Beruflich Dokumente

Kultur Dokumente

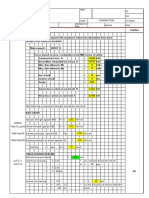

T5 Calculations

Hochgeladen von

MatAlengCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T5 Calculations

Hochgeladen von

MatAlengCopyright:

Verfügbare Formate

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

1 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

TRUSS ANALYSIS & DESIGN : LOADING (CP 3 : Chapter V : Part 1 : 1972)

1

Dead Load

Self weight

0.060

kN/m2

0.460

kN/m2

Battens

0.030

kN/m2

Services

0.120

kN/m2

Ceiling

0.130

kN/m2

Gk

0.800

kN/m2

Qk

0.250

kN/m2

Roofing

(Concrete tile)

Live Load

Imposed load

Wind Load(CP 3 : Chapter V : Part 2 : 1972)

Basic Wind Speed, Vb

35.000 m/s

5.4 Topography Factor, S1

1.000

5.6 Statistical Factor, S3

1.000

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

2 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

5.5 Ground Roughness

Where Building Class, Category & Height Above Ground (H) :

Class A:

All units of cladding, glazing and roofing and their immediate fixings

and individual members of unclad structures

[

Class B:

All buildings and structures where neither the greatest horizontal

dimension nor the greatest vertical dimension exceeds 50m(165ft)

[

Class C:

All buildings and structures whose greatest horizontal dimension or

greatest vertical dimension exceeds 50m (165 ft)

[

Category (1) :

Open country with no obstructions

[

Category (2) :

Open country with scattered windbreaks

[

Category (3) :

Country with many windbreaks; small towns; outskirts of large cities

[

Category (4) :

Surface with large and frequent obstructions e.g. city centres

[

Table 3 :

Height, H =

Take, Factor, S2 =

6.697

m

0.681

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

3 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

5.1 Design Wind Speed, VS

6.0 Dynamic Pressure,

qs

where k

Vb.S1.S2.S3

35.000

23.819

m/s

kVs2

0.613 (

0.348

kN/m2

0.61

(in S. I. Units)

1.000 X

0.681

23.819 )2 / 1000 kN/m2

7.2 Pressure Coefficients (Cpe & Cpi)

Table 8 : Pressure Coefficients Cpe for Pitch Roofs of Rectangular Clad Buildings

Building height, h

6.697 m

Building width, w

9.403 m

Building height/width

6.697

0.712

i.e

1/2

Roof Slope, f

25

Wind Angle, a

9.403

ratio, h/w

h/w

1 1/2

1.000

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

4 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

External Coefficient, Cpe

-0.450 Windward

External Coefficient, Cpe

-0.500 Leeward

Internal Coefficient, Cpi

-0.300

(Appendix E)

7.2 : Wind Load, P = (Cpe Cpi). qs

Wind Load (Windward)

Ww

{Cpe - Cpi} qs

{ -0.450

Wind Load (Leeward)

WL

Wind

(a = 0)

-0.052 kN/m2

{Cpe - Cpi} qs

{ -0.500

-0.070

-(

kN/m2

-0.300 ) } X

0.348 kN/m2

UpLift

-0.300 ) } X

Uplift

0.348 kN/m2

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

5 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

LOAD CASES(The loadings are combined into different load cases and applied with

further factors as per BS 5950 : Part 5 : 1996)

1)

1.0 Gk

0.800

kN/m2

2)

1.0 Qk

0.250

kN/m2

3)

1.4

Ww

-0.073 kN/m2

4)

1.4

WL

-0.097 kN/m2

5)

1.4

Gk

1.6 Qk

1.520

kN/m2

6)

1.2

Gk

1.2 Qk

1.2

WL

1.177

kN/m2

6a)

1.2

Gk

1.2 Qk

1.2

Ww

1.197

kN/m2

7)

1.0

Gk

1.4

Ww

0.727

kN/m2

7a)

1.0

Gk

1.4

WL

0.703

kN/m2

8)

1.0

Gk

1.0 Qk

1.050

kN/m2

CRITICAL LOAD CASES

Case

: Being the most critical load case, it is to be used as Design Load to check

axial and bending capacities.

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

6 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

DESIGN STANDARDS(BS 5950 : Part 5)

BENDING & AXIAL CHECK FOR WEB MEMBER :

Member in Bending :

Member No.

