 Field Verification For in Line Inspection 1707929297Sajjad k. AmhawiNoch keine Bewertungen

- Dlms Yellow Book PDFDokument35 SeitenDlms Yellow Book PDFvamsi mohanNoch keine Bewertungen

- Inspection of Fusion Joints in Plastic Pipe: February 23, 2006 EWI Project No. 47033GTHDokument160 SeitenInspection of Fusion Joints in Plastic Pipe: February 23, 2006 EWI Project No. 47033GTHelectroscribd0% (1)

- FM Global 2510Dokument50 SeitenFM Global 2510IngénieurCivil100% (1)

- CRK 2-130-13 A-W-A-AuuvDokument5 SeitenCRK 2-130-13 A-W-A-AuuvBepdjNoch keine Bewertungen

- Draft Songo Moyamba Road ConceptDokument16 SeitenDraft Songo Moyamba Road ConceptBepdjNoch keine Bewertungen

- Natura Supplement & Finished ListDokument6 SeitenNatura Supplement & Finished ListBepdjNoch keine Bewertungen

- Undp Sle EnergyprofileDokument100 SeitenUndp Sle EnergyprofileBepdjNoch keine Bewertungen

- Evaluation of The Geothermal Energy Potential For South AfricaDokument8 SeitenEvaluation of The Geothermal Energy Potential For South AfricaBepdjNoch keine Bewertungen

- Road Deterioration in Developing CountriesDokument74 SeitenRoad Deterioration in Developing CountriesBepdjNoch keine Bewertungen

- Cap 437Dokument99 SeitenCap 437anandrao789100% (1)

- NJH Group Profile TradingDokument30 SeitenNJH Group Profile TradingBepdjNoch keine Bewertungen

- Ascend Trading BrochureDokument8 SeitenAscend Trading BrochureBepdjNoch keine Bewertungen

- The International Student's Guide To de La Salle University: Produced in 2016 by The Office For Strategic CommunicationsDokument22 SeitenThe International Student's Guide To de La Salle University: Produced in 2016 by The Office For Strategic CommunicationsBepdjNoch keine Bewertungen

- Specification - DC FineDokument1 SeiteSpecification - DC FineBepdjNoch keine Bewertungen

- CIBODokument16 SeitenCIBOBepdjNoch keine Bewertungen

- Specs Des Full Fat FineDokument1 SeiteSpecs Des Full Fat FineBepdjNoch keine Bewertungen

- Admission Statement of ResponsibilitiesDokument1 SeiteAdmission Statement of ResponsibilitiesMIGUEL DIEGO PANGILINANNoch keine Bewertungen

- PT. Citilink Indonesia NPWP: 02.827.597.2-093.000 Jl. Raya Juanda Sawotratap Gedangan SidoarjoDokument3 SeitenPT. Citilink Indonesia NPWP: 02.827.597.2-093.000 Jl. Raya Juanda Sawotratap Gedangan SidoarjoBepdjNoch keine Bewertungen

- Consent Form DlsuDokument3 SeitenConsent Form Dlsulee borioNoch keine Bewertungen

- Admission Recommendation 2016 2017 PDFDokument2 SeitenAdmission Recommendation 2016 2017 PDFAngelica NabayraNoch keine Bewertungen

- Admission Declaration As New StudentDokument1 SeiteAdmission Declaration As New StudentBepdjNoch keine Bewertungen

- Eco Physiology of Fruit TreesDokument14 SeitenEco Physiology of Fruit TreesBepdjNoch keine Bewertungen

- Admission Sec Scholastic RecordDokument1 SeiteAdmission Sec Scholastic RecordHarold ApostolNoch keine Bewertungen

- Office of Admissions and ScholarshipsDokument7 SeitenOffice of Admissions and ScholarshipsBepdjNoch keine Bewertungen

- 08 - UnescoDokument21 Seiten08 - UnescoBepdjNoch keine Bewertungen

- Admission1516t1 Expression of Interest Admission STCDokument1 SeiteAdmission1516t1 Expression of Interest Admission STCBepdjNoch keine Bewertungen

- BirthstonesDokument5 SeitenBirthstonesBepdjNoch keine Bewertungen

- Seafood ChowderDokument3 SeitenSeafood ChowderBepdjNoch keine Bewertungen

- Quotation: ALATAS Singapore Pte LTDDokument1 SeiteQuotation: ALATAS Singapore Pte LTDBepdjNoch keine Bewertungen

- The Scent of StressDokument25 SeitenThe Scent of StressBepdjNoch keine Bewertungen

- Lengua A La Sevillana IngredientsDokument2 SeitenLengua A La Sevillana IngredientsBepdjNoch keine Bewertungen

