Beruflich Dokumente

Kultur Dokumente

15) Average Least Dimension

Hochgeladen von

Pn EkanayakaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

15) Average Least Dimension

Hochgeladen von

Pn EkanayakaCopyright:

Verfügbare Formate

Method for determining the Average Least Dimension

Introduction:

The least dimension of an aggregate particle is the smallest perpendicular distance between two

parallel plates through which the particle will just past. The average least dimension is the

arithmetic mean of all the measured least dimensions of the aggregate particles measured.

This method describes a procedure to be followed to determine the Average Least Dimension of a

cover aggregate intended for use in a bituminous surface treatment or seal coat. The Average

Least Dimension of the cover aggregate is used to determine the starting spread rate for seal coat

operations.

Objectives:

Objective of this test is to determine the Average Least Dimension of a cover aggregate

intended for use in a bituminous surface treatment or seal coat.

Apparatus:

The following apparatus are required.

1) Set of Sieves including the following; 12.5 mm, 9.5 mm, 6.9 mm, 4.76 mm, 2.36 mm,

1.18 mm and pan (Figure 1).

2) A balance readable to at least 0.01 g.

3) A metal thickness gauge or special sieves having elongated apertures to determine the

Flakiness Index.

Procedure:

Figure 1 Set of Sieves

1) Procedure for determining the Median size of the cover aggregate

A surface-dry sample of the cover aggregate was weighed and determined the distribution

of particle sizes listed in Table 1 by means of sieves with square openings.

On completion of sieving, the material retained on each sieve was weighed on a balance

sensitive to 0.1 percent of weight of the test sample.

Data were recorded on a work sheet and calculated the weight passing each sieve,

expressed as a percentage of the total weight of the sample.

The results were recorded to the nearest 1 percent and plotted the grading curve on a

grading sheet.

The Median Size of the cover material was determined and recorded. The median size is

the theoretical sieve size in mm through which 50 percent of the cover material will pass.

Table 1 - Distribution of particle size

Standard

Sieve

Designation

Passing

12.5 mm

9.5 mm

6.9 mm

4.76 mm

2.36 mm

1.18 mm

Pan

2) Flakiness Index

The Flakiness Index was determined and recorded using BS 812: 105.

3) Average Least Dimension

The Average Least Dimension of the cover material was determined and recorded by

using the previously determined Median Size and Flakiness Index.

Figure 1 in Annex 1 was used and proceeded horizontally from the median size on the

vertical axis to the diagonal line representing the Flakiness Index for the sample. From this

intersection, proceeded vertically to the horizontal axis and read off and recored the Average

Least Dimension.

Observation:

Observations are given in Annex 1 & 2.

Calculations and result:

The average least dimension is reported to the nearest 0.1 mm.

Specimen Calculation:

Sieve

Size

Weight of

Sieve

(g)

Aggregate

wt.+ Sieve

(g)

Weight of

Aggregate

(g)

12.5 mm

9.5 mm

6.9 mm

4.76 mm

2.36 mm

1.18 mm

Pan

1161.4

1250.4

1157.8

528.0

524.4

478.4

503.2

1161.4

1285.0

3322.8

890.8

610.0

498.2

522.6

0

34.6

2165.0

362.8

85.6

19.8

19.4

As per the grading curve in Annex 2,

Median size of the cover aggregate = 9.0 mm

From Figure 1 in Annex 1,

Cumulativ

e

Weight

(g)

0

34.6

2199.6

2562.4

2648.0

2667.8

2687.2

Percent

Retained

(%)

Percent

Passing

(%)

0

1.29

81.85

95.35

98.54

99.28

100

100

98.71

18.15

4.65

1.46

0.72

0

Average Least Dimension = 7.2 mm

Discussion:

1) Discuss the importance of Average Least Dimension test in road construction.