Used Section:

21

, M

0.858

kNm

T153075GAL box-up

t

t

YS

0.750

550.000

mm

Nmm-2

D

Zx

74.250

mm

5.840

Py

550.000

X 10 3

Nmm-2

mm3

B

Maximum bending stress, M/ Zx

0.858 X 10

/

-2

146.918 Nmm

5.840 X 10

Nmm-2

5.2.2.2 Maximum allowable bending stress

Po

{1.13 - 0.0019 ( D / T ) ( Ys / 280 )1/2 } Py

{1.13 - 0.0019 ( 74.250

476.505

Nmm-2 >

/ 0.750 )( 550.000 / 280)1/2 } X

146.918

Nmm-2

OK !

Member in Compression :

Member No.

Used Section:

14 ( length

1415.000 mm), F =

12.338 kN

T153075GAL

lx

10.950

X 104 mm4

rx

30.370

Ae

118.710

mm

mm2

ly

2.130

X 104 mm4

ry

13.400

mm

550.000 Nmm-2

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

7 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

6.2 Flexural Buckling

6.2.2 Maximum Slenderness, Le

Le/ry

1.000

1.0L

X 1415.0

105.597 <

180.000

PI2 X ( 200 ) X ( 10.950 X 10 4 )

OK !

13.400

6.2.3 Ultimate Load Buckling Resistance Load (Pc)

Pcs

Pe

Py x Ae

550.000

X 118.710 X 10 -3

65.291

kN

p2 E I

Le2

0.002 ( Le / ry 20 )

0.002 (

0.171

Buckling Resistance Pc

Where

( 1415.000 )

107.980

kN

65.291

}]

105.597 20 )

/2[ - { 2 - 4Pe. Pcs} ]

Pcs + (1 + n).Pe

65.291

191.756

+ [( 1 +

0.171 )

191.756

107.980

Buckling Resistance

1

Pc

/2[ - { 2 - 4Pe. Pcs} ]

=

=

1/2

191.756

- {

1/2

191.756

- {

36770.406

-(

1/2

191.756

- {

8570.116

)]

1/2

191.756

49.591

>

F=

92.575

12.338

kN

- (4 X

107.980

28200.291

OK !

X

)]

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

8 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

Combined Bending & Compression :

6.4.2 Local Capacity Check

( Fc / Pcs ) + (Mx / Mcx )

=

12.338

0.497

65.291 ) + (

< 1.000

146.9

/ 476.505 )

OK !

Member in Tension :

Member No.

Used Section:

, F

2.153

kN

T153060GAL

Ae

95.330

mm2

Py

550.000

Nmm-2

Ae.Py

95.330 X 550.000 /

52.432 kN

7.2.1 Tensile capacity, Pt

>

2.153

Combined Bending & Tension :

7.3

Local Capacity Check

( Ft / Pt ) + (Mx / Mcx )

2.153

0.349

52.432

< 1.000

) + (

OK !

146.9 /

476.505 )

1000.000 kN

kN

OK !

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

9 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

Deflection ( ) :

7

, Length L =

3183

mm, s (supported span deflection) = 0.949 mm

Member No.

L

2.4.2 Table 3 Deflection Limits

Supported span :

22

3183

/ 200 =

15.915 >

, Length L =

914

mm, c (Cantilever deflection)

OK!

= 1.605 mm

Member No.

L / 200 =

L

2.4.2 Table 3 Deflection Limits

Cantilever

L / 180 =

914

/ 180 =

5.078

>

OK!

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

10 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

CONNECTION STRENGTH CHECK

Fastener

#14 Gauge Teks (Class 2) Hex Head Self-Drilling Screw

d =

5.800

mm

#10 Gauge Teks (Class 2) Hex Head Self-Drilling Screw

d =

4.100

mm

or

ps (min)

py (min)

= 375.000 Nmm-2

= 550.000 Nmm-2

d

t3

4.100 mm

0.600 mm

t4

0.750 mm

ds

8.000 mm

Appendix A

A. 1,4

(a)

Shear Capacity, Ps

for t4 / t3

1.0

the smaller of

3 1/2

Ps

= 3,2 (t3 d) py

0.600 3 x 4.100 )1/2

3.2 (

1.656 kN

550 Nmm-2

and

Ps

= 2,1 t3 d py

=

Thus,

Ps

2.1 x 0.600 x 4.100 x

2.84

kN

1.66

kN

550 Nmm-2

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

11 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

for t4 / t3

2.5

Ps

2,1

t

d py

=

3

(b)

2.84

kN

1,0 < t4 / t3 < 2,5

t4 / t3

= 1.25

Ps

= interpolation between (a) and (b)

(c)

1.85

kN

The most suitable Ps to use is

4

(a)

(b)

(c)

nos .(min) drilling screw in shear strength (Member no. 23 ))

=

4

X 1.85 kN

=

7.415 kN

> 4.101 kN

OK !

