Beruflich Dokumente

Kultur Dokumente

RandD Shaft

Hochgeladen von

loloOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RandD Shaft

Hochgeladen von

loloCopyright:

Verfügbare Formate

Flexible Shaft Couplings_Grosvenor Leaflet IMPO 02/09/2014 10:56 Page 1

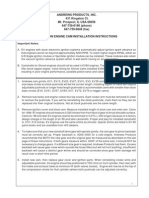

INSTALLATION PROCEDURE FOR R & D MARINE COUPLINGS

1. Roughly align engine and stern gear without flexible coupling i.e. only two rigid half couplings pushed together.

2. Bolt R & D Marine coupling between the two rigid couplings. Tightening details as below.

Check Gap

3. Check alignment of engine by placing feeler gauges between the RED CONE

HEADED BOLT and the rigid half coupling. Repeat for the SAME bolt at 90 intervals by

rotating the shaft.

4. If the gap is the same in all four positions, the engine is accurately aligned. Recommended

minimum to maximum gap difference: 0.25 mm / 0.010 inch.

5. Run installation to bring engine compartment to working temperature.

Gearbox

Re-check torque settings.

Flange

Shaft

Flange

Recommended tightening torque:

M8 - 27 Nm 20 lbsft 3/8 UNF - 40 Nm 30 lbsft M10 - 61 Nm 45 lbsft 7/16 UNF - 81 Nm 60 lbsft M12 - 108 Nm 80 lbsft

1/2 UNF - 100 Nm 75 lbsft 5/8 UNF - 210 Nm 155 lbsft M18 - 338 Nm 250 lbsft 3/4 UNF - 366 Nm 270 lbsft

Flexible Shaft Couplings

EARTHING CONNECTORS

For engines 5 to 1500 HP

R & D Marine Earthing Connector consists of a silver impregnated rubber strip, which when fitted through the axis of the coupling

between the two fail safe straps gives electrical continuity. R & D have sizes to fit most 910 series couplings.

Reduces engine noise and

vibration transmission

INSTALLATION PROCEDURE FOR R&D EARTHING CONNECTORS

1.

2.

3.

4.

Fail safe design

While carrying out the following procedure, ensure that the connector is not contaminated by grease or dirt.

Before fitting the coupling into the drive train, remove 2 off bolts holding one of the fail safe straps.

Remove the fail safe strap to uncover the hole in the centre of the coupling.

Roll up the earthing connector (lengthways)

R & D Marine Earthing Connector Application Guide

as tight as possible.

5. Push into the hole previously uncovered by removing the strap

as far as possible.

6. Replace the fail safe strap ensuring that the connector is not

damaged, replace 2 off bolts.

7. Fit the coupling as per the installation instructions.

8. Check electrical continuity on installation and thereafter

at three to six month intervals.

Part No

103-036

103-037

103-038

103-039

103-040

103-041

103-042

103-043

103-044

103-047

103-053

Size (mm)

9 x 57

11 x 57

15 x 57

17 x 57

19 x 57

23 x 57

25 x 57

15 x 75

17 x 75

9 x 30

19 x 75

Bolts between existing shaft

flanges

To Suit Coupling

910-021

910-001, 002, 007, 013, 014, 019, 020, 028, 043

910-004, 005

910-003, 006, 009, 012, 036, 037, 044, 052

910-017, 018, 025, 026

910-029, 038, 039, 040

910-032, 033

910-015, 016, 022, 024, 046, 048, 053

910-030, 041, 042, 047, 051

910-035, 045, 049, 050

910-062

Requires no machining

Simple to install

Simple to periodically check

alignment

R & D Marine has developed a wide range of competitively priced Flexible

Couplings to fit all major installations.

Designs are subject to constant review and

improvement therefore we reser ve the right

to amend any dimension or detail specified or

illustrated in this publication without notice

and without incurring any obligation to provide

such modification to products previously

delivered.

The R & D Flexible Couplings reduce engine noise, vibration transmission and

are designed to accept propeller thrust, a separate thrust bearing and bulk head

are not required.

The couplings are made from a polyester elastomer which is not affected by salt

water, diesel and lubrication fluids.

Wide range of stock

Accepts propeller thrust

Impervious to salt water,

diesel and lubrication oils

If electrical continuity is required an earthing connector can be fitted in the

centre of most Flexible Couplings.

Fast installation time

Installation is quick and easy as the R & D Coupling requires no machining and

comes supplied with bolts to connect between the two existing shaft flanges.

Electrical continuity

available

Meadow Works

Clothall Road

Baldock

Hertfordshire

England

SG7 6PD

Checking alignment on installation and during service checks is quick and easy

using the red cone headed bolt.

Contact Us By:

Tel: +44 (0)1462 892391

Fax: +44 (0)1462 896448

Web Site: www.randdmarine.com

E mail: info@randdmarine.com

Worldwide availability

Products are available ex-stock and worldwide through our distribution network.

Competitively priced

9/14

Flexible Shaft Couplings_Grosvenor Leaflet IMPO 02/09/2014 10:56 Page 2

R & D Marine Flexible Shaft Couplings

Coupling Selection Guide

How to Select (details required)

ALLISON

1. Engine horse power and Engine Speed

2. Gearbox type and reduction ratio

3. Gearbox flange details. Diameter of flange. Diameter of register. Pitch circle diameter of fixing holes. Size and quantity of holes

(Pitch circle diameter is the distance between the centre of hole at 12 O`clock position to the centre of the hole at 6 o`clock)

M25

Example

4" Flange

70C

71C

500

1000

1500

5" Flange

Horse Power of Engine x Reduction Ratio x 100 = HP/100rpm

Engine Speed

150 x 2 x 100 = 12 HP/100 rpm

2500

Coupling Required 910-009 Borg Warner

The R & D 910 Series couplings consist of a contoured flexible disc moulded in tough yet resilient new type Polyester Elastomer. The contoured disc gives

clearance for bolt heads, and is able to flex freely to take up any temporary misalignment of the engine and shaft, due to flexing of the boat structure or the

engine moving on its rubber vibration isolation mountings. Forward thrust is taken in compression on the disc between the two half couplings and reverse thrust

is taken again in compression on the disc between the two fail safe straps. In the unlikely event of a disc failure, the steel straps make the coupling fail safe and

ensure drive is maintained in both forward and reverse.

Couplings as standard are non-conducting but we can supply a silver impregnated rubber element to fit in the centre of the coupling between the two

fail safe straps to give continuity if required.

