Beruflich Dokumente

Kultur Dokumente

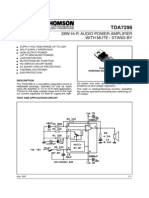

Data Sheet

Hochgeladen von

selocaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheet

Hochgeladen von

selocaCopyright:

Verfügbare Formate

tm

TE

CH

Preliminary T8300AD

PWM Control 1200mA Step-Down Converter

Built-sensitive switch hysteresis control function

FEATURES

GENERAL DESCRIPTION

Wide Input Voltage Range: 4.5V to 30V

LED Output Current Up to 1200mA

Soft-start

Single pin on/off and brightness control

using DC voltage or PWM

High efficiency (up to 97%)

CCTV IR LED Driver add CDS control

Built-sensitive switch hysteresis control

function

Up to 1MHz switching frequency

Typical 5% output current accuracy

SOP-8 Lead-free Package

The T8300AD is a continuous mode inductive

step-down converter, designed for driving

single or multiple series connected LEDs

efficiently from a voltage source higher than

the LED voltage. The device operates from an

input supply between 4.5V and 30V and

provides an externally adjustable output

current of up to 1200mA. Depending upon

supply voltage and external components, this

can provide up to 29 watts of output power.

The T8300AD includes the output switch and

a high-side output current sensing circuit,

which uses an external resistor to set the

nominal average output current. The T8300AD

is available in SOP-8 Lead-free package.

Applications

PART NUMBER EXAMPLES

LED/Display Back Light Driver

Lightings

Portable Communication Devices

Handheld Electronics

CCTV IR LED Driver

PART NO.

T8300AD

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 1

PACKAGE

SOP-8

Publication Date: Dec. 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

PIN ARRANGEMENT (Top view)

T8300AD

SOP-8

PIN DESCRIPTION

Symbol

SOP-8

Description

LX

3,4

Drain of NMOS switch

GND

5.6

Ground

CDI

CDO

ISENSE

VIN

CDS Application Input &Enable control signal, H: Active, L: Power

Down CDI longer than 3 seconds, to maintain a high voltage

Enable Application OutInput for IR Cut Driver

Connect resistor Rs from this pin to VIN to define nominal average output

current IOUTnom=0.1/Rs

Input voltage (4.5V to 30V).

Decouple to ground with 47uF or higher X7R ceramic capacitor close to

device.

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 2

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

ABSOLUTE MAXIMUM RATINGS

Parameter

Symbol

Value

Unit

VIN

-0.3 to +40

ISENSE pin Voltage

-5 to +0.3

CDI pin CDO pin Voltage

-0.3 to +6

Voltage on input pin relative to GND

Operating pn junction Temperature Range

Tj

-40 to 150

Operating Temperature Range

TA

-40 to 85

TLEAD

300

TS

-65 to +150

Power Dissipation, PD @ TA=25

SOP-8

0.8

Package Thermal Resistance, JA

SOP-8

50

/W

Maximum Soldering Temperature (at lead, 10sec)

Storage Temperature Range

Electrical Characteristics

(TA=-40 to 105 unless otherwise noted. Typical values are at TA=25, VDD=24V)

Symbol

Description

VIN

Input voltage

UVLO

Under Voltage lock out

VIRU

Internal regulator start-up threshold

VIRD

Conditions

Min.

Typ.

Max.

Unit

4.5

30

3.6

VIN rising

3.65

Internal regulator shutdown

VIN falling

3.55

IQOff

Quiescent supply current with output off

CDI&CDO pin grounded

170

uA

IQOn

Quiescent supply current with output CDI&CDO pin floating

switching

fsw= 250kHz

ISENSE

Mean current sense threshold voltage

(Defines LED current setting accuracy)

ISENTH

Sense threshold hysteresis

ISENSE

Measured on ISENSE pin with

respect to VIN,

95

System current hysteresis

IOUT=0.5A1.2A

ISENSE pin input current

VSENSE = VIN -0.1

CDO Output Voltage High

VOL CDO

CDO Output Voltage Low

CDI Positive Trigger Threshold Voltage

V CDI VP

VCDI VN

100

105

mV

%

%

10

uA

50

ppm/K

5

Output High Current

<400A

TTL OUTPUT

CDI Negatie Trigger Threshold Voltage

5

0

1.8

(Note2)

