Beruflich Dokumente

Kultur Dokumente

United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0128143 A1

Hochgeladen von

Muhammad Yahya HanifOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0128143 A1

Hochgeladen von

Muhammad Yahya HanifCopyright:

Verfügbare Formate

US 20070128143Al

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2007/0128143 A1

(43) Pub. Date:

Gruning et al.

(54)

POLYETHER-MODIFIED POLYSILOXANES

WITH BLOCK CHARACTER AND USE

THEREOF FOR PRODUCING COSMETIC

FORMULATIONS

(75) Inventors: Burghard Gruning, Essen, DE (US);

Wilfried Knott, Essen, DE (US);

Holger Leidreiter, Hattingen, DE (US);

Jurgen Meyer, Munster, DE (US)

Correspondence Address:

Leopold Presser, Scully, Scott, Murphy &

Presser

400 Garden City Plaza

Garden City, NY 11530 (US)

(73) Assignee: Goldschmidt GmbH, Essen (DE)

(21) Appl. No.:

11/633,378

(22) Filed:

Dec. 4, 2006

(30)

Foreign Application Priority Data

Dec. 3, 2005

(DE) ........................ .. 10 2005 057 857.8

Jun. 7, 2007

Publication Classi?cation

(51)

(52)

(57)

Int. Cl.

A61K 8/89

C08G 77/38

(2006.01)

(2006.01)

Us. or. ....................................... .. 424/7012; 525/476

ABSTRACT

The invention provides a method of producing organomodi

?ed siloxanes With domain-type distribution obtained by

partial or complete reaction of

A) hydrogensiloxanes With a degree of distribution (persis

tency ratio) (11) of components [A] and [B] in the copolymer

[AB]

of 11>l, preferably >l.l, in particular 21.2, With B) ole

?nically and/or acetylenically unsaturated compounds, the

compounds resulting therefrom and their use.

Jun. 7, 2007

US 2007/0128143 A1

POLYETHER-MODIFIED POLYSILOXANES WITH

BLOCK CHARACTER AND USE THEREOF FOR

PRODUCING COSMETIC FORMULATIONS

FIELD OF THE INVENTION

[0001] The invention relates to organomodi?ed polysilox

anes With block character produced by hydrosilylation and

to their use for producing cosmetic and pharmaceutical

formulations.

BACKGROUND OF THE INVENTION

[0002] A large part of cosmetic and pharmaceutical for

mulations consists of emulsions. The majority of these

emulsions is usually of the oil-in-Water type, i.e., the oil

phase (disperse phase) is very ?nely distributed in the

form of small droplets in the Water phase (coherent phase).

In addition, Water-in-oil emulsions are also knoWn Which are

characterized in that Water drops are present in dispersed

form in a continuous oil phase. These Water-in-oil emulsions

exhibit a number of application advantages. Thus, for

example, they enable an occlusive ?lm to form on the

surface of the skin, Which prevents the skin from drying out.

At the same time, Water-in-oil emulsions are knoWn for their

excellent Water resistance.

[0003] Cosmetic emulsions comprise, irrespective of the

type of emulsion, on average 20 to 30% oil phase for reasons

of skin feel. In cases of Water-in-oil emulsions, this means

that, on account of the high internal phase content,

extremely high stabiliZation of the Water drops against

coalescence is required.

[0004] It is knoWn that this stabiliZation can take place, for

example, in an excellent manner by alkyl polyethersiloxanes

reference is made in its entirety With regard to the present

invention, a method for the targeted production of domain

type polydimethylsiloxane-poly(methylhydrogen)siloxane

copolymers interspersed With SiH functions is described.

[0011] Here, mixtures consisting of methylhydrogenpol

ysiloxane, hexamethyldisiloxane and siloxane cycles are

brought into contact over a macro-crosslinked cation

exchange resin containing sulfonic acid groups at a tem

perature of from 100 C. to 1200 C., and the resulting

equilibrated organosiloxanes are isolated. The cation

exchange resin used is characteriZed in that its product P of

its speci?c surface area and of its average pore diameter is

P<2.2><10_3 m3/kg, in particular <1.5><10_3 m3/kg, particu

larly preferably <1><10_3 m3/kg, and the speci?c surface area

A is <50 m2/g, in particular A<35 m2/g and particularly

preferably A<25 m2/ g.

[0012] The ion exchange phase characterized in this Way

ensures, depending on the design, the partial or predominant

presence of methylhydrogensiloxane domains in the result

ing polydimethylsiloxane-poly(methylhydrogen-)siloxane

copolymers.

[0013]

The de?nition of domains is used as far as content

is concerned in agreement With the de?nition of persistence

ratio in the publication by P. Cancouet et al. Functional

Polysiloxanes, I. Microstructure of Poly(hydrogenmethylsi

loxane-co-dimethylsiloxane)s Obtained by Cationic Copo

lymeriZation, J. of Polymer Science, ParA: Polymer Chem

istry, Vol 38, 826-836 (2000). According to this, persistency

ratio (11) is a measure of the degree of distribution of

components [A] and [B] in the copolymer [AB]:

With a comb-like structure, as are described in EP-A-0 176

884.

[0005] The use of terminally modi?ed polyethersiloxanes

in cosmetic emulsions is also Widespread. Besides their

emulsion-stabilizing e?fect, these compounds are character

iZed by a velvety-silky skin feel Which they impart to

cosmetic emulsions.

[0006] Such an oil-in-Water emulsi?er is described, for

example, in EP-A-1 125 574.

[0014] According to this, the persistency ratio Ti charac

teriZes the ratio of experimentally determined block length

of one monomer sequence in a copolymer to the statistically

[0007] Another prominent substance class of the organo

expected block length in the case of complete distribution.

modi?ed siloxanes for cosmetic applications is based on the

[0015] Accordingly, components [A] and [B] tend toWard

pure alkyl-group-modi?ed siloxanes or silicone Waxes

Which are used, for example, for improving the spreading of

cosmetic oils, or alternatively as Wetting dispersion addi

tives for producing color-improved pigment-containing for

mulations.

an alternating distribution When Ti is <1, to a regular

distribution When T=1 and to a domain-type distribution

When 11 is >1. Analytically, the cumulation of SiH function

alities can be demonstrated by evaluating high-resolution

29Si-NMR spectra. The equilibration products used accord

ing to the invention according to the application With the ?le

[0008] Finally, the use of siloxanes modi?ed With cationic

organo groups for haircare, as described, for example, in

EP-B-0 294 642, also belongs to the prior art.

reference: 10 2005 001 039.3 have 11 values >1.

[0009] The continually groWing demands on cosmetic

formulations, for example in the direction of greater formu

content of the present invention.

lation ?exibility or With regard to more elegant sensory

[0017] These products are especially noteWorthy therefore

pro?les cannot be improved further using the described

siloxane derivatives from the prior art. There is thus a need

for neW types of siloxanes With Whose help further improved

formulation properties can be established in a targeted Way.

SUMMARY OF THE INVENTION

[0010] According to a proposal (?le reference 10 2005 001

039.3) Which is hitherto still not published and to Which

[0016] The content of the above publication is hereby

incorporated as reference and serves as part of the disclosure

since it Was not possible using the knoWn prior art equili

bration catalysts to produce equilibrates With a block-type

structure, i.e., With locally increased functionaliZation den

sities (SiH clusters) along the siloxane structure, in a tar

geted and reproducible Way.

[0018] In a second reaction stage, the hydrogensiloxanes

With a domain-type structure produced in this Way can be

Jun. 7, 2007

US 2007/0128143 A1

reacted With hydrocarbons having multiple bonds and/or

unsaturated polyoxyalkyl ethers.

DETAILED DESCRIPTION OF THE

INVENTION

[0019] This second stage of the production can take place

here in accordance With the knoWn hydrosilylation pro

cesses, as described, for example, in Us. Pat. Nos. 3,234,

ducing organomodi?ed siloxanes With domain-type distri

252, 4,047,958, and 3,427,271.

[0020] HoWever, ?rst application tests on block-type poly

ethersiloxanes produced in this Way for technical applica

tions such as, for example, for stabilizing ?exible polyure

thane foams, shoWed that the performance of these

[0027]

The invention therefore provides a method of pro

bution obtained by partial or complete reaction of

[0028]

l. hydrogensiloxanes With a degree of distribu

tion (persistency ratio) (11) of components [A] and [B]

in the copolymer [AB]:

polyethersiloxanes With a domain-type structure Was con

siderably Worse than conventionally produced random poly

ethersiloxanes.

[0021]

Even more surprisingly, it has noW been found that

the reaction products of the domain-type structured hydro

gensiloxanes produced in the ?rst stage With hydrocarbons

having multiple bonds and/or unsaturated polyoxyalkyl

ethers produce interface-active products With neW kinds of

excellent application properties in cosmetic and pharmaceu

tical formulations.

[0022] When using alkyl polyethersiloxanes With a block

type structure as emulsi?ers for Water-in-oil emulsions, it

Was entirely surprising to ?nd that it is possible to achieve

[0029] of 11>l, preferably >l.l, in particular 21.2,

With

[0030] 2. ole?nically and/or acetylenically unsaturated

compounds.

[0031]

The invention further provides a method of pro

ducing organomodi?ed siloxanes, Wherein, for producing

the methylhydrogensiloxanes, a mixture of hexamethyldisi

loxane, poly(methyl)hydrogensiloxane and siloxane cycles

are equilibrated as starting material.