Flexible Coupling Information

Manufacturer

Diameter

mm

910-001 B/W, PRM, ZF-Hurth, Technodrive 101.6

101.6

910-002 Yanmar

910-003 B/W, PRM, ZF-Hurth, Twin Disc 146.0

101.6

910-004 B/W,PRM, ZF-Hurth

101.6

910-005 Paragon

146.0

910-006 Twin Disc, ZF-Hurth

101.6

910-007 Volvo

127.0

910-009 B/W, PRM, ZF-Hurth, Volvo

127.0

910-012 Yanmar

90.0

910-013 Bukh

910-014 B/W, PRM, ZF-Hurth, Technodrive 101.6

222.2

910-015 Self Change 350HD

260.4

910-016 Self Change 700HD

184.2

910-017 Twin Disc

184.2

910-018 PRM

101.6

910-019 Volvo

101.6

910-020 Volvo

101.6

910-021 Enfield, Sonic

228.6

910-022 Twin Disc

266.7

910-024 Twin Disc

910-025 B/W, PRM, ZF-Hurth, Twin Disc 146.0

146.0

910-026 Twin Disc

225

910-027 ZF W320 320A

90.0

910-028 Bukh

127.0

910-029 B/W, ZF-Hurth, Volvo

292.1

910-030

910-032 B/W, PRM, ZF-Hurth, Twin Disc 146.0

146.0

910-033 Twin Disc, ZF-Hurth

910-034 Open Centre V Drive 52mm Bore 127.0

340.0

910-035

127.0

910-036 Twin Disc

130.0

910-037 Yanmar

178.0

910-038 Taipeoungyang TK 250

184.2

910-039 Twin Disc

184.2

910-040 PRM

292.1

910-041

287.2

910-042 Dong-I DMT 170HL

101.6

910-043 Yanmar

127.0

910-044 B/W, PRM, ZF-Hurth, Volvo

340.0

910-045

228.6

910-046 Allison M25

292.1

910-047 Dong-I DMT 260H

228.6

910-048 Twin Disc MG 5111 SC

205.0

910-049 ZF 325-1A Volvo Flange

230.0

910-050 Twin Disc 510A/5114A

279.4

910-051 Twin Disc MG 521

120.7

910-052 Lister

218

910-053 Dong-I DMT 150H

910-054 Open Centre V Drive 58mm Bore 146.0

910-055 Open Centre V Drive 52mm Bore 127.0

127.0

910-057 B/W, Hurth, Volvo

178.0

910-058 Dong-I DMT 70T, 90T, 100T

101.6

910-059 Volvo

112.8

910-060 TMP

Open

Cntre

V

Drive

52mm

Bore

127.0

910-061

910-062 Dong-I DMT 140H

198.0

910-063 Open Centre V Drive 58mm Bore 146.0

910-064 Open Centre V Drive 67mm Bore 184.2

Inch

4.00

4.00

5.75

4.00

4.00

5.75

4.00

5.00

5.00

3.54

4.00

8.75

10.25

7.25

7.25

4.00

4.00

4.00

9.00

10.5

5.75

5.75

8.86

3.54

5.00

11.5

5.75

5.75

5.00

13.38

5.00

5.12

7.00

7.25

7.25

11.5

11.3

4.00

5.00

13.38

9.00

11.5

9.00

8.07

9.00

11.00

4.75

8.58

5.75

5.00

5.00

7.00

4.00

4.44

5.00

7.80

5.75

7.25

71C

72C

5000

6" Flange

73C

7000

910-001, 910-004, 910-014

910-009(BW) 910-029,

910-044(BW), 910-057

910-003, 910-025, 910-032

BUKH

4" Flange

910-013, 910-028

DONG I

Gearbox Flange Dimensions

Flexible

Coupling

910-046

BORG WARNER

To calculate Power of coupling required.

1. Ford 150 HP at 2500 RPM

2. Borg Warner Velvet Drive 72C 2:1 Reduction

3. 5 Flange, 2.500 dia Register, 4.250 PCD,

4 off holes 0.437 diameter

9" Flange

No

Nom Dia

Bolts Of Holes

Inch

mm

10.0

0.39

4

10.0

0.39

4

12.7

0.50

6

10.0

0.39

4

9.7

0.38

4

16.0

0.63

6

10.0

0.39

4

11.2

0.44

4

10.0

0.39

4

8.1

0.32

4

10.0

0.39

4

11.2

0.44

6

16.0

0.63

6

19.0

0.75

6

16.0

0.63

6

10.0

0.39

4

10.0

0.39

4

11.2

0.44

2

22.6

0.89

8

25.4

1.00

8

12.7

0.5

6

16.0

0.63

6

17.0

0.67

8

8.1

0.32

4

11.2

0.44

4

25.4

1.00

8

12.7

0.5

6

16.0

0.63

6

11.2

0.44

4

25.4

1.00

8

10.0

0.39

4

12.3

0.48

4

14.3

0.56

6

19.0

0.75

6

16.0

0.63

6

25.4

1.00

8

25.1

0.98

6

10.0

0.39

4

11.2

0.44

4

25.4

1.00

8

19.0

0.75

8

21.0 0.826

6

0.89

6 (8) 22.6

18.0

0.71

10

22.6

0.89

8

19.0

0.75

8

11.2

0.44

6

20.0

0.79

6

12.7

0.50

6

11.2

0.44

4

11.2

0.44

4

16.0

0.63

6

10.0

0.39

4

11.2

0.44

2

11.2

0.44

4

16.0

0.63

6

12.7

0.50

6

16.0

0.63

6

Flexible Coupling Details

Bolt Pitch

Circle

Inch

mm

82.55

3.25

78.00

3.07

120.6

4.75

82.55

3.25

82.55

3.25

120.6

4.75

80.0

3.15

107.9

4.25

100.0

3.93

74.5

2.93

82.55

3.25

190.5

7.50

228.6

9.00

152.4

6.00

152.4

6.00

80.0

3.15

80.0

3.15

76.0

3.00

190.5

7.50

222.2

8.75

120.6

4.75

120.6

4.75

196

7.72

74.5

2.93

107.9

4.25

247.6

9.75

120.6

4.75

120.6

4.75

107.9

4.25

295.3 11.63

104.8

4.13

107.9

4.25

152.0 5.984

152.4

6.00

152.4

6.00

247.6

9.75

240.0

9.45

78.0

3.07

107.9

4.25

295.3 11.63

190.5

7.50

240.0

9.45

190.5

7.50

170.0

6.69

190.5

7.50

241.3

9.50

98.5

3.88

180.0

7.09

120.6

4.75

107.9

4.25

107.9

4.25

152.0 5.984

80.0

3.15

81.0

3.19

107.9

4.25

170.0

6.69

120.6

4.75

152.4

6.00

O These couplings are fitted with a shouldered bush to locate in the gearbox flange