P. 3

V

0.8

2

0.8

(Note2)

TM Technology, Inc. reserves the right

to change products or specifications without notice.

mA

25

CDO Output Voltage

VOH CDO

15

VREF /T Temperature coefficient of VREF

VCDO

1.8

V

V

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

VCDI VH

Hysteresis Voltage (Note2)

1.2

T CDI VTH

High Hold up time (Note3)

VCDI 2V

1.2

T CDI VTN

Low Hold time

VCDI 0.8V

30

uS

VDT

Slow start

Vref=1.25V

300

ILXM

Continuous LX switch current(Note1)

TA=85

RLX

LX Switch On resistance

VIN12V @ILX=1.2A

SOP -8

ILXI

LX switch leakage current

TTP

Thermal Shutdown Protect

1.2

0.4

155

1.2

0.45

uA

160

TONmin

Minimum switch ON time

CDI/CDO pin floating,

L=33uH(0.093ohm)

IOUT=1.2A @VLED=3.6V

Driving 1LED

LX switch ON

TOFFmin

Minimum switch OFF time

LX switch OFF

200

ns

TPWmin

minimum switch ON time

LX switch 'ON' or OFF

800

ns

fLXmax

DLX

maximum operating frequency

Recommended duty cycle range of output

switch at Flx max

TPD

Internal comparator propagation delay

fLX

Operating frequency

280

KHz

240

ns

1

0.2

MHz

0.9

50

ns

Notes :

**Note1.Operating temperature 85 and adequate cooling conditions, the temperature, the higher the maximum

current decreasing

**Note2

CDI HYSTERESIS

**Note3

CDI&CDO Timing Diagram

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 4

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

Block Diagram

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 5

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

Functional Description

The device, in conjunction with the coil (L1) and current sense resistor (RS), forms a selfoscillating

continuous-mode buck converter.

Device operation

Operation can be best understood by assuming that the EN pin of the device is unconnected and the

voltage on this pin (VCDI) appears directly at the (+) input of the comparator

When input voltage VIN is first applied, the initial current in L1 and RS is zero and there is no

output from the current sense circuit. Under this condition, the (-) input to the comparator is at

ground and its output is high. This turns MN on and switches the LX pin low, causing current to

flow from VIN to ground, via RS, L1 and the LED(s). The current rises at a rate determined by VIN

and L1 to produce a voltage ramp (VSENSE) across RS. The supply referred voltage VSENSE is

forced across internal resistor R1 by the current sense circuit and produces a proportional current in

internal resistors R2 and R3. This produces a ground referred rising voltage at the (-) input of the

comparator.When MN is off, the current in L1 continues to flow via D1 and the LED(s) back to

VIN. The current decays at a rate determined by the LED(s) and diode forward voltages to produce a

falling voltage at the input of the comparator.

Switching thresholds

Define an average VSENSE switching threshold of 100mV (measured on the ISENSE pin with

respect to VIN). The average output current IOUTnom is then defined by this voltage and RS

according to:

IOUTnom = 100mV/RS

Nominal ripple current is 15mV/RS

Output shutdown

The output of the low pass filter drives the shutdown circuit. When the input voltage to this circuit

falls below the threshold, the internal regulator and the output switch are turned off. The voltage

reference remains powered during shutdown to provide the bias current for the shutdown circuit.

Quiescent supply current during shutdown is nominally 35uA and switch leakage is below 5uA.

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 6

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

Applications Information

Setting nominal average output current with external resistor RS

The nominal average output current in the LED(s) is determined by the value of the external current

sense resistor (RS) connected between VIN and ISENSE and is given by:

IOUTnom = 0.1/RS [for RS 0.083 ohm]

The table below gives values of nominal average output current for several preferred values of

current setting resistor (RS) in the typical application circuit :

RS (ohm)

0.083

0.125

0.2

0.285

Nominal average

1200

800

500

350

output current (mA)

The above values assume that the EN pin is floating.

Shutdown mode

Taking the CDI pin to a voltage below 0.8V for more than approximately 100us, will turn off the

output and supply current will fall to a low standby level of 35uA nominal.

