Beruflich Dokumente

Kultur Dokumente

Kertas Penerangan Update (KP) Kbs

Hochgeladen von

Mohd Ezuan AtokOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kertas Penerangan Update (KP) Kbs

Hochgeladen von

Mohd Ezuan AtokCopyright:

Verfügbare Formate

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 1 drpd 11

INSTITUT KEMAHIRAN BELIA NEGARA

KEMENTERIAN BELIA DAN SUKAN

KERTAS PENERANGAN

(INFORMATION SHEET)

KOD DAN NAMA

PROGRAM /

PROGRAMS CODE &

HT-013-2:2011 BAKERY PRODUCTION

NAME

TAHAP / LEVEL

2 (TWO)

KOD DAN TAJUK UNIT

KOMPETENSI /

COMPETENCY UNIT

HT-013-2:2011(C06) MUFFIN PREPARATION

CODE AND TITLE

NO. DAN PENYATAAN

AKTIVITI KERJA / WORK

ACTIVITIES NO. AND

STATEMENT

1.

2.

3.

4.

5.

6.

IDENTIFY MUFFIN PREPARATION REQUIREMENTS

PREPARE MUFFIN MISE EN PLACE

CARRY OUT MUFFIN PREPARATION

CHECK MUFFIN QUALITY AND QUANTITY

CARRY OUT MUFFIN FINISHING WORK

RECORD MUFFIN PREPARATION ACTIVITIES

ID UNIT KOMPETENSI /

COMPETENCY UNIT ID

HT-013-2:2011(C06)/KP(1/7)

TITLE

: SAFETY, HEALTH AND HYGIENE PRACTICES GUIDELINES

OBJECTIVE

: TO OBTAIN KNOWLEDGE ON MUFFIN SAFETY, HEALTH AND HYGIENE

PRACTICES GUIDELINES.

Cawangan Pembangunan Kurikulum

2014 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 2 drpd 11

INFORMATION:

1. Introduction to Food Safety.

The bakery business can be an enjoyable and rewarding profession, but some bakery

processes can also be hazardous. Persons who work in bakery operations should be

instructed in how to avoid or prevent potential hazards and be properly trained to follow

recommended safe work practices.

Slips and falls are common bakery accidents due to wet floors, spilled dough, batter,

and dry ingredients, as well as uneven or obstructed floor surfaces. Stack materials

neatly to keep walkways and production areas clear. Immediately clean up spills and

post warning signs when floors are wet or slippery. Use a degreasing solution on oil and

grease spills. Gets safety training on use of ladders and stepstools. Slip-resistant floor

coverings and shoe soles prevent slips and falls.

Bakery equipment such as moving blades, mixing arms, and conveyors on dough

brakes, pie and tart machines, mixers, rollers and dividers pose cutting and

caught/crush hazards. Maintain equipment in good condition. Guard moving and sharp

parts. Keep equipment clearances to avoid accidentally bumping into moving parts. Use

safety devices such as power interlocks, two-handed controls, and emergency-stop

bars. Practice lockout/tag out during maintenance and cleaning. Place warning signs on

equipment with moving equipment dangers.

Breathing flour dust can cause asthma and nose, throat, and eye irritation. Repeated

exposure to flour and dough can sensitize skin. Control flour dust with enclosed storage

bins, adequate ventilation, and enclosed mixing. Dont sweep flour from floors; use a

high-efficiency vacuum cleaner or wet mopping. Clean work surfaces throughout the day

to prevent dough and flour buildup. Use a nuisance dust mask if flour dust cannot be

controlled. Gloves and long sleeves protect your hands and arms from dough and flour

exposure.

2. OSHA

2.1 Definitions

OSHA or Occupational Safety and Health Administration, founded in 1993 was

initially formed to provide a general occupational safety & health consulting & training

offerings to the business within Malaysia. The Occupational Safety and Health Act is an

Act which provides the legislative framework to secure the safety, health and welfare

among all Malaysian workforces and to protect others against risks to safety or health in

connection

with

the

activities

of

persons

at

work.

This Act was gazette on 24th February 1994 and was cited as the Occupational Safety

and Health Act 1994. This Act is a practical tool superimposed on existing safety and

health legislation.

The aims of this Act are to:

Cawangan Pembangunan Kurikulum

2014 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 3 drpd 11

secure the safety, health and welfare of persons at work against risks to safety or

health arising out of the activities of persons at work

protect person at a place of work other than persons at work against risks to safety or

health arising out of the activities of persons at work

promote an occupational environment for persons at work which is adapted to their

physiological and psychological needs

Provide the means whereby the associated occupational safety and health legislation

may be progressively replaced by a system of regulations and approved industry

codes of practice operating in combination with the provisions of this Act designed to

maintain or improve the standards of safety and health.

