Beruflich Dokumente

Kultur Dokumente

AE03

Hochgeladen von

Vicente Bergamini PugliaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AE03

Hochgeladen von

Vicente Bergamini PugliaCopyright:

Verfügbare Formate

C

Chapter 1. Introduction to Acoustic

Emission Testing . . . . . . . . . . . . . . 1

Part 1. Nondestructive Testing . . . . 2

Part 2. Management of Acoustic

Emission Testing . . . . . . . . 13

Part 3. History of Acoustic Emission

Testing . . . . . . . . . . . . . . . 21

Part 4. Measurement Units for

Acoustic Emission

Testing . . . . . . . . . . . . . . . 25

Chapter 2. Fundamentals of Acoustic

Emission Testing . . . . . . . . . . . . .

Part 1. Introduction to Acoustic

Emission Technology . . . .

Part 2. Acoustic Emission Noise . .

Part 3. Acoustic Emission Signal

Characterization . . . . . . . .

Part 4. Acoustic Emission

Transducers and Their

Calibration . . . . . . . . . . . .

Part 5. Macroscopic Origins of

Acoustic Emission . . . . . .

Part 6. Microscopic Origins of

Acoustic Emission . . . . . .

Part 7. Wave Propagation . . . . . . .

31

32

41

45

51

61

69

79

Chapter 3. Modeling of Acoustic

Emission in Plates . . . . . . . . . . . 109

Part 1. Wave Propagation in

Plates . . . . . . . . . . . . . . . . 110

Part 2. Formal Analytic

Solution . . . . . . . . . . . . . 114

Chapter 4. Acoustic Emission Source

Location . . . . . . . . . . . . . . . . . .

Part 1. Fundamentals of Acoustic

Emission Source

Location . . . . . . . . . . . . .

Part 2. Overdetermined Source

Location . . . . . . . . . . . . .

Part 3. Waveform Based Source

Location . . . . . . . . . . . . .

121

O N TE N T S

Chapter 5. Acoustic Emission Signal

Processing . . . . . . . . . . . . . . . . . 147

Part 1. Digital Signal

Processing . . . . . . . . . . . . 148

Part 2. Pattern Recognition and

Signal Classification . . . . 157

Part 3. Classification of Failure

Mechanism Data from

Fiberglass Epoxy Tensile

Specimens . . . . . . . . . . . . 167

Part 4. Neural Network Prediction

of Burst Pressure in

Graphite Epoxy Pressure

Vessels . . . . . . . . . . . . . . . 171

Chapter 6. Acoustic Leak Testing . . . 181

Part 1. Principles of Sonic and

Ultrasonic Leak

Testing . . . . . . . . . . . . . . 182

Part 2. Instrumentation for

Ultrasound Leak

Testing . . . . . . . . . . . . . . 191

Part 3. Ultrasound Leak Testing

of Pressurized Industrial

and Transportation

Systems . . . . . . . . . . . . . . 198

Part 4. Ultrasound Leak Testing

of Evacuated Systems . . . 211

Part 5. Ultrasound Leak Testing

of Engines, Hydraulic

Systems, Machinery and

Vehicles . . . . . . . . . . . . . . 213

Part 6. Electrical Inspection . . . . 215

Part 7. Ultrasound Leak Testing

of Pressurized Telephone

Cables . . . . . . . . . . . . . . . 218

Part 8. Acoustic Emission

Monitoring of Leakage

from Vessels, Tanks and

Pipelines . . . . . . . . . . . . . 220

122

131

135

Acoustic Emission Testing

Chapter 7. Acoustic Emission Testing

for Process and Condition

Monitoring . . . . . . . . . . . . . . . . 227

Part 1. Acoustic Emission Testing

in Milling . . . . . . . . . . . . 228

Part 2. Acoustic Emission Testing

of Resistance Spot

Welding . . . . . . . . . . . . . 232

Part 3. Acoustic Emission Weld

Monitoring of Aluminum

Lithium Alloy . . . . . . . . . 235

Part 4. Acoustic Emission Testing

for Machinery Condition

Monitoring . . . . . . . . . . . 243

Part 5. Acoustic Emission Testing

during Grinding . . . . . . . 251

Part 6. Crack Detection during

Straightening of Axles

and Shafts . . . . . . . . . . . . 263

Chapter 8. Acoustic Emission Testing

of Pressure Vessels, Pipes and

Tanks . . . . . . . . . . . . . . . . . . . . .

Part 1. Acoustic Emission Testing

of Spheres and Other

Pressure Vessels . . . . . . . .

Part 2. Acoustic Emission

Testing of Composite

Overwrapped Pressure

Vessels . . . . . . . . . . . . . . .

Part 3. Acoustic Emission Testing

of Pipelines . . . . . . . . . . .

Part 4. Acoustic Emission Testing

of Delayed Coke

Drums . . . . . . . . . . . . . . .

Part 5. Acoustic Emission Testing

of Tank Floors . . . . . . . . .

Chapter 9. Acoustic Emission Testing

of Infrastructure . . . . . . . . . . . .

Part 1. Acoustic Emission Testing

of Bridges . . . . . . . . . . . .

Part 2. Acoustic Emission

Monitoring of Crack

Growth in Steel Bridge

Components . . . . . . . . . .

Part 3. Evaluation of Slope

Stability by Acoustic

Emission Testing . . . . . . .