Capacitor selection

A low ESR capacitor should be used for input decoupling, as the ESR of this capacitor appears in

series with the supply source impedance and lowers overall efficiency. This capacitor has to supply

the relatively high peak current to the coil and smooth the current ripple on the input supply. A

minimum value of 47uF is acceptable if the input source is close to the device, but higher values

will improve performance at lower input voltages, especially when the source impedance is high. In

order to avoid high frequency noise influence and improve circuit stability, it is recommended to

shunt a value of 0.22uF Capacitor. The input capacitor should be placed as close as possible to the

IC. For maximum stability over temperature and voltage, capacitors with X7R, X5R, or better

dielectric are recommended. Capacitors with Y5V dielectric are not suitable for decoupling in this

application and should not be used.

Inductor selection

Recommended inductor values for the T8300AD are in the range 33uH to 100uH. Higher values of

inductance are recommended at higher supply voltages in order to minimize errors due to switching

delays, which result in increased ripple and lower efficiency. Higher values of inductance also result

in a smaller change in output current over the supply voltage range. The inductor should be mounted

as close to the device as possible with low resistance connections to the LX and VIN pins. The

chosen coil should have a saturation current higher than the peak output current and a continuous

current rating above the required mean output current.

The inductor value should be chosen to maintain operating duty cycle and switch 'on'/'off' times

within the specified limits over the supply voltage and load current range.

LX switch on time : ton = LI / (VIN VLED - Iavg (RS+rL+RLX)) , note: ton min > 240ns

LX switch off time : toff = LI / (VLED + VD + Iavg (RS+rL)) , note: toff min > 200ns

Where:

L is the coil inductance (H)

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 7

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

I is the coil peak-peak ripple current (A) {Internally set to 0.3 x Iavg}

rL is the coil resistance (ohm)

RS is the current sense resistance

Iavg is the required LED current (A)

VIN is the supply voltage (V)

VLED is the total LED forward voltage (V)

RLX is the switch resistance (ohm) {=0.4 ohm nominal}

VD is the diode forward voltage at the required load current (V)

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 8

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

TYPICAL APPLICATION CIRCUITS

T8300AD

SOP-8

* note : When outputs the big current, the noise are big, this and the system environment and PCB layout have the

influential, may defer to the actual need to increase the capacitor filtration noise.

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 9

Publication Date: Dec . 2014

Revision:A

tm

TE

CH

Preliminary T8300AD

PACKAGE DIMENSIONS

8-LEAD SOP

B

B1

T h e rm a l P a d *

A1

C1

C2

F

D

Symbol

A

A1

B

B1

C

C1

C2

D

E

F

J

K

H

Min.

5.70

3.75

1.35

0

0.31

0.30

0.10

Dimension in mm

Typ.

6.00

3.95

1.27

1.55

0.41

0.50

0.15

2.23 REF

2.97 REF

0~8

Max.

6.30

4.10

5.13

1.80

1.75

0.15

0.51

0.70

0.25

Min.

0.224

0.148

0.052

0.000

0.012

0.012

0.004

Dimension in inch

Typ.

0.236

0.156

0.050

0.061

0.016

0.020

0.006

0.088 REF

0.117 REF

0~8

Max.

0.248

0.164

0.202

0.071

0.069

0.006

0.020

0.028

0.010

*Note :

The thermal pad on the ICs bottom has to be mounted on the copper foil.

To eliminate the noise influence, the thermal pad is suggested to be connected to GND on PCB.

In addition, desired thermal conductivity will be improved, if a heat-conducting copper foil on PCB is soldered with

thermal pad. The thermal pad enhances the power dissipation. As a result, a large amount of current can be sunk safely

in one package.

TM Technology, Inc. reserves the right

to change products or specifications without notice.

P. 10

Publication Date: Dec . 2014

Revision:A

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- TE CH: Features General DescriptionDokument10 SeitenTE CH: Features General DescriptionJuan VillanuevaNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- PWM Control 1A Step-Down Converter Data Sheet: TM Technology IncDokument12 SeitenPWM Control 1A Step-Down Converter Data Sheet: TM Technology IncselocaNoch keine Bewertungen

- PT4115 89eDokument15 SeitenPT4115 89eAnonymous aDAfzvNoch keine Bewertungen

- PT4115EDokument18 SeitenPT4115Edragom2Noch keine Bewertungen

- 700ma H V A C R W E C: IGH Oltage Djustable Urrent Egulator ITH Nable OntrolDokument6 Seiten700ma H V A C R W E C: IGH Oltage Djustable Urrent Egulator ITH Nable OntrolNathan WilliamsNoch keine Bewertungen