Pf s

6.80

kN (provided by manufacturer)

Pf s

> 1.25 Ps

6.800 kN

>

2.32

kN

OK !

Tensile Capacity, Pt

A. 1,5

Pulling of the base material over the screw head or washer (t < 2,00mm & dw < 25mm)

(a)

Pt

= 1,1t3 ds py

= 2.904 kN

Pull out from the base material (t4 > 0,9mm)

Pt

= 0,65t4 ds py

(b)

NIL

kN

Tensile failure of the screw itself

Pf t

=

11.90

kN (provided by manufacturer)

(c)

Pf t

> 1.25 Pt

11.900 kN

>

3.63

The smallest value among (a), (b) or (c)

4

kN

2.90

OK !

kN

nos .(min) drilling screw in tensile strength (Member no.

3)

=

4

X 2.904 kN

=

11.616 kN

OK !

> 2.153 kN

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

12 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

BATTEN CHECK(BS 5950 : Part 5 )

N121042GAL

Used Section:

Batten span,L =

31.580 mm

t

Ys

0.420

Ix

0.885

Zx

0.540

Py

mm

550.000 Nmm-2

X 104 mm4

X 103 mm3

550.000 Nmm-2

1.351 m & Batten c/c spacing =

0.320

Loadings :

Batten self weight =

Concrete tile

=

0.030 kN/m2

0.320 m

0.010

kN/m

0.460 kN/m2

0.320 m

0.147

kN/m

Imposed load (w)

0.250 kN/m2

0.320 m

0.080

kN/m

0.237

kN/m

Strength Check :

Max. Bending Moment, Mmax

= WL2/8

=

Max. Bending Stress, M/Zx

5.2.2.2

0.237

0.054

)(

1.351 )2

X 10 6 /

0.054 kNm

/ 8 =

0.540

X 103 =

100.048

N/mm2

Max. Allowable Bending Stress = {1.13 0.0019(D/T)(Ys/280)1/2}Py

=

=

{1.13 - 0.0019 ( 31.580

/ 0.420 )( 550.000 / 280 )1/2 }

511.376 Nmm-2 > Max. Bending Stress

OK !

550.000 N/mm2

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

13 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

Deflection Check :

Max. Deflection

Table 3

5wL4/384EI

5(

1.96

1.351

X 103)4 / 384 (2X105) X

1.351

6.755

mm >

0.080

Max. Allowable Deflection =

)(

0.885

X 104

mm

L/200

103

200 mm

Max. Deflection

OK !

COOLDEC METAL INDUSTRIES SDN. BHD.

Project :

Subject :

Client :

Job. No :

Calc by:

Cadangan Membina Rumah Berkembar Di Mukim Kenor, Jajahan Kuala Kerai, Kelantan.

Truss Analysis Design T5 Construction Rev00

OKG - 02 - 010 - SD01 ( Cons )

Checked by:

Date:

Sheet :

Fikri

Lee HY

6-Mar-2013

14 of 14

BS 5950 Part 5 : Code of Practice for Design of Cold Formed Thin Sections

ROOF TRUSSES BRACING CHECK(BS 5950 : Part 5 )

Strength Check :

N121042GAL

Used Section:

Py

Ae

Bottom Chord Length

8.364

Roof Pitch ,PI

25

Truss Spacing

1.351

550.000 Nmm-2

47.700 Nmm-2

Design Forces for Bracing Chords are assumed to be 1/3 of the overall roof loading (1.4 Gk + 1.6 Qk)

acting horizontally to and in the weak axis of the roof truss. Such Design Forces are further assumed

to be taken by the Bracing Chord in the form of horizontal & axial tensile force.

Design Force

1/3 [(1.4 Gk + 1.6 Qk ) x {(Bottom Chord Length ) / cos PI} x Truss Spacing]

1/3 X [

6.317

1.520

X {

8.364 / cos 25 } X

1.351

kN

Tensile Strength of Bracing Chord

Py X Ae

550.000 X 47.700

26.235 kN

>

/

6.317

1000

kN

OK !