271

272

281

284

290

296

305

306

Chapter 10. Electric Power

Applications of Acoustic

Emission Testing . . . . . . . . . . . . 331

Part 1. Acoustic Emission Location

of Incipient Faults in

Power Transformers . . . . 332

Part 2. Acoustic Emission Testing

of High Energy Seam

Welded Piping . . . . . . . . 342

Part 3. Acoustic Emission

Monitoring of Loose

Parts . . . . . . . . . . . . . . . . 347

Part 4. Acoustic Emission Testing

of Steam Turbines . . . . . . 354

Chapter 11. Aerospace Applications

of Acoustic Emission Testing . . 359

Part 1. Acoustic Emission Testing

of Aircraft . . . . . . . . . . . . 360

Part 2. Fatigue Crack Monitoring

of Aircraft Engine

Cowling in Flight . . . . . . 367

Part 3. Acoustic Emission

Monitoring of Rocket

Motor Case during

Hydrostatic Testing . . . . 377

Part 4. Acoustic Emission

Prediction of Burst Pressure

in Fiberglass Epoxy

Pressure Vessels . . . . . . . 383

Chapter 12. Special Applications of

Acoustic Emission Testing . . . . 391

Part 1. Acoustic Emission Testing

Using Moment Tensor

Analysis . . . . . . . . . . . . . 392

Part 2. Acoustic Emission Testing

for Structural Design of

Grand Prix Cars . . . . . . . 401

Part 3. Acoustic Emission

Monitoring of Sand in

Petroleum Wells . . . . . . . 408

Part 4. Active Corrosion

Detection Using Acoustic

Emission . . . . . . . . . . . . . 415

310

Chapter 13. Acoustic Emission

Testing Glossary . . . . . . . . . . . . 427

315

Index

. . . . . . . . . . . . . . . . . . . . . . . . . 435

Figure Sources . . . . . . . . . . . . . . . . . . . 446

Movie Sources . . . . . . . . . . . . . . . . . . . 447

Acoustic Emission Testing

U LT I M E D I A

O N T E N T S

Chapter 1. Introduction to Acoustic

Emission Testing

Movie. Discontinuities in steel . . . . 6

Movie. Plastic deformation causes

cry of tin . . . . . . . . . . . . . . 21

Chapter 2. Fundamentals of Acoustic

Emission Testing

Movie. Acoustic emission differs

from other methods . . . . . 32

Movie. Pencil break source . . . . . . 36

Movie. Guard transducers control

noise . . . . . . . . . . . . . . . . . 42

Chapter 5. Acoustic Emission Signal

Processing

Movie. System with one

channel . . . . . . . . . . . . . . 150

Chapter 6. Acoustic Leak Testing

Movie. Vibration at ultrasonic

frequencies of gas molecules

escaping from orifice . . . 183

Sound. Audible analog of

ultrasonic signal . . . . . . . 194

Movie. Steam system leak test . . 202

Movie. Amplitude rise heard

through ultrasound

detector as rough and

raspy . . . . . . . . . . . . . . . . 214

Chapter 7. Acoustic Emission Testing

for Process and Condition

Monitoring

Movie. Discontinuities from

welds . . . . . . . . . . . . . . . . 232

Chapter 13. Acoustic Emission

Testing Glossary

Movie. Pencil break source . . . . . 431

Acoustic Emission Testing

Figure Sources

Chapter 5. Acoustic Emission

Signal Processing

Figure 1 Vallen-Systeme GmbH, Munich, Germany.

Chapter 7. Acoustic Emission

Testing for Process and Condition

Monitoring

Figures 19-26 Holroyd Instruments, Bonsall Near

Matlock, Derbyshire, United Kingdom

Chapter 11. Aerospace

Applications for Acoustic Emission

Testing

Figures 1-11 ASTM International, West

Conshohocken, PA.

446

Acoustic Emission Testing

Movie Sources

Chapter 1. Introduction to

Acoustic Emission Testing

Movie. Discontinuities in steel Physical Acoustics

Corporation, Princeton, NJ; for the Federal Highway

Administration, United States Department of

Transportation, Washington, DC.

Movie. Plastic deformation causes cry of tin Physical

Acoustics Corporation, Princeton, NJ; for the

Federal Highway Administration, United States

Department of Transportation, Washington, DC.

Chapter 2. Fundamentals of

Acoustic Emission Testing

Movie. Acoustic emission differs from other methods

Physical Acoustics Corporation, Princeton, NJ; for

the Federal Highway Administration, United States

Department of Transportation, Washington, DC.

Movie. Pencil break source Physical Acoustics

Corporation, Princeton, NJ.

Movie. Guard transducers control noise Physical

Acoustics Corporation, Princeton, NJ; for the

Federal Highway Administration, United States

Department of Transportation, Washington, DC.

Chapter 5. Acoustic Emission

Signal Processing

Movie. System with one channel Physical Acoustics

Corporation, Princeton, NJ; for the Federal Highway

Administration, United States Department of

Transportation, Washington, DC.

Chapter 6. Acoustic Leak Testing

Movie. Ultrasonic vibration of gas molecules escaping

orifice UE Systems, Elmsford, NY.

Sound. Audible analog of ultrasonic signal UE Systems,

Elmsford, NY.

Movie. Steam system leak test UE Systems, Elmsford,

NY.

Movie. Amplitude rise heard through ultrasound detector

as rough and raspy UE Systems, Elmsford, NY.

Chapter 7. Acoustic Emission

Testing for Process and

Condition Monitoring

Movie. Discontinuities from welds Physical Acoustics

Corporation, Princeton, NJ; for the Federal Highway

Administration, United States Department of

Transportation, Washington, DC.

Chapter 13. Acoustic Emission

Testing Glossary

Movie. Pencil break source Physical Acoustics

Corporation, Princeton, NJ; for the Federal Highway

Administration, United States Department of

Transportation, Washington, DC.

Index

447

H A P T E R

Modeling of Acoustic

Emission in Plates

Richard L. Weaver, University of Illinois, Urbana, Illinois

PART 1. Wave Propagation in Plates

Background

Crack Growth

Brittle crack growth emits acoustic energy

and acoustic emission testing of structures

is attractive for damage and remaining life

assessment. Because it is often difficult to

distinguish valid from false indications,

conventional monitoring techniques are

usually confined to representing each

event by a small number of parameters

such as energy, duration, frequency and

time of occurrence. For this reason, it is

difficult to distinguish events. The

techniques used, in which a small number

of parameters are extracted from each

waveform, neglect much of the detailed

information presumably present in an

often very complicated waveform.

Technological developments in

waveform processing hardware and

software and in acoustic emission

transducers have made it feasible to carry

out fully quantitative acoustic emission

analyses in real time. If the entire

waveform is analyzed in an elastodynamic

propagation model, the character and

position of the source may be extractable

from that analysis. This approach was

proposed in the early 1980s but

implementation was expensive.1,2 After

hardware and software improved, the

problem of theoretical elastodynamic

analysis of complex acoustic emission

waveforms has been revisited.

Forward and Inverse Problems

In an arbitrary and complicated structure

(consider for example a multiply riveted

and ribbed, curved shell), elastic wave

propagation is very complex. The forward

problem of calculating a response from a

specified source in such a structure may

be treated in principle by finite elements.

Such computations can be burdensome.

Furthermore, such analysis provides no

insight into the important inverse

problem of identifying the source from

the waveform. But if the structure is more

homogeneous (for example, a half space

or a flat plate), other techniques can be

used to solve the forward problem.