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- Tl082cp Datasheet de National Semiconductor para Sustituir Ci de Etapa Pre Amplificador Bunker Mx2400 2Dokument12 SeitenTl082cp Datasheet de National Semiconductor para Sustituir Ci de Etapa Pre Amplificador Bunker Mx2400 2Jess AJNoch keine Bewertungen

- TL082 EqualizerDokument16 SeitenTL082 EqualizerMecabot DzibNoch keine Bewertungen

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDokument10 SeitenNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNoch keine Bewertungen

- OpAmp - LF451Dokument8 SeitenOpAmp - LF451Ludwig SchmidtNoch keine Bewertungen

- TL081Dokument9 SeitenTL081Vero PorrasNoch keine Bewertungen

- Boost Controller With Power Factor CorrectionDokument14 SeitenBoost Controller With Power Factor CorrectionChiseledPrawnNoch keine Bewertungen

- tl082cp DatasheetDokument15 Seitentl082cp DatasheetHeriberto Flores AmpieNoch keine Bewertungen

- LM324 OpampDokument9 SeitenLM324 OpampYuvarajaNoch keine Bewertungen

- Thyristor Control Heater Panel GuideDokument63 SeitenThyristor Control Heater Panel Guidevaithy1990Noch keine Bewertungen

- BM2596Dokument9 SeitenBM2596Anton AdrianNoch keine Bewertungen

- Aerosemi: Features ApplicationsDokument9 SeitenAerosemi: Features Applicationsttnaing100% (1)

- LM 1875Dokument13 SeitenLM 1875pblhnrqNoch keine Bewertungen

- Dual Half Bridge Driver: Multipower BCD TechnologyDokument9 SeitenDual Half Bridge Driver: Multipower BCD TechnologyDan EsentherNoch keine Bewertungen

- TC120 PWM/PFM Step-Down Combination Regulator/Controller: Features General DescriptionDokument12 SeitenTC120 PWM/PFM Step-Down Combination Regulator/Controller: Features General DescriptionRijal SaifurNoch keine Bewertungen

- Pam8610 PDFDokument15 SeitenPam8610 PDFRaka Satria PradanaNoch keine Bewertungen

- lx1692 PDFDokument15 Seitenlx1692 PDFvideosonNoch keine Bewertungen

- Features Description: LT3085 Adjustable 500ma Single Resistor Low Dropout RegulatorDokument28 SeitenFeatures Description: LT3085 Adjustable 500ma Single Resistor Low Dropout Regulatoram1liNoch keine Bewertungen

- Valley Current Mode Control Buck Converter: Description Features and BenefitsDokument15 SeitenValley Current Mode Control Buck Converter: Description Features and BenefitsAlfonso MercadoNoch keine Bewertungen

- TD1501Dokument18 SeitenTD1501Hernando GamaNoch keine Bewertungen

- Act 4065Dokument9 SeitenAct 4065bob75Noch keine Bewertungen

- ZXSC410 420Dokument12 SeitenZXSC410 420Catalin TirtanNoch keine Bewertungen

- AOZ1021AIDokument15 SeitenAOZ1021AIJohnny La Mesa100% (1)

- TP2L-3W - 3KVDCDokument3 SeitenTP2L-3W - 3KVDCtoppowerNoch keine Bewertungen

- Line Regulator Controller: Features General DescriptionDokument16 SeitenLine Regulator Controller: Features General DescriptionfuzulibabaNoch keine Bewertungen

- Xtr117 Current Loop TransmiterDokument17 SeitenXtr117 Current Loop TransmiterGerman GodiNoch keine Bewertungen

- Ame 1085Dokument17 SeitenAme 1085Eduardo GarcíaNoch keine Bewertungen

- tl082 Op Amp DatasheetDokument23 Seitentl082 Op Amp DatasheetnurburgNoch keine Bewertungen

- 7805 Regulator DatasheetDokument11 Seiten7805 Regulator DatasheetPrabeesh P PrasanthiNoch keine Bewertungen

- TSM 101Dokument15 SeitenTSM 101thiemncNoch keine Bewertungen

- SI 3010KM DatasheetDokument9 SeitenSI 3010KM DatasheetAndres GuioNoch keine Bewertungen