OSHA's mission is to "assure safe and healthful working conditions for working men

and women by setting and enforcing standards and by providing training, outreach,

education and assistance

2.2 OSHA Standards

OSHA standards are rules that describe the methods that employers must use to

protect their employees from hazards. These standards limit the amount of hazardous

chemicals workers can be exposed to, require the use of certain safe practices and

equipment, and require employers to monitor hazards and keep records of workplace

injuries and illnesses.

Examples of OSHA standards include requirements to: provide fall protection, prevent

trenching cave-ins, prevent infectious diseases, ensure that workers safely enter

confined spaces, prevent exposure to harmful substances like asbestos, put guards on

machines, provide respirators or other safety equipment, and provide training for

certain dangerous jobs.

Employers must also comply with the General Duty Clause of the OSH Act, which

requires employers to keep their workplace free of serious recognized hazards. This

clause is generally cited when no OSHA standard applies to the hazard.

The Occupational Safety and Health Act 1994 is enforced by the Department of

Occupational Safety and Health (DOSH), a government department under the Ministry

of Human Resources Malaysia.

Department of Occupational Safety and Health (DOSH) will ensure through enforcement

and promotional works that employers, self-employed persons, manufacturers,

designers, importers, suppliers and employees always practice safe and health work

culture, and always comply with existing legislation, guidelines and codes of practice.

Department of Occupational Safety and Health (DOSH) will also formulate and review

legislation, policies, guidelines and codes of practice pertaining to occupational safety,

health and welfare as a basis in ensuring safety and health at work.

Department of Occupational Safety and Health (DOSH) is also the secretariat to

National Council for Occupational Safety and Health, a council established under

section 8 of the Occupational Safety and Health Act 1994.

Cawangan Pembangunan Kurikulum

2012 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 4 drpd 11

The National Council for Occupational Safety and Health shall have power to do all

things expedient or reasonably necessary for or incidental to the carrying out of the

objects of this Act.

3. Environmental Quality Act 1974 (Act127)

3.1 Definition

The legislation is related to the prevention, abatement, control of pollution and

enhancement of the environment in compliance with the government standards.

Malaysia has had environmentally-related legislation since the early 1920s But the

legislation is limited in scope and inadequate for handling complex emerging

environmental problems. So through EQA, 1974, a more comprehensive form of

legislation and an agency to control pollution was established.

EQA is an enabling piece of legislation for preventing, abating and controlling pollution,

and enhancing the environment, or for other related purposes. Pollution, as declared in

EQA, includes the direct or indirect alteration of any quality of the environment or any

part of it by means of a positive act or act of omission.

Pollution is controlled through the mechanism of licenses issued by the Department of

Environment. The mode of control is by prescribing, by means of a ministerial

regulation, that licenses are mandatory for:

The use and occupation of prescribed premises;

Discharging or emitting wastes exceeding acceptable conditions into the

atmosphere, as well as noise pollution, polluting or causing the pollution of any soil

or surface of any land;

Emitting, discharging or depositing any wastes or oil, in excess of acceptable

conditions, into inland waters or Malaysian waters.

The provision of "acceptable conditions" is controversial because the polluter is not

liable for prosecution if the discharges are within those acceptable conditions, even if

the effluents are sufficient to severely damage the environment. Most people adversely

affected by pollution do not want to seek legal remedy through common law because of

the prolonged nature of such hearings and the costs incurred.

Currently, 16 sets of regulations and orders are enforced by the Department of

Environment under EQA. Despite government efforts to implement environmental laws

and regulations, it has been found that enforcement measures need to be further

enhanced to ensure the full compliance with laws and regulations. With regard to

monitoring and enforcement, surveillance capability will be strengthened. The penalty

structure related to environment offences will be revised to ensure a more effective

deterrent, especially in the case of repeat offenders. The enforcement function of

agencies such as the Department of Environment, Health Department, Pesticide Board

and local authorities will be rationalized and streamlined, and adequate training will be

provided for their enforcement staff.

Environmental laws and regulations

Cawangan Pembangunan Kurikulum

2014 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 5 drpd 11

One of the three strategies embodied in EQA, 1974, is for the regulation of pollution.

The other two strategies are for preventing and abating any form of pollution. To bring

the law and other environmentally-related laws into effect, the laws and regulations

listed below have been introduced and are strictly enforced by the Department of

Environment.

(i)

Control of agro-based water pollution

Environmental Quality (Licensing) Regulations, 1977

Environmental Quality (Prescribed Premises) (Crude Palm Oil) Order, 1977

Environmental Quality (Prescribed Premises) (Crude Palm Oil) Regulations,

1977, and (Amendment) 1982

Environmental Quality (Prescribed Premises) (Raw Natural Rubber) Order, 1978

Environmental Quality (Prescribed Premises) (Raw Natural Rubber) Regulations,

1978

(ii) Control of municipal and industrial waste water pollution

Environmental Quality (Sewage and Industrial Effluents) Regulations, 1979

Environmental Quality (Prohibition on the Use of Controlled Substance in Soap,

Synthetic Detergent and Other Cleaning Agents) Order, 1995

(iii) Control of industrial emissions

Environmental Quality (Clean Air) Regulations, 1978

Environmental Quality (Compounding of Offenses) Rules, 1978

(iv) Control of motor vehicle emissions

Motor Vehicles (Control of Smoke and Gas Emission) Rules, 1977 (made under

the Road Traffic Ordinance of 1958)