Even in a simple homogeneous

structure like a plate, elastic wave

propagation is complicated. There are two

110

Acoustic Emission Testing

distinct approaches commonly employed

in plates, that of generalized rays and that

of guided modes. In a ray approach, each

reflection from a top or bottom surface

and the associated generation of mode

converted rays must be considered. There

are a large number of rays to track, even

after a moderate propagation time. The

ray picture is most useful only at short

times and distances. By implication, it is

also most relevant for frequencies that

exceed thickness resonances.

Calculation of elastic wave responses in

isotropic uniform plates by means of

generalized rays has been treated3 and is

now widely carried out using a published

algorithm and software code.4 The

computations can become burdensome

because of the need to track so many

generalized rays at source-to-receiver

distances of several plate thicknesses.

Computation time increases exponentially

with the time to be studied. Nevertheless,

the technique has been used because it

can calculate responses at arbitrarily high

frequencies with little additional effort.

The chief application has been to

laboratory characterization of materials, of

receivers and of simulated acoustic

emission sources.5,6 The techniques are

not useful for the calculation of waves

from realistic acoustic emission events in

the field over the distances and times

typical for such applications.

Wave Modes

Expansion of responses in terms of the

guided modes of wave propagation

provides an alternative technique of

calculation,1,2,7-9 with a computational

burden that grows approximately

quadratically with source-to-receiver

distance. Unlike the ray approach, higher

frequencies demand extra computational

resources. Thus, the technique is well

suited for calculation of wave propagation

over the distances and times typical for

practical acoustic emission. Most

importantly, the technique yields analytic

expressions that can inform the important

inverse problem.2

One study1 considered the

axisymmetric problem of a concentrated

normal step force applied to the surface of

a 10 mm (0.4 in.) thick glass plate and its

normal surface displacement response at a

distance of four to forty plate thicknesses.

The work considered only the first eight

branches of wave propagation, thus

limiting the accuracy to a frequency range

below 800 kHz.

That analysis is extended here to

arbitrarily buried and arbitrarily oriented

strain nuclei sources, corresponding to

brittle growth of small cracks. Orientable

sources like cracks will give rise to

nonaxisymmetric waves. In principle, the

problem posed here is much harder than

the original problem that considered the

axisymmetric problem of a normally

oriented point surface force.1,2 However,

because interest is restricted to responses

written in terms of normal surface

displacements, the nonaxisymmetric part

remains irrelevant. This is formally shown

below, where the stated problem of the

surface normal displacement response to a

buried strain nucleus source is

transformed using reciprocity into the

entirely equivalent problem of the

calculation of the strain response at a

buried location to a step force on the

plate surface.

Below, the mathematical problem is

formally posed as a partial differential

equation with initial conditions and

boundary conditions for a vector field u

that represents the elastodynamic

displacement response to a buried strain

nucleus source. The Greens dyadic for the

plate is defined as the displacement

response (at an arbitrary position) to an

arbitrary, buried, concentrated step force.

The posed problem is then solved

formally and exactly in terms of that

Greens dyadic. It transpires that it suffices

to consider the Greens dyadic for the

normal surface step force.

The Greens dyadic is then expressed in

terms of the normal modes of the plate,

resulting in an expression for the desired

response as a sum over branches b, each

of which involves an integral with respect

to wavenumber k. The integrand is given

as a closed form transcendental function

of the symmetry or antisymmetry of the

branch b; the wavenumber k; the distance

r from source to receiver; the depth of the

buried strain nucleus source; the time, the

strength and the orientation of that

source and the implicit (and tabulated)

solution of the dispersion relation b(k).

on one surface of the plate. The position

of the receiver is taken to be at the

coordinate origin (r = 0 in polar

coordinates) on the upper (z = +h) side of

the plate of thickness 2h. The coordinate

system is shown in Fig. 1. The source S is

located at position xS, with polar

coordinates rS = |xS|, = 0, z = zS. The

dynamic force distribution f (x,t) is given

as a strain nucleus12 (or moment tensor13)

by the following function of x:

(1)

fi ( x,t )

Mil

3

( x xS ) (t )

xl

where the summation convention over

repeated indices is in force, where the

symmetric matrix M contains information

about the orientation and strength of the

source and where the time dependence

has been taken to be (t), the unit step

function. Other time dependencies may

be obtained by suitable convolution with

the calculated responses. The force

distribution may also be written as:

(2)

fi ( x,t )

Mil

3

( x xS ) (t )

xSl

The sign convention used for our

definition of M is such that positive

principal values, or eigenvalues, of the

matrix correspond to compressive loads.12

By way of illustration, it may be noted

that a suddenly broken bond that was

initially under tension releases what had

been a compressive load on the

FIGURE 1. Geometry of a plate with thickness 2h. A receiver,

sensitive to vertical displacement, is placed on the top

surface above the coordinate origin. A transient step

function source acts at position rS, S, zS and is characterized

by its moment tensor M. Without loss of generality, the

X axis is taken coincident with the line rs. Thus, S = 0.

Z

Receiver

Problem Formulation

It is desired to calculate the linear

elastodynamic response to a step strain

nucleus in an infinite plate with stress free

surfaces.10,11 The notion of a strain

nucleus is equivalent to a set of double

forces, that is, double couples without

moment. Such nuclei are expected to

describe any pointlike source smaller than

a wavelength. Of interest is the vertical

(outward) normal displacement response

rS

Mij

zS

Y

h

h

X

Legend

h = half plate thickness

Mij = moment tensor

rS = radial position

zS = depth position

S = axial position

Modeling of Acoustic Emission in Plates

111

surrounding material. The force is

equivalent to a constant compressive load

plus a suddenly applied tensile load.

Because only the dynamic part is of

concern, this is equivalent to only the

suddenly applied tensile part. Thus, such

a process is represented by a negative

principal value in M.

The following initial value boundary

value problem consists of the partial

differential equation:

(3)

ij u j ( x, t )

u j ( x,t )

u j ( x,t )

t

3m

v (t )

u3 (r = 0, z = + h, t )

The tensor differential operator ij is

defined by:

(7)

ij

( x) ij

2

k cikjl ( x) l

t 2

where m indicates (xm)1. In the

present case, the material density and

the material stiffnesses cijkl are presumed

isotropic and homogeneous:

(8)

ij

2

t 2

ik + ij kl

il jk

k l

where and are the lam moduli.

The desired response is the solution to

Eq. 3. It may be written in terms of the

Greens dyadic Gjk for the plate, which is

the displacement response to a step

concentrated force load. It is the solution

Gjk to:

112

(x, xS, t )

ij Mkl Gjk

xSl

x xS

Mil 3

(t )

xSl

Equation 10 repeats the force distribution

of a strain nucleus as described in Eq. 2.