X These flexible couplings have been approved by LLOYDS REGISTER OF SHIPPING

Register

mm

63.5

50.0

76.2

63.5

66.7

76.2

60.0

63.5

65.0

47.0

63.5

152.4

152.4

95.25

95.25

60.0

60.0

---152.4

127.0

76.2

76.2

140

47.0

63.5

152.4

76.2

76.2

63.5

152.4

63.5

63.5

100

95.25

95.25

152.4

160.0

50.0

63.5

152.4

152.4

150.0

152.4

140.0

152.4

152.4

63.5

140.0

76.2

63.5

63.5

100.0

60.0

---63.5

130.0

76.2

95.25

Inch

2.50

1.97

3.00

2.50

2.63

3.00

2.36

2.50

2.56

1.85

2.50

6.00

6.00

3.75

3.75

2.36

2.36

---6.00

5.00

3.00

3.00

5.51

1.85

2.50

6.00

3.00

3.00

2.50

6.00

2.50

2.50

3.94

3.75

3.75

6.00

6.30

1.97

2.50

6.00

6.00

5.90

6.00

5.51

6.00

6.00

2.50

5.51

3.00

2.50

2.50

3.94

2.36

---2.50

5.12

3.00

3.75

Diameter

mm

114.3

114.3

152.4

114.3

114.3

152.4

114.3

143.0

135.0

114.3

114.3

222.2

276.4

190.5

190.5

114.3

114.3

108.0

222.2

276.4

152.4

152.4

228.6

114.3

143.0

292.1

152.4

152.4

162.0

348.0

143.0

143.0

190.5

190.5

190.5

292.1

292.1

114.3

143.0

348.0

222.2

292.1

222.2

223.0

230.0

260.4

150.9

222.2

172.0

162.0

143.0

190.5

114.3

112.8

162.0

210.0

172.0

230.0

Inch

4.5

4.5

6.0

4.5

4.5

6.0

4.5

5.63

5.31

4.5

4.5

8.75

10.88

7.5

7.5

4.5

4.5

4.25

8.75

10.88

6.0

6.0

9.0

4.5

5.63

11.5

6.0

6.0

6.38

13.7

5.63

5.63

7.50

7.50

7.50

11.5

11.5

4.5

5.6

13.7

8.75

11.5

8.75

8.78

9.00

11.25

5.94

8.75

6.77

6.38

5.63

7.50

4.5

4.44

6.38

8.27

6.77

9.06

Length

Inch

mm

32.5

1.28

32.5

1.28

47.5

1.87

35.6

1.40

34.5

1.35

47.5

1.87

43.7

1.72

45.0

1.77

45.0

1.77

32.5

1.28

32.5

1.28

44.5

1.75

58.0

2.28

60.7

2.39

60.7

2.39

32.5

1.28

32.5

1.28

41.7

1.64

44.5

1.75

56.7

2.23

49.8

1.96

49.8

1.96

44.5

1.75

32.5

1.28

52.4

2.06

58.4

2.30

55.4

2.18

55.4

2.18

45.0

1.77

108.0 4.25

45.0

1.77

51.1

2.01

63.3

2.49

63.3

2.49

63.3

2.49

58.4

2.30

58.4

2.30

32.5

1.28

45.0

1.77

108.0 4.25

44.5

1.75

58.4

2.30

62.7

2.47

124.0 4.88

101.6

4.0

58.4

2.30

69.9

2.75

45.0

1.77

47.5

1.87

45.0

1.77

52.4

2.06

63.3

2.49

35.6

1.40

38.1

1.50

52.6

2.07

48.2

1.90

55.5 2.185

63.8

2.51

Bolt

Dia

M10

M10

1/2 UNF

M10

3/8 UNF

1/2 UNF

M10

7/16 UNF

M10

M8

M10

7/16 UNF

5/8 UNF

5/8 UNF

5/8 UNF

M10

M10

7/16 UNF

1/2 UNF

5/8 UNF

1/2 UNF

1/2 UNF

1/2 UNF

M8

7/16 UNF

5/8 UNF

1/2 UNF

1/2 UNF

7/16 UNF

5/8 UNF

M10

7/16 UNF

M14

5/8 UNF

5/8 UNF

5/8 UNF

5/8 UNF

M10

7/16 UNF

3/4 UNF

1/2 UNF

5/8 UNF

1/2 UNF

M18

1/2 UNF

5/8 UNF

7/16 UNF

1/2 UNF

1/2 UNF

7/16 UNF

7/16 UNF

5/8 UNF

M10

7/16 UNF

7/16 UNF

M16

1/2 UNF

5/8 UNF

Capacity

/100 rpm

HP

kW

3.73

5

2.24

3

14.92 20

5.97

8

5.22

7

14.92 20

2.24

3

9.69

13

7.46

10

2.24

3

2.24

3

32.1

43

48.47 65

29.84 40

29.84 40

2.24

3

3.73

5

1.87

2.5

48.47 65

63.38 85

20.88 28

20.88 28

48.47 65

3.73

5

14.92 20

89.48 120

27.6

37

27.6

37

8.95

12

119.3 160

7.46

10

9.69

13

41.0

55

41.0

55

41.0

55

104.4 140

67.0

90

3.73

5

5.97

8

171.5 230

48.47 65

67.0

90

48.47 65

56

75

63.38 85

89.48 120

7.46

10

35.8

48

17.9

24

5.2

7

18.64 25

41.0

55

5.96

8

2.42 3.25

14.16 19

47.0

63

23.8

32

37.3

50

Ref

XO

OXO

XO

910-062

910-053

910-042

910-047

O

XO

OXO

XO

OXO

OXO

XO

OXO

O

O

OXO

O

#

O

O

O

O

O

O

O

OXO

O

O

2 Bolt

910-021

LISTER

910-052

NEWAGE PRM

S= Shallow Case, D= Deep Case

4" Flange

910-001, 910-004, 910-014

Delta

80

120

150

5" Flange

910-009(PR) 910-044(PR)

101

910-029

140

160

260

6" Flange

910-003, 910-025, 910-032

175

265

301

302

310

401

402

500

750

601 3:1

1000 3:1

7 14" Flange

910-018, 910-040

601 4:1

1000 4:1

1200S

1500S

1750S

10 12" Flange

910-024

1200D

1500D

1750D

PARAGON

#

TWIN DISC cont`d

4 Flange

910-001, 910-004, 910-014

TMC30

TMC40

TMC50

TMC60

TM260

5" Flange

910-009(PR) 910-029

TM93 - needs spacer 202-560 910-044(PR)

TM93A

TM170

TM170A

TM345

TM345A

TM485A

TM545A

TM880A

6" Flange

910-006, 910-026, 910-033

TM130B

TM200B up to 1.28: 1

TM265

TM265A

7 14" Flange

910-018

TMC200B up to 4.48: 1

TM1200A

9" Scalloped Flange

MG5111SC

MG5114SC

9" Flange

MG510SC

MG510A

MG5111A

MG5114A

MG5111V,

MG5114V

MG514CU

MG514U

MG5135A

10 12" Flange

MG5091DC

MG509DC

MG510DC

MG5111DC

MG5114DC

MG5113

MG514

TMP

4" Flange

MS

RB

4" Flange

MS 2

MS 10

MS 15

MS25

5" Flange

MS 3

MS4

MS5

HS25A

HS45A

HS63A

6" Flange

HS80A

2 Bolt

5" Flange

12000

910-060

910-009(PR) 910-044(PR)

TWIN DISC

4 12" Flange

O These flexible couplings have been approved by BUREAU VERITAS

# For the Hurth HBW 150 V Gearbox an adaptor 202-351 is required (22.3 mm 0.875" long)

KW x 1.341 = HP

910-058

ENFIELD and SONIC DRIVES

For the IRM 220A Gearbox, we can supply adapter plate 202-384 (54mm 2.125" long) and for the Twin Disc 502 Gearbox, adapter plate 202-148 (54mm 2.125" long) that bolt onto

flexible coupling 910-003, 910-025 or 910-032 and with half coupling 202-037 or 202-054, alternatively clamp type 202-176 or 202-178

HP x 0.7457 = KW

DMT 70T 178 mm Flange

DMT 90T

DMT 100T

DMT 140H 198 mm Flange

DMT 150H 218 mm Flange

DMT 170HL 287 mm Flange

DMT 260H 292 mm Flange

TECHNODRIVE

4" Flange

910-005

SELF CHANGE GEARS

8 34" Flange

350HD

10 34" Flange

700

910-015

910-016

TAIPEOUNGYANG

178 mm Flange

TK250

910-038

SC= Shallow Case, DC= Deep Case

4" Flange

910-001, 910-004, 910-014

MG 340

MG 360

MG5010SC

MG5011SC

MG5010V

4 34" Flange

Adaptor 202-148 with

MG502-I

910-003, 910-025, 910-032

MG502-V

5" Flange 4 18 PCD

910-036

MG5010A

MG5011A

5" Flange 4 14 PCD 910-009(PR) 910-044(PR)

MG5005A

910-029, 910-057

MG5012SC

MG5015A

MG5020SC

MG5055A

6" Flange

910-006, 910-026, 910-033

MG5010DC

MG5050

MG5050-V

MG5050-A

MG5061SC

MG5061-A

MG5061V

MG5062V

MG506-1

MG506A-1

MG507-1

MG507A-1

MG5075IV

MG5075-A

MG5075SC

7 14" Flange

910-017, 910-039

MG506DC

MG5065A

MG507-1

MG507-1SC

MG507-2SC

MG507A-2

MG5075A needs adaptor 202-356

MG5075SC

MG5075IV

MG5081SC

MG5081A needs adaptor 202-356

MG5082A

MG5082SC

MG5085SC needs adaptor 202-356

MG5085A needs adaptor 202-356

MG5090A

MG509SC

MG509U

MG5091SC

MG5095A

MGX5095A

ZF HURTH cont`d

910-048

910-022, 910-050

910-024

VOLVO

910-007

910-019, 910-020, 910-059

910-009(VO), 910-029

910-044(VO), 910-057

910-006, 910-026

910-033

YANMAR (KANZAKI)

4" Flange 78mm PCD

910-002

KBW10

910-043

KM2

KM3

KM35

5" Flange 100mm PCD

910-012

KBW20

KBW21

KM4

KM4A

KMH4A

5 12"Flange 4 14 PCD 910-009, 910-029, 910-037

KM40

910-057

KM5

KMH50

6" Flange

910-006, 910-026, 910-033

KMH6

KMH60

KMH61A

KMH61V

910-063

ZF-HURTH

4" Flange

910-001, 910-004, 910-014

ZF

35 HBW

35

40 HBW

4M

50 HBW

5M

100 HBW

10M

125H HSW

12

125 HBW

12M

150 HBW

15M

150A HBW

15MA

250 HBW

25M

250H HSW

25

250A HSW

25A

25MA

30M

45A 1.25:1

450D HSW

45C

4 34 "

Adaptor 202-384 with 910-003

910-025, 910-032

ZF

220A-1 IRM

220A

225A

Couplings 910-030, 910-035, 910-041 and 910-045 will require suitable adaptors for the gearbox flange

5" Flange

HBW

360

HSW

910-009(PR), 910-029

910-044(PR), 910-057

ZF

450H2

450A2

450D

630H1

630A1

630D

45A

45C

63

63A

63C

88C

90TS

90ATS

110TS

6" Flange 13.2 mm bolt holes

910-003,

910-025, 910-032

ZF

45-1

6" Flange 16.3mm bolt holes

910-006,

910-026, 910-033

HSW

IRM

ZF

800A2

80A

800A3

80-1A

85A

220 needs adaptor

202-329

280A

280-1

280V-LD 280-1A

280PL

280IV

280

285A

285IV

286

286A

286IV

300TS

300-1TS

300ATS

300-1ATS

301PL-2

301C

301A-2

301A

300VTS

300IVTS

110ATS

110IVTS

7 14" Flange

910-017

IRM

311

8" Flange

910-049

IRM

ZF

311PL

311

325-1A Volvo

335A

350PL-2

350

350A-2

350A

350PL-1

350A-1

350 TS

350 ATS

350V

350V

350V-LD 350 IV

360A

500A

500-1A

834" Flange

910-027

IRM

ZF

320-2

W320

320A

ZF-HURTH V DRIVE

4" Flange

Adaptor 202-351 with

HSW

ZF

910-034, 910-055, 910-061

150V

15M IV

5" Flange

910-034, 910-055, 910-061

HSW

ZF

90 IVTS

630V

63 IV

6" Flange

910- 054, 910-063

HSW

ZF

110 IVTS

220V-2

220 IV

800V

80 IV

800V2

80-1IV

714" Flange

Adaptor 202-552 with

ZF

910-064

302 IV

8" Flange

910-049

ZF

325 IV

350-IV

370V

500-1 IV

Flexible Shaft Couplings_Grosvenor Leaflet IMPO 02/09/2014 10:56 Page 2

R & D Marine Flexible Shaft Couplings

Coupling Selection Guide

How to Select (details required)