Das könnte Ihnen auch gefallen

- Unit SS Design Calculations For PrecastDokument13 SeitenUnit SS Design Calculations For PrecastKumar SureshNoch keine Bewertungen

- Technical Reference 2007 CompleteDokument782 SeitenTechnical Reference 2007 CompleteIvan GradNoch keine Bewertungen

- Example of Structural CalculationDokument18 SeitenExample of Structural Calculationdeua2004Noch keine Bewertungen

- Column Design LSMDokument7 SeitenColumn Design LSMVMRAJAN100% (1)

- Compressive Strength Beam DesignDokument70 SeitenCompressive Strength Beam DesignDjuned0% (1)

- ElevatedStorageTank Standards Dec2012Dokument29 SeitenElevatedStorageTank Standards Dec2012Sharon LambertNoch keine Bewertungen

- Structural Design of Raft FoundationDokument31 SeitenStructural Design of Raft Foundationshakirhamid668780% (15)

- 2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoDokument12 Seiten2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoJohn SmithNoch keine Bewertungen

- RC Corbel DesignerDokument1 SeiteRC Corbel DesignerHari Amudhan IlanchezhianNoch keine Bewertungen

- Geotextile Design AnalisisDokument12 SeitenGeotextile Design AnalisisJeff L DjambakNoch keine Bewertungen

- Pile Cap Check For PE7PTC-15,30 15-07-20 (Shear Enhancement)Dokument5 SeitenPile Cap Check For PE7PTC-15,30 15-07-20 (Shear Enhancement)mayoo1986Noch keine Bewertungen

- MS PurliDokument4 SeitenMS PurliJennifer PearsonNoch keine Bewertungen

- Portal Frames DDokument48 SeitenPortal Frames DMukonyora SirMartinNoch keine Bewertungen

- Retainingwall bs8110Dokument11 SeitenRetainingwall bs8110unionewNoch keine Bewertungen

- Steel Expert ECDokument35 SeitenSteel Expert ECglasscrankerNoch keine Bewertungen

- Interaction Diagram Column DesignDokument10 SeitenInteraction Diagram Column DesignKiboyNoch keine Bewertungen

- Week 7 Truss DesignDokument39 SeitenWeek 7 Truss DesignFoo He XuanNoch keine Bewertungen

- Fundamentals of Marketing NotebookDokument24 SeitenFundamentals of Marketing NotebookMorrisa AlexanderNoch keine Bewertungen

- Structural CalcDokument28 SeitenStructural CalcHariHaran100% (1)

- Design Project1Dokument19 SeitenDesign Project1Syed Munawar Ali100% (1)

- ATRUCTDokument75 SeitenATRUCTRadu StratilaNoch keine Bewertungen

- Design Truss Tower R2 PDFDokument41 SeitenDesign Truss Tower R2 PDFPrashant HuddarNoch keine Bewertungen

- Design details for 1st floor slab and beamsDokument47 SeitenDesign details for 1st floor slab and beamsZayyan Romjon100% (2)

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDokument29 SeitenMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- Structural Calculations ST04 AMD 4th FL BEAMDokument35 SeitenStructural Calculations ST04 AMD 4th FL BEAMSun PonloeuNoch keine Bewertungen

- Steel Section Capacities BS 5950 SpreadsheetDokument366 SeitenSteel Section Capacities BS 5950 SpreadsheetAfendi AriffNoch keine Bewertungen

- Sepakat Setia Perunding SDN BHD: Design Information DimensionsDokument30 SeitenSepakat Setia Perunding SDN BHD: Design Information Dimensionsعصام السامرائيNoch keine Bewertungen

- Bored Pile - Estimated Pile Length & Capacity: RB6191-DASHDokument6 SeitenBored Pile - Estimated Pile Length & Capacity: RB6191-DASHHoihogo HoiNoch keine Bewertungen

- Kelvin Pile Set CalculationDokument1 SeiteKelvin Pile Set CalculationKelvin LauNoch keine Bewertungen

- Approach SlabDokument4 SeitenApproach SlabjamesNoch keine Bewertungen

- Bsae PlateDokument12 SeitenBsae PlatesallymazeeraNoch keine Bewertungen

- Roof Beam DesignDokument68 SeitenRoof Beam DesignUlasi IfeanyiNoch keine Bewertungen

- BS5400 Bridge Section DesignDokument3 SeitenBS5400 Bridge Section DesignFrederick TanNoch keine Bewertungen