[0032]

The invention further provides a method of pro

ducing organomodi?ed siloxanes, Wherein the ole?nically

a similarly high emulsion-stabilizing effect as through the

use of randomly uniform alkyl polyethersiloxanes.

unsaturated compounds of the general formula (1)

[0023] An advantage of using polyethersiloxanes With a

radical selected from the folloWing:

CH2=CHRi(CH2)n-A are used, in Which A is at least one

block-type structure, moreover, is the loWer emulsion vis

cosity. This loWer emulsion viscosity offers the advantage of

better spreadability of the formulation on the skin, improved

absorption behavior, and a generally someWhat lighter skin

feel. Here, the alkylpolyethersiloxanes With a block-type

structure generally appear to impart a more marked velvety

silky skin feel than is knoWn from the randomly constructed

[0033] l. optionally substituted linear and/or cyclic

hydrocarbons Which may optionally contain functional

groups,

[0034] 2. randomly or blockWise constructed oxyalky

lene chains i(OAlk)S-R,

alkylpolyethersiloxanes.

[0035] in Which

[0024]

[0036] R is H, a Cl_18-alkyl radical Which is option

ally substituted and/or optionally contains heteroat

Surprisingly, it has also been found that the block

type modi?ed alkylpolyethersiloxanes, especially When

using high fractions of silicone oils (e.g., cyclopentasilox

oms, or the radical of a monobasic and/or polybasic

anes, dimethicones) in the oil phase, are able to convey a

Cl_22-carboxylic acid, Which can optionally contain

similarly velvety-silky skin feel as Was previously knoWn

only from terminally modi?ed polyethersiloxanes, Which are

conventionally used as emulsi?ers for stabiliZing such

hydroxyl groups, the radical of an inorganic acid

selected from the group sulfuric acid, sulfonic acid,

Water-in-silicone emulsions. At the same time, the alky

lpolyethersiloxanes With a domain-type structure, hoWever,

exhibit a clearly better emulsion stabiliZation than do these.

[0025] Quite generally, it may be stated that the velvety

silky skin feel, Which in particular is a feature of organosi

loxanes With relatively long unmodi?ed siloxane chains,

can, With the help of these novel organosiloxanes With a

domain-type structure, be combined signi?cantly more eas

ily With the functionalities required for the particular

intended use than Was possible for the hitherto obtainable

randomly distributed organosiloxanes.

phosphoric acid,

[0037] OAlk is the radical -(EO)bi(PO)Ci(BO)d

(DO)ei(SO)fi Where

[0038]

[0039]

[0040]

[0041]

E0 is ethylene oxide radical,

PO is propylene oxide radical,

B0 is butylene oxide radical,

D0 is dodecenyl oxide radical,

[0042] S0 is optionally alkyl-substituted styrene

oxide radical,

[0026] Thus, both emulsi?ers With a domain-type struc

ture and based on alkyl polyethersiloxanes, and also perfor

[0043] b, c, d, e, fare 20, in particularb is 0 to 50,

mance improvers based on alkylsiloxanes exhibited an

[0044] d, e, f are identical or different and are 0 to

10 and the sum

improved skin feel. Haircare additives based on cationically

modi?ed domain-type organosiloxanes are characterized by

a softer hand.

c is 0 to 50,

[0045]

b+c+d+e+f is a and

Jun. 7, 2007

US 2007/0128143 A1

[0046] a is l to 50, preferably 1 to 30, in particular

3 to 20,

-continued

4g

[0047] and

[0048]

3. radicals containing oxirane groups of the

formulae 3a to 3d

4h

32.

OCH2CHCH2

O

3b

41'

OH

: CH3

O

4k

[0049] (and When X=0)

30

00

[0052]

and Z may be one of the radicals

3d

[0050]

4. at least one amine/ammonium radical, -MZ,

-[M-Z]g+h*Xj', in Which

[0051]

40

M is a divalent radical chosen from the group

45.

OCH2CHCH2

OH

4b

O CH2 CH

CH2 OH

40

CH CH2

OH

4d

R4

CH CH2 OH

4e

CH3

OH

[0053] in Which

4f

[0054] R1, R2, R3, R4, independently of one another,

are H, Cl_22-alkyl radicals Which may also contain

CH3

hydroxyl groups,

OH

[0055] R5, R6 are Cl_22-alkyl radicals Which may

also contain hydroxyl groups,

Jun. 7, 2007

US 2007/0128143 A1

[0056] D is 4O- or iNR7i Where R7=alkyl or

hydroxyalkyl radical With 1-4 carbon atoms,

[0074]

[0075]

in Which

G is a guanidino group With the general for

mula (6a', 6a2)

[0057]

X- may be an organic or inorganic anion,

[0058]

h*j is the same as the numerical value of g;

[0059] 5. polyhydroxyorganyl radicals of the general

formula iRSiPH, Where the radical

[0060] R8 acts as spacer betWeen siloxane backbone

and polyhydroxyorganyl radical or sugar radical and

is of the type knoWn from the prior art for polyhy

droxyorganyl- or sugar-modi?ed siloxanes,

[0061]

PH is a polyhydroxyorganyl radical Which

contains a de?ned number n of (CiOH) groups,

Where n is 22, preferably 5 to 15,

[0062]

from the group mono-, di-, oligo- or

polysaccharide, their glycosides or corresponding

derivatives, in particular glucose, maltose, raf?

nose, sorbitol, glucosamine, glucopyranosy

lamine, glucamine, N-methylglucamine, isomalta

[0076]

and/or salts or hydrates thereof, in Which

[0077] R12 independently of the others, is hydrogen

or an optionally branched hydrocarbon radical

optionally containing double bonds, or

mine, gluconic acid, heptagluconic acid;

0078

R12 may be Rl2 oran alky lene grouP Which is

joined to M via carbon atoms or heteroatoms and

thus forms a 5- to 8-membered ring and

[0079] N is a di- or polyvalent hydrocarbon radical

having at least 4 carbon atoms Which has a hydroxyl

group and Which may be interrupted by one or more

oxygen atoms or nitrogen atoms or quaternary

ammonium groups or esters or amide functions,

[0063]

[0080]

6. betaine groups,

Q+ is a radical of the formula (6d)

[0064] in Which

(6d)

R13

[0065] X is icooi, so;, P042,

[0066] R9 is alkylene radicals having up to 10

carbon atoms,

R14

[0067] R10 is alkylene radicals having up to 2 to 6

carbon atoms,

[0068]

y is 0 or 1,

[0069]

Z is 0 or 1,

[0070]

Z' is l, 2 or 3,

[0081] R13, R14 are alkyl radicals having 1 to 4

carbon atoms,

[0082] R15 is

[0071] and

[0072]

R1, R2 are identical or different and have

the meaning given above, together form an imi

daZoline

ring

or

are

4CH2iCH2iOH,

i(CH2)ZiX$

[0073]

7. guanidine groups of the formulae (6a, 6b or

6c)

RU=iN-G

(6a)

RU=iN-Q*A

(6b)

[0083] R16 may be a monovalent hydrocarbon radical

having 1 to 22 carbon atoms,

[0084]

g is 0 to 6

[0085]

h is 0 or 1,

[0086]

A is an inorganic or organic anion Which

originates from a customary physiologically compat

ible acid HA,

Jun. 7, 2007

US 2007/0128143 A1

[0087]

S is H, a polyalkylene oxide polyether of the

general formula

and hair, sunscreen products, pigment-containing products

from the ?eld of decorative cosmetics (e.g., makeup, lip

sticks, poWders, products for lid/eyelash coloring), products

for conditioning hair, nailcare products or antiperspirants/

deodorants.

[0089] m is 1 to 6, in particular 3, 6,

[0100] In these formulations, the compounds according to

[0090] n, 0, independently of one another, are 0 to

100, in particular 0 to 20 and the polyether has a

the invention can be used together With the formulation

constituents knoWn for these ?elds of use, such as oil

molecular Weight betWeen 100 and 6000 g/mol and

[0091]

R17 is H or an optionally branched aromatic or

alicyclic hydrocarbon radical having 2 to 30 carbon

atoms, preferably 4 to 22 carbon atoms, and option

ally containing double bonds, or a UV-absorbing

group, in particular cinnamic acid or methoxycin

namic acid.

[0092] The compounds listed are linked to the SiH silox

anes by methods knoWn to those skilled in the art. The

compounds and the methods of producing the organomodi

?ed siloxanes are described in detail in the following US.

Pat. Nos. 6,645,842, 4,698,178, 5,204,433, 4,891,166,

4,833,225, and 4,609,750. The contents of each of the

aforementioned patents are hereby incorporated as reference

and serves as part of the disclosure content of the present

components, cosurfactants and coemulsi?ers, consistency

regulators, thickeners, Waxes, UV photoprotective ?lters,

antioxidants, hydrotropes, deodorant and antiperspirant

active ingredients, active ingredients, dyes, preservatives

and perfumes.

[0101] Suitable cosmetic oils are, in particular, mono- or

diesters of linear and/or branched mono- and/or dicarboxylic

acids having 2 to 44 carbon atoms With linear and/or

branched saturated or unsaturated alcohols having 1 to 22

carbon atoms.