Thus, Eq. 10 indicates that the desired

waveform, the response to a strain

nucleus, is given in terms of G:

(11)

M kl

G3k ( x, xS, t )

xSl

where z = h for all r and . Of particular

interest is the displacement response v(t)

at the position of the receiver, located on

the Z axis above the coordinate origin at

the top surface, where r = 0 and z = +h:

(6)

fi ( x, t )

at r = 0 and z = +h. By reciprocity, spatial

arguments and indices in G may be

exchanged so the above is also equal to:

at

z

(10)

for all x and for t = 0. The partial

differential equation is also supplemented

by traction free boundary conditions:

(5)

ij Gjk ( x, xS ,t ) = ik 3 ( x xS ) (t )

Gjk (x, xS, t) is the displacement response

in the j direction at position x to a unit

step force in the k direction at position xS.

By taking a spatial derivative ( xSl)1 of

Eq. 9 and multiplying by the matrix Mkl,

the above becomes:

f i ( x, t )

supplemented by quiescent initial

conditions:

(4)

(9)

Acoustic Emission Testing

(12)

Mkl G3k

(xS, x, t )

xSl

at r = 0, z = +h. Equation 12 indicates that

the desired waveform is equal to M times

the strain response at xS to a vertical step

load applied at r = 0 and z = +h.

This reciprocal form (Eq. 12) for the

response (Eq. 11) will be especially useful,

because it permits the calculation of the

strain response to a vertical step load at

the origin and equates that to the vertical

displacement response to a strain nucleus

source. Because vertical step loads are

axisymmetric, there is no component to

the displacement response and no

dependence to that field. Thus, the strains

resulting from a vertical step force are

confined to the quantities rr, zz, rz and

zr. (The strain plays a minor role.) The

originally stated problem may therefore

be recast more simply to calculate only

the axisymmetric displacement response

u(x,t) to a step load on the upper surface

at the origin1 and then to construct the

linear combination of its spatial

derivatives:

(13)

=

=

+

M :

ur

uz

M rr

+ M zz

r

z

u

uz

M rz r +

r

z

u

M r

r

where the dummy variable xS is replaced

with x. The colon (:) represents a

complete inner product between the

tensors.

The result is, by reciprocity, equal to

the originally stated problem concerning

the vertical displacement response at the

origin to a strain nucleus source M at x. In

this restatement, it may be seen that the

nonaxisymmetric modes do not enter nor

do the shear horizontal waves. If the

in-plane displacements caused by a strain

nucleus source were required, it would be

necessary to consider these waves too.

Modeling of Acoustic Emission in Plates

113

PART 2. Formal Analytic Solution

The formal development of the response

of an infinite plate to a step vertical load

(that is, the quantities u in Eq. 13) has

been described in the literature.1,2 The

description involved an expansion in

terms of the discrete normal modes of a

finite plate of large radius R. If the

(irrelevant) boundary conditions at R are

chosen conveniently, then each of these

modes belongs to a definite branch of the

rayleigh lamb dispersion relation (Fig. 2).

The properties of such modes are

discussed in standard references.14-16 The

relevant formulas are summarized below.

The plates eigen modes antisymmetric

and symmetric with respect to z are

described separately.

and axisymmetric with respect to are

given by Eqs. 14 to 23:

Antisymmetric Modes

(16)

At wavenumber k and frequency , modes

that are antisymmetric with respect to z

FIGURE 2. Dispersion curve for rayleigh lamb waves in a steel

plate. The three straight dashed lines correspond to bulk

longitudinal waves (the steepest line), bulk shear waves (the

line of intermediate slope) and compressional waves in water

(the line of least slope). The bold and unbold curves are

respectively the symmetric and antisymmetric branches.

(14) ur = U a (z ) J 0 (kr )

=

(15) uz = W a (z ) J 0 (kr )

=

Frequency

(ratio of dilational wave speed to thickness)

[B cos z + Ck

cos z

J 0 (kr )

=

where J is a bessel function and prime ()

indicates a derivative with respect to

argument. Equations 14 and 15 define the

function U(z) and W(z) for antisymmetric

modes. The coefficients B and C are given

by:

B

2 k 2 sin h

(18) C

(k

(17)

10

2 sin h

The antisymmetric rayleigh lamb

dispersion relation is:

9

8

Ra ( , k )

1 2

k 2

4 k 2 cos h sin h

(19)

) sin h cos h

2

The vertical wavenumbers and are

given by:

3

2

2

(20)

(21) 2

1

0

0

10

12

14

16

18

Wave number k = t 1, where t is thickness

(arbitrary unit)

114

[B sin z C sin z]

k J 0 (kr )

[ B sin z C sin z ]

k J1(kr )

Acoustic Emission Testing

20

2

cd2

2

ce2

k2

k2

where cd and ce are respectively the

dilatational and shear (or equivoluminal)

wave speeds of the plate material. There is

a potential ambiguity in that the vertical

wavenumbers and are defined only up

to an unspecified sign. This ambiguity is

of no consequence: the sign is arbitrary

and final results are independent of the

choice of sign as long as it is made

consistently. It may also be noted that

and may be imaginary. This happens,

respectively, whenever k > cd1 or

k > ce1. In these cases, the usual

identities apply: sin i = i sinh ;

cos i = cosh . In these cases, it may

also happen that the modes themselves

become complex.

Equations 19 and 20 implicitly

determine as a function of k. There is a

discrete infinity of solutions for each

real k. If desired, they may be enumerated

by a branch index b = 1, 2 . . . .

As explained in previous work,1 if k is

restricted to a discrete set of values with

small uniform spacing R1 chosen by the

relation J0(kR) = 0 and if is one of the

solutions of the dispersion relation

(Eq. 19), then these are vibration modes

of the large radius (R ) disk with

rigid-smooth boundary conditions at the

outer rim. The mode has a squared norm:

(22)

Na

2 Ma

(23) Ma =

(z )2

2 h

sin 2 h

= B2

+ 2 k2

2

2

Cd

2 2

W s (z ) J 0 (kr )

(25) uz

+ 4 B C k 2 sin h cos h

Symmetric (with respect to z) but

axisymmetric (with respect to ) modes

with wavenumber k and frequency are

given by:

sin z

The coefficients A and D are given by:

(26)

2k 2 cos h

(27)

(k

2 cos h

The symmetric rayleigh lamb dispersion

relation is:

(28)

Rs ( , k )