- Banas Dairy ETP Training ReportDokument38 SeitenBanas Dairy ETP Training ReportEagle eye0% (2)

- Development OrderDokument3 SeitenDevelopment OrderMatAlengNoch keine Bewertungen

- Pile Set CalculationDokument2 SeitenPile Set CalculationMuhammad Syahmi Adli SamNoch keine Bewertungen

- A Brief Guide To Performing Umrah - Umrah Badal: by Ronf WasmiDokument3 SeitenA Brief Guide To Performing Umrah - Umrah Badal: by Ronf WasmiormindrfweijiNoch keine Bewertungen

- Sheet Pile 2 Report r1Dokument10 SeitenSheet Pile 2 Report r1jackcoolsNoch keine Bewertungen

- Ruj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekDokument5 SeitenRuj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekHafiz Budean RahmanNoch keine Bewertungen

- Group 4 HR201 Last Case StudyDokument3 SeitenGroup 4 HR201 Last Case StudyMatt Tejada100% (2)

- BQ Preliminaries Projek Paip Air Dan Jalan Di Besut2Dokument12 SeitenBQ Preliminaries Projek Paip Air Dan Jalan Di Besut2MatAleng100% (2)

- Alfa Laval Complete Fittings CatalogDokument224 SeitenAlfa Laval Complete Fittings CatalogGraciele SoaresNoch keine Bewertungen

- 3.000 M X 1.200 M Board (CKE 8+430)Dokument12 Seiten3.000 M X 1.200 M Board (CKE 8+430)UmesgNoch keine Bewertungen

- Appendix 16.a Example - Grass ChannelDokument4 SeitenAppendix 16.a Example - Grass Channelkhoohuikiang100% (1)

- Cold Form Lipped C Purlin Design Calculations and ChecksDokument8 SeitenCold Form Lipped C Purlin Design Calculations and ChecksKTMONoch keine Bewertungen

- 10M Steel Pole Design CalculationsDokument26 Seiten10M Steel Pole Design Calculationsatokku50% (2)

- Two Way Slab Load Distribution On BeamDokument4 SeitenTwo Way Slab Load Distribution On Beamamit_saxena_10Noch keine Bewertungen

- Basic Steps For Foundation DesignDokument3 SeitenBasic Steps For Foundation Designsujith s pNoch keine Bewertungen

- CALCULATION SHEETPILE Intake v.2Dokument68 SeitenCALCULATION SHEETPILE Intake v.2Dica Rasyid MaulidhaniNoch keine Bewertungen

- DESIGN VALUES FOR STRIP FOOTINGDokument16 SeitenDESIGN VALUES FOR STRIP FOOTINGShazreel AmirNoch keine Bewertungen

- Wind Loading DesignDokument5 SeitenWind Loading DesignMuhammad Azuan TukiarNoch keine Bewertungen

- Engineering Calculation Sheet Consulting EngineersDokument27 SeitenEngineering Calculation Sheet Consulting Engineersazhar ahmadNoch keine Bewertungen

- Project: Date: Location: Job Ref: Column:: Column Design SUN - U, Phase1 Part 2 7-12-21 ACE.09.206Dokument15 SeitenProject: Date: Location: Job Ref: Column:: Column Design SUN - U, Phase1 Part 2 7-12-21 ACE.09.206Lem TeohNoch keine Bewertungen

- Pad Footing Analysis and Design (Bs8110-1:1997)Dokument6 SeitenPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79Noch keine Bewertungen

- Timber AssignmentDokument16 SeitenTimber AssignmentRobert WalusimbiNoch keine Bewertungen

- Project Title: East View Primary School Client CPG Designed by Trang Checked by BKT Code: BS 5950 - PART 1: 2000 Job: Purlin DesignDokument110 SeitenProject Title: East View Primary School Client CPG Designed by Trang Checked by BKT Code: BS 5950 - PART 1: 2000 Job: Purlin DesignSơn Nguyễn-Lê100% (1)

- Typical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sDokument6 SeitenTypical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sJennifer PearsonNoch keine Bewertungen

- Portal FrameDokument31 SeitenPortal Framenicklok123Noch keine Bewertungen

- Analysis and Design of A Combined Triangular Shaped Pile Cap Due To Pile EccentricityDokument7 SeitenAnalysis and Design of A Combined Triangular Shaped Pile Cap Due To Pile Eccentricityazhar ahmad100% (1)