[0102] LikeWise suitable are the esteri?cation products of

aliphatic, difunctional alcohols having 2 to 36 carbon atoms

With monofunctional aliphatic carboxylic acids having 1 to

22 carbon atoms. Monoesters suitable as oil components are,

for example, the methyl esters and isopropyl esters of fatty

acids having 12 to 22 carbon atoms, such as, for example,

invention.

methyl laurate, methyl stearate, methyl oleate, methyl eru

[0093] The invention further provides the use of the orga

nopolysiloxanes With a domain-type structure obtained by

the method according to the invention for producing cos

metic formulations. These exhibit excellent application

cate, isopropyl palmitate, isopropyl myristate, isopropyl

stearate, isopropyl oleate. Other suitable monoesters are, for

properties.

example, n-butyl stearate, n-hexyl laurate, n-decyl oleate,

isooctyl stearate, isononyl palmitate, isononyl isononanoate,

2-ethylhexyl palmitate, 2-ethylhexyl laurate, 2-hexyldecyl

[0094]

cate, erucyl oleate, and esters Which are obtainable from

The organosiloxanes With a block-type structure

according to the invention can be used, for example, as

emulsi?ers or dispersion additives, as additives for an

improved skin feel or an improved hand, or generally as

performance improvers for example for better processing of

other ingredients, depending on the type, number and dis

tribution of the substituents.

stearate, 2-octyldodecyl palmitate, oleyl oleate, oleyl eru

technical-grade aliphatic alcohol cuts and technical-grade,

aliphatic carboxylic acid mixtures, e. g., esters of unsaturated

fatty alcohols having 12 to 22 carbon atoms and saturated

and unsaturated fatty acids having 12 to 22 carbon atoms, as

are accessible from animal and vegetable fats. HoWever,

naturally occurring monoester and Wax ester mixtures as are

[0095] The invention further provides the use of the orga

nosiloxanes With a domain-type structure according to the

invention in cosmetic formulations for the care and cleaning

of skin and hair, in sunscreen products, in antiperspirants/

present, for example, in jojoba oil or in sperm oil are also

suitable.

deodorants, and in pigment-containing formulations from

the ?eld of decorative cosmetics.

di(2-hexyldecyl)succinate, diisotridecyl aZelate. Suitable

diol esters are, for example, ethylene glycol dioleate, eth

[0096]

ylene glycol diisotridecanoate, propylene glycol di(2-ethyl

The invention further provides the use of the com

[0103]

Suitable dicarboxylic esters are, for example, di-n

butyl adipate, di-n-butyl sebacate, di(2-ethylhexyl)adipate,

pounds produced according to the invention in pharmaceu

hexanoate), butanediol diisostearate and neopentyl glycol

tical formulations.

dicaprylate.

[0097] The invention further provides the use of the orga

nosiloxanes With a domain-type structure according to the

invention in compositions for the cleaning and care of hard

surfaces, and for the cleaning and care of textiles.

[0104] Further fatty acid esters Which can be used are the

esteri?cation products of benZoic acid With linear or

branched fatty acids having 8 to 22 carbon atoms.

[0098]

esters Which can carry linear or branched alkyl chains

Moreover, the use of the inventive compounds as

coating additives in the form of, for example, substrate

Wetting agents, slide and How improvers, deaerating agents,

scratch resistance improvers, inter alia, is provided by the

invention.

[0099] Preference is given to the use of the interface

active compounds according to the invention in cosmetic

formulations for the care and cleaning of skin and hair.

These may, for example, be creams or lotions for skincare,

surfactant-based products for the cleaning and care of skin

[0105]

Suitable oil components are also dialkylcarboxylic

having 6 to 22 carbon atoms.

[0106]

As an oil component, it is likeWise possible to use

fatty acid triglycerides, With the naturally occurring oils and

fats among these being preferred. Thus, for example, natu

ral, vegetable oils, e.g. olive oil, sun?oWer oil, soybean oil,

peanut oil, rapeseed oil, almond oil, palm oil, but also the

liquid fractions of coconut oil or of palm kernel oil, and

animal oils, such as, for example, neatsfoot oil, the liquid

fractions of beef talloW or else synthetic triglycerides, such

Jun. 7, 2007

US 2007/0128143 A1

as reaction products With caprylic/capric acid mixtures or

PPG-20/6 dimethicone, PEG/PPG-20/20 dimethicone,

With isostearic acid, triglycerides of technical-grade oleic

bis-PEG/PPG-20/20 dimethicone, PEG-12 or PEG-14

acid or of palmitic acid/oleic acid mixtures are suitable as oil

dimethicone, PEG/PPG-14/4 or 14/12 or 20/20 or

components.

[0107] In addition, hydrocarbons, in particular, liquid par

are products such as bis-PEG/PPG-14/ 14 dimethicone

or PEG/PPG-16/16 PEG/PPG-16/16 dimethicone

af?ns and isoparaf?ns, can be used. Examples of hydrocar

bons Which can be used are para?in oil, isohexadecane,

polydecene, vaseline, paraf?num perliquidum, squalane.

[0108]

In addition, it is also possible to use linear or

branched fatty alcohols, such as oleyl alcohol or octyldode

canol, and fatty alcohol ethers, such as dicaprylyl ether.

[0109]

Suitable silicone oils and silicone Waxes are, for

example, polydimethylsiloxanes, cyclomethylsiloxanes, and

aryl- or alkyl- or alkoxy-substituted polymethylsiloxanes

not claimed according to the invention.

18/18 or 17/18 or 15/15. Of particular suitability here

[0120] polysiloxane-polyalkyl-polyether

copolymers

Which do not have a domain character according to the

invention, or corresponding derivatives, such as, for

example, lauryl or cetyl dimethicone copolyols

[0121] mixed esters of pentaerythritol, fatty acids, citric

acid and fatty alcohol as in DE-B-l 165 574 and/or

mixed esters of fatty acids having 6 to 22 carbon atoms,

methylglucose and polyols, preferably glycerol or

polyglycerol.

[0122]

Anionic emulsi?ers or surfactants can also addi

[0110] Furthermore, surfactants, emulsi?ers or dispersion

tionally be used.

auxiliaries can additionally be used. These are preferably

nonionic, anionic, cationic or amphoteric surfactants or

emulsi?ers.

[0123] These contain hydrophilic anionic groups, such as,

for example, carboxylate, sulfate, sulfonate or phosphate

[0111]

Suitable nonionogenic emulsi?ers or surfactants

are compounds from at least one of the following groups:

[0112]

addition products of from 2 to 30 mol of ethylene

oxide and/or 0 to 5 mol of propylene oxide onto linear

fatty alcohols having 8 to 22 carbon atoms, onto fatty

acids having 12 to 22 carbon atoms and onto alkylphe

nols having 8 to 15 carbon atoms in the alkyl group

[0113] Cl2/l8 fatty acid monoesters and diesters of addi

tion products of from 1 to 30 mol of ethylene oxide

onto glycerol

[0114] glycerol mono- and diesters and sorbitan mono

and diesters of saturated and unsaturated fatty acids

having 6 to 22 carbon atoms and ethylene oxide addi

tion products thereof

groups and a lipophilic radical. Skin-compatible anionic

surfactants are knoWn to those skilled in the art in large

numbers and are commercially available. These are, in

particular, alkyl sulfates or alkyl phosphates in the form of

their alkali metal, ammonium or alkanolammonium salts,

alkyl ether sulfates, alkyl ether carboxylates, acyl sarcosi

nates, and sulfosuccinates and acyl glutamates in the form of

their alkali metal or ammonium salts. Suitable anionic

emulsi?ers are also neutralized or partially neutralized citric

acid esters, such as, for example, glyceryl stearate citrate, or

partially saponi?ed glyceryl stearate (glyceryl stearate SE).

[0124]

added.

Cationic emulsi?ers and surfactants can also be

[0125] Quaternary ammonium compounds in particular

can be used as such, for example, alkyltrimethylammonium

halides, such as, for example, cetyltrimethylammonium

[0115] alkyl mono- and oligoglycosides having 8 to 22

carbon atoms in the alkyl radical and ethylene oxide

addition products thereof

ride, but also dialkyldimethylammonium halides, such as,

for example, distearyldimethylammonium chloride. In addi

[0116] addition products of from 2 to 200 mol of

ethylene oxide onto castor oil and/or hydrogenated

midopropyltrimethylammonium chloride or corresponding

castor oil

[0117] partial esters based on linear, branched, unsatur

ated or saturated C6_22 fatty acids, ricinoleic acid, and

12-hydroxystearic acid and glycerol, polyglycerol, pen

taerythritol, dipentaetythritol, sugar alcohols (e.g., sor

bitol), alkyl glucosides (e.g., methyl glucoside, lauryl

glucoside or cetearyl glucoside), and polyglucosides

(e.g., cellulose). Here, the use of partial esters of

glycerol and of polyglycerol is preferred. These are, for

example, glycerol oleate, glycerol isostearate, polyg

lycerol laurates, polyglycerol isostearates, polyglycerol

oleates, polyglycerol polyricinoleates, polyglycerol

poly-12-hydroxystearates, distearoyl polyglyceryl-3

dimer dilinoleate or polyglyceryl-4 diisostearate poly

hydroxystearate sebacate

[0118] mono-, di- and trialkyl phosphates, and mono-,

di- and/or tri-PEG alkyl phosphates and salts thereof

[0119] polysiloxane-polyether copolymers (dimethi

chloride or bromide or behenyltrimethylammonium chlo

tion, monoalkylamidoquats, such as, for example, palmita

dialkylamidoquats can be used. It is also possible to use

readily biodegradable quaternary ester compounds, Which

are mostly quaterniZed fatty acid esters based on mono-, di

or triethanolamine. In addition, alkylguanidinium salts can

be added as cationic emulsi?ers.