Das könnte Ihnen auch gefallen

- Determine Bitumen Ductility TestDokument3 SeitenDetermine Bitumen Ductility TestSanthaKumar Muthu ThankaveluNoch keine Bewertungen

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Dokument10 SeitenMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnNoch keine Bewertungen

- Determination of Aggregate CrushingDokument8 SeitenDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- Viscosity Penetration Test ReportDokument7 SeitenViscosity Penetration Test ReportMoganraj100% (2)

- Ecg354-Aggregate Impact TestDokument7 SeitenEcg354-Aggregate Impact TestNurin AdlinaNoch keine Bewertungen

- Experiment 1 - 4Dokument24 SeitenExperiment 1 - 4fatinjaweNoch keine Bewertungen

- Asphalt ExtractionDokument4 SeitenAsphalt ExtractionOsikur RahamanNoch keine Bewertungen

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDokument12 SeitenQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- Cube TestDokument10 SeitenCube Testridhuanzainal100% (1)

- Workability Test (Slump Test) Lab ReportDokument10 SeitenWorkability Test (Slump Test) Lab ReportMAC DARREL MICHAEL MAC DARREL MICHAELNoch keine Bewertungen

- AGGREGATE Shape TESTSDokument7 SeitenAGGREGATE Shape TESTSBernard KitosiNoch keine Bewertungen

- Physical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachDokument8 SeitenPhysical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachSEP-PublisherNoch keine Bewertungen

- WorkabilityDokument3 SeitenWorkabilityyay94rebuildNoch keine Bewertungen

- Standard Proctor Compaction Test ExplainedDokument10 SeitenStandard Proctor Compaction Test ExplainedChaminduKrishanRupasinghe0% (1)

- Determination of PenetrationDokument57 SeitenDetermination of Penetrationtunlaji0% (2)

- AIVDokument4 SeitenAIVAfiq SafwanNoch keine Bewertungen

- Softening Point ReportDokument10 SeitenSoftening Point Reportmuhd qayyumNoch keine Bewertungen

- Direct Shear Box TestDokument4 SeitenDirect Shear Box Testarid132Noch keine Bewertungen

- Civil Engineering Lab Report on Light StructuresDokument95 SeitenCivil Engineering Lab Report on Light StructuresKHAI HONG GANNoch keine Bewertungen

- Liquid Limit and Plastic Limit Tests - Lab ExperimentsDokument8 SeitenLiquid Limit and Plastic Limit Tests - Lab ExperimentsbilalNoch keine Bewertungen

- Ductility Test PDFDokument4 SeitenDuctility Test PDFAshishJamadarNoch keine Bewertungen

- Aggregate Impact Value TestDokument5 SeitenAggregate Impact Value TestMind Rip100% (1)

- AGGREGATE ABRASION TEST VALUESDokument6 SeitenAGGREGATE ABRASION TEST VALUESAbdur RazzakNoch keine Bewertungen

- C6- Standard Consistency Cement PasteDokument4 SeitenC6- Standard Consistency Cement PasteMuhamad FarhanNoch keine Bewertungen

- Highway - Lab Sheet (Aggregate Impact Value - Bs 812 Part III) (22.12.13)Dokument5 SeitenHighway - Lab Sheet (Aggregate Impact Value - Bs 812 Part III) (22.12.13)shahidatulahmadNoch keine Bewertungen

- 34) Extraction of Bitumen From Paving MixturesDokument6 Seiten34) Extraction of Bitumen From Paving MixturesPn EkanayakaNoch keine Bewertungen

- Lab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Dokument3 SeitenLab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Kashif IqbaljNoch keine Bewertungen

- M.E QuestionsDokument7 SeitenM.E QuestionsStephen John ClementeNoch keine Bewertungen

- Crushing Test PDFDokument4 SeitenCrushing Test PDFAshishJamadarNoch keine Bewertungen

- Determination of Flakiness and Elongation Index For The Given Aggregate Sample.Dokument4 SeitenDetermination of Flakiness and Elongation Index For The Given Aggregate Sample.Huma AliNoch keine Bewertungen

- Penetration Test Lab ReportDokument6 SeitenPenetration Test Lab ReportbawanlavaNoch keine Bewertungen

- L1-Physical Characteristic of SoilDokument78 SeitenL1-Physical Characteristic of SoilTAN PANG ZORNoch keine Bewertungen

- Sieve Analysis TestDokument8 SeitenSieve Analysis TestFahmi MaSyukzz100% (1)

- Atterberg Limits Test Determines Soil BehaviorDokument6 SeitenAtterberg Limits Test Determines Soil BehaviorMuhammadZAmjadNoch keine Bewertungen