- Building An Aquarium 2Dokument15 SeitenBuilding An Aquarium 2garycwkNoch keine Bewertungen

- Checklist For Visa Application Tourism and Visit To Family / FriendsDokument4 SeitenChecklist For Visa Application Tourism and Visit To Family / FriendsBepdjNoch keine Bewertungen

- Bentley s1 Workshop Manual 1Dokument29 SeitenBentley s1 Workshop Manual 1Diogo Trindade0% (1)

- Iso 14581 CSK ScrewDokument1 SeiteIso 14581 CSK ScrewMitesh MakvanaNoch keine Bewertungen

- Yamatake Actuator 1Dokument12 SeitenYamatake Actuator 1Carlos UchôaNoch keine Bewertungen

- Sirco HD Part Cat06Dokument280 SeitenSirco HD Part Cat06Israel Islas OrtizNoch keine Bewertungen

- 1950 Supplement To Screw Thread StandardDokument125 Seiten1950 Supplement To Screw Thread StandardDejan AntanasijevicNoch keine Bewertungen

- 螺丝代号对照表Dokument38 Seiten螺丝代号对照表里差Noch keine Bewertungen

- Modern Graphics CommunicationDokument80 SeitenModern Graphics CommunicationRotax_Kid50% (2)

- ORD5796 Rev 2Dokument2 SeitenORD5796 Rev 2AvijitSinharoyNoch keine Bewertungen

- 3 - Timber-Screwed Connections - Kerto ManualDokument29 Seiten3 - Timber-Screwed Connections - Kerto ManualJulianNoch keine Bewertungen

- Pipe FittingsDokument26 SeitenPipe Fittingsmajid fardniaNoch keine Bewertungen

- BS 1366 - Part 5 - Service Ducts and ShaftsDokument28 SeitenBS 1366 - Part 5 - Service Ducts and ShaftsNathan BlakeNoch keine Bewertungen

- Astm F-1136Dokument2 SeitenAstm F-1136tai100% (3)

- Parker Thread SealsDokument24 SeitenParker Thread SealscjfgksNoch keine Bewertungen

- As 1275 Metric Threaded FastenersDokument20 SeitenAs 1275 Metric Threaded FastenersJunnoKaiserNoch keine Bewertungen

- TF 000085Dokument2 SeitenTF 000085api-299556237Noch keine Bewertungen

- NOV Lock Wiring Guide: Document No ASP00019Dokument9 SeitenNOV Lock Wiring Guide: Document No ASP00019Mohammed JalalNoch keine Bewertungen

- H28 2aDokument49 SeitenH28 2ajwsiglerNoch keine Bewertungen

- Part List Commander 400Dokument38 SeitenPart List Commander 400Gabino Ubilio MurilloNoch keine Bewertungen

- Me208: Fundamentals of Machine Design CREDITS 6 (L 4, T 0, P 2)Dokument3 SeitenMe208: Fundamentals of Machine Design CREDITS 6 (L 4, T 0, P 2)s_nimalanNoch keine Bewertungen

- Probolt Brochure Fastener PDFDokument32 SeitenProbolt Brochure Fastener PDFRazali AhmadNoch keine Bewertungen

- Annular Dissassembly ExtractDokument2 SeitenAnnular Dissassembly ExtractAshraf GabrNoch keine Bewertungen

- Screw Jacks CalculationDokument27 SeitenScrew Jacks CalculationTarmana Antt0% (1)

- ATT III - 9. Appropriate Use of Hand Tools, Machine Tools and Measuring Instruments For Fabrication and Repair On BoardDokument8 SeitenATT III - 9. Appropriate Use of Hand Tools, Machine Tools and Measuring Instruments For Fabrication and Repair On BoardGideon TariganNoch keine Bewertungen

- Plastic-Glass Skylight PDFDokument5 SeitenPlastic-Glass Skylight PDFJonathan SchauderNoch keine Bewertungen

- Design of Machine Element-1Dokument23 SeitenDesign of Machine Element-1rutvikvavale0375Noch keine Bewertungen

- Basics of Small Bore FittingsDokument9 SeitenBasics of Small Bore FittingsJosh LeBlancNoch keine Bewertungen

- Whitepaper Bolted ConnectionsDokument18 SeitenWhitepaper Bolted ConnectionsdanaosajoNoch keine Bewertungen

- Anc Storm ValveDokument9 SeitenAnc Storm ValveCarlos Holguin100% (1)

- Precision Gage Solutions: Thread Check IncDokument51 SeitenPrecision Gage Solutions: Thread Check IncAngel Alvarez CarrilloNoch keine Bewertungen

- Murray Mxua 19-21675 (881224-224)Dokument15 SeitenMurray Mxua 19-21675 (881224-224)Yew Lim100% (1)