Environmental Quality (Control of Lead Concentration in Motor Gasoline)

Regulations, 1985

Environmental Quality (Motor Vehicle Noise) Regulations, 1987

(v) Control of toxic and hazardous waste management

Environmental Quality (Scheduled Wastes) Regulations, 1989

Environmental Quality (Prescribed Premises) (Scheduled Wastes Treatment and

Disposal Facilities) Order, 1989

Environmental Quality (Prescribed Premises) (Scheduled Wastes Treatment and

Disposal Facilities) Regulations, 1989

Promotion of Investments (Promoted Activities and Products) (Amendment) (No.

10) Order, 1990 (made under the Promotion of Investments Act, 1986)

4. HACCP

4.1 Definition

Cawangan Pembangunan Kurikulum

2012 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 6 drpd 11

Hazard Analysis And Critical Control Points, or HACCP, is a systematic

preventive approach to food safety and pharmaceutical safety that identifies

physical, chemical, and biological hazards in production processes that can

cause the finished product be unsafe, and designs measurements to reduce

these risks to a safe level. In this manner, HACCP is referred as the prevention

of hazards rather than finished product inspection.

4.2 Hazard Analysis

A hazard is anything which may cause harm to your customers.

There are three types of hazards: biological

chemical

physical

4.2.1 Biological Hazards

Biological hazard include food poisoning bacteria such as

Salmonella, E-coli and Bacillus cereus, which are hazardous

because they can: Survive inadequate cooking

Multiply to harmful levels in food given the right conditions

Spread from raw foods to ready to eat foods (cross contamination)

4.2.2 Chemical Hazards

Chemical hazards may be present on certain foods in the form of

pesticides or cleaning residues.

Chemical hazards may also arise from incorrect storage and misuse of

cleaning chemicals or rodent bait. Not using food grade equipment may

also contaminate the food.

4.2.3 Physical Hazards

Physical hazards include contamination from foreign bodies like glass,

wood, metal, hair, flies etc.

To identify all the hazards associated within your business, you may

wish to consider what

process steps are applicable to your business.

You will then need to think about the three hazards at each

stage/ process step of your operation.

4.3 Process steps

Cawangan Pembangunan Kurikulum

2014 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 7 drpd 11

This is a stage in the business operation to produce a certain food.

You will need to think what stages are applicable to your business and either

takes a generic or specific approach to the foods you produce.

For example; purchase/ receipt/ collect

delivery

storage

preparation

cooking

cooling

storage

service

4.3.1 Critical Control Points (CCPs)

CCPs are the stage of your process where the hazards must be

controlled for the food to be safe to eat.

a. Critical Limit

Critical limits are specified safety limits at your CCPs

which separates acceptable (safe food) from unacceptable

(unsafe food).

Critical limits are usually numerical values based on

scientific finding. Example: Critical limit for the storage of

food in a fridge.

0-5C

8C

10C

this is good practice but the food stored at

this temperature is not critical

this is the critical limit

this has exceeded the critical limit and is

potentially

4.3.2 Monitoring

Monitoring produces would need to be established to ensure

hazards are controlled at CCPs. Such monitoring activity

may involve temperature checks, visual inspection and time

recording.

4.3.3 Corrective Action

Corrective action are produces to be taken when monitoring

(at CCPs) has identified that the critical limit has been or is

Cawangan Pembangunan Kurikulum

2012 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 8 drpd 11

likely to be exceeded.

Such action must either make the food safe or prevent its

entry into the food chain.

For example, the fridge temperature is 10C. Your corrective

action may state to; re-monitor in one hour, relocate the food

to another fridge operating at or below 8C, call the

Manager/owner, call the fridge engineer.

4.3.4 Verification

This involves taking an overview of your HACCP based system to

ensure it is working effectively.

It is checking that the checks already done at true and effective at

controlling your hazard.

For example, Managers weekly checks and food sampling would

be

verification procedures.

4.3.5 Documentation

A HACCP based system must have appropriate documentation to

demonstrate it is working effectively.

These will usually incorporate HACCP charts, work instructions,

written procedures/ policies,

training record, monitoring records, sampling records, invoices,

receipts etc.

4.3.6 Review

To ensure the HACCP is working effectively, it is important to review

the food safety system at regular intervals. This may be when there is

a change of menu, a complaint, a new product, a new premise or a

visit from the Environmental Health Officer. It is good practice to

review the system at least once a year.