- PRACTICAL NO. 6 (2.5kg 4.5kg Rammer)Dokument5 SeitenPRACTICAL NO. 6 (2.5kg 4.5kg Rammer)slawek780303Noch keine Bewertungen

- Nanyang Technological University School of Civil and Structural EngineeringDokument44 SeitenNanyang Technological University School of Civil and Structural EngineeringZhwan AnwarNoch keine Bewertungen

- Compressive Strength of ConcreteDokument9 SeitenCompressive Strength of ConcreteAmos kiprutoNoch keine Bewertungen

- Ductility of Bituminous MaterialsDokument2 SeitenDuctility of Bituminous MaterialsAhmad Ismail67% (3)

- Ring and Ball TestDokument4 SeitenRing and Ball TestMuhd Farhan Bin IbrahimNoch keine Bewertungen

- Water Cement Ratio (Gate60 Short Notes)Dokument4 SeitenWater Cement Ratio (Gate60 Short Notes)akash rathodNoch keine Bewertungen

- Lab Sheet - Sieve AnalysisDokument7 SeitenLab Sheet - Sieve AnalysisLuqman YusofNoch keine Bewertungen

- Aggregate Angularity NumberDokument5 SeitenAggregate Angularity NumberAdnan AhmadNoch keine Bewertungen

- LABSHEET Ukur Aras Terkini PDFDokument6 SeitenLABSHEET Ukur Aras Terkini PDFLogarithemNoch keine Bewertungen

- Atterberg LimitsDokument8 SeitenAtterberg LimitsrbhavishNoch keine Bewertungen

- 3 Methods of Determining Workability of ConcreteDokument4 Seiten3 Methods of Determining Workability of Concretesuryakantame100% (1)

- Direct Shear Test ReprtDokument4 SeitenDirect Shear Test ReprtShivaraj SubramaniamNoch keine Bewertungen

- Ultrasonic Pulse VelocityDokument3 SeitenUltrasonic Pulse VelocitySougata DasNoch keine Bewertungen

- Consolidation TestDokument2 SeitenConsolidation TestTenzinKesang100% (1)

- Sand Patch TestDokument5 SeitenSand Patch TestgreatpicNoch keine Bewertungen

- Field Density Lab ReportDokument21 SeitenField Density Lab ReportAnonymous DR3NznNoch keine Bewertungen

- Los Angeles Abrasion TestDokument5 SeitenLos Angeles Abrasion Testদেওয়ানসাহেবNoch keine Bewertungen

- Outflow MeterDokument5 SeitenOutflow MeterFirash ImranNoch keine Bewertungen

- Building Mat 08-09Dokument39 SeitenBuilding Mat 08-09takishiNoch keine Bewertungen

- CBR TEST CompleteDokument9 SeitenCBR TEST CompleteRazman Fozi0% (1)

- Determining Aggregate Impact ValueDokument6 SeitenDetermining Aggregate Impact ValuelawvishNoch keine Bewertungen

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- Scope: CautionDokument0 SeitenScope: Cautionandy981Noch keine Bewertungen

- Thickness (Caliper) of Towel, Tissue, Napkin and Facial Products (Proposed New Provisional Method)Dokument0 SeitenThickness (Caliper) of Towel, Tissue, Napkin and Facial Products (Proposed New Provisional Method)andy981Noch keine Bewertungen

- Astm C 167Dokument4 SeitenAstm C 167dorbarelNoch keine Bewertungen

- PT Lectures 5-6Dokument14 SeitenPT Lectures 5-6zxynnvdNoch keine Bewertungen

- Limit States Design in Structural Steel 8th EdDokument392 SeitenLimit States Design in Structural Steel 8th EdPn EkanayakaNoch keine Bewertungen

- Tapping DirectTappingDuctileIronPipeinPolyethylene PDFDokument7 SeitenTapping DirectTappingDuctileIronPipeinPolyethylene PDFPn EkanayakaNoch keine Bewertungen

- Angus MonitorsDokument16 SeitenAngus Monitorsmuhammadtayyab_87Noch keine Bewertungen

- Mat Foundation Design CalculationDokument4 SeitenMat Foundation Design CalculationPn EkanayakaNoch keine Bewertungen