ALLISON

1. Engine horse power and Engine Speed

2. Gearbox type and reduction ratio

3. Gearbox flange details. Diameter of flange. Diameter of register. Pitch circle diameter of fixing holes. Size and quantity of holes

(Pitch circle diameter is the distance between the centre of hole at 12 O`clock position to the centre of the hole at 6 o`clock)

M25

Example

4" Flange

70C

71C

500

1000

1500

5" Flange

Horse Power of Engine x Reduction Ratio x 100 = HP/100rpm

Engine Speed

150 x 2 x 100 = 12 HP/100 rpm

2500

Coupling Required 910-009 Borg Warner

The R & D 910 Series couplings consist of a contoured flexible disc moulded in tough yet resilient new type Polyester Elastomer. The contoured disc gives

clearance for bolt heads, and is able to flex freely to take up any temporary misalignment of the engine and shaft, due to flexing of the boat structure or the

engine moving on its rubber vibration isolation mountings. Forward thrust is taken in compression on the disc between the two half couplings and reverse thrust

is taken again in compression on the disc between the two fail safe straps. In the unlikely event of a disc failure, the steel straps make the coupling fail safe and

ensure drive is maintained in both forward and reverse.

Couplings as standard are non-conducting but we can supply a silver impregnated rubber element to fit in the centre of the coupling between the two

fail safe straps to give continuity if required.

Flexible Coupling Information

Manufacturer

Diameter

mm

910-001 B/W, PRM, ZF-Hurth, Technodrive 101.6

101.6

910-002 Yanmar

910-003 B/W, PRM, ZF-Hurth, Twin Disc 146.0

101.6

910-004 B/W,PRM, ZF-Hurth

101.6

910-005 Paragon

146.0

910-006 Twin Disc, ZF-Hurth

101.6

910-007 Volvo

127.0

910-009 B/W, PRM, ZF-Hurth, Volvo

127.0

910-012 Yanmar

90.0

910-013 Bukh

910-014 B/W, PRM, ZF-Hurth, Technodrive 101.6

222.2

910-015 Self Change 350HD

260.4

910-016 Self Change 700HD

184.2

910-017 Twin Disc

184.2

910-018 PRM

101.6

910-019 Volvo

101.6

910-020 Volvo

101.6

910-021 Enfield, Sonic

228.6

910-022 Twin Disc

266.7

910-024 Twin Disc

910-025 B/W, PRM, ZF-Hurth, Twin Disc 146.0

146.0

910-026 Twin Disc

225

910-027 ZF W320 320A

90.0

910-028 Bukh

127.0

910-029 B/W, ZF-Hurth, Volvo

292.1

910-030

910-032 B/W, PRM, ZF-Hurth, Twin Disc 146.0

146.0

910-033 Twin Disc, ZF-Hurth

910-034 Open Centre V Drive 52mm Bore 127.0

340.0

910-035

127.0

910-036 Twin Disc

130.0

910-037 Yanmar

178.0

910-038 Taipeoungyang TK 250

184.2

910-039 Twin Disc

184.2

910-040 PRM

292.1

910-041

287.2

910-042 Dong-I DMT 170HL

101.6

910-043 Yanmar

127.0

910-044 B/W, PRM, ZF-Hurth, Volvo

340.0

910-045

228.6

910-046 Allison M25

292.1

910-047 Dong-I DMT 260H

228.6

910-048 Twin Disc MG 5111 SC

205.0

910-049 ZF 325-1A Volvo Flange

230.0

910-050 Twin Disc 510A/5114A

279.4

910-051 Twin Disc MG 521

120.7

910-052 Lister

218

910-053 Dong-I DMT 150H

910-054 Open Centre V Drive 58mm Bore 146.0

910-055 Open Centre V Drive 52mm Bore 127.0

127.0

910-057 B/W, Hurth, Volvo

178.0

910-058 Dong-I DMT 70T, 90T, 100T

101.6

910-059 Volvo

112.8

910-060 TMP

Open

Cntre

V

Drive

52mm

Bore

127.0

910-061

910-062 Dong-I DMT 140H

198.0

910-063 Open Centre V Drive 58mm Bore 146.0

910-064 Open Centre V Drive 67mm Bore 184.2

Inch

4.00

4.00

5.75

4.00

4.00

5.75

4.00

5.00

5.00

3.54

4.00

8.75

10.25

7.25

7.25

4.00

4.00

4.00

9.00

10.5

5.75

5.75

8.86

3.54

5.00

11.5

5.75

5.75

5.00

13.38

5.00

5.12

7.00

7.25

7.25

11.5

11.3

4.00

5.00

13.38

9.00

11.5

9.00

8.07

9.00

11.00

4.75

8.58

5.75

5.00

5.00

7.00

4.00

4.44

5.00

7.80

5.75

7.25

71C

72C

5000

6" Flange

73C

7000

910-001, 910-004, 910-014

910-009(BW) 910-029,

910-044(BW), 910-057

910-003, 910-025, 910-032

BUKH

4" Flange

910-013, 910-028

DONG I

Gearbox Flange Dimensions

Flexible

Coupling

910-046

BORG WARNER

To calculate Power of coupling required.

1. Ford 150 HP at 2500 RPM

2. Borg Warner Velvet Drive 72C 2:1 Reduction

3. 5 Flange, 2.500 dia Register, 4.250 PCD,

4 off holes 0.437 diameter

9" Flange

No

Nom Dia

Bolts Of Holes

Inch

mm

10.0

0.39

4

10.0

0.39

4

12.7

0.50

6

10.0

0.39

4

9.7

0.38

4

16.0

0.63

6

10.0

0.39

4

11.2

0.44

4

10.0

0.39

4

8.1

0.32

4

10.0

0.39

4

11.2

0.44

6

16.0

0.63

6

19.0

0.75

6

16.0

0.63

6

10.0

0.39

4

10.0

0.39

4

11.2

0.44

2

22.6

0.89

8

25.4

1.00

8

12.7

0.5

6

16.0

0.63

6

17.0

0.67

8

8.1

0.32

4

11.2

0.44

4

25.4

1.00

8

12.7

0.5

6

16.0

0.63

6

11.2

0.44

4

25.4

1.00

8

10.0

0.39

4

12.3

0.48

4

14.3

0.56

6

19.0

0.75

6

16.0

0.63

6

25.4

1.00

8

25.1

0.98

6

10.0

0.39

4

11.2

0.44

4

25.4

1.00

8

19.0

0.75

8

21.0 0.826

6

0.89

6 (8) 22.6

18.0

0.71

10

22.6

0.89

8

19.0

0.75

8

11.2

0.44

6

20.0

0.79

6

12.7

0.50

6

11.2

0.44

4

11.2

0.44

4

16.0

0.63

6

10.0

0.39

4

11.2

0.44

2

11.2

0.44

4

16.0

0.63

6

12.7

0.50

6

16.0

0.63

6

Flexible Coupling Details

Bolt Pitch

Circle

Inch

mm

82.55

3.25

78.00

3.07

120.6

4.75

82.55

3.25

82.55

3.25

120.6

4.75

80.0

3.15

107.9

4.25

100.0

3.93

74.5

2.93

82.55

3.25

190.5

7.50

228.6

9.00

152.4

6.00

152.4

6.00

80.0

3.15

80.0

3.15

76.0

3.00

190.5

7.50

222.2

8.75

120.6

4.75

120.6

4.75

196

7.72

74.5

2.93

107.9

4.25

247.6

9.75

120.6

4.75

120.6

4.75

107.9

4.25

295.3 11.63

104.8

4.13

107.9

4.25

152.0 5.984

152.4

6.00

152.4

6.00

247.6

9.75

240.0

9.45

78.0

3.07

107.9

4.25

295.3 11.63

190.5

7.50

240.0

9.45

190.5

7.50

170.0

6.69

190.5

7.50

241.3

9.50

98.5

3.88

180.0

7.09

120.6

4.75

107.9

4.25

107.9

4.25

152.0 5.984

80.0

3.15

81.0

3.19

107.9

4.25

170.0

6.69

120.6

4.75

152.4

6.00

O These couplings are fitted with a shouldered bush to locate in the gearbox flange