- Eco-Friendly Raft Pile System, Innovative Solution For Soft Soil Problem (2012) - DID PDFDokument16 SeitenEco-Friendly Raft Pile System, Innovative Solution For Soft Soil Problem (2012) - DID PDFDuan YuNoch keine Bewertungen

- Far Western University Civil Engineering CourseDokument5 SeitenFar Western University Civil Engineering Coursedinesh100% (1)

- Anchor Design - Hilti (HP)Dokument6 SeitenAnchor Design - Hilti (HP)Harikrishnan PNoch keine Bewertungen

- Column Design - As Per BS8110Dokument16 SeitenColumn Design - As Per BS8110Parthiban ArivazhaganNoch keine Bewertungen

- Wind Load Calculation Using EurocodeDokument3 SeitenWind Load Calculation Using EurocodeemmanuelNoch keine Bewertungen

- Bearing Capacity Shallow FoundationDokument12 SeitenBearing Capacity Shallow FoundationMika Vernadeth SingNoch keine Bewertungen

- Continental Steel - Structural SteelDokument191 SeitenContinental Steel - Structural SteelDesmond TongNoch keine Bewertungen

- Pile Group Eccentricity Calculations and ResultsDokument1 SeitePile Group Eccentricity Calculations and ResultsNwe OoNoch keine Bewertungen

- 85SP Single Analysis Report PLS-POLE ResultDokument6 Seiten85SP Single Analysis Report PLS-POLE ResultDESIGNNoch keine Bewertungen

- SL Chan FacadeDokument29 SeitenSL Chan FacadeKayBee DatilesNoch keine Bewertungen

- Structural calculations for purlin sizingDokument1 SeiteStructural calculations for purlin sizing_jessecaNoch keine Bewertungen

- Item Date Checker Contact Email Pilegroup Analysis 10-May-07 Tayeb KazemiDokument4 SeitenItem Date Checker Contact Email Pilegroup Analysis 10-May-07 Tayeb KazemirigaschNoch keine Bewertungen

- BS Bolt DesignDokument3 SeitenBS Bolt Designbalamurali031Noch keine Bewertungen

- Sample Two Way Slab Design CalculationDokument11 SeitenSample Two Way Slab Design Calculationsandeep kumarNoch keine Bewertungen

- Appendix ADokument42 SeitenAppendix Ayliu8877100% (1)

- Isolation JointsDokument1 SeiteIsolation JointsMatAlengNoch keine Bewertungen

- What Is A Septic Tank??Dokument10 SeitenWhat Is A Septic Tank??MatAlengNoch keine Bewertungen

- Summary of Cube Test Result UdmDokument4 SeitenSummary of Cube Test Result UdmMatAlengNoch keine Bewertungen

- Designandanalysisofoverheadcrane 140412022645 Phpapp01Dokument44 SeitenDesignandanalysisofoverheadcrane 140412022645 Phpapp01MatAlengNoch keine Bewertungen

- 1 Beam DeflectionDokument5 Seiten1 Beam DeflectionqazilaNoch keine Bewertungen

- Plan - GR FloorDokument1 SeitePlan - GR FloorMatAlengNoch keine Bewertungen

- Timeless Collection Brochure FA2 Web ViewDokument19 SeitenTimeless Collection Brochure FA2 Web ViewMatAlengNoch keine Bewertungen

- TradingDokument100 SeitenTradingMatAlengNoch keine Bewertungen

- Sample QuoDokument6 SeitenSample QuoMatAlengNoch keine Bewertungen

- 20.12 - Assignment of Contract ProceedsDokument16 Seiten20.12 - Assignment of Contract ProceedsMatAlengNoch keine Bewertungen

- Plan - SectionDokument1 SeitePlan - SectionMatAlengNoch keine Bewertungen

- 20 X 70Dokument102 Seiten20 X 70MatAlengNoch keine Bewertungen

- Sample QUODokument4 SeitenSample QUOMatAlengNoch keine Bewertungen

- Weekly Plan Jun 2013Dokument15 SeitenWeekly Plan Jun 2013MatAlengNoch keine Bewertungen

- Financial y Btul2 YerDokument17 SeitenFinancial y Btul2 YerMatAlengNoch keine Bewertungen

- Optimize Water Supply SystemDokument2 SeitenOptimize Water Supply SystemMatAlengNoch keine Bewertungen