Establishing an HACCP system

Identify hazards and assess their severity and risk

Determine critical control points (CCPs)

Establish critical limits

Establish a system to monitor the control of the CCPs)

Establish corrective action to be taken whenever monitoring indicates that a CCP is not under

control)

Cawangan Pembangunan Kurikulum

2014 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 9 drpd 11

Establish procedures to verify that the HACCP system is working effectively

Confirm documentation in place for all procedures and records needed for an effective HACCP

system

5. Good Manufacturing Practices (GMP)

5.1 Definitions

Good Manufacturing Practices (GMP) certification is a scheme which can assist

manufacturers of food products and food related products to provide assurance

to their customers that their products are manufactured in a hygienic manner and

in accordance to best practices in manufacturing.

Since GMP is one of the pre-requisite programmes (PRP) required to be

established before Hazard Analysis and Critical Control Points (HACCP) can be

implemented, having GMP certification would definitely pave the way to an easier

HACCP implementation and certification.

Generally, GMP consists of aspect such as design and facilities in the

establishment, control of operations by equipment, temperature, time, pH or

water activity control, maintenance and sanitation, personal hygiene, personnel

training, transportation, conveyors, product information and consumer

awareness. In short, it comprises the basic requirements of a manufacturing

facility covering establishment, infrastructure, equipment design, construction,

maintenance, process controls and personnel hygiene and awareness.

MS 1514 is the standard for prescribing the requirements of pre-requisite

programmes which is required to be established before the implementation of

HACCP. The standard is applicable to all food manufacturers, primary and

secondary processors, food catering and service operators, food retailers and

food related industries

A good manufacturing practice (GMP) is a production and testing practice that helps to

ensure a quality product. Many countries have legislated that pharmaceutical and

medical device companies must follow GMP procedures, and have created their own

GMP guidelines that correspond with their legislation. Basic concepts of all of these

guidelines remain more or less similar to the ultimate goals of safeguarding the health of

the patient as well as producing good quality medicine, medical devices or active

pharmaceutical products. In the U.S. a drug may be deemed adulterated if it passes all

of the specifications tests but is found to be manufactured in a condition which violates

current good manufacturing guidelines. Therefore, complying with GMP is a mandatory

aspect in pharmaceutical manufacturing.

Although there are a number of them, all guidelines follow a few basic principles:

Manufacturing processes are clearly defined and controlled. All critical processes are

validated to ensure consistency and compliance with specifications.

Cawangan Pembangunan Kurikulum

2012 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 10 drpd 11

Manufacturing processes are controlled, and any changes to the process are

evaluated. Changes that have an impact on the quality of the drug are validated as

necessary.

Instructions and procedures are written in clear and unambiguous language. (Good

Documentation Practices)

Operators are trained to carry out and document procedures.

Records are made, manually or by instruments, during manufacture that demonstrate

that all the steps required by the defined procedures and instructions were in fact

taken and that the quantity and quality of the drug was as expected. Deviations are

investigated and documented.

Records of manufacture (including distribution) that enable the complete history of a

batch to be traced are retained in a comprehensible and accessible form.

The distribution of the drugs minimizes any risk to their quality.

A system is available for recalling any batch of drug from sale or supply.

Complaints about marketed drugs are examined, the causes of quality defects are

investigated, and appropriate measures are taken with respect to the defective drugs

and to prevent recurrence.

GMP guidelines are not prescriptive instructions on how to manufacture products. They

are a series of general principles that must be observed during manufacturing. When a

company is setting up its quality program and manufacturing process, there may be

many ways it can fulfil GMP requirements. It is the company's responsibility to determine

the most effective and efficient quality process.

QUESTION :

1. What is OSHA?

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

2. Explain in simple sentence about HACCP.

____________________________________________________________________________

_____________________________________________________________________________

3. What is MS 1514?

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

4. List three types of hazards

Cawangan Pembangunan Kurikulum

2014 (versi 1)

Kod Kertas

HT-013-2:2011/C06/KP(1/7)

Muka surat : 11 drpd 11

5. Complete the Establishing of HACCP system

Identify hazards and assess their severity and risk

Determine critical control points (CCPs)

Establish critical limits

Establish a system to monitor the control of the CCPs)

Establish corrective action to be taken whenever monitoring indicates that a CCP is not under

control)

Establish procedures to verify that the HACCP system is working effectively

Confirm documentation in place for all procedures and records needed for an effective HACCP

system

RUJUKAN:

1. Courtine R.J. & Larousse The Hamlyn Publishing Group (1988) Gastronomique Cookery

Encyclopedia, ISBN 0-749-30316-6

2. Friberg B., John Wiley & Sons (2002), The Professional Pastry Chef: Fundamental of

Baking and Pastry (4th edition)