X These flexible couplings have been approved by LLOYDS REGISTER OF SHIPPING

Register

mm

63.5

50.0

76.2

63.5

66.7

76.2

60.0

63.5

65.0

47.0

63.5

152.4

152.4

95.25

95.25

60.0

60.0

---152.4

127.0

76.2

76.2

140

47.0

63.5

152.4

76.2

76.2

63.5

152.4

63.5

63.5

100

95.25

95.25

152.4

160.0

50.0

63.5

152.4

152.4

150.0

152.4

140.0

152.4

152.4

63.5

140.0

76.2

63.5

63.5

100.0

60.0

---63.5

130.0

76.2

95.25

Inch

2.50

1.97

3.00

2.50

2.63

3.00

2.36

2.50

2.56

1.85

2.50

6.00

6.00

3.75

3.75

2.36

2.36

---6.00

5.00

3.00

3.00

5.51

1.85

2.50

6.00

3.00

3.00

2.50

6.00

2.50

2.50

3.94

3.75

3.75

6.00

6.30

1.97

2.50

6.00

6.00

5.90

6.00

5.51

6.00

6.00

2.50

5.51

3.00

2.50

2.50

3.94

2.36

---2.50

5.12

3.00

3.75

Diameter

mm

114.3

114.3

152.4

114.3

114.3

152.4

114.3

143.0

135.0

114.3

114.3

222.2

276.4

190.5

190.5

114.3

114.3

108.0

222.2

276.4

152.4

152.4

228.6

114.3

143.0

292.1

152.4

152.4

162.0

348.0

143.0

143.0

190.5

190.5

190.5

292.1

292.1

114.3

143.0

348.0

222.2

292.1

222.2

223.0

230.0

260.4

150.9

222.2

172.0

162.0

143.0

190.5

114.3

112.8

162.0

210.0

172.0

230.0

Inch

4.5

4.5

6.0

4.5

4.5

6.0

4.5

5.63

5.31

4.5

4.5

8.75

10.88

7.5

7.5

4.5

4.5

4.25

8.75

10.88

6.0

6.0

9.0

4.5

5.63

11.5

6.0

6.0

6.38

13.7

5.63

5.63

7.50

7.50

7.50

11.5

11.5

4.5

5.6

13.7

8.75

11.5

8.75

8.78

9.00

11.25

5.94

8.75

6.77

6.38

5.63

7.50

4.5

4.44

6.38

8.27

6.77

9.06

Length

Inch

mm

32.5

1.28

32.5

1.28

47.5

1.87

35.6

1.40

34.5

1.35

47.5

1.87

43.7

1.72

45.0

1.77

45.0

1.77

32.5

1.28

32.5

1.28

44.5

1.75

58.0

2.28

60.7

2.39

60.7

2.39

32.5

1.28

32.5

1.28

41.7

1.64

44.5

1.75

56.7

2.23

49.8

1.96

49.8

1.96

44.5

1.75

32.5

1.28

52.4

2.06

58.4

2.30

55.4

2.18

55.4

2.18

45.0

1.77

108.0 4.25

45.0

1.77

51.1

2.01

63.3

2.49

63.3

2.49

63.3

2.49

58.4

2.30

58.4

2.30

32.5

1.28

45.0

1.77

108.0 4.25

44.5

1.75

58.4

2.30

62.7

2.47

124.0 4.88

101.6

4.0

58.4

2.30

69.9

2.75

45.0

1.77

47.5

1.87

45.0

1.77

52.4

2.06

63.3

2.49

35.6

1.40

38.1

1.50

52.6

2.07

48.2

1.90

55.5 2.185

63.8

2.51

Bolt

Dia

M10

M10

1/2 UNF

M10

3/8 UNF

1/2 UNF

M10

7/16 UNF

M10

M8

M10

7/16 UNF

5/8 UNF

5/8 UNF

5/8 UNF

M10

M10

7/16 UNF

1/2 UNF

5/8 UNF

1/2 UNF

1/2 UNF

1/2 UNF

M8

7/16 UNF

5/8 UNF

1/2 UNF

1/2 UNF

7/16 UNF

5/8 UNF

M10

7/16 UNF

M14

5/8 UNF

5/8 UNF

5/8 UNF

5/8 UNF

M10

7/16 UNF

3/4 UNF

1/2 UNF

5/8 UNF

1/2 UNF

M18

1/2 UNF

5/8 UNF

7/16 UNF

1/2 UNF

1/2 UNF

7/16 UNF

7/16 UNF

5/8 UNF

M10

7/16 UNF

7/16 UNF

M16

1/2 UNF

5/8 UNF

Capacity

/100 rpm

HP

kW

3.73

5

2.24

3

14.92 20

5.97

8

5.22

7

14.92 20

2.24

3

9.69

13

7.46

10

2.24

3

2.24

3

32.1

43

48.47 65

29.84 40

29.84 40

2.24

3

3.73

5

1.87

2.5

48.47 65

63.38 85

20.88 28

20.88 28

48.47 65

3.73

5

14.92 20

89.48 120

27.6

37

27.6

37

8.95

12

119.3 160

7.46

10

9.69

13

41.0

55

41.0

55

41.0

55

104.4 140

67.0

90

3.73

5

5.97

8

171.5 230

48.47 65

67.0

90

48.47 65

56

75

63.38 85

89.48 120

7.46

10

35.8

48

17.9

24

5.2

7

18.64 25

41.0

55

5.96

8

2.42 3.25

14.16 19

47.0

63

23.8

32

37.3

50

Ref

XO

OXO

XO

910-062

910-053

910-042

910-047

O

XO

OXO

XO

OXO

OXO

XO

OXO

O

O

OXO

O

#

O

O

O

O

O

O

O

OXO

O

O

2 Bolt

910-021

LISTER

910-052

NEWAGE PRM

S= Shallow Case, D= Deep Case

4" Flange

910-001, 910-004, 910-014

Delta

80

120

150

5" Flange

910-009(PR) 910-044(PR)

101

910-029

140

160

260

6" Flange

910-003, 910-025, 910-032

175

265

301

302

310

401

402

500

750

601 3:1

1000 3:1

7 14" Flange

910-018, 910-040

601 4:1

1000 4:1

1200S

1500S

1750S

10 12" Flange

910-024

1200D

1500D

1750D

PARAGON

#

TWIN DISC cont`d

4 Flange

910-001, 910-004, 910-014

TMC30

TMC40

TMC50

TMC60

TM260

5" Flange

910-009(PR) 910-029

TM93 - needs spacer 202-560 910-044(PR)

TM93A

TM170

TM170A

TM345

TM345A

TM485A

TM545A

TM880A

6" Flange

910-006, 910-026, 910-033

TM130B

TM200B up to 1.28: 1

TM265

TM265A

7 14" Flange

910-018

TMC200B up to 4.48: 1

TM1200A

9" Scalloped Flange

MG5111SC

MG5114SC

9" Flange

MG510SC

MG510A

MG5111A

MG5114A

MG5111V,

MG5114V

MG514CU

MG514U

MG5135A

10 12" Flange

MG5091DC

MG509DC

MG510DC

MG5111DC

MG5114DC

MG5113

MG514

TMP

4" Flange

MS

RB

4" Flange

MS 2

MS 10

MS 15

MS25

5" Flange

MS 3

MS4

MS5

HS25A

HS45A

HS63A

6" Flange

HS80A

2 Bolt

5" Flange

12000

910-060

910-009(PR) 910-044(PR)

TWIN DISC

4 12" Flange

O These flexible couplings have been approved by BUREAU VERITAS

# For the Hurth HBW 150 V Gearbox an adaptor 202-351 is required (22.3 mm 0.875" long)

KW x 1.341 = HP

910-058

ENFIELD and SONIC DRIVES

For the IRM 220A Gearbox, we can supply adapter plate 202-384 (54mm 2.125" long) and for the Twin Disc 502 Gearbox, adapter plate 202-148 (54mm 2.125" long) that bolt onto

flexible coupling 910-003, 910-025 or 910-032 and with half coupling 202-037 or 202-054, alternatively clamp type 202-176 or 202-178