- Sewerage Product CategoryDokument7 SeitenSewerage Product CategoryMatAlengNoch keine Bewertungen

- S Tructural Design Log: Faculty of Civil Engineering MalaysiaDokument1 SeiteS Tructural Design Log: Faculty of Civil Engineering MalaysiaMatAlengNoch keine Bewertungen

- Forward Plan For The Month of May 2014: Okg Jitu Resources SDN BHDDokument1 SeiteForward Plan For The Month of May 2014: Okg Jitu Resources SDN BHDMatAlengNoch keine Bewertungen

- BS5950 Building Designer Quick Start GuideDokument155 SeitenBS5950 Building Designer Quick Start GuideIvan KlyuchkaNoch keine Bewertungen

- Forward Plan For The Month of May 2014: Okg Jitu Resources SDN BHDDokument1 SeiteForward Plan For The Month of May 2014: Okg Jitu Resources SDN BHDMatAlengNoch keine Bewertungen

- Astm500 Sections SizesDokument2 SeitenAstm500 Sections SizesAgarry EmmanuelNoch keine Bewertungen

- 2006-07 (Supercupa) AC Milan-FC SevillaDokument24 Seiten2006-07 (Supercupa) AC Milan-FC SevillavasiliscNoch keine Bewertungen

- Law of TortsDokument22 SeitenLaw of TortsRadha KrishanNoch keine Bewertungen

- iec-60896-112002-8582Dokument3 Seiteniec-60896-112002-8582tamjid.kabir89Noch keine Bewertungen

- I. ICT (Information & Communication Technology: LESSON 1: Introduction To ICTDokument2 SeitenI. ICT (Information & Communication Technology: LESSON 1: Introduction To ICTEissa May VillanuevaNoch keine Bewertungen

- Portable dual-input thermometer with RS232 connectivityDokument2 SeitenPortable dual-input thermometer with RS232 connectivityTaha OpedNoch keine Bewertungen

- Model:: Powered by CUMMINSDokument4 SeitenModel:: Powered by CUMMINSСергейNoch keine Bewertungen

- TX Set 1 Income TaxDokument6 SeitenTX Set 1 Income TaxMarielle CastañedaNoch keine Bewertungen

- L-1 Linear Algebra Howard Anton Lectures Slides For StudentDokument19 SeitenL-1 Linear Algebra Howard Anton Lectures Slides For StudentHasnain AbbasiNoch keine Bewertungen

- B3 Zoning Diagram, Atlantic Yards/Pacific ParkDokument4 SeitenB3 Zoning Diagram, Atlantic Yards/Pacific ParkNorman OderNoch keine Bewertungen

- Software EngineeringDokument3 SeitenSoftware EngineeringImtiyaz BashaNoch keine Bewertungen

- Safety QualificationDokument2 SeitenSafety QualificationB&R HSE BALCO SEP SiteNoch keine Bewertungen

- A320 Normal ProceduresDokument40 SeitenA320 Normal ProceduresRajesh KumarNoch keine Bewertungen

- 3 Intro To Ozone LaundryDokument5 Seiten3 Intro To Ozone LaundrynavnaNoch keine Bewertungen

- BlueDokument18 SeitenBluekarishma nairNoch keine Bewertungen

- As 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsDokument6 SeitenAs 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsSAI Global - APACNoch keine Bewertungen

- StandardsDokument3 SeitenStandardshappystamps100% (1)

- Ice Cream Cost Benefit AnalysisDokument12 SeitenIce Cream Cost Benefit AnalysischarlotteNoch keine Bewertungen

- An Overview of Tensorflow + Deep learning 沒一村Dokument31 SeitenAn Overview of Tensorflow + Deep learning 沒一村Syed AdeelNoch keine Bewertungen

- Max 761 CsaDokument12 SeitenMax 761 CsabmhoangtmaNoch keine Bewertungen

- Impact of Coronavirus On Livelihoods of RMG Workers in Urban DhakaDokument11 SeitenImpact of Coronavirus On Livelihoods of RMG Workers in Urban Dhakaanon_4822610110% (1)

- ABBBADokument151 SeitenABBBAJeremy MaraveNoch keine Bewertungen

- Berry B Brey Part IDokument49 SeitenBerry B Brey Part Ikalpesh_chandakNoch keine Bewertungen

- 5.0 A Throttle Control H-BridgeDokument26 Seiten5.0 A Throttle Control H-Bridgerumellemur59Noch keine Bewertungen