- XX3842 Series FunctionDokument7 SeitenXX3842 Series FunctionbernabethNoch keine Bewertungen

- LM341, LM78M05, LM78M12, LM78M15: LM341/LM78MXX Series 3-Terminal Positive Voltage RegulatorsDokument13 SeitenLM341, LM78M05, LM78M12, LM78M15: LM341/LM78MXX Series 3-Terminal Positive Voltage RegulatorskevharveyNoch keine Bewertungen

- Unisonic Technologies Co., LTD: Low Noise Quad J-Fet Operational AmplifierDokument5 SeitenUnisonic Technologies Co., LTD: Low Noise Quad J-Fet Operational Amplifiergaldos08Noch keine Bewertungen

- Richtek RT7247ADokument15 SeitenRichtek RT7247Ajhg-crackmeNoch keine Bewertungen

- PT1301Dokument9 SeitenPT1301dcastrelos2000Noch keine Bewertungen

- Datasheet LF 353Dokument14 SeitenDatasheet LF 353Anggridho MeilandanuNoch keine Bewertungen

- Iso122sensor de TensionDokument15 SeitenIso122sensor de TensionRichard ZerpaNoch keine Bewertungen

- Ace 701331anDokument13 SeitenAce 701331ansivakrishna8055Noch keine Bewertungen

- Data Sheet: TDA8380ADokument21 SeitenData Sheet: TDA8380Ajvazquez501Noch keine Bewertungen

- Linear Integrated Circuit: 1A Low Dropout Positive Voltage RegulatorDokument7 SeitenLinear Integrated Circuit: 1A Low Dropout Positive Voltage RegulatorRogério Machiaveli SavellaNoch keine Bewertungen

- 600Khz, 18V 2.0A Synchronous Step-Down Converter: Features General DescriptionDokument8 Seiten600Khz, 18V 2.0A Synchronous Step-Down Converter: Features General DescriptionalfredoNoch keine Bewertungen

- 28W Hi-Fi Audio Power Amplifier With Mute / Stand-By: DescriptionDokument11 Seiten28W Hi-Fi Audio Power Amplifier With Mute / Stand-By: DescriptionbaczonifNoch keine Bewertungen

- Ic 3843Dokument4 SeitenIc 3843nishatiwari82Noch keine Bewertungen

- Green Mode PWM Controller Ap384XgDokument13 SeitenGreen Mode PWM Controller Ap384XgbaphometabaddonNoch keine Bewertungen

- Mp1423 - MonolithicPowerDokument11 SeitenMp1423 - MonolithicPowerJuanKaNoch keine Bewertungen

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDokument9 Seiten20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66Noch keine Bewertungen

- STCC05-B: Home Appliance Control CircuitDokument13 SeitenSTCC05-B: Home Appliance Control Circuitsvhanu4010Noch keine Bewertungen

- LM1875TDokument11 SeitenLM1875TEdgar RodriguezNoch keine Bewertungen

- Pam8403 PDFDokument11 SeitenPam8403 PDFShahzad RafiqNoch keine Bewertungen

- DatasheetDokument6 SeitenDatasheetselocaNoch keine Bewertungen

- DatasheetDokument4 SeitenDatasheetselocaNoch keine Bewertungen

- DatasheetDokument4 SeitenDatasheetselocaNoch keine Bewertungen

- 4-/6-Channel Digital Potentiometers:, 50 K, 100 K 2.7 V Dual SupplyDokument11 Seiten4-/6-Channel Digital Potentiometers:, 50 K, 100 K 2.7 V Dual SupplyselocaNoch keine Bewertungen

- Si1433DH: Vishay SiliconixDokument5 SeitenSi1433DH: Vishay SiliconixselocaNoch keine Bewertungen

- DatasheetDokument2 SeitenDatasheetselocaNoch keine Bewertungen

- DatasheetDokument80 SeitenDatasheetselocaNoch keine Bewertungen

- DC Cooling Fan 60x60x25mm: Fax: 01371 875075 WWW - Dubilier.co - Uk Tel: 01371 875758Dokument1 SeiteDC Cooling Fan 60x60x25mm: Fax: 01371 875075 WWW - Dubilier.co - Uk Tel: 01371 875758selocaNoch keine Bewertungen