HP x 0.7457 = KW

DMT 70T 178 mm Flange

DMT 90T

DMT 100T

DMT 140H 198 mm Flange

DMT 150H 218 mm Flange

DMT 170HL 287 mm Flange

DMT 260H 292 mm Flange

TECHNODRIVE

4" Flange

910-005

SELF CHANGE GEARS

8 34" Flange

350HD

10 34" Flange

700

910-015

910-016

TAIPEOUNGYANG

178 mm Flange

TK250

910-038

SC= Shallow Case, DC= Deep Case

4" Flange

910-001, 910-004, 910-014

MG 340

MG 360

MG5010SC

MG5011SC

MG5010V

4 34" Flange

Adaptor 202-148 with

MG502-I

910-003, 910-025, 910-032

MG502-V

5" Flange 4 18 PCD

910-036

MG5010A

MG5011A

5" Flange 4 14 PCD 910-009(PR) 910-044(PR)

MG5005A

910-029, 910-057

MG5012SC

MG5015A

MG5020SC

MG5055A

6" Flange

910-006, 910-026, 910-033

MG5010DC

MG5050

MG5050-V

MG5050-A

MG5061SC

MG5061-A

MG5061V

MG5062V

MG506-1

MG506A-1

MG507-1

MG507A-1

MG5075IV

MG5075-A

MG5075SC

7 14" Flange

910-017, 910-039

MG506DC

MG5065A

MG507-1

MG507-1SC

MG507-2SC

MG507A-2

MG5075A needs adaptor 202-356

MG5075SC

MG5075IV

MG5081SC

MG5081A needs adaptor 202-356

MG5082A

MG5082SC

MG5085SC needs adaptor 202-356

MG5085A needs adaptor 202-356

MG5090A

MG509SC

MG509U

MG5091SC

MG5095A

MGX5095A

ZF HURTH cont`d

910-048

910-022, 910-050

910-024

VOLVO

910-007

910-019, 910-020, 910-059

910-009(VO), 910-029

910-044(VO), 910-057

910-006, 910-026

910-033

YANMAR (KANZAKI)

4" Flange 78mm PCD

910-002

KBW10

910-043

KM2

KM3

KM35

5" Flange 100mm PCD

910-012

KBW20

KBW21

KM4

KM4A

KMH4A

5 12"Flange 4 14 PCD 910-009, 910-029, 910-037

KM40

910-057

KM5

KMH50

6" Flange

910-006, 910-026, 910-033

KMH6

KMH60

KMH61A

KMH61V

910-063

ZF-HURTH

4" Flange

910-001, 910-004, 910-014

ZF

35 HBW

35

40 HBW

4M

50 HBW

5M

100 HBW

10M

125H HSW

12

125 HBW

12M

150 HBW

15M

150A HBW

15MA

250 HBW

25M

250H HSW

25

250A HSW

25A

25MA

30M

45A 1.25:1

450D HSW

45C

4 34 "

Adaptor 202-384 with 910-003

910-025, 910-032

ZF

220A-1 IRM

220A

225A

Couplings 910-030, 910-035, 910-041 and 910-045 will require suitable adaptors for the gearbox flange

5" Flange

HBW

360

HSW

910-009(PR), 910-029

910-044(PR), 910-057

ZF

450H2

450A2

450D

630H1

630A1

630D

45A

45C

63

63A

63C

88C

90TS

90ATS

110TS

6" Flange 13.2 mm bolt holes

910-003,

910-025, 910-032

ZF

45-1

6" Flange 16.3mm bolt holes

910-006,

910-026, 910-033

HSW

IRM

ZF

800A2

80A

800A3

80-1A

85A

220 needs adaptor

202-329

280A

280-1

280V-LD 280-1A

280PL

280IV

280

285A

285IV

286

286A

286IV

300TS

300-1TS

300ATS

300-1ATS

301PL-2

301C

301A-2

301A

300VTS

300IVTS

110ATS

110IVTS

7 14" Flange

910-017

IRM

311

8" Flange

910-049

IRM

ZF

311PL

311

325-1A Volvo

335A

350PL-2

350

350A-2

350A

350PL-1

350A-1

350 TS

350 ATS

350V

350V

350V-LD 350 IV

360A

500A

500-1A

834" Flange

910-027

IRM

ZF

320-2

W320

320A

ZF-HURTH V DRIVE

4" Flange

Adaptor 202-351 with

HSW

ZF

910-034, 910-055, 910-061

150V

15M IV

5" Flange

910-034, 910-055, 910-061

HSW

ZF

90 IVTS

630V

63 IV

6" Flange

910- 054, 910-063

HSW

ZF

110 IVTS

220V-2

220 IV

800V

80 IV

800V2

80-1IV

714" Flange

Adaptor 202-552 with

ZF

910-064

302 IV

8" Flange

910-049

ZF

325 IV

350-IV

370V

500-1 IV

Flexible Shaft Couplings_Grosvenor Leaflet IMPO 02/09/2014 10:56 Page 1

INSTALLATION PROCEDURE FOR R & D MARINE COUPLINGS

1. Roughly align engine and stern gear without flexible coupling i.e. only two rigid half couplings pushed together.

2. Bolt R & D Marine coupling between the two rigid couplings. Tightening details as below.

Check Gap

3. Check alignment of engine by placing feeler gauges between the RED CONE

HEADED BOLT and the rigid half coupling. Repeat for the SAME bolt at 90 intervals by

rotating the shaft.

4. If the gap is the same in all four positions, the engine is accurately aligned. Recommended

minimum to maximum gap difference: 0.25 mm / 0.010 inch.

5. Run installation to bring engine compartment to working temperature.

Gearbox

Re-check torque settings.

Flange

Shaft

Flange

Recommended tightening torque:

M8 - 27 Nm 20 lbsft 3/8 UNF - 40 Nm 30 lbsft M10 - 61 Nm 45 lbsft 7/16 UNF - 81 Nm 60 lbsft M12 - 108 Nm 80 lbsft

1/2 UNF - 100 Nm 75 lbsft 5/8 UNF - 210 Nm 155 lbsft M18 - 338 Nm 250 lbsft 3/4 UNF - 366 Nm 270 lbsft

Flexible Shaft Couplings

EARTHING CONNECTORS

For engines 5 to 1500 HP

R & D Marine Earthing Connector consists of a silver impregnated rubber strip, which when fitted through the axis of the coupling

between the two fail safe straps gives electrical continuity. R & D have sizes to fit most 910 series couplings.

Reduces engine noise and

vibration transmission

INSTALLATION PROCEDURE FOR R&D EARTHING CONNECTORS

1.

2.

3.

4.

Fail safe design

While carrying out the following procedure, ensure that the connector is not contaminated by grease or dirt.

Before fitting the coupling into the drive train, remove 2 off bolts holding one of the fail safe straps.

Remove the fail safe strap to uncover the hole in the centre of the coupling.

Roll up the earthing connector (lengthways)

R & D Marine Earthing Connector Application Guide

as tight as possible.

5. Push into the hole previously uncovered by removing the strap

as far as possible.

6. Replace the fail safe strap ensuring that the connector is not

damaged, replace 2 off bolts.

7. Fit the coupling as per the installation instructions.

8. Check electrical continuity on installation and thereafter

at three to six month intervals.

Part No

103-036

103-037

103-038

103-039

103-040

103-041

103-042

103-043

103-044

103-047

103-053

Size (mm)

9 x 57

11 x 57

15 x 57

17 x 57

19 x 57

23 x 57

25 x 57

15 x 75

17 x 75

9 x 30

19 x 75

Bolts between existing shaft

flanges

To Suit Coupling

910-021

910-001, 002, 007, 013, 014, 019, 020, 028, 043

910-004, 005

910-003, 006, 009, 012, 036, 037, 044, 052

910-017, 018, 025, 026

910-029, 038, 039, 040

910-032, 033

910-015, 016, 022, 024, 046, 048, 053

910-030, 041, 042, 047, 051

910-035, 045, 049, 050

910-062

Requires no machining

Simple to install

Simple to periodically check

alignment

R & D Marine has developed a wide range of competitively priced Flexible

Couplings to fit all major installations.

Designs are subject to constant review and

improvement therefore we reser ve the right

to amend any dimension or detail specified or

illustrated in this publication without notice

and without incurring any obligation to provide

such modification to products previously

delivered.

The R & D Flexible Couplings reduce engine noise, vibration transmission and

are designed to accept propeller thrust, a separate thrust bearing and bulk head

are not required.

The couplings are made from a polyester elastomer which is not affected by salt

water, diesel and lubrication fluids.