[0126] It is also possible to use amphoteric surfactants,

such as, for example, betaines, amphoacetates or amphop

ropionates together With the polyglycerol esters according to

the invention.

[0127]

In addition, knoWn stabiliZers and thickeners for oil

and Water phases can be used.

[0128] For thickening oil phases, all thickeners knoWn to

one skilled in the art are suitable. In particular, mention may

be made here of Waxes, such as hydrogenated castor Wax,

beesWax or microWax. In addition, it is also possible to use

inorganic thickeners, such as silica, alumina or sheet sili

cates (e.g., hectorite, laponite, saponite). Preferably, these

inorganic oil phase thickeners are hydrophobically modi?ed.

cone copolyols) Which do not have a domain character

[0129] Suitable consistency regulators for oil-in-Water

according to the invention, such as, for example, PEG/

emulsions are primarily fatty alcohols or hydroxy fatty

Jun. 7, 2007

US 2007/0128143 A1

alcohols having 12 to 22 and preferably 16 to 18 carbon

copolymer With a domain-type structure (SiH value: 3.53

atoms and also partial glycerides, fatty acids or hydroxy

Val/kg) Were heated to 900 C. and admixed With 10 ppm of

fatty acids.

platinum (based on the total mixture in the form of cis

diamminoplatinum(II) chloride). 30 g of hexadecene-1 Were

[0130]

Suitable thickeners for Water phases are, for

example, polysaccharides, in particular xanthan gum, guar

and guar derivatives, agar agar, alginates and tyloses, cel

lulose and cellulose derivatives, such as, for example, car

boxymethylcellulose, hydroxyethylcellulose, hydroxymeth

ylpropylcellulose, also alkyl-modi?ed sugar derivatives,

such as, for example, cetylhydroxyethylcellulose, also

higher molecular Weight polyethylene glycol mono- and

diesters of fatty acids, carbomers (crosslinked polyacry

lates), polyacrylamides, polyvinyl alcohol and polyvinylpyr

rolidone, surfactants, such as, for example, ethoxylated fatty

acid glycerides, esters of fatty acids With polyols, such as,

for example, pentaerythritol or trimethylolpropane, fatty

added, Whereupon the hydrosilylation reaction started. After

about 30 minutes, the reaction mixture Was admixed With

47.7 g of a hydroxyfunctional allyl polyether constructed

from ethylene oxide units Which had an average molecular

Weight of about 500 g/mol. One hour after the addition of

reactants Was complete, a further 33.3 g of hexadecene-1

Were added and the mixture Was left for a further 2 hours at

the reaction temperature. Gas-volumetric SiH determination

(decomposition of an aliquot sample amount With sodium

butoxide solution in a gas burette) ensured a quantitative

conversion. The virtually colorless, but cloudy alkylpoly

ethersiloxane could be used directly as an emulsi?er.

alcohol ethoxylates With a narroWed homolog distribution or

EXAMPLE 3 (NOT ACCORDING TO THE

alkyl oligoglucosides.

[0131]

INVENTION)

Active ingredients are understood as meaning, for

example, tocopherol, tocopherol acetate, tocopherol palmi

[0138] Analogously to example 2, 100 g of a randomly

equally distributed polydimethylsiloxane-poly(methylhy

tate, ascorbic acid, deoxyribonucleic acid, coenZyme Q10,

retinol derivatives and retinyl derivatives, bisabolol, allan

toin, phytantriol, panthenol, AHA acids, amino acids, hyalu

ronic acid, creatin (and creatin derivatives), guanidine (and

heated to 900 C. and admixed With 10 ppm of platinum

(based on the total mixture in the form of cis-diammino

guanidine derivatives), ceramides, phyto sphingo sine (and

phytosphingosine derivatives), sphingo sine (and sphin

hexadecene-1, the mixture Was stirred for half an hour and

gosine derivatives), pseudoceramides, essential oils, pep

tides, protein hydrolysates, plant extracts and vitamin com

drogen)siloxane copolymer (SiH value: 3.53 Val/kg) Were

platinum(II) chloride). Following the addition of 30 g of

the reaction mixture Was supplemented through the addition

of 47.7 g of a hydroxyfunctional allyl polyether constructed

from ethylene oxide units (average molecular Weight of

plexes.

[0132] Suitable UV ?lters, self-tanning agents, preserva

tives, antioxidants, hydrotropes, antiperspirant active ingre

dient, deodorants, dyes, perfume oils, insect repellents, as

about 500 g/mol). After one hour, a further 33.3 g of

hexadecene-1 Were added and after-reacted for 2 hours.

Gas-volumetric SiH determination (decomposition of an

aliquot sample amount With sodium butoxide solution in a

are described in the prior art, can also be used.

gas burette) demonstrated a quantitative conversion. The

[0133] The folloWing examples are provided for illustra

virtually colorless, clear alkylpolyethersiloxane could be

tive purposes and in no Ways are intended to limit the scope

used directly as an emulsi?er.

of the present invention.

EXAMPLE 4 (ACCORDING TO THE

INVENTION)

EXAMPLE 1 (NOT ACCORDING TO THE

INVENTION)

[0139]

Preparation of an Alkylsiloxane With a Domain

[0134] Preparation of a Polydimethylsiloxane-poly(meth

Type Structure and Ammonium-Functional Groups

ylhydrogen)siloxane Copolymer Interspersed With SiH

Functions in a Domain-Type Manner

[0140] In a 250 ml four-neck ?ask ?tted With KPG stirrer,

re?ux condenser and nitrogen blanketing, 100 g of the

[0135]

polydimethylsiloxane-poly(methylhydrogen)siloxane

In a 2 l four-neck round-bottomed ?ask With KPG

stirrer, re?ux condenser and nitrogen blanketing, 16.3 g of

copolymer With a domain-type structure obtained as in

hexamethyldisiloxane Were admixed With 256.6 g of a

example 1 (SiH value: 3.53 Val/kg) Were heated to 900 C.

and admixed With 10 ppm of platinum (based on the total

poly(methylhydrogen)siloxane (molar mass: 2868.1 g/mol,

SiH value: 15.69 Val/kg) and 867.7 g of decamethylcyclo

pentasiloxane and With 68.5 g of a predried Purolite C 150

MBH (crosslinked, macroporous sulfonic acid polystyrene

resin), and the reaction mixture Was heated at 600 C. for 6

hours With stirring. The sulfonic acid solid-phase catalyst

Was removed by ?ltration after cooling the reaction matrix.

mixture in the form of cis-diamminoplatinum(II) chloride).

55.5 g of hexadecene-1 Were added, Whereupon the hydrosi

lylation reaction started. After about 30 minutes, 15.7 g of

allyl glycidyl ether Were added. The mixture Was left for 2

hours at the reaction temperature and then a gas-volumetric

SiH determination (decomposition of an aliquot sample

amount With sodium butoxide solution in a gas burette) Was

EXAMPLE 2 (ACCORDING TO THE

INVENTION)

[0136]

Preparation of an Alkyl Polyethersiloxane With a

Domain-Type Structure:

[0137] In a 250 ml four-neck ?ask ?tted With KPG stirrer,

re?ux condenser and nitrogen blanketing, 100 g of the

polydimethylsiloxane-poly(methylhydrogen)siloxane

carried out, Which con?rmed a quantitative conversion. The

re?ux condenser Was replaced With a distillation bridge and

excess allyl glycidyl ether as Well as a small amount of

siloxane cycles Were distilled off at reduced pressure (30

mPas). The epoxy oxygen content in the cooled reaction

mixture Was 1%.

[0141] In the next step, 167.6 g of the epoxy-modi?ed

alkylsiloxane Were added dropWise to a mixture consisting

Jun. 7, 2007

US 2007/0128143 A1

Application Example 2

of 31.6 g of coconut fatty acid amide amine (amid CNF/

Degussa) and 6.6 g of acetic acid, and 50 g of isopropanol

With stirring at 250 C. in a 500 ml four-neck ?ask. The

mixture Was heated at the re?ux temperature for 6 hours and

then the clear ?ask contents Were left to cool.

[0148]

For the formulation of Water-in-silicone emulsions,

as are used primarily for example in the areas of antiper

spirants/deodorants or in the ?eld of decorative cosmetics,

previously mostly polyethersiloxanes With a linearly con

APPLICATION EXAMPLES

[0142]

The application examples beloW are intended to

illustrate the subject matter of the invention in more detail

Without limiting it to these examples. The concentration data

in all of the examples is given as % by Weight.

structed ot-u) structure have been used in practice. The

reason for this is the excellent compatibility of the unmodi

?ed siloxane backbone of such a molecule With the silicone

oil phase.

[0149]

Although such emulsi?ers are characterized by a

very pleasant, velvety-silky skin feel, their stabiliZation

potential is limited.

Application Example 1

[0143] This application example is intended to shoW that

a typical comb-type alkylpolyethersiloxane With a domain

type structure and constructed according to the invention

(synthesis example 1) displays excellent application prop

erties as Water-in-oil emulsi?er, Which have additional

advantages over the already excellent application properties

of Water-in-oil emulsi?ers based on randomly constructed,

comb-type alkylpolyethersiloxanes.