3. Gail Sokol Thomson Delmar Lerning (2006). About Professional Baking. 2nd Edition

4. Geerts R., Vantage House (1989), Belgian Sweet and savouries

5. Gisslen W., John Wiley & Sons Inc (2009), Professional Baking. 5th Edition

6. John C., Hodder Education (2008), Practical Cookery. 11th Edition

7. Joseph Amendola, Nicole Rees, John Wiley & Sons (2002) The Bakers Manual

FifthEdition , ISBN 0-471-40525-6

8. Karangkraf, Bakeri. ISBN: 978-967-5234-98-9

9. Labensky, S.R., Tenbergen, K.G., VanDamme, E & Martel P., Prentice Hall (2004), On

baking: A Textbook of Baking and Pastry Fundamentals

10. Lian M., Times Book International (1981), Guide to Hotel & Catering Services, ISBN 9-97165093-2

11. Oppeneder R. (1995). Simply Sweet and savoury. Robert Oppeneder

12. Peter P, John Wiley and Sons (2007).Sweet and savoury & Confections

13. Roux M.&A., Mcdonald & Co. Ltd, The Roux Brothers on Patisserie, ISBN 0-356-12379-0

14. Y.H.Hui, Harold Corke, Wiley Blacwell (2006), Bakery Products, Science and Technology,

ISBN: 9-780-81380187-2

Cawangan Pembangunan Kurikulum

2012 (versi 1)

Das könnte Ihnen auch gefallen

- Note Kulinary M01 (1/1)Dokument12 SeitenNote Kulinary M01 (1/1)Nur Faizah SelamatNoch keine Bewertungen

- c01 Hygiene Safety and Food HandlingDokument13 Seitenc01 Hygiene Safety and Food Handlingsunflower rapsodyNoch keine Bewertungen

- Kertas Kerja: Code & NameDokument6 SeitenKertas Kerja: Code & NameKhairul Haizal MansorNoch keine Bewertungen

- Assgnmnt Sheet Wa 01 DTRDokument5 SeitenAssgnmnt Sheet Wa 01 DTRNana TanNoch keine Bewertungen

- Wim Osmm - HT-010-2 - 2012-C01Dokument199 SeitenWim Osmm - HT-010-2 - 2012-C01shikhohNoch keine Bewertungen

- Supervisory Administrative FunctionDokument10 SeitenSupervisory Administrative Functionnur hidayahNoch keine Bewertungen

- Kertas Penerangan: Program'S Code & NameDokument19 SeitenKertas Penerangan: Program'S Code & Namearefif100% (1)

- Cocu 2 (Sweet and Savoury Filling Preparation)Dokument13 SeitenCocu 2 (Sweet and Savoury Filling Preparation)nadyaNoch keine Bewertungen

- Rice and Farinaceous ProductionDokument7 SeitenRice and Farinaceous Productionnur hidayahNoch keine Bewertungen

- SENARAI PERALATAN DAN KUTLERI YANG DIGUNAKAN (Restoran)Dokument3 SeitenSENARAI PERALATAN DAN KUTLERI YANG DIGUNAKAN (Restoran)Asmin CasioNoch keine Bewertungen

- HT2 CoCU 1 Hygiene, Kitchen Safety and Food HandlingDokument1 SeiteHT2 CoCU 1 Hygiene, Kitchen Safety and Food HandlingNorsyamsiah Binti Abdul KadirNoch keine Bewertungen

- Pelan Mengajar Amali HOUSEKEEPINGDokument7 SeitenPelan Mengajar Amali HOUSEKEEPINGZurr Izaty Zolkepli100% (1)

- HT2 CoCU 9 Catering Set-Up ActivitiesDokument8 SeitenHT2 CoCU 9 Catering Set-Up ActivitiesNama Saya Suhail Hadri50% (2)

- Kertas Penerangan 2Dokument16 SeitenKertas Penerangan 2amad100% (1)

- 2.KP2 Basic ButcheriDokument15 Seiten2.KP2 Basic ButcheriAhmad Ruhaifi ZahariNoch keine Bewertungen

- HT2 CoCU 4 Main Course ProductionDokument10 SeitenHT2 CoCU 4 Main Course ProductionNama Saya Suhail Hadri0% (1)

- c01 Hygiene, Safety and Food HandlingDokument18 Seitenc01 Hygiene, Safety and Food HandlingAmira AzaniNoch keine Bewertungen

- Kertas Kerja Update (KK) KbsDokument10 SeitenKertas Kerja Update (KK) KbsMohd Ezuan Atok100% (1)

- Kertas Kerja 43Dokument11 SeitenKertas Kerja 43Athirah RamliNoch keine Bewertungen

- PPM Co 2,7,8Dokument750 SeitenPPM Co 2,7,8ppki smklNoch keine Bewertungen

- HT2 CoCU E1 Basic Kitchen Equipment Maintenance PDFDokument7 SeitenHT2 CoCU E1 Basic Kitchen Equipment Maintenance PDFandyNoch keine Bewertungen

- Analisis Wim Utk JPK 2021Dokument28 SeitenAnalisis Wim Utk JPK 2021Mohd Fadhli0% (1)

- HT2 CoCU 3 Stock, Soups and Hot Sauce ProductionDokument9 SeitenHT2 CoCU 3 Stock, Soups and Hot Sauce ProductionNama Saya Suhail Hadri100% (1)

- KP 1Dokument9 SeitenKP 1Naimah Adenan100% (1)