1 2

k 2 cos h sin h

4 k 2 cos h sin h

As discussed elsewhere,1 these are the

(symmetric and axisymmetric) modes of

the large radius (R ) disk with

rigid-to-smooth boundary conditions at

the outer rim, if k is restricted to a discrete

set of values with uniform spacing R1

and if is the one of the solutions of the

dispersion relation (Eq. 28). This mode

has a squared norm:

(29) N

u ud A dz

2 Ms

R

k

where the integral is over the entire

volume of the disk shaped plate and

where Ms is:

(30)

Symmetric Modes

J 0 (kr )

+ C k

2h

sin 2 h

2 k 2

2

2

ce

[ A sin z + D k

R

k

2

+ W a (z ) dz

[ A cos z + D cos z]

k J 0 (kr )

[ A cos z + D cos z ]

k J1 (kr )

u u d A dz

where the integral is over the entire

volume of the disk shaped plate and Ma is

given by an integral over the thickness of

the plate, z going from h to +h:

U s (z ) J 0 (kr )

(24) ur

U (z) + W (z) dz

h

sin 2 h

= {A

( k )

2

c

Ms =

2

d

2h

sin 2h

+ D 2 k 2 2 + 2 k 2

2

ce

+ 4 ADk 2

)

cos h sin h}

Modeling of Acoustic Emission in Plates

115

The solutions of the dispersion

relations in Eq. 19 and Eq. 28 are

discussed in many places in the

literature.1,2,7,14-17 See also the equivalent

formulas for anisotropic plates.18,19 For

each k, there is a discrete infinity of real

solutions b(k) for each of the two cases of

symmetric and antisymmetric modes.

From each such solution b(k), it is simple

to obtain the values for the coefficients B

and C or A and D and , and M.

So the response becomes:

(34)

+

+

The Greens dyadic (needed in Eq. 12 for

the desired waveform) can be expressed as

a sum over the above normalized

vibration modes:

(m )

(m )

(x) u j (x)

1 cos ( m t )

i

2

m

N

where the sum is over all of the eigen

modes m. The index m is equivalent, in a

manner that need not be detailed, to

specification of the wavenumber k and

the branch b. The quantity N is the

normalization of the mode m;

N = 2M Rk1.

Because the case j = 3 and source

position x are required at the point

r = 0, z = h, it may be noted that

nonaxisymmetric modes (none of which

were specified above) do not contribute. It

is further noted that u3(m)(x) = W(h) and

(after Eq. 13):

(32)

v =

{M

rr U

(z ) r J0 (kr )

+ M zz z W (z ) J 0 (kr )

+ M

U (z )

r

J 0 (kr ) + M rz

[

1 cos [ t ]

[W (h)]

R

]}

W (z )r J 0 (kr ) + zU (z ) J 0 (kr )

m

2 m M

where the sum is over all axisymmetric

modes: every branch b of the dispersion

relations above and every discrete value of

k along each branch. The sum may be

replaced with an integral along the

branch and a sum over branches:

(33)

116

Acoustic Emission Testing

dk

b

k dk [W (h)]

1

{M U (z) J (kr )

rr

r 0

M zz z W (z ) J 0 (kr )

M rz W (z ) r J0 (kr )

z U (z ) J o (kr )

U (z )

r

J 0 (kr )

1 cos b (k )t

2 b (k ) M

2

where the integral over k runs from zero

to infinity and the sum is now a sum over

the infinite number of branches b of the

dispersion relation, both symmetric and

antisymmetric. The function (k) has

been given a subscript b to emphasize that

it is the solution of the dispersion relation

corresponding to the bth branch. The b

and k dependencies of W and U and M

have been suppressed; similarly, the

superscripts (a) and (s) on U and W are

suppressed.

The case of a step upward normal

surface force (equivalent for dynamic

purposes to a step release of a downward

normal force) of magnitude F0 is similar

to the above expression for the response

to a strain nucleus:

(35)

k dk F W (h)

1 cos [ (k ) t ]

1

Greens Function

(31) Gij ( x, x, t ) =

2 b (k ) M

2

An extra factor of 1 must be inserted to

each antisymmetric branch in Eq. 35

when the source and receiver are on

opposite sides.

Equation 34 is the main result of this

calculation. It permits numerical

calculations of the response of a normal

surface displacement detector to a distant

buried oriented strain nucleus of step

function time dependence. In practice,

the detector will not be ideal, so the

above time dependent v(t) must be

convolved with the transducer function.

Similarly, it may be convolved with the

time derivative of the source function if

the source function is thought to differ

from (t).

In practice, transducers may also be

not pointlike. Under the assumption that

the transducer does not affect the

structure and that the transducer is

axisymmetric around its own nominal

position, its spatial footprint may be

accounted for by inserting, into the above

integral, a factor of the hankel transform

of the transducer footprint. In the case of

a piston receiver of radius R, this factor is

essentially:

(36)

2

R2

(kr ) r dr

2 J1 (k R )

Equation 34 may be rewritten in terms of

the coefficients Q of distinct bessel

functions:

[M

zz

Q 3 (k )

k Mr r U ( z )

(40) Q4 (k )

k M U (z )

()

] 2 M

z (z )

W h

Displacement (arbitrary unit)

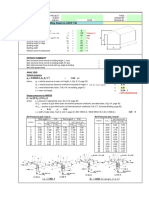

FIGURE 3. Out-of-plane displacement prediction for a

cracklike source located 0.9 m (3 ft) from the transducer and

connected to the same surface, in Unified Numbering

System G43400 alloy steel.

0.3

0.2

0.1

0

0.1

0.2

200 240 280

320 360 400 440 480

Time (s)

520

2 M

W (h)

2 M

W (h)

2 M

The response v(t) is then given by:

(41)

k dk [Q (k) J

1

(kr )

Q2 (k ) J 0 (kr ) + Q3 (k ) J 0 (kr )

Q4 (k )

J 0 (kr ) 1 cos b (k )t

2

kr

b (k )

Thus, there are four distinct amplitudes

needed for each k and b. All four are

needed for an exact calculation of

waveforms. They are functions of the

parameters M that represent source

orientation and strength; they are

functions also of the depth of the source

represented by the coordinate z and of the

wavenumber and branch number of the

mode of interest. However, for an estimate

of the relative importance of each mode

at asymptotic distances rk >> 1, it suffices

to consider only a single effective

amplitude Qeff for each type of strain

nucleus source and each source depth and

each mode. At asymptotic distances,

J0 (kr) is about J0(kr); J0 is /2 radians

(90 deg) out of phase with J0 and

J0(kr)(kr)1 is negligible hence the

definition of a single effective amplitude:

(42) Q eff (k ) =

160

Mrz kW (z ) + z U (z )

kR

Inverse Problem

Q 2 (k )

W (h)

(39)

which has been normalized to unity for a

point sensor R 0.