[0150] Comb-type

alkylpolyethersiloxanes

With

domain-type structure according to the invention as from

synthesis example 1 noW lead, especially in the ?eld of W/ Si

emulsions, to a similarly pleasant, velvety-silky skin feel,

but exhibit signi?cantly improved stability (as can be seen

from the comparison table).

[0151] The comparative example chosen is a customary

W/ Si emulsi?er With ot-u) modi?cation (bis-PEG/PPG-14/14

dimethicone).

Emulsions

1

Alkylpolyethersiloxane

C1

2.00%

C2

Emulsions

2.00%

With a domain-type

structure from

synthesis example 2

Randomly constructed

2.00%

2.00%

0.10%

0.10%

C2

1.00%

structure from

from comp. Ex. 3

Hydrogenated castor oil

Microcrystalline Wax

0.10%

0.10%

0.10%

0.10%

Caprylic capric triglyceride

8.90%

8.90%

Ethylhexyl palmitate

Paraf?num perliquidum

Glycerol

8.90%

8.90%

Bronopol

Water

3.10%

0.80%

0.05%

ad 100

3.10%

0.80%

0.05%

ad 100

Stability

Viscosity* [Pas]

stable

36

very

NaCl

2.00%

With a domain-type

alkylpolyethersiloxane

Alkylpolyethersiloxane

C1

Application properties

good

6.00%

11.80%

3.10%

6.00%

11.80%

3.10%

0.80%

0.80%

0.05%

ad 100

0.05%

ad 100

stable

45

stable

31

stable

37

good

very

good

good

*Brook?eld RVT spindle C, 10 rpm

synthesis example 2

Bis-PEG/PPG-14/14

dimethicone

Cyclopentasiloxane

B

NaCl

Bronopol

Water

Stability

Viscosity* [Pas]

Application properties

2.00%

1.00%

23.00%

23.00%

24.00% 24.00%

0.60%

0.60%

0.60%

0.60%

0.05%

ad 100

0.05%

ad 100

0.05%

ad 100

0.05%

ad 100

stable

moderatel)

stable

poor2)

23

very

26

very

20

very

31

very

good

good

good

good

*Brook?eld RVT spindle C, 10 rpm

l)Signi?cant Water separation after three freeze-thaw cycles (3x 150

C./20 C.)

2)Emulsion decomposition after three thaW cycles (3x 150 C./20O C.);

signi?cant Water separation after storage for one month at 450 C.

[0144]

The Water-in-oil emulsions 1 and 2 according to the

invention exhibited stabilities Which are absolutely compa

[0152] The investigated emulsions are extremely critical,

rable With those knoWn from randomly modi?ed alkylpoly

ethersiloxanes. Moreover, in the example emulsions 1 and 2

according to the invention, hoWever, a loWer emulsion

Wax-free formulations. The emulsions With a reduced emul

viscosity Was observed.

[0145]

si?er content of 1% in particular disclose the enormously

strong stabiliZation effect of the polyethersiloxanes accord

ing to the invention.

A loWer emulsion viscosity for a constant stability

is advantageous in the case of W/O inasmuch as it alloWs

better spreadability of the emulsion on the skin.

[0146] Additionally, the emulsions according to the inven

Application Example 3

[0153] This application example is intended to shoW that

tion exhibited a generally someWhat lighter skin feel than

a typical comb-type alkylpolyethersiloxane With a domain

type structure constructed according to the invention (syn

Was the case With the comparison emulsions based on

thesis example 2) displays excellent application properties

randomly modi?ed alkylpolyethersiloxanes.

[0147] Thus, the block-type alkylpolyethersiloxanes

according to the invention are characteriZed by surprisingly

as ingredient in skin-cleaning compositions, Which has

additional advantages over the already excellent application

properties of knoWn refatting agents based on randomly

positive application properties.

constructed, comb-type alkylpolyethersiloxanes.

Jun. 7, 2007

US 2007/0128143 A1

Skin-cleaning composition

Sodium laureth sulfate 28%

Perfume

Alkylpolyethersiloxane With a domain-type

C1

C2

C3

32.0%

0.5%

32.0%

0.5%

32.0%

0.5%

32.0%

0.5%

0.5%

0.5%

ABIL B 88184 PEG/PPG-20/6 dimethicone

0.5%

ABIL B 8832 Bis-PEG/PPG-20/20 dimethicone

0.5%

REWOTERIC AM C Sodium cocoamphoacetate 30%

TEGO betaine F 50

6.0%

6.0%

6.0%

6.0%

6.0%

6.0%

6.0%

6.0%

Citric acid (30% in Water)

ANTIL 200 PEG-200 hydrogenated glyceryl

1.5%

1.5%

1.5%

1.5%

1.5%

1.5%

1.5%

1.5%

1%

ad 100

1%

ad 100

1%

ad 100

1%

ad 100

4.2

3.2

4.5

structure from synthesis example 2

Randomly constructed alkylpolyethersiloxane

from comp. Ex. 3 ABIL EM 90 Cetyl

PEG/PPG-10/1 Dimethicone

palmate; PEG-7 glyceryl cocoate

Sodium chloride

Water

Evaluation:

Skin feel

[0154] Compared to comparison products C1 to C3, the

skin-cleaning composition 1 according to the invention

Application Example 4

exhibits the best skin feel. This parameter evaluates skin

smoothness and softness, the absence of sticky residues and

the perceived skin moisture in the in-vivo experiment on

human skin. Fonnulation C3 in Which a polyethersiloxane

[0155] This application example is intended to shoW that

a typical comb-type alkylsiloxane With ammonium-func

With an undisturbed polydimethylsiloxane Was used With

bis-PEG/PPG-20/20 dimethicone also exhibits a Weaker

tional groups and With a domain-type structure and con

structed according to the invention (synthesis example 4)

1 according to the invention. The evaluation detailed in the

exhibits excellent application properties as conditioner for

haircare products, Which have additional advantages over

the already excellent application properties of knoWn con

table Was carried out on the scale: 1=poor to 5=excellent.

ditioners based on modi?ed siloxanes.

evaluation in skin feel than the skin-cleansing composition

Hair shampoos

Sodium laureth sulfate, 28%

Perfume

Alkylsiloxane With ammonium-?anctional groups

C1

C2

32.0%

0.5%

32.0%

0.5%

32.0%

0.5%

32.0%

0.5%

0.5%

0.5%

ABIL Quat 3272 Quatemium-80

Jaguar C 162 Hydroxypropyl Guar

0.5%

0.5%

0.2%

0.2%

REWOTERIC AM C Sodium cocamphoacetate 30%

TEGO betaine F 50

6.0%

6.0%

6.0%

6.0%

6.0%

6.0%

6.0%

6.0%

Citric acid (30% in Water)

ANTIL 200 PEG-200 Hydrogenated glyceryl

1.5%

1.5%

1.5%

1.5%

1.5%

1.5%

1.5%

1.5%

1%

ad 100%

1%

ad 100%

1%

ad 100%

1%

ad 100%

With a domain-type structure from synthesis

example 4

Hydroxypropyltrimonium chloride

palmate; PEG-7 glyceryl cocoate

Sodium chloride

Water

Evaluation:

Wet combability

3.5

2.5

4.5

3.0

Wet feel

4.2

2.5

4.5

3.2

Dry combability

Dry feel

4.0

4.5

3.5

3.2

4.5

5.0

3.5

3.8

Jun. 7, 2007

US 2007/0128143 A1

[0156] Compared to the comparison products Cl and C2,

the hair shampoos l and 2 according to the invention each

B0 is butylene oxide radical,

exhibit better conditioning properties. In particular, the

D0 is dodecenyl oxide radical,

evaluation of the feel of the Wet hair and after drying comes

out signi?cantly better in the case of shampoos l and 2

containing the conditioner according to the invention as in

example 4. The evaluations detailed in the table are made on

the scale: l=poor to 5=excellent. The assessment Was made

S0 is styrene oxide radical,

using sections of hair by an evaluation panel.

[0157] While the invention has been described herein With

reference to speci?c embodiments, features and aspects, it

Will be recogniZed that the invention is not thus limited, but

rather extends in utility to other modi?cations, variations,

b, c, d, e, f are 20 in particular

b is 0 to 50,

c is 0 to 50,

d, e, f are identical or different and are 0 to 10

and the sum

applications, and embodiments, and accordingly all such

other modi?cations, variations, applications, and embodi

b+c+d+e+f is a and

ments are to be regarded as being Within the spirit and scope

of the invention.

a is l to 50,

What is claimed is:

1. A method of producing organomodi?ed siloxanes With

domain-type distribution comprising, partially or com

and

3. radicals containing oxirane groups of the formulae 3a

to 3d

pletely reacting

A) hydrogensiloxanes With a degree of distribution (per

sistency ratio) (11) of components [A] and [B] in the

copolymer [AB]

of 11>l, With

B) ole?nically unsaturated compounds, acetylenically

unsaturated compounds or a mixture of said unsatur

ated compounds.

2. The method of producing organomodi?ed siloxanes as

claimed in claim 1, Wherein, for producing methylsiloxanes,

a mixture of hexamethyldisiloxane, poly(methyl)hydrogen

siloxane and siloxane cycles are equilibrated as starting

material.