- Kertas Penerangan: Program'S Code & NameDokument5 SeitenKertas Penerangan: Program'S Code & NamearefifNoch keine Bewertungen

- C08 - Dessert Production (Versi BPK)Dokument213 SeitenC08 - Dessert Production (Versi BPK)Wahida Aida100% (1)

- Bakery & Patisserie Theory - I - 27.11.2014Dokument2 SeitenBakery & Patisserie Theory - I - 27.11.2014Kumar SatyamNoch keine Bewertungen

- Competency Profile Chart (CPC)Dokument2 SeitenCompetency Profile Chart (CPC)Leya TarmiziNoch keine Bewertungen

- HT2 CoCU 2 Cooking TechniqueDokument10 SeitenHT2 CoCU 2 Cooking TechniqueNama Saya Suhail HadriNoch keine Bewertungen

- Level 2 I561-005!2!2022 Food PreparationDokument168 SeitenLevel 2 I561-005!2!2022 Food PreparationMuhammad AminNoch keine Bewertungen

- Jadual Pembahagian Wim Amali (Latest) - Lesson PlanDokument2 SeitenJadual Pembahagian Wim Amali (Latest) - Lesson PlanshikhohNoch keine Bewertungen

- C04-P (1 6) PMDokument9 SeitenC04-P (1 6) PMPijja0% (1)

- CONTOH CoCU 5Dokument6 SeitenCONTOH CoCU 5Ekhwan RahimNoch keine Bewertungen

- Kertas Kerja 32Dokument11 SeitenKertas Kerja 32Athirah Ramli100% (1)

- Matriks Core Abilities DAT (2020)Dokument1 SeiteMatriks Core Abilities DAT (2020)Pokcik ZaidNoch keine Bewertungen

- Cocu 6 (Malaysian Dessert and Kuih Preparation)Dokument15 SeitenCocu 6 (Malaysian Dessert and Kuih Preparation)Norbaizura Abd RahmanNoch keine Bewertungen

- Dokumen KSKV HSK 101 Fundamental of Culinary ArtsDokument13 SeitenDokumen KSKV HSK 101 Fundamental of Culinary ArtsLee Yoke HanNoch keine Bewertungen

- HT2 CoCU E3 Basic Butchery PDFDokument13 SeitenHT2 CoCU E3 Basic Butchery PDFandyNoch keine Bewertungen

- CONTOH QUOTATION BARU (Repaired)Dokument3 SeitenCONTOH QUOTATION BARU (Repaired)Citra WathiNoch keine Bewertungen

- Training Material & EquipmentDokument5 SeitenTraining Material & EquipmentPrabakaran MuniandyNoch keine Bewertungen

- Daftar NOSS Version 24 April 2013 PDFDokument238 SeitenDaftar NOSS Version 24 April 2013 PDFMuhammad Asraf Nor Asyrafjpk100% (1)

- Pembuatan Pastri Tahap 3 Tajuk NossDokument4 SeitenPembuatan Pastri Tahap 3 Tajuk NossEija NorhaijaNoch keine Bewertungen

- Cocu 2 (Dough and Batter Preparation)Dokument15 SeitenCocu 2 (Dough and Batter Preparation)firdanieyNoch keine Bewertungen

- New e - Menu Card Menu Planning by GroupDokument10 SeitenNew e - Menu Card Menu Planning by GroupNur AinaaNoch keine Bewertungen

- c01 P Hygiene, Safety and Food HandlingDokument13 Seitenc01 P Hygiene, Safety and Food HandlingAmira Azani67% (3)

- Food & Beverage Service OperationDokument62 SeitenFood & Beverage Service Operationmages warieNoch keine Bewertungen

- Tahap 3 Core Abilities Modul 1 Samb...Dokument4 SeitenTahap 3 Core Abilities Modul 1 Samb...Intan FarhanaNoch keine Bewertungen

- Vira International: Application FormDokument8 SeitenVira International: Application FormKazawali Kakarla SubbannaNoch keine Bewertungen

- ModuleDokument211 SeitenModulemmammerNoch keine Bewertungen

- HT CoCU 1 F - B Hygiene and Work Safety PracticeDokument9 SeitenHT CoCU 1 F - B Hygiene and Work Safety PracticeAnien Margaret FranklingNoch keine Bewertungen

- Trip To VitagenDokument9 SeitenTrip To VitagenFatin Izzati Zainal Abidin100% (2)

- Introduction To Hospitality Fifth Edition John R. Walker: Chapter 2: TourismDokument34 SeitenIntroduction To Hospitality Fifth Edition John R. Walker: Chapter 2: TourismZohaib ChandioNoch keine Bewertungen

- Menu Evaluation Form (Project)Dokument4 SeitenMenu Evaluation Form (Project)YekannaNapagamNoch keine Bewertungen

- BBNP - 4103 680330-08-5927 - Performance AppraisalDokument12 SeitenBBNP - 4103 680330-08-5927 - Performance AppraisalAminuddin Mukhtar0% (1)