Wide range of stock

Accepts propeller thrust

Impervious to salt water,

diesel and lubrication oils

If electrical continuity is required an earthing connector can be fitted in the

centre of most Flexible Couplings.

Fast installation time

Installation is quick and easy as the R & D Coupling requires no machining and

comes supplied with bolts to connect between the two existing shaft flanges.

Electrical continuity

available

Meadow Works

Clothall Road

Baldock

Hertfordshire

England

SG7 6PD

Checking alignment on installation and during service checks is quick and easy

using the red cone headed bolt.

Contact Us By:

Tel: +44 (0)1462 892391

Fax: +44 (0)1462 896448

Web Site: www.randdmarine.com

E mail: info@randdmarine.com

Worldwide availability

Products are available ex-stock and worldwide through our distribution network.

Competitively priced

9/14

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- PYI RD Catalog 2011Dokument20 SeitenPYI RD Catalog 2011pacificbikerguyNoch keine Bewertungen

- TSKDokument4 SeitenTSKar174_569868987Noch keine Bewertungen

- Power Stream Couplings-Specn SheetsDokument6 SeitenPower Stream Couplings-Specn SheetsAmol PatkiNoch keine Bewertungen

- R&D Flexible Shaft CouplingsDokument4 SeitenR&D Flexible Shaft CouplingssaxonpirateNoch keine Bewertungen

- Acoplamientos TSK PDFDokument4 SeitenAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesNoch keine Bewertungen

- Hi-Performance Transmissions: Super T10Dokument20 SeitenHi-Performance Transmissions: Super T10Lisa DurdenNoch keine Bewertungen

- Cam EV80Dokument4 SeitenCam EV80Zubair AamirNoch keine Bewertungen

- Dv300 STD MMDokument40 SeitenDv300 STD MMjacklyn ade putraNoch keine Bewertungen

- Marine Propulsion Systems: DescriptionDokument4 SeitenMarine Propulsion Systems: DescriptionlatrancaNoch keine Bewertungen

- ZF 10M TransmissionDokument4 SeitenZF 10M Transmissionisland14Noch keine Bewertungen

- Alignment Coupling Operation Manual Tyre-FlexDokument37 SeitenAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelNoch keine Bewertungen

- Инструкция по установке коннических опорDokument19 SeitenИнструкция по установке коннических опорSergei KurpishNoch keine Bewertungen

- MAN ShaftErrosion SL2008-498Dokument18 SeitenMAN ShaftErrosion SL2008-498flipflop12100% (1)

- John Crane Met A StreamDokument4 SeitenJohn Crane Met A StreamGNoch keine Bewertungen

- Continental TorquesDokument13 SeitenContinental Torquesfredtanner100% (2)

- CE232 - Alternator Flameproof PDFDokument6 SeitenCE232 - Alternator Flameproof PDFbutaberusNoch keine Bewertungen

- Gearbox SuperDokument15 SeitenGearbox Super10delpiNoch keine Bewertungen

- 168-056 - Falk Drive One Model C, Type D Series, Sizes M1220-M1250 Conveyor Drives - Owners Manual PDFDokument16 Seiten168-056 - Falk Drive One Model C, Type D Series, Sizes M1220-M1250 Conveyor Drives - Owners Manual PDFFernando CastroNoch keine Bewertungen

- Tiger Pro 46Dokument10 SeitenTiger Pro 46Rodrigo TeodoroNoch keine Bewertungen

- Autoflex Catalogue PDFDokument24 SeitenAutoflex Catalogue PDFDenis AugustoNoch keine Bewertungen

- Shimpo Circulute 3000 CatalogDokument35 SeitenShimpo Circulute 3000 CatalogElectromateNoch keine Bewertungen

- Catalogo Giunti Samiflex - GB PDFDokument8 SeitenCatalogo Giunti Samiflex - GB PDFDANE80Noch keine Bewertungen

- Tyre CouplingDokument4 SeitenTyre CouplingRavi KrishnanNoch keine Bewertungen

- CP Carrillo HardwareDokument23 SeitenCP Carrillo HardwarePaul ZiddyNoch keine Bewertungen

- Embragues para Motores EstacionariosDokument12 SeitenEmbragues para Motores EstacionariosJiyaYsqn100% (1)

- Bowex Fle-Pa Bowex-Elastic: Flange Coupling For I. C.-EnginesDokument14 SeitenBowex Fle-Pa Bowex-Elastic: Flange Coupling For I. C.-EnginesÓscar PereiraNoch keine Bewertungen

- Mud Agitator ManualDokument7 SeitenMud Agitator ManualCatalin RadNoch keine Bewertungen

- Falk Type UbDokument12 SeitenFalk Type UbJuan GalvesNoch keine Bewertungen

- 100284156Dokument10 Seiten100284156Shumail ZafarNoch keine Bewertungen

- Catálogo de Camisas MELLINGDokument24 SeitenCatálogo de Camisas MELLINGricassterNoch keine Bewertungen

- Falk Coupling SGDokument16 SeitenFalk Coupling SGJorge Ernesto PinzonNoch keine Bewertungen

- Thrustor Brakes PDFDokument5 SeitenThrustor Brakes PDFtadela_553439598Noch keine Bewertungen

- Spicer Wing Bearing Driveshafts CatalogueDokument38 SeitenSpicer Wing Bearing Driveshafts CatalogueJose Israel Correa CortesNoch keine Bewertungen

- SKF Shaft CouplingsDokument24 SeitenSKF Shaft CouplingsEmilio PortelaNoch keine Bewertungen

- KZ1000 KZ1100Dokument370 SeitenKZ1000 KZ1100motomech100% (12)

- Cable Reeling DrumDokument4 SeitenCable Reeling DrumBanamali NaskarNoch keine Bewertungen

- 143T-449T TECO Welding House GeneralDokument9 Seiten143T-449T TECO Welding House GeneralChristian TorresNoch keine Bewertungen

- Falk Quadrive Shaft Mounted Drive - Interchange Guide 371810Dokument12 SeitenFalk Quadrive Shaft Mounted Drive - Interchange Guide 371810Anonymous ntE0hG2TPNoch keine Bewertungen

- Gear 1Dokument52 SeitenGear 1Omar SakajiNoch keine Bewertungen

- Wren160 ManualDokument21 SeitenWren160 ManualStefany CarrenoNoch keine Bewertungen

- 371 810 Falk Quadrive Shaft Mounted Drive Interchange GuideDokument12 Seiten371 810 Falk Quadrive Shaft Mounted Drive Interchange GuideVirginia Venus Visuette MarínNoch keine Bewertungen

- CA Motors Product DetailsDokument25 SeitenCA Motors Product DetailsP Venkata Suresh100% (2)

- Jost CatalogueDokument227 SeitenJost CatalogueLechien LeNoch keine Bewertungen

- PM Series PB 2006Dokument64 SeitenPM Series PB 2006speed844Noch keine Bewertungen

- Sew Brake MotorsDokument6 SeitenSew Brake MotorsMohd Baharuddin Mohd Abu100% (1)

- Acople Falk-WrapflexDokument16 SeitenAcople Falk-Wrapflexhenkis73Noch keine Bewertungen

- General Information: Torque SpecificationsDokument3 SeitenGeneral Information: Torque SpecificationsLuis TepezanoNoch keine Bewertungen

- Taper-Lok Pressure Energised ConnectorsDokument0 SeitenTaper-Lok Pressure Energised Connectorsabhi1648665Noch keine Bewertungen

- Thomson Super Metric Ball Bushing Bearings SpecsheetDokument11 SeitenThomson Super Metric Ball Bushing Bearings SpecsheetElectromateNoch keine Bewertungen

- U35000 PDFDokument16 SeitenU35000 PDFsujit5584Noch keine Bewertungen

- TCM Torque LimitsDokument13 SeitenTCM Torque Limitsrav100% (1)

- HY13 1590 010 Installation OperationDokument4 SeitenHY13 1590 010 Installation OperationMatthew NeubergerNoch keine Bewertungen

- Cooper BearingDokument8 SeitenCooper BearingPrasantaKumarMallikaNoch keine Bewertungen

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Von EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Bewertung: 5 von 5 Sternen5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsVon EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsBewertung: 5 von 5 Sternen5/5 (2)

- BoatWorks Diesel TipsDokument4 SeitenBoatWorks Diesel TipsloloNoch keine Bewertungen

- The Cutting of Water Saturated Sand, The SolutionDokument21 SeitenThe Cutting of Water Saturated Sand, The SolutionloloNoch keine Bewertungen