The evaluation of Eqs. 34 and 35 has

been coded. The algorithm requires first

the multibranched solution of the

rayleigh lamb dispersion relation on a

sufficiently fine grid in wavenumber k

and out to a sufficiently large frequency

. A separate code uses the instances of

and k for each branch as obtained in the

first code and then evaluates the

quantities M, U(z), W(z) and their

derivatives, at the source coordinate z,

and also W(h), for each branch b and each

wavenumber k along that branch by using

Eqs. 14 to 30. The numerical integral is

then straightforward.

An example is shown (Fig. 3) for the

predicted out-of-plane displacement for a

cracklike acoustic emission source (set of

double sources) connected to the same

surface as the sensor. For this example,

the source is 0.9 m (3 ft) from the

transducer.

(37) Q1 (k )

(38)

k

b (k )

[Q2 (k)] + [Q1 (k) Q3 (k)]

2

This single quantity represents the

contribution of a given mode {k,b}. It is

useful to plot it versus for each

branch b, for each of several parameters

M relating source orientation to strength

and for source coordinate z thereby

illustrating the relative contributions of

different sources to different modes. If

source character is to be ascertained

through examination of the waveform, it

must necessarily be by means of this

quantity Qeff; all information about the

source is transmitted through Qeff. This

observation forms the basis of the inverse

procedure below.

Modeling of Acoustic Emission in Plates

117

(43)

k dk

F0

(k ) J0 (kr )]

1 cos [ b (k ) t ]

2

b (k )

Q 1stepload

where Q 1stepload(k) is:

(44)

Q1stepload (k )

(sign)

W 2 (h)

2 M

where sign = 1 if the branch is an

antisymmetric branch and if the source

and receiver are on opposite sides of the

plate; sign = +1 otherwise. Thus,

Q 2 = Q3 = Q4 = 0 is identified for the step

force source. The effective Q is given again

by Eq. 42:

(45) Q

eff

(k )

k Q1stepload (k )

b (k )

The inverse problem thus reduces to

estimating, from measured waveforms,

the effective modal amplitudes Qeff at

each {k,b}. A waveform in the time

domain at given time t may be

understood as a superposition of the

many modes {k,b} that propagate at the

same group velocity.2 At asymptotically

large source-to-receiver distances, the time

of signal arrival equals the time of source

event plus the ratio of distance to Vgb():

(46)

Time of signal

arrival

Time of source

event

Distance

Vgb ( )

where Vgb is the group velocity:

(47) Vgb

d b

dk

Group velocity depends on plate material

and thickness and on the branch in

question and the frequency of interest but

not on source type or distance. Time of

arrival is different for different branches

and frequencies.

Thus, at any time t, there are several

modes contributing to the waveform, all

with different effective amplitudes Q and

all with different frequencies. The result is

a complex beat pattern. Extracting the

118

Acoustic Emission Testing

modal amplitudes Q from that pattern is

difficult because each such mode, having

a different frequency, has been affected

differently by the transducer sensitivity,

the amplifier gain and the source

function. Conversely, the waveform in the

frequency domain can be understood as

an interference pattern between the many

branches that have the same frequency

but different amplitudes Q and different

arrival times. In either domain, the

waveform is complex, because there are so

many interfering branches at the same

point.

The best way to analyze these

waveforms is in neither the frequency

domain nor the time domain but rather

by means of a simultaneous time and

frequency decomposition. If signal

processing can effect this decomposition,

the only remaining interferences would be

at the occasional places where two

branches have the same group velocity

and frequency.

Much signal processing literature tries

to optimize such decompositions. Work

has focused on the spectrogram, that is,

on the square of the short time fourier

transform, and on the wigner transform.

The simplest analysis of time versus

frequency, the spectrogram, has been

found to be adequate. A spectrogram

calculated from a theoretical waveform

(an evaluation of Eq. 34) is shown in

Fig. 4, where amplitudes concentrated

along the loci of frequency versus arrival

time are evident. Similar spectrograms are

FIGURE 4. Spectrogram obtained from a theoretical acoustic

emission waveform. Amplitudes are confined to specific loci

in the space of time versus frequency.

1.0

0.9

0.8

Frequency (MHz)

The case of a step vertical surface load

(Eq. 35) is also of interest:

0.7

0.6

0.5

0.4

0.3

0.2

S0

0.1

A0

0

100

200

300

400

500

Time (s)

Legend

S0 = asymmetric S wave

A0 = symmetric P wave

600

700

800

shown in this NDT Handbook volumes

chapter on source location. From such

spectrograms, the distance to the source

can be extracted by comparing the times

of arrival of different modes of known

group velocity. For example, it is clear

that the rayleigh wave arrives around time

tR = 325 s. The S0 mode arrives around

tS0 = 60 s. Thus, distance of the source

can be calculated:

(48)

t R t S0

1

1

cS 0

cR

By analyzing multiple points in such

plots, it is possible in principle to obtain

highly accurate source distances.

It is far more challenging to attempt to

characterize the source. It has been found

that source character can be determined

from the amplitudes in plots of time

versus frequency such as that of Fig. 4.

The ability of such a plot to isolate a

single mode, and thereby estimate its

effective Q is critical. Comparison with

theoretical values of Qeff then permits a

determination of the source character. The

procedure is described in detail in this

NDT Handbook volumes chapter on

source location.

Key to the technique is the recognition

that time functions for source and

receiver are irrelevant if the effective

amplitudes of different modes at the same

frequency are compared. If those modes

arrive at different times, then they do not

interfere and a plot like that of Fig. 4

permits the evaluation of the ratio of

effective Qs. A set of 13 mode pairs has

been identified for which one frequency

arrives at two distinct times and no other

modes arrive at that time, with that

frequency.

For example, the color version of the

screen shown in Fig. 4 displays the

amplitude of the S0 and A0 modes at a

frequency of 0.1 MHz. Under these

conditions, there is no interference and

the effective mode amplitudes can be

estimated without ambiguity from the

strength of the corresponding points of

the spectrogram. Although the amplitude

itself is a function of the source strength

and time function and receiver

characteristics, the ratio of effective Qs of

different modes of the same frequency is a

function of only source character and

source depth. Those many ratios are then

compared to the values of those ratios for

each source in a catalog of candidate

sources and the best fit candidates are

presented together with their fit quality.