3. The method of producing organomodi?ed siloxanes as

claimed in claim 1, Wherein the ole?nically unsaturated

compounds of the general formula (1) CH2=CHRi

(CH2)n-A are used, in WhichA is at least one radical selected

from the group of

l. optionally substituted linear and/or cyclic hydrocarbons

Which optionally contain functional groups,

2. randomly or blockWise constructed oxyalkylene chains

i(OAlk)S-R, in Which

R is H, a Cl_l8-alkyl radical Which is optionally sub

stituted and/or optionally contains heteroatoms, or

the radical of a monobasic and/or polybasic Cl_22

carboxylic acid, Which can optionally contain

hydroxyl groups, the radical of an inorganic acid

selected from the group sulfuric acid, sulfonic acid,

phosphoric acid,

OAlk is the radical -(EO)bi(PO)Ci(BO)d-(DO)ei

(SO)fi Where

E0 is ethylene oxide radical,

PO is propylene oxide radical,

(and When x=0)

4. at least one amine/ammonium radical, -MZ, -[M-Z]g+

h*XJ', in Which

M is a divalent radical chosen from the group

Jun. 7, 2007

US 2007/0128143 A1

11

-continued

-continued

4r

Q42

CH3

R3

4f

in Which

R1, R2, R3, R4, independently of one another, are H,

CH3

Cl_22-alkyl radicals Which may also contain

OH

hydroxyl groups,

R5, R6 are Cl_22-alkyl radicals Which may also contain

hydroxyl groups,

OH

D is iOi or iNR7i Where R7=alkyl or hydroxy

alkyl radical With 1-4 carbon atoms,

X- may be an organic or inorganic anion,

h*j is the same as the numerical value of g,

5. polyhydroxyorganyl radicals of the general formula

iRSiPH, Where the radical

R8 acts as spacer betWeen siloxane backbone and poly

hydroxyorganyl radical or sugar radical and is of the

type knoWn from the prior art for polyhydroxyorga

nyl- or sugar-modi?ed siloxanes,

4k

PH is a polyhydroxyorganyl radical Which contains a

de?ned number n of (C4OH) groups, Where n is

22, preferably 5 to 15,

from the group mono-, di-, oligo- or polysaccharide,

their glycosides or corresponding derivatives, in

particular glucose, maltose, raf?nose, sorbitol, glu

cosamine, glucopyranosylamine, glucamine, N-me

thylglucamine, isomaltamine, gluconic acid, hepta

gluconic acid;

and Z may be one of the radicals

6. betaine groups,

40

in Which

X is %OOi, S03, PO42,

R9 is alkylene radicals having up to 10 carbon atoms,

R10 is alkylene radicals having up to 2 to 6 carbon

atoms,

yis0orl,

ZisOorl,

Z'isl,2or3,

and R1, R2 are identical or different and have the

meaning given above, together form an imidaZo

line ring or are 4CH24CH24OH, i(CH2)Zi

X.

Jun. 7, 2007

US 2007/0128143 A1

A is an inorganic or organic anion Which originates from

7. guanidine groups of the formulae (6a, 6b or 6c)

RU=iN-G

(6a)

RU=iN-Q*A

(6b)

R=i(N)XiS

in Which

(6c)

a customary physiologically compatible acid HA,

S is H, a polyalkylene oxide polyether of the general

formula

CmH2mO(C2H4O)m(C3H6O)oR7

G is a guanidino group With the general formula (6a',

6a2)

in Which

m is l to 6, in particular 3, 6,

R12

(631)

R12

Weight betWeen 100 and 6000 g/mol and

N||NR12

RIZ/

R17 is H or an optionally branched aromatic or alicyclic

(632)

12'

12

N||NR12

R12

n, 0, independently of one another, are 0 to 100, in

particular 0 to 20 and the polyether has a molecular

hydrocarbon radical having 2 to 30 carbon atoms,

preferably 4 to 22 carbon atoms, and optionally

containing double bonds, or a UV-absorbing group,

in particular cinnamic acid or methoxycinnamic

acid.

4. An organomodi?ed siloxane With block character pro

duced as claimed in accordance to claim 1.

5. A method for producing and stabiliZing cosmetic for

mulations comprising adding at least one organomodi?ed

R12

siloxane With a block character obtained in accordance to

claim 1 to a cosmetic formulation in an amount effect to

and/or salts or hydrates thereof, in Which

R12, independently of the others, is hydrogen or an

optionally branched hydrocarbon radical optionally

stabiliZe said cosmetic formulation.

6. The method as claimed in claim 5, Wherein, for

R12 may be R12 or an alkylene group Which is joined

producing methylsiloxanes, a mixture of hexamethyldisilox

ane, poly(methyl)hydrogensiloxane and siloxane cycles are

equilibrated as starting material.

to M via carbon atoms or heteroatoms and thus forms

a 5- to 8-membered ring and

?nically unsaturated compounds of the general formula (1)

containing double bonds, or

N is a di- or polyvalent hydrocarbon radical having at

least 4 carbon atoms Which has a hydroxyl group and

7. The method as claimed in claim 5, Wherein the ole

CH2=CHRi(CH2)n-A are used, in Which A is at least one

radical selected from the group of

Which may be interrupted by one or more oxygen

atoms or nitrogen atoms or quaternary ammonium

l. optionally substituted linear and/or cyclic hydrocarbons

groups or esters or amide functions,

2. randomly or blockWise constructed oxyalkylene chains

i(OAlk)S-R, in Which

Q+ is a radical of the formula (6d)

R13

Which optionally contain functional groups,

(6d)

R14

R13, R14 are alkyl radicals having 1 to 4 carbon atoms,

R is H, a CHS-alkyl radical Which is optionally sub

stituted and/or optionally contains heteroatoms, or

the radical of a monobasic and/or polybasic Cl_22

carboxylic acid, Which can optionally contain

hydroxyl groups, the radical of an inorganic acid

selected from the group sulfuric acid, sulfonic acid,

phosphoric acid,

OAlk is the radical -(EO)bi(PO)Ci(BO)d-(DO)ei

(SO)fi Where

E0 is ethylene oxide radical,

PO is propylene oxide radical,

B0 is butylene oxide radical,

D0 is dodecenyl oxide radical,

S0 is styrene oxide radical,

R16 may be a monovalent hydrocarbon radical having

1 to 22 carbon atoms,

b, c, d, e, fare 20, in particular

b is to 50,

gis0to6

c is 0 to 50,

his0orl,

d, e, f are identical or different and are 0 to 10

US 2007/0128143 A1

Jun. 7, 2007

l3

and the sum

.

-continued

b+c+d+e+f1s a and

a is l to 50,

4g

OH

and

3. radicals containing oxirane groups of the formulae 3a

4h

to 3d

35_

OH

OCH2CHCH2

\0

Bb

4J

OH

4k

(and When X=0)

4@

OH

4. at least one amine/ammonium radical, -MZ, -[M-Z]g+

h*XJ_, in Which

M is a divalent radical chosen from the group

4

m

R1

/

30

\R2

4n

3d

1'14

N[-CH2-]TDJ-|R5

40

_N||R6

K/N

.

4P

and Z may be one of the radicals

'

R1

NR3

45.

OCH2CHCH2

OH

R2

4b

4q

R3

OCH2CH

CH2OH

|

40

CHCH2

OH

4r

1'8

4d

I|\I[-CH2-]TDJ-|R5

X

R3

CHCH2OH

4e

'

CH3

OH

in Which

R1, R1, R3, R4, independently of one another, are H,

4f

Cl_22-alkyl radicals Which may also

contain

hydroxyl groups,

CH3

OH

R5, R6 are Cl_22-alkyl radicals Which may also contain

hydroxyl groups,

D is iOi or iNR7i Where R7=alkyl or hydroxy

alkyl radical With 1-4 carbon atoms,

Jun. 7, 2007

US 2007/0128143 A1

X may be an organic or inorganic anion,

-continued

h*j is the same as the numerical value of g,

(632)

5. polyhydroxyorganyl radicals of the general formula

iRSiPH, Where the radical

R8 acts as spacer betWeen siloxane backbone and poly

hydroxyorganyl radical or sugar radical and is of the

type knoWn from the prior art for polyhydroxyorga

nyl- or sugar-modi?ed siloxanes,

PH is a polyhydroxyorganyl radical Which contains a

de?ned number n of (C4OH) groups, Where n is

22, preferably 5 to 15,

R12

R12

I _ l2

N||N R

A.