- DatasheetDokument35 SeitenDatasheetselocaNoch keine Bewertungen

- External Dimensions: Fan Accessories Metal Finger GuardDokument1 SeiteExternal Dimensions: Fan Accessories Metal Finger GuardselocaNoch keine Bewertungen

- Data SheetDokument4 SeitenData SheetselocaNoch keine Bewertungen

- LM324 Quad Differential Input Operational Amplifier: Features Pin ArrangementDokument2 SeitenLM324 Quad Differential Input Operational Amplifier: Features Pin ArrangementselocaNoch keine Bewertungen

- DatasheetDokument6 SeitenDatasheetselocaNoch keine Bewertungen

- Type: CAA373: Product DescriptionDokument1 SeiteType: CAA373: Product DescriptionselocaNoch keine Bewertungen

- DatasheetDokument9 SeitenDatasheetselocaNoch keine Bewertungen

- 32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen FreeDokument9 Seiten32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen FreeselocaNoch keine Bewertungen

- DatasheetDokument3 SeitenDatasheetselocaNoch keine Bewertungen

- Data SheetDokument3 SeitenData SheetselocaNoch keine Bewertungen

- Mplifiers: Broadband Small Signal Amplifiers 0. 5 To 18GhzDokument3 SeitenMplifiers: Broadband Small Signal Amplifiers 0. 5 To 18GhzselocaNoch keine Bewertungen

- DatasheetDokument9 SeitenDatasheetselocaNoch keine Bewertungen

- 1767vol IIIDokument183 Seiten1767vol IIIKrishna ManandharNoch keine Bewertungen

- Unit - 3 MCQ'sDokument7 SeitenUnit - 3 MCQ'srishavr2001Noch keine Bewertungen

- Password Based Circuit BreakerDokument4 SeitenPassword Based Circuit Breakersulthan_81100% (1)

- FAX30 Service Manual B3 12-15-10Dokument34 SeitenFAX30 Service Manual B3 12-15-10Leovard69Noch keine Bewertungen

- Datasheetumix U5Dokument2 SeitenDatasheetumix U5AlexNoch keine Bewertungen

- EEE 312 Lecture1Dokument11 SeitenEEE 312 Lecture1Zeynal Abidin ŞabaşNoch keine Bewertungen

- Extruder Flowchart AnderitzDokument8 SeitenExtruder Flowchart AnderitzThien NguyenngocNoch keine Bewertungen

- Terminal Date Sheet-Fall21Dokument7 SeitenTerminal Date Sheet-Fall21Tayyab ShahzadNoch keine Bewertungen

- Elements of Technology (Eot) : Assignment 3Dokument38 SeitenElements of Technology (Eot) : Assignment 3nikitaNoch keine Bewertungen

- Bpac SLDokument84 SeitenBpac SLROHITH BKNoch keine Bewertungen

- Lec 1Dokument17 SeitenLec 1mezo4326Noch keine Bewertungen

- ED3CC2-ID21V1 (SkyAir R32 Non-Inverter - Ceiling Concealed FDMC - AV14 + RC - AV (Y) 14)Dokument36 SeitenED3CC2-ID21V1 (SkyAir R32 Non-Inverter - Ceiling Concealed FDMC - AV14 + RC - AV (Y) 14)marsetioNoch keine Bewertungen

- RS603MDokument3 SeitenRS603Melkin_oviedoNoch keine Bewertungen

- Vector Group of Transformer - Electrical Notes & ArticlesDokument22 SeitenVector Group of Transformer - Electrical Notes & ArticlesManoj Kumar PadmanabanNoch keine Bewertungen

- Dac7611 Ic DatasheetDokument14 SeitenDac7611 Ic Datasheetriddhishukla025Noch keine Bewertungen

- Barreras de Seguridad Intrinseca RocwellDokument68 SeitenBarreras de Seguridad Intrinseca RocwellZuñiga AntonioNoch keine Bewertungen

- Winpower Standby Troubleshooting GuideDokument4 SeitenWinpower Standby Troubleshooting GuideosanebiNoch keine Bewertungen

- Electrical Safety ChecklistDokument2 SeitenElectrical Safety ChecklistMohamad ShariinNoch keine Bewertungen

- Time To Digital Converter SlidesDokument12 SeitenTime To Digital Converter SlidesburakgonenNoch keine Bewertungen

- Electronics RegularDokument169 SeitenElectronics RegularNazeerNoch keine Bewertungen