Success with real waveforms, possibly

with limited bandwidth and perhaps

shorter distances from source to receiver is

not documented in the present

discussion. Source orientation and depth

were recovered from waveforms as

generated by Eq. 34 or 35 and from their

spectrograms like that of Fig. 4. Success

was best when distance from source to

receiver was greater than 100 times the

plate thickness. This is perhaps

unsurprising because large distances lead

to better separation of modes with

different group velocity.

It is clear that the best resolution of

source type will be obtained if waveforms

are wideband enough to encompass

several of the 13 mode pairs identified as

most useful. These mode pair frequencies

range up to about the cutoff of the tenth

branch, that is, to a frequency of about

400 kHz in 25 mm (1 in.) thick steel.

Modeling of Acoustic Emission in Plates

119

References

1. Weaver, R.L. and Y.-H. Pao.

Axisymmetric Waves Excited by a

Point Source in a Plate. Journal of

Applied Mechanics. Vol. 49.

New York, NY: ASME International

(1982): p 821-836.

2. Weaver, R.L. and Y.-H. Pao. Spectra of

Transient Waves in Elastic Plates.

Journal of the Acoustical Society of

America. Vol. 72. Melville, NY:

American Institute of Physics, for the

Acoustical Society of America (1982):

p 1933-1941.

3. Ceranoglu, A.N. and Y.-H. Pao.

Propagation of Elastic Pulses and

Acoustic Emission in a Plate. Journal

of Applied Mechanics. Vol. 48.

New York, NY: ASME International

(1981): p 125-147.

4. Hsu, N.N. Dynamic Greens Functions of

an Infinite Plate A Computer Program.

NBSIR 85-3234. Gaithersburg, MD:

National Institute of Standards and

Technology (1985).

5. Breckenridge, F., T. Proctor, N.N. Hsu,

D. Fick and D. Eitzen. Transient

Sources for AE Work. Progress in

Acoustic Emission V. Tokyo, Japan:

Japanese Society for Nondestructive

Inspection (1990): p 10-37.

6. Sachse, W. Recent Developments in

Quantitative AE. Proceedings of the

IUTAM Symposium on Elastic Waves and

Ultrasonic Nondestructive Evaluation

[1989]. Amsterdam, Netherlands:

Elsevier, for the International Union of

Theoretical and Applied Mechanics

(1990).

7. Santosa, F. and Y.-H. Pao. Transient

Axially Asymmetric Response of an

Elastic Plate of Finite Thickness. Wave

Motion. Vol. 11. Amsterdam,

Netherlands: Elsevier (1999):

p 271-295.

8. Mal, A.K. and T.C.T. Ting, eds. Wave

Propagation in Structural Composites.

AMD-90. Materials Park, OH: ASME

International (1988).

9. Mal, A.K. Wave Propagation in

Layered Composite Laminates under

Periodic Surface Loads. Wave Motion.

Vol. 10. Amsterdam, Netherlands:

Elsevier (1988): p 257-266.

10. Pao, Y.-H. Theory of Acoustic

Emission. Elastic Waves and

Nondestructive Testing of Materials.

AMD-29. New York, NY: ASME

International (1978): p 107-128.

120

Acoustic Emission Testing

11. Pao, Y.-H. Elastic Waves in Solids.

Journal of Applied Mechanics. Vol. 50.

New York, NY: ASME International

(1983): p 1152-1164.

12. Love, A.E.H. A Treatise on the

Mathematical Theory of Elasticity.

New York, NY: Dover (1927).

13. Aki, K. and P. Richards. Quantitative

Seismology Theory and Methods. San

Francisco, CA: W.H. Freeman (1980).

14. Achenbach, J.D. Wave Propagation in

Elastic Solids. Amsterdam, Netherlands:

North Holland (1973).

15. Miklowitz, J. Theory of Elastic Waves

and Waveguides. Amsterdam,

Netherlands: Elsevier/North Holland

(1978).

16. Graff, K.F. Wave Motion in Elastic Solids.

New York, NY: Dover (1975).

17. Weaver, R.L. Diffuse Waves in Finite

Plates. Journal of Sound and Vibration.

Vol. 94. San Diego, CA: Academic

Press (1984): p 319-335.

18. Nayfeh, A. and D. Chimenti.

Ultrasonic Wave Reflection from

Liquid Coupled Orthotropic Plates

with Applications to Fibrous

Composites. Journal of Applied

Mechanics. Vol. 55. New York, NY:

ASME International (1988): p 863-870.

19. Banerjee, S., A.K. Mal and

W.H. Prosser. Analysis of Transient

Lamb Waves Generated by Dynamic

Surface Sources in Thin Composite

Plates. Journal of the Acoustical Society

of America. Vol. 115, No. 5. Melville,

NY: American Institute of Physics, for

the Acoustical Society of America

(2004): p 1905-1911.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Mechanism and Dynamics of Machinery - Hamilton H. MabieDokument330 SeitenMechanism and Dynamics of Machinery - Hamilton H. MabieErick Muñoz71% (7)

- Calculation of The Current Transformer Accuracy Limit FactorDokument14 SeitenCalculation of The Current Transformer Accuracy Limit FactorWeiKiat Goh67% (3)

- The Effect of Atom Position on X-Ray Diffraction IntensitiesDokument29 SeitenThe Effect of Atom Position on X-Ray Diffraction IntensitiesJorge De Jesus Torres ReyesNoch keine Bewertungen

- SchmertmannDokument13 SeitenSchmertmannkabasy20150% (1)

- Computational Modeling and Design of New Random Microheterogeneous MaterialsDokument227 SeitenComputational Modeling and Design of New Random Microheterogeneous MaterialsVicente Bergamini PugliaNoch keine Bewertungen

- Eleanor Oliphant Is Completely - Gail HoneymanDokument63 SeitenEleanor Oliphant Is Completely - Gail HoneymanVicente Bergamini Puglia0% (2)

- PULSE Data ManagerDokument70 SeitenPULSE Data ManagerVicente Bergamini PugliaNoch keine Bewertungen

- ZohdiDokument227 SeitenZohdiVicente Bergamini PugliaNoch keine Bewertungen

- Anil MisraDokument12 SeitenAnil MisraVicente Bergamini PugliaNoch keine Bewertungen

- Screw Conveyor Engineering Manual PDFDokument68 SeitenScrew Conveyor Engineering Manual PDFnadNoch keine Bewertungen

- Junbo Jia (Auth.) - Modern Earthquake Engineering - Offshore and Land-Based Structures-Springer-Verlag Berlin Heidelberg (2017) PDFDokument859 SeitenJunbo Jia (Auth.) - Modern Earthquake Engineering - Offshore and Land-Based Structures-Springer-Verlag Berlin Heidelberg (2017) PDFVicente Bergamini Puglia100% (2)