- L1-M02-01 03-T - HONESTY AND INTEGRITY Vol. 1Dokument7 SeitenL1-M02-01 03-T - HONESTY AND INTEGRITY Vol. 1Nurul Huda AliNoch keine Bewertungen

- Catering ServicesDokument23 SeitenCatering Servicesmisrael guinaNoch keine Bewertungen

- Introduction To Restaurant ServiceDokument5 SeitenIntroduction To Restaurant ServiceHazwani HamzahNoch keine Bewertungen

- Lab 3 (Determination of Fatty Acids) PDFDokument17 SeitenLab 3 (Determination of Fatty Acids) PDFnur syaza haniNoch keine Bewertungen

- Briefing Points For Industrial TrainingDokument28 SeitenBriefing Points For Industrial TrainingYash ChhabraNoch keine Bewertungen

- Chapter 2 - OSHA 1994 NoteDokument14 SeitenChapter 2 - OSHA 1994 NoteFx Niubie75% (4)

- Service Sticker PDFDokument1 SeiteService Sticker PDFMohd Ezuan AtokNoch keine Bewertungen

- Nota THN 5 Utk LatihanDokument4 SeitenNota THN 5 Utk LatihanMohd Ezuan AtokNoch keine Bewertungen

- Plywood Design Application GuideDokument36 SeitenPlywood Design Application GuideArnaldo BenitezNoch keine Bewertungen

- Kertas Kerja Update (KK) KbsDokument10 SeitenKertas Kerja Update (KK) KbsMohd Ezuan Atok100% (1)

- 06 - Cocu Cu1 - Component Drawing DevelopmentDokument12 Seiten06 - Cocu Cu1 - Component Drawing DevelopmentMohd Ezuan AtokNoch keine Bewertungen

- Plywood Design Application GuideDokument36 SeitenPlywood Design Application GuideArnaldo BenitezNoch keine Bewertungen

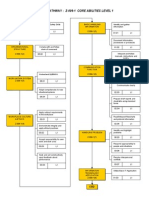

- Training Pathway L2Dokument1 SeiteTraining Pathway L2Mohd Ezuan AtokNoch keine Bewertungen

- RPK Core Abilities L1Dokument2 SeitenRPK Core Abilities L1Mohd Ezuan AtokNoch keine Bewertungen

- Training Pathway: Z-009-1 Core Abilities Level 1: StartDokument1 SeiteTraining Pathway: Z-009-1 Core Abilities Level 1: StartEmily Jampong EmilyNoch keine Bewertungen

- Hazard Analysis Critical Control Point: (Haccp) PlanDokument23 SeitenHazard Analysis Critical Control Point: (Haccp) PlanChrezzel FeridoNoch keine Bewertungen

- Pns+bafs+233 2018Dokument64 SeitenPns+bafs+233 2018jeffrey sarolNoch keine Bewertungen

- Van Donk - 2004. Food Safety Hygiene Systematic Layout Plannin of Food ProcessesDokument10 SeitenVan Donk - 2004. Food Safety Hygiene Systematic Layout Plannin of Food ProcessesMolly0630Noch keine Bewertungen

- HACCP Example - KraftDokument83 SeitenHACCP Example - KraftRichard Ingram100% (2)

- A Model For Implementation of HACCP System For PreDokument6 SeitenA Model For Implementation of HACCP System For PreAloryito LucyNoch keine Bewertungen

- Haccp Team Responsibility Matrix: S. # Designation Role ResponsibilitiesDokument2 SeitenHaccp Team Responsibility Matrix: S. # Designation Role ResponsibilitiesSmsajid Waqas67% (3)

- MC DonaldDokument77 SeitenMC DonaldNeha MishraaNoch keine Bewertungen

- Appendix D Risk AnalysisDokument13 SeitenAppendix D Risk AnalysisElamal ismailNoch keine Bewertungen

- Haccp Manual: Approval No.335Dokument210 SeitenHaccp Manual: Approval No.335helloNoch keine Bewertungen

- Gulkand Flavoured Milk...Dokument51 SeitenGulkand Flavoured Milk...Rahul RathodNoch keine Bewertungen

- CooksafeDokument107 SeitenCooksafeoztrich0% (1)

- C9 - VNFPP LTD (IIMB)Dokument9 SeitenC9 - VNFPP LTD (IIMB)Debaloy DeyNoch keine Bewertungen

- Advanced Applications of Food Safety Systems Principles: Case Study - IcecreamDokument20 SeitenAdvanced Applications of Food Safety Systems Principles: Case Study - IcecreamMihai Bejan100% (1)

- Iata Catering Quality Assurance ProgrammeDokument44 SeitenIata Catering Quality Assurance Programmesadbad6100% (3)

- Approaching Risk Assessment: Tools and MethodsDokument23 SeitenApproaching Risk Assessment: Tools and MethodsTim Sandle100% (1)

- The Right Training To Continuously Develop - : Transforming People and BusinessesDokument15 SeitenThe Right Training To Continuously Develop - : Transforming People and BusinessesjohanaristoNoch keine Bewertungen