- NCP81253 5 V MOSFET Driver Compatible With Single-Phase IMVP8 ControllersDokument11 SeitenNCP81253 5 V MOSFET Driver Compatible With Single-Phase IMVP8 ControllersTom TomNoch keine Bewertungen

- Darlington: Silicon NPN Triple Diffused Planar TransistorDokument1 SeiteDarlington: Silicon NPN Triple Diffused Planar TransistorsilvertronicNoch keine Bewertungen

- PX4211 1Dokument3 SeitenPX4211 1kalpanaNoch keine Bewertungen

- 7SR45 Argus Catalogue SheetDokument16 Seiten7SR45 Argus Catalogue Sheetmuhammad zakirNoch keine Bewertungen

- MR-1010R2 Im Eng 0 PDFDokument72 SeitenMR-1010R2 Im Eng 0 PDFRobin LalNoch keine Bewertungen

- Jint-G1C R8-Frame 380-500V Coated Main Circuit Board Jint: Product-DetailsDokument4 SeitenJint-G1C R8-Frame 380-500V Coated Main Circuit Board Jint: Product-DetailsAlessandro DamascenoNoch keine Bewertungen

- As 60974.11-2005 Arc Welding Equipment Electrode HoldersDokument8 SeitenAs 60974.11-2005 Arc Welding Equipment Electrode HoldersSAI Global - APACNoch keine Bewertungen

- Thermal Power Plant Simulator TPP 200 Laboratory Exercise Tutorial N1: Rolling Up of Turbine Train and Connection of Generator To The GridDokument13 SeitenThermal Power Plant Simulator TPP 200 Laboratory Exercise Tutorial N1: Rolling Up of Turbine Train and Connection of Generator To The GridPriyajit SahooNoch keine Bewertungen

- APFCDokument12 SeitenAPFCpandiNoch keine Bewertungen

- Wave Propagation On Metallic Transmission LinesDokument3 SeitenWave Propagation On Metallic Transmission LinesAnkita AgarwalNoch keine Bewertungen

- Summary: Trading in the Zone: Trading in the Zone: Master the Market with Confidence, Discipline, and a Winning Attitude by Mark Douglas: Key Takeaways, Summary & AnalysisVon EverandSummary: Trading in the Zone: Trading in the Zone: Master the Market with Confidence, Discipline, and a Winning Attitude by Mark Douglas: Key Takeaways, Summary & AnalysisBewertung: 5 von 5 Sternen5/5 (15)

- I Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Von EverandI Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Bewertung: 4.5 von 5 Sternen4.5/5 (13)

- The Millionaire Fastlane, 10th Anniversary Edition: Crack the Code to Wealth and Live Rich for a LifetimeVon EverandThe Millionaire Fastlane, 10th Anniversary Edition: Crack the Code to Wealth and Live Rich for a LifetimeBewertung: 4.5 von 5 Sternen4.5/5 (90)

- Summary: The Gap and the Gain: The High Achievers' Guide to Happiness, Confidence, and Success by Dan Sullivan and Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisVon EverandSummary: The Gap and the Gain: The High Achievers' Guide to Happiness, Confidence, and Success by Dan Sullivan and Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisBewertung: 5 von 5 Sternen5/5 (4)

- Summary of 10x Is Easier than 2x: How World-Class Entrepreneurs Achieve More by Doing Less by Dan Sullivan & Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisVon EverandSummary of 10x Is Easier than 2x: How World-Class Entrepreneurs Achieve More by Doing Less by Dan Sullivan & Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (24)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedVon EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedBewertung: 5 von 5 Sternen5/5 (81)

- Quotex Success Blueprint: The Ultimate Guide to Forex and QuotexVon EverandQuotex Success Blueprint: The Ultimate Guide to Forex and QuotexNoch keine Bewertungen

- The Millionaire Fastlane: Crack the Code to Wealth and Live Rich for a LifetimeVon EverandThe Millionaire Fastlane: Crack the Code to Wealth and Live Rich for a LifetimeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Sleep And Grow Rich: Guided Sleep Meditation with Affirmations For Wealth & AbundanceVon EverandSleep And Grow Rich: Guided Sleep Meditation with Affirmations For Wealth & AbundanceBewertung: 4.5 von 5 Sternen4.5/5 (105)