RIZ/ \Rlz

and/or salts or hydrates thereof, in Which

R12, independently of the others, is hydrogen or an

optionally branched hydrocarbon radical optionally

containing double bonds, or

from the group mono-, di-, oligo- or polysaccharide,

their glycosides or corresponding derivatives, in

particular glucose, maltose, raf?nose, sorbitol, glu

cosamine, glucopyranosylamine, glucamine, N-me

thylglucamine, isomaltamine, gluconic acid, hepta

gluconic acid;

R12 may be R12 or an alkylene group Which is joined

to M via carbon atoms or heteroatoms and thus forms

a 5- to 8-membered ring and

N is a di- or polyvalent hydrocarbon radical having at

least 4 carbon atoms Which has a hydroxyl group and

Which may be interrupted by one or more oxygen

atoms or nitrogen atoms or quaternary ammonium

groups or esters or amide functions,

Q+ is a radical of the formula (6d)

(6d)

R13

++cH2>gR15->hR16

6. betaine groups,

R14

in Which

X is 400*, $03, PO42,

R9 is alkylene radicals having up to 10 carbon atoms,

R13, R14 are alkyl radicals having 1 to 4 carbon atoms,

R15 is

R10 is alkylene radicals having up to 2 to 6 carbon

atoms,

yis0orl,

Zis0orl,

R16 may be a monovalent hydrocarbon radical having

Z'isl,2or3,

1 to 22 carbon atoms, g is 0 to 6 h is 0 or 1,

and R1, R2 are identical or different and have the

meaning given above, together form an imidaZo

line ring or are 4CH24CH2iOH, i(CH2)ni

Xs

A is an inorganic or organic anion Which originates from

a customary physiologically compatible acid HA,

S is H, a polyalkylene oxide polyether of the general

formula

CrnH2rnO(C2H4O)n(C3H6O)oR7

7. guanidine groups of the formulae (6a, 6b or 6c)

RU=iN-G

(6a)

in Which

RU=iN-Q+A

(6b)

m is l to 6, in particular 3, 6,

R=i(N)XiS

(6c)

n, 0, independently of one another, are 0 to 100, in

particular 0 to 20 and the polyether has a molecular

in Which

Weight betWeen 100 and 6000 g/mol and

G is a guanidino group With the general formula (6a',

6a2)

R12

12

N||NR12

RIZ/

(6&1)

R17 is H or an optionally branched aromatic or alicyclic

hydrocarbon radical having 2 to 30 carbon atoms,

preferably 4 to 22 carbon atoms, and optionally con

taining double bonds, or a UV-absorbing group, in

particular cinnamic acid or methoxycinnamic acid.

8. A formulation Which comprises one or more organo

modi?ed siloxanes With block character as claimed in claim

4.

Das könnte Ihnen auch gefallen

- Patent Application Publication (10) Pub. No.: US 2009/0192234 A1Dokument26 SeitenPatent Application Publication (10) Pub. No.: US 2009/0192234 A1Deva DrillTechNoch keine Bewertungen

- European Patent Application: Manufacturing Process For Tablet Formulations Comprising CefuroximeDokument7 SeitenEuropean Patent Application: Manufacturing Process For Tablet Formulations Comprising CefuroximeDezar D'pharmaCistNoch keine Bewertungen

- Silicon Wax Emulsion For Polyurethane Water Release AgentDokument3 SeitenSilicon Wax Emulsion For Polyurethane Water Release Agentmyosi laboratoriumNoch keine Bewertungen

- Emulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyVon EverandEmulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyShahin RoohinejadNoch keine Bewertungen

- Encapsulation and Controlled Release Technologies in Food SystemsVon EverandEncapsulation and Controlled Release Technologies in Food SystemsDr Jamileh M. LakkisNoch keine Bewertungen

- EP0338486A2Dokument12 SeitenEP0338486A2Gemblung01Noch keine Bewertungen

- EP2414464B1Dokument48 SeitenEP2414464B1vipin1222Noch keine Bewertungen

- TEPZZ 975 - Z7A - T: European Patent ApplicationDokument17 SeitenTEPZZ 975 - Z7A - T: European Patent Applicationfehmi BenjeddouNoch keine Bewertungen

- US20040224869A1Dokument3 SeitenUS20040224869A1Dileepa DissanayakeNoch keine Bewertungen

- Drying of Formulations Containing Surfactants and PolymersDokument18 SeitenDrying of Formulations Containing Surfactants and Polymersحيدر الوائليNoch keine Bewertungen

- Spray Drying Techniques for Food Ingredient EncapsulationVon EverandSpray Drying Techniques for Food Ingredient EncapsulationNoch keine Bewertungen

- Ghasemi2020 Article PreparationOfStableMultipleEmuDokument9 SeitenGhasemi2020 Article PreparationOfStableMultipleEmuDaffa RamadhaniNoch keine Bewertungen

- US4790877Dokument4 SeitenUS4790877indoarmy145Noch keine Bewertungen

- Carbinol FunctionalDokument6 SeitenCarbinol FunctionalJesus Chucho BruzualNoch keine Bewertungen

- United States Patent: 6, 1989 Patent Number: Date of Patent: Shimuzu Et AlDokument8 SeitenUnited States Patent: 6, 1989 Patent Number: Date of Patent: Shimuzu Et AlEsat KostakNoch keine Bewertungen

- Transparent Bar Soap Composition Comprising Glycerine Derivative US6656893 PDFDokument15 SeitenTransparent Bar Soap Composition Comprising Glycerine Derivative US6656893 PDFpertmasterNoch keine Bewertungen

- United States Patent (10) Patent No.: US 8,143,340 B2Dokument5 SeitenUnited States Patent (10) Patent No.: US 8,143,340 B2Awais KhanNoch keine Bewertungen

- Pva and Polyalkylene GlycolDokument7 SeitenPva and Polyalkylene Glycolhaqmaula81Noch keine Bewertungen

- US20050197421A1Dokument7 SeitenUS20050197421A1Talha RafiqueNoch keine Bewertungen

- Can Wetting and Dispersing Additives Improve The Durability of CoatingsDokument10 SeitenCan Wetting and Dispersing Additives Improve The Durability of CoatingsManuel ChireNoch keine Bewertungen

- US3585051Dokument3 SeitenUS3585051Archa UnniNoch keine Bewertungen

- LesitinDokument29 SeitenLesitinsilviaramadhani232Noch keine Bewertungen

- Cellulose Derivatives Such As Methylcellulose, Hydroxypropyl Cellulose, and Carboxymethyl Cellulose (CMC)Dokument22 SeitenCellulose Derivatives Such As Methylcellulose, Hydroxypropyl Cellulose, and Carboxymethyl Cellulose (CMC)Demeke Gezahegn TeseraNoch keine Bewertungen

- Synthesis and Characterization of Porous Silica Gels For Biomedical ApplicationsDokument5 SeitenSynthesis and Characterization of Porous Silica Gels For Biomedical ApplicationsPham Thi Thu HongNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0086848 A1Dokument14 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0086848 A1梅汉Noch keine Bewertungen

- New Research Progress of The Demulsification of Produced Liquid by Polymer FloodingDokument7 SeitenNew Research Progress of The Demulsification of Produced Liquid by Polymer FloodingximenaesgNoch keine Bewertungen

- Son Enteric Film-CoatingDokument2 SeitenSon Enteric Film-CoatingLina Tadeo FabiánNoch keine Bewertungen

- Improved Water Barrier Properties of Calcium Alginate Capsules Modified by Silicone OilDokument11 SeitenImproved Water Barrier Properties of Calcium Alginate Capsules Modified by Silicone OilFabrice BassamaNoch keine Bewertungen

- Molecules: Development of Water-in-Oil Emulsions As Delivery Vehicles and Testing With A Natural Antimicrobial ExtractDokument15 SeitenMolecules: Development of Water-in-Oil Emulsions As Delivery Vehicles and Testing With A Natural Antimicrobial ExtractKing in The northNoch keine Bewertungen

- Hybrid Topcoat Formulations For PaperDokument11 SeitenHybrid Topcoat Formulations For PaperRakeshNoch keine Bewertungen

- Us20080076843a1 PDFDokument13 SeitenUs20080076843a1 PDFBilen SeleshiNoch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2004/0191514 A1Dokument5 SeitenPatent Application Publication (10) Pub. No.: US 2004/0191514 A1Xiaofeng MengNoch keine Bewertungen

- Polyurethanes: Science, Technology, Markets, and TrendsVon EverandPolyurethanes: Science, Technology, Markets, and TrendsBewertung: 1 von 5 Sternen1/5 (1)

- Waterborne Nitrocellulose Lacquer EmulsionDokument8 SeitenWaterborne Nitrocellulose Lacquer EmulsionCheng Soon FattNoch keine Bewertungen

- Literature Review On Starch ModificationDokument7 SeitenLiterature Review On Starch Modificationekvxrxrif100% (1)

- European Patent Application A61K 31/43, A61K 31/424,: Pharmaceutical Formulations Comprising Amoxicillin and ClavulanateDokument12 SeitenEuropean Patent Application A61K 31/43, A61K 31/424,: Pharmaceutical Formulations Comprising Amoxicillin and Clavulanatejibran khanNoch keine Bewertungen

- Soil Release FinishesDokument30 SeitenSoil Release Finishestanveer_buitemsNoch keine Bewertungen

- Nanocellulose From Cocoa Shell in Pickering EmulsiDokument21 SeitenNanocellulose From Cocoa Shell in Pickering EmulsiRahita MelyssaNoch keine Bewertungen

- Accepted ManuscriptDokument22 SeitenAccepted ManuscriptMehmet ÖzdemirNoch keine Bewertungen

- Foaming ProductsDokument9 SeitenFoaming ProductsMukti RaoNoch keine Bewertungen

- Electrospinning Cellulose and Cellulose Derivatives: Margaret W. FreyDokument15 SeitenElectrospinning Cellulose and Cellulose Derivatives: Margaret W. FreyDanielle JuaisNoch keine Bewertungen

- Polymers: Enzyme-Catalyzed Modifications of Polysaccharides and Poly (Ethylene Glycol)Dokument20 SeitenPolymers: Enzyme-Catalyzed Modifications of Polysaccharides and Poly (Ethylene Glycol)Cuong CaoNoch keine Bewertungen

- A New Mix Composition To Increase The Shelf Life of Emulsion Based BitumenDokument9 SeitenA New Mix Composition To Increase The Shelf Life of Emulsion Based BitumenDaniyal AhmadNoch keine Bewertungen