- AE02Dokument82 SeitenAE02Vicente Bergamini PugliaNoch keine Bewertungen

- B Value (Marzziotti Sandri 2003)Dokument12 SeitenB Value (Marzziotti Sandri 2003)Vicente Bergamini PugliaNoch keine Bewertungen

- ArtigoDokument12 SeitenArtigoVicente Bergamini PugliaNoch keine Bewertungen

- 1629 Pujol Smalley 1990Dokument14 Seiten1629 Pujol Smalley 1990Vicente Bergamini PugliaNoch keine Bewertungen

- Solving Problems in Scientific Computing Using Maple and MatlabDokument500 SeitenSolving Problems in Scientific Computing Using Maple and MatlabVicente Bergamini PugliaNoch keine Bewertungen

- WILLIAM, K. J WARNKE, E. P. Constitutive Model For The Triaxial Behaviour of Concrete.Dokument30 SeitenWILLIAM, K. J WARNKE, E. P. Constitutive Model For The Triaxial Behaviour of Concrete.Vicente Bergamini PugliaNoch keine Bewertungen

- H.S. ShangDokument8 SeitenH.S. ShangVicente Bergamini PugliaNoch keine Bewertungen

- Multi-Directional Modeling of Crack Pattern in 2D R/C MembersDokument14 SeitenMulti-Directional Modeling of Crack Pattern in 2D R/C MembersVicente Bergamini PugliaNoch keine Bewertungen

- W S YinDokument7 SeitenW S YinVicente Bergamini PugliaNoch keine Bewertungen

- Multi-Directional Modeling of Crack Pattern in 2D R/C MembersDokument14 SeitenMulti-Directional Modeling of Crack Pattern in 2D R/C MembersVicente Bergamini PugliaNoch keine Bewertungen

- Fatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressDokument17 SeitenFatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressVicente Bergamini PugliaNoch keine Bewertungen

- Andrzej LitewkaDokument21 SeitenAndrzej LitewkaVicente Bergamini PugliaNoch keine Bewertungen

- 03-05-20 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Adv - 2017 - P1 - GTA-13 - P-I - QPDokument19 Seiten03-05-20 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Adv - 2017 - P1 - GTA-13 - P-I - QPsaloni guptaNoch keine Bewertungen

- Surface Area of A Semi-Cylinder WorksheetDokument1 SeiteSurface Area of A Semi-Cylinder WorksheetvirtualmathsNoch keine Bewertungen

- 2 Alternating CurrentsDokument20 Seiten2 Alternating CurrentsJaseela NaufalNoch keine Bewertungen

- Basic Inertial NavigationDokument38 SeitenBasic Inertial Navigationleneneck9057100% (1)

- Compiled FluMach Problems - GROUP6 - BSME31Dokument58 SeitenCompiled FluMach Problems - GROUP6 - BSME31Jhun Briones100% (1)

- Change of Order of IntegrationDokument4 SeitenChange of Order of IntegrationShubham Teju100% (2)

- Kirchhoff's Laws: Sample Problem 1Dokument5 SeitenKirchhoff's Laws: Sample Problem 1Eduard LauronNoch keine Bewertungen

- CH 04Dokument17 SeitenCH 04Vishal PanwarNoch keine Bewertungen

- Valence MOTheoryDokument50 SeitenValence MOTheoryRodolfo Angulo OlaisNoch keine Bewertungen

- Chemical Thermodynamics: Module - 4Dokument25 SeitenChemical Thermodynamics: Module - 4TeachingTrainingCoaching KnowledgeSharingSessionNoch keine Bewertungen

- Section A: Multiple Choice Questions (20 Marks)Dokument4 SeitenSection A: Multiple Choice Questions (20 Marks)saed cabdiNoch keine Bewertungen

- Evaluation of Dynamic Increment Component of Earth Pressure Behind The Retaining WallsDokument7 SeitenEvaluation of Dynamic Increment Component of Earth Pressure Behind The Retaining WallsSivaramakrishnanNoch keine Bewertungen

- Math 2280 - Lecture 4: Separable Equations and Applications: Dylan Zwick Fall 2013Dokument8 SeitenMath 2280 - Lecture 4: Separable Equations and Applications: Dylan Zwick Fall 2013Kawsar MobinNoch keine Bewertungen

- Physics Investigatory ProjectDokument18 SeitenPhysics Investigatory ProjectRΛJIBUL ISLΛMNoch keine Bewertungen

- An Introduction To DC Generator Using Matlab/Simulink: Debabrata PalDokument4 SeitenAn Introduction To DC Generator Using Matlab/Simulink: Debabrata PalMohammad H Al-QaisiNoch keine Bewertungen

- Voltage and Frequency Control of Inverters Connected in Parallel Forming A Micro-GridDokument6 SeitenVoltage and Frequency Control of Inverters Connected in Parallel Forming A Micro-GridShad Rahman100% (1)

- WKST - 1.4 Converting Graphs - ChallengeDokument8 SeitenWKST - 1.4 Converting Graphs - Challengefaltu accountNoch keine Bewertungen

- Ossd U1Dokument26 SeitenOssd U1huangjunxiang4Noch keine Bewertungen

- EquiprobabilityDokument2 SeitenEquiprobabilitydanny222Noch keine Bewertungen

- Design of 6.6 KV, 100 A Saturated DC Reactor Type Superconducting Fault Current LimiterDokument4 SeitenDesign of 6.6 KV, 100 A Saturated DC Reactor Type Superconducting Fault Current LimiterwaleedkhanpelNoch keine Bewertungen

- Column Design Prokon.Dokument16 SeitenColumn Design Prokon.akankwasaNoch keine Bewertungen

- Lectu 14Dokument4 SeitenLectu 14YeviraArinDiyanaNoch keine Bewertungen

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Dokument2 SeitenWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldNoch keine Bewertungen

- Case Based CH-3 Motion in Straight LineDokument5 SeitenCase Based CH-3 Motion in Straight LineGaneshNoch keine Bewertungen

- APEGBC Eng Syllabus MechanicalDokument22 SeitenAPEGBC Eng Syllabus MechanicalbaljinderNoch keine Bewertungen

- Large Deflections of Cantilever BeamsDokument4 SeitenLarge Deflections of Cantilever BeamsHasan Ayouby100% (1)

- 02 AtomsDokument3 Seiten02 AtomsZigmund Bryan CortezaNoch keine Bewertungen