- Rich Dad Poor Dad: What the Rich Teach Their Kids About Money That the Poor and Middle Class Do NotVon EverandRich Dad Poor Dad: What the Rich Teach Their Kids About Money That the Poor and Middle Class Do NotNoch keine Bewertungen

- Financial Intelligence: How to To Be Smart with Your Money and Your LifeVon EverandFinancial Intelligence: How to To Be Smart with Your Money and Your LifeBewertung: 4.5 von 5 Sternen4.5/5 (540)

- Broken Money: Why Our Financial System Is Failing Us and How We Can Make It BetterVon EverandBroken Money: Why Our Financial System Is Failing Us and How We Can Make It BetterBewertung: 5 von 5 Sternen5/5 (3)

- Unshakeable: Your Financial Freedom PlaybookVon EverandUnshakeable: Your Financial Freedom PlaybookBewertung: 4.5 von 5 Sternen4.5/5 (618)

- Meet the Frugalwoods: Achieving Financial Independence Through Simple LivingVon EverandMeet the Frugalwoods: Achieving Financial Independence Through Simple LivingBewertung: 3.5 von 5 Sternen3.5/5 (67)

- A Happy Pocket Full of Money: Your Quantum Leap Into The Understanding, Having And Enjoying Of Immense Abundance And HappinessVon EverandA Happy Pocket Full of Money: Your Quantum Leap Into The Understanding, Having And Enjoying Of Immense Abundance And HappinessBewertung: 5 von 5 Sternen5/5 (159)

- The Wyckoff Methodology in Depth: How to trade financial markets logicallyVon EverandThe Wyckoff Methodology in Depth: How to trade financial markets logicallyBewertung: 5 von 5 Sternen5/5 (28)

- Bitter Brew: The Rise and Fall of Anheuser-Busch and America's Kings of BeerVon EverandBitter Brew: The Rise and Fall of Anheuser-Busch and America's Kings of BeerBewertung: 4 von 5 Sternen4/5 (52)

- A History of the United States in Five Crashes: Stock Market Meltdowns That Defined a NationVon EverandA History of the United States in Five Crashes: Stock Market Meltdowns That Defined a NationBewertung: 4 von 5 Sternen4/5 (11)

- The Holy Grail of Investing: The World's Greatest Investors Reveal Their Ultimate Strategies for Financial FreedomVon EverandThe Holy Grail of Investing: The World's Greatest Investors Reveal Their Ultimate Strategies for Financial FreedomBewertung: 5 von 5 Sternen5/5 (7)

- Summary of I Will Teach You to Be Rich: No Guilt. No Excuses. Just a 6-Week Program That Works by Ramit SethiVon EverandSummary of I Will Teach You to Be Rich: No Guilt. No Excuses. Just a 6-Week Program That Works by Ramit SethiBewertung: 4.5 von 5 Sternen4.5/5 (23)

- Baby Steps Millionaires: How Ordinary People Built Extraordinary Wealth--and How You Can TooVon EverandBaby Steps Millionaires: How Ordinary People Built Extraordinary Wealth--and How You Can TooBewertung: 5 von 5 Sternen5/5 (324)

- The 4 Laws of Financial Prosperity: Get Conrtol of Your Money Now!Von EverandThe 4 Laws of Financial Prosperity: Get Conrtol of Your Money Now!Bewertung: 5 von 5 Sternen5/5 (389)

- Fluke: Chance, Chaos, and Why Everything We Do MattersVon EverandFluke: Chance, Chaos, and Why Everything We Do MattersBewertung: 4.5 von 5 Sternen4.5/5 (20)

- Rich Bitch: A Simple 12-Step Plan for Getting Your Financial Life Together . . . FinallyVon EverandRich Bitch: A Simple 12-Step Plan for Getting Your Financial Life Together . . . FinallyBewertung: 4 von 5 Sternen4/5 (8)

- Rich Dad's Cashflow Quadrant: Guide to Financial FreedomVon EverandRich Dad's Cashflow Quadrant: Guide to Financial FreedomBewertung: 4.5 von 5 Sternen4.5/5 (1387)

- Financial Literacy for All: Disrupting Struggle, Advancing Financial Freedom, and Building a New American Middle ClassVon EverandFinancial Literacy for All: Disrupting Struggle, Advancing Financial Freedom, and Building a New American Middle ClassNoch keine Bewertungen