- United States Patent: (10) Patent N0.: (45) Date of PatentDokument24 SeitenUnited States Patent: (10) Patent N0.: (45) Date of PatentAlberto BuenoNoch keine Bewertungen

- US20020026015A1Dokument11 SeitenUS20020026015A1Alexander Franco CastrillonNoch keine Bewertungen

- ?nite States Tent n91: AssigneeDokument3 Seiten?nite States Tent n91: AssigneeererNoch keine Bewertungen

- Us 4371639Dokument5 SeitenUs 4371639atnmmm100Noch keine Bewertungen

- Enzyme-Based Biohybrid Foams Designed For Continuous Flow Heterogeneous Catalysis and Biodiesel ProductionDokument5 SeitenEnzyme-Based Biohybrid Foams Designed For Continuous Flow Heterogeneous Catalysis and Biodiesel ProductionAnna Leticia PighinelliNoch keine Bewertungen

- Porous Cellulose - Aerogels - Cellu-ILDokument13 SeitenPorous Cellulose - Aerogels - Cellu-ILfran tonholiNoch keine Bewertungen

- Competitive Adsorption of Proteins With Methylcellulose and Hydroxypropyl MethylcelluloseDokument7 SeitenCompetitive Adsorption of Proteins With Methylcellulose and Hydroxypropyl MethylcelluloseRayito HernándezNoch keine Bewertungen

- 06-Mechanisms of Crude Oil DemulsificationDokument10 Seiten06-Mechanisms of Crude Oil DemulsificationajostosNoch keine Bewertungen

- Us20090162517a1 PDFDokument8 SeitenUs20090162517a1 PDFPriya NarayananNoch keine Bewertungen

- Progress in Organic Coatings: Kamakshi. R. Christopher, Amarjeet Pal, Girish Mirchandani, Tapan DharDokument6 SeitenProgress in Organic Coatings: Kamakshi. R. Christopher, Amarjeet Pal, Girish Mirchandani, Tapan DharZahratun NurNoch keine Bewertungen

- TEG Improve ProcessDokument7 SeitenTEG Improve ProcessRENNY JAIR BASTIDAS PE�ANoch keine Bewertungen

- Technical PaperDokument10 SeitenTechnical Paperalfosoa5505Noch keine Bewertungen

- US20050282931A1Dokument6 SeitenUS20050282931A1Dr. Ahmed Abdel-HakimNoch keine Bewertungen

- Surface AdditivesDokument24 SeitenSurface AdditivesHai PhongNoch keine Bewertungen

- Food Hydrocolloid Edible Films and CoatingsDokument34 SeitenFood Hydrocolloid Edible Films and CoatingsLiani FarahanaNoch keine Bewertungen

- NR 006 2001-05 ExAct 06 PDFDokument16 SeitenNR 006 2001-05 ExAct 06 PDFMostofa RubalNoch keine Bewertungen

- ANALYTICAL CHEMISTRY Lecture1 (2012)Dokument28 SeitenANALYTICAL CHEMISTRY Lecture1 (2012)Muhammad Yahya HanifNoch keine Bewertungen

- ITS Research 18125 TablesDokument1 SeiteITS Research 18125 TablesMuhammad Yahya HanifNoch keine Bewertungen

- GHS AgendaDokument2 SeitenGHS AgendaMuhammad Yahya HanifNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0128143 A1Dokument15 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0128143 A1Muhammad Yahya HanifNoch keine Bewertungen

- ANALYTICAL CHEMISTRY Lecture1 (2012)Dokument28 SeitenANALYTICAL CHEMISTRY Lecture1 (2012)Muhammad Yahya HanifNoch keine Bewertungen

- Spektrum Asam AskrbtDokument1 SeiteSpektrum Asam AskrbtMuhammad Yahya HanifNoch keine Bewertungen

- Translate TPS (Bahasa Indonesia)Dokument3 SeitenTranslate TPS (Bahasa Indonesia)Muhammad Yahya HanifNoch keine Bewertungen

- Intro To Analytical Chemistry08Dokument47 SeitenIntro To Analytical Chemistry08Muhammad Yahya HanifNoch keine Bewertungen

- Proposal IYF2014 SpeakerDokument10 SeitenProposal IYF2014 SpeakerMuhammad Yahya HanifNoch keine Bewertungen

- Introduction To Analytical ChemistryDokument15 SeitenIntroduction To Analytical ChemistryMuhammad Yahya HanifNoch keine Bewertungen

- II. 8 .2 Alat Laboratorium 2Dokument290 SeitenII. 8 .2 Alat Laboratorium 2085270710307Noch keine Bewertungen

- Food MicrobiologyDokument16 SeitenFood MicrobiologyrajeevkusugalNoch keine Bewertungen

- Introduction To Analytical ChemistryDokument15 SeitenIntroduction To Analytical ChemistryMuhammad Yahya HanifNoch keine Bewertungen

- Protective Effect of Potato Peel Extract Against Carbon Tetrachloride-Induced Liver Injury in RatsDokument17 SeitenProtective Effect of Potato Peel Extract Against Carbon Tetrachloride-Induced Liver Injury in RatsAzmi SevenfoldismNoch keine Bewertungen

- Data Persediaan Medis XL OceDokument38 SeitenData Persediaan Medis XL OceRonyChanyaNoch keine Bewertungen

- Prometric Mcqs Plus CaculationsDokument147 SeitenPrometric Mcqs Plus CaculationsShanaz KhanNoch keine Bewertungen

- Daftar Barang Astro 30 Maret 2023Dokument34 SeitenDaftar Barang Astro 30 Maret 2023ngawi farmasiNoch keine Bewertungen

- Cholinergic MCQ Www.1aimDokument68 SeitenCholinergic MCQ Www.1aimSarah Ahmed100% (2)

- Bio Oil Tebu 24 Jan 2022Dokument13 SeitenBio Oil Tebu 24 Jan 2022Haniif PrasetyawanNoch keine Bewertungen

- OxidationDokument20 SeitenOxidationPranayNoch keine Bewertungen

- Journal of Pharmacognosy and PhytochemistryDokument15 SeitenJournal of Pharmacognosy and PhytochemistryMaryamNoch keine Bewertungen

- Pharma La La La LaDokument32 SeitenPharma La La La LaAndie AlbinoNoch keine Bewertungen

- Food Packaging Technology: BS-Final Year 18-March-2020Dokument15 SeitenFood Packaging Technology: BS-Final Year 18-March-2020SONIA NABINoch keine Bewertungen

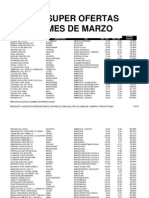

- Super Ofertas Mes de Marzo: Ahorro Articulo Laboratorio SAL Pre - Pub Pre - Ofe OfertaDokument12 SeitenSuper Ofertas Mes de Marzo: Ahorro Articulo Laboratorio SAL Pre - Pub Pre - Ofe Ofertagustavoadolfo3210Noch keine Bewertungen

- Daftar Obat FormulariumDokument16 SeitenDaftar Obat FormulariumIFRS MEDIMASNoch keine Bewertungen

- Structural IsomerismDokument3 SeitenStructural IsomerismKimberly IgbalicNoch keine Bewertungen

- Boric Acid as Catalysts for the Esterification of α-Hydroxycarboxylic AcidsDokument4 SeitenBoric Acid as Catalysts for the Esterification of α-Hydroxycarboxylic Acidshager98Noch keine Bewertungen

- Perry - Heat of VapDokument5 SeitenPerry - Heat of VapJia Yuan ChngNoch keine Bewertungen

- Mitsunobu ReactionDokument6 SeitenMitsunobu ReactionVirat KohNoch keine Bewertungen

- De HydrationnnnnnnDokument2 SeitenDe HydrationnnnnnnMoon YoungheeNoch keine Bewertungen

- Module 7 RationaleDokument2 SeitenModule 7 RationaleG INoch keine Bewertungen

- Format Stock Opname FarmasiDokument51 SeitenFormat Stock Opname FarmasiHamid zeroNoch keine Bewertungen

- Stokon Vs Detil PenjualanDokument240 SeitenStokon Vs Detil Penjualanasthenia8Noch keine Bewertungen

- Biomolecules - Shobhit Nirwan-2 PDFDokument37 SeitenBiomolecules - Shobhit Nirwan-2 PDFKanik100% (1)

- Organic Compounds ActivitiesDokument11 SeitenOrganic Compounds Activitiesjoan marie PeliasNoch keine Bewertungen

- Ahmad Mauludin MubarokDokument6 SeitenAhmad Mauludin Mubarokmamat mubarokNoch keine Bewertungen

- Chapter 17: Alcohols and PhenolsDokument29 SeitenChapter 17: Alcohols and Phenols張湧浩Noch keine Bewertungen

- BaruDokument7 SeitenBaruKoasNoch keine Bewertungen

- MCQs On Amino Acids For NEET 2023 PDFDokument1 SeiteMCQs On Amino Acids For NEET 2023 PDFAli HassanNoch keine Bewertungen

- RFQ Medicine 20170523Dokument16 SeitenRFQ Medicine 20170523Vijay BarreyNoch keine Bewertungen

- Cholesterol Risk ChartDokument2 SeitenCholesterol Risk ChartNishantha SenaratneNoch keine Bewertungen

- IzatinDokument141 SeitenIzatinthamizh555Noch keine Bewertungen

- Protein Synthesis GizmoDokument6 SeitenProtein Synthesis GizmomInd prOceSsNoch keine Bewertungen