- Food SafetyDokument22 SeitenFood SafetyMuhammad RehmanNoch keine Bewertungen

- 8 Principles of TQMDokument8 Seiten8 Principles of TQMMomina TariqNoch keine Bewertungen

- Evm Dalilah NazirahDokument16 SeitenEvm Dalilah NazirahAr-Rayyan AshNoch keine Bewertungen

- Introduction To Food SafetyDokument12 SeitenIntroduction To Food SafetyCorine Joy TapoNoch keine Bewertungen

- Foodservice Management Principles and Practices 12th Edition by Monica Theis - Test BankDokument11 SeitenFoodservice Management Principles and Practices 12th Edition by Monica Theis - Test Banksarenaholer25% (4)

- HACCP Hotel CateringDokument29 SeitenHACCP Hotel CateringHACCPEuropaNoch keine Bewertungen

- BrochureDokument2 SeitenBrochureNur SyawanieNoch keine Bewertungen

- Quality Management Guide For The Olive Oil Industry: Packing PlantsDokument17 SeitenQuality Management Guide For The Olive Oil Industry: Packing Plantsjibun100000rockNoch keine Bewertungen

- On Overview Pleasant Food PVT Limited FOR: A Project Report On Study OFDokument11 SeitenOn Overview Pleasant Food PVT Limited FOR: A Project Report On Study OFramu rajakannuNoch keine Bewertungen

- Sugarcane Juice Processing Microbiological Monitoring 2157 7110 1000607Dokument5 SeitenSugarcane Juice Processing Microbiological Monitoring 2157 7110 1000607Honshu KimNoch keine Bewertungen

- 2 4 13+WQA+Manufactured+Food+Standard+Version+8 PDFDokument64 Seiten2 4 13+WQA+Manufactured+Food+Standard+Version+8 PDFROCIONoch keine Bewertungen

- What Is HaccpDokument6 SeitenWhat Is HaccpMostafa HamdyNoch keine Bewertungen

- McDonald's India (North East) - Media Fact Book - October - 2011Dokument33 SeitenMcDonald's India (North East) - Media Fact Book - October - 2011viralbasopia88Noch keine Bewertungen

- Food Quality and Safety Management Systems:A Brief Analysis of The Individual and Integrated ApproachesDokument8 SeitenFood Quality and Safety Management Systems:A Brief Analysis of The Individual and Integrated ApproachesbrunoNoch keine Bewertungen

- Ukraine: What Everyone Needs to KnowVon EverandUkraine: What Everyone Needs to KnowBewertung: 4.5 von 5 Sternen4.5/5 (117)

- Waste: One Woman’s Fight Against America’s Dirty SecretVon EverandWaste: One Woman’s Fight Against America’s Dirty SecretBewertung: 5 von 5 Sternen5/5 (1)

- Introduction to Ecology and Environmental Laws in IndiaVon EverandIntroduction to Ecology and Environmental Laws in IndiaNoch keine Bewertungen

- The Cyanide Canary: A True Story of InjusticeVon EverandThe Cyanide Canary: A True Story of InjusticeBewertung: 4 von 5 Sternen4/5 (52)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaVon EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaBewertung: 4 von 5 Sternen4/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionVon EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionBewertung: 3 von 5 Sternen3/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionVon Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNoch keine Bewertungen

- Slow Violence and the Environmentalism of the PoorVon EverandSlow Violence and the Environmentalism of the PoorBewertung: 4 von 5 Sternen4/5 (5)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastVon EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastBewertung: 4.5 von 5 Sternen4.5/5 (76)

- The Rights of Nature: A Legal Revolution That Could Save the WorldVon EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldBewertung: 5 von 5 Sternen5/5 (1)

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawVon EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawBewertung: 4 von 5 Sternen4/5 (334)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontVon EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontBewertung: 4.5 von 5 Sternen4.5/5 (18)

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Von EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Bewertung: 5 von 5 Sternen5/5 (2)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksVon EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNoch keine Bewertungen

- Down to the Wire: Confronting Climate CollapseVon EverandDown to the Wire: Confronting Climate CollapseBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Busted!: Drug War Survival Skills and True Dope DVon EverandBusted!: Drug War Survival Skills and True Dope DBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Introduction to Ecology and Environmental Laws in IndiaVon EverandIntroduction to Ecology and Environmental Laws in IndiaNoch keine Bewertungen

- Environmental Education in Practice: Concepts and ApplicationsVon EverandEnvironmental Education in Practice: Concepts and ApplicationsNoch keine Bewertungen

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontVon EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Principles of direct and superior responsibility in international humanitarian lawVon EverandPrinciples of direct and superior responsibility in international humanitarian lawNoch keine Bewertungen

- Obstacles to Environmental Progress: A U.S. perspectiveVon EverandObstacles to Environmental Progress: A U.S. perspectiveNoch keine Bewertungen