- Bottom Line On Torque vs. Horsepower: It's Just Math. Deal With It!Dokument3 SeitenBottom Line On Torque vs. Horsepower: It's Just Math. Deal With It!Nik TsufiaNoch keine Bewertungen

- Ship StabilityDokument22 SeitenShip Stabilityanz_izwanNoch keine Bewertungen

- Pipe Thread Data: Cooling ItemsDokument1 SeitePipe Thread Data: Cooling ItemsloloNoch keine Bewertungen

- 3 Tables Friction Loss AquacultureDokument10 Seiten3 Tables Friction Loss Aquaculture45saulNoch keine Bewertungen

- Piping ComparisonDokument1 SeitePiping ComparisonDenstar Ricardo SilalahiNoch keine Bewertungen

- 3 - Miedema - The Cutting of Water Saturated Sand, The Final SolutionDokument12 Seiten3 - Miedema - The Cutting of Water Saturated Sand, The Final SolutionloloNoch keine Bewertungen

- Propeller CourseDokument32 SeitenPropeller Coursebgynm100% (2)

- A 03130109Dokument9 SeitenA 03130109theijesNoch keine Bewertungen

- Propeller CourseDokument32 SeitenPropeller Coursebgynm100% (2)

- 2 - Miedema - New Developments of Cutting Theories With Respect To Dredging The Cutting of Clay and RockDokument16 Seiten2 - Miedema - New Developments of Cutting Theories With Respect To Dredging The Cutting of Clay and RockloloNoch keine Bewertungen

- m673ld3-4 5kw1Dokument2 Seitenm673ld3-4 5kw1loloNoch keine Bewertungen

- Equipment Sheet: Stationary, Sea-Worthy Cutter Suction DredgerDokument2 SeitenEquipment Sheet: Stationary, Sea-Worthy Cutter Suction DredgerloloNoch keine Bewertungen

- Datasheet QSD20Dokument2 SeitenDatasheet QSD20loloNoch keine Bewertungen

- Kamus PerkapalanDokument0 SeitenKamus Perkapalanmustain_henyNoch keine Bewertungen

- OM673L3 Operator's ManualDokument40 SeitenOM673L3 Operator's ManualloloNoch keine Bewertungen

- Plan View: D-4462 Installation Dimensions A 05-78010Dokument1 SeitePlan View: D-4462 Installation Dimensions A 05-78010loloNoch keine Bewertungen

- D 4449Dokument1 SeiteD 4449loloNoch keine Bewertungen

- Rudder Torque2Dokument1 SeiteRudder Torque2danilo laraNoch keine Bewertungen

- Welding Aluminum Alloy 6061 With The Opposing Dual-Torch GTAW ProcessDokument5 SeitenWelding Aluminum Alloy 6061 With The Opposing Dual-Torch GTAW ProcessloloNoch keine Bewertungen

- Rudder Torque2Dokument1 SeiteRudder Torque2danilo laraNoch keine Bewertungen

- Rudder Torque2Dokument1 SeiteRudder Torque2danilo laraNoch keine Bewertungen

- D3-110Dokument2 SeitenD3-110loloNoch keine Bewertungen

- Operators Manual MG540Dokument85 SeitenOperators Manual MG540Juan Carlos Puma Reátegui100% (2)

- 112 E337 TigDokument8 Seiten112 E337 TigloloNoch keine Bewertungen

- AGA Aluminum Welding BrochureDokument16 SeitenAGA Aluminum Welding Brochureaghosh704Noch keine Bewertungen

- Kumera Gear 4s PDFDokument4 SeitenKumera Gear 4s PDFloloNoch keine Bewertungen

- 12 Propellers and Propulsion: (Continued On Next Page)Dokument8 Seiten12 Propellers and Propulsion: (Continued On Next Page)pothirajkalyanNoch keine Bewertungen

- Elementary Electronics 1968-09-10Dokument108 SeitenElementary Electronics 1968-09-10Jim ToewsNoch keine Bewertungen

- Starbucks Progressive Web App: Case StudyDokument2 SeitenStarbucks Progressive Web App: Case StudyYesid SuárezNoch keine Bewertungen

- CLASS XI (COMPUTER SCIENCE) HALF YEARLY QP Bhopal Region Set-IIDokument4 SeitenCLASS XI (COMPUTER SCIENCE) HALF YEARLY QP Bhopal Region Set-IIDeepika AggarwalNoch keine Bewertungen

- M.T Nautica Batu Pahat: Clean Product Tanker 4,497 BHPDokument1 SeiteM.T Nautica Batu Pahat: Clean Product Tanker 4,497 BHPSuper 247Noch keine Bewertungen

- CCNP SWITCH 300-115 - Outline of The Official Study GuideDokument31 SeitenCCNP SWITCH 300-115 - Outline of The Official Study GuidehammiesinkNoch keine Bewertungen

- Computer in Community Pharmacy by Adnan Sarwar ChaudharyDokument10 SeitenComputer in Community Pharmacy by Adnan Sarwar ChaudharyDr-Adnan Sarwar Chaudhary100% (1)

- FT FocusDokument19 SeitenFT Focusobi1kenobyNoch keine Bewertungen

- Commercial BanksDokument11 SeitenCommercial BanksSeba MohantyNoch keine Bewertungen

- TOR AND SCOPING Presentation SlidesDokument23 SeitenTOR AND SCOPING Presentation SlidesSRESTAA BHATTARAINoch keine Bewertungen

- Lyka Kendall B. Adres: Personal Na ImpormasyonDokument2 SeitenLyka Kendall B. Adres: Personal Na ImpormasyonKendall BarbietoNoch keine Bewertungen

- Catalogue Laboratory Products - Heraeus KulzerDokument288 SeitenCatalogue Laboratory Products - Heraeus KulzerDentaDentNoch keine Bewertungen

- Robbie Hemingway - Text God VIP EbookDokument56 SeitenRobbie Hemingway - Text God VIP EbookKylee0% (1)

- 2 Year Spares List For InstrumentationDokument2 Seiten2 Year Spares List For Instrumentationgudapati9Noch keine Bewertungen

- Enemies Beyond Character Creation SupplementDokument8 SeitenEnemies Beyond Character Creation SupplementCain BlachartNoch keine Bewertungen

- ERP22006Dokument1 SeiteERP22006Ady Surya LesmanaNoch keine Bewertungen

- License Fee PaidDokument1 SeiteLicense Fee Paidmy nNoch keine Bewertungen

- 5070 s17 QP 22 PDFDokument20 Seiten5070 s17 QP 22 PDFMustafa WaqarNoch keine Bewertungen

- Acute Leukemia The Scientist's Perspective and ChallengeDokument438 SeitenAcute Leukemia The Scientist's Perspective and ChallengemedskyqqNoch keine Bewertungen

- Geopolitica y Medio Ambiente - Tarea 4 - Evaluacion FinalDokument7 SeitenGeopolitica y Medio Ambiente - Tarea 4 - Evaluacion FinalKATERINENoch keine Bewertungen

- 100 IdeasDokument21 Seiten100 IdeasNo ID100% (1)

- EstoqueDokument56 SeitenEstoqueGustavo OliveiraNoch keine Bewertungen

- 8. Nguyễn Tất Thành- Kon TumDokument17 Seiten8. Nguyễn Tất Thành- Kon TumK60 TRẦN MINH QUANGNoch keine Bewertungen

- Ccu 3900alDokument3 SeitenCcu 3900alTourchianNoch keine Bewertungen

- @InglizEnglish-4000 Essential English Words 6 UzbDokument193 Seiten@InglizEnglish-4000 Essential English Words 6 UzbMaster SmartNoch keine Bewertungen

- Retail Visibility Project of AircelDokument89 SeitenRetail Visibility Project of Aircelabhishekkraj100% (1)

- Lupon National Comprehensive High School Ilangay, Lupon, Davao Oriental Grade 10-Household ServicesDokument4 SeitenLupon National Comprehensive High School Ilangay, Lupon, Davao Oriental Grade 10-Household ServicesJohn Eirhene Intia BarreteNoch keine Bewertungen

- British Birds 10 LondDokument376 SeitenBritish Birds 10 Londcassy98Noch keine Bewertungen

- A Sample Script For Public SpeakingDokument2 SeitenA Sample Script For Public Speakingalmasodi100% (2)

- Amine Processing Unit DEADokument9 SeitenAmine Processing Unit DEAFlorin Daniel AnghelNoch keine Bewertungen

- Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting MachineDokument61 SeitenComputerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting MachineAmira's ClothesNoch keine Bewertungen