- Concrete Mix Design SpreadsheetDokument4 SeitenConcrete Mix Design SpreadsheetSmith SivaNoch keine Bewertungen

- Morecambe Marina Feasibility Study Main Report PDFDokument59 SeitenMorecambe Marina Feasibility Study Main Report PDFharyanto99100% (1)

- S3-TL4 Bridge Railing PDFDokument1 SeiteS3-TL4 Bridge Railing PDFPn EkanayakaNoch keine Bewertungen

- O 06 Dcty DFLCTNDokument9 SeitenO 06 Dcty DFLCTNCarlos Rene Mamani TrujilloNoch keine Bewertungen

- Standard Construction Drawings - 20meg PDFDokument100 SeitenStandard Construction Drawings - 20meg PDFPn EkanayakaNoch keine Bewertungen

- Design Criteria For RCCDokument7 SeitenDesign Criteria For RCCAtifkhan132Noch keine Bewertungen

- Mit - Concepte Cedare RCDokument9 SeitenMit - Concepte Cedare RCRada IoanNoch keine Bewertungen

- Lighting Structures PDFDokument30 SeitenLighting Structures PDFScott TrainorNoch keine Bewertungen

- Details of WDETAILS OF WATER SAMPLING STATION - Pdfater Sampling StationDokument31 SeitenDetails of WDETAILS OF WATER SAMPLING STATION - Pdfater Sampling StationHong Leong KuNoch keine Bewertungen

- Axial and Lateral Load Piles Fem v1.6Dokument60 SeitenAxial and Lateral Load Piles Fem v1.6Shahab KhaledNoch keine Bewertungen

- SSB05 Detailed Design of Trusses 2010-03-22Dokument131 SeitenSSB05 Detailed Design of Trusses 2010-03-22DN GHNoch keine Bewertungen

- Concrete Floor Slabs On Grade Subjected To Heavy Loads PDFDokument57 SeitenConcrete Floor Slabs On Grade Subjected To Heavy Loads PDFPn EkanayakaNoch keine Bewertungen

- Pile Cap Design - ColumnsDokument6 SeitenPile Cap Design - Columnsntah8450% (2)

- Market Analysis Marina DevelopmentDokument88 SeitenMarket Analysis Marina DevelopmentPn EkanayakaNoch keine Bewertungen

- Watermain STD Dwgs-101101Dokument37 SeitenWatermain STD Dwgs-101101Pn EkanayakaNoch keine Bewertungen

- PennDOT Truss Gusset Plate Analysis SpreadsheetDokument11 SeitenPennDOT Truss Gusset Plate Analysis SpreadsheetPn EkanayakaNoch keine Bewertungen

- Guide For Designing Energy Efficient Building EnclosuresDokument242 SeitenGuide For Designing Energy Efficient Building EnclosuresPn EkanayakaNoch keine Bewertungen

- Chapter 4 - Slender ColumnsDokument26 SeitenChapter 4 - Slender ColumnsMohamed Salah100% (1)

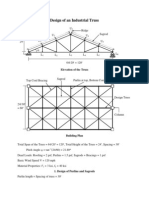

- Industrial Truss Design and AnalysisDokument15 SeitenIndustrial Truss Design and AnalysisGurnam Singh Sodhi100% (3)

- Book Understanding Housing Defects Second Edition PDFDokument353 SeitenBook Understanding Housing Defects Second Edition PDFPn Ekanayaka50% (2)

- MIAA Australian Marina Profile Report - Nov 2010Dokument13 SeitenMIAA Australian Marina Profile Report - Nov 2010Pn EkanayakaNoch keine Bewertungen

- Annual Reports Grand Harbour Marina 2014Dokument90 SeitenAnnual Reports Grand Harbour Marina 2014Pn EkanayakaNoch keine Bewertungen

- Guide RFP WritingDokument3 SeitenGuide RFP WritingSunilBhandari100% (1)

- Yacht Marina ReviewDokument21 SeitenYacht Marina ReviewPn EkanayakaNoch keine Bewertungen

- Facility StandardsDokument94 SeitenFacility StandardsPn EkanayakaNoch keine Bewertungen

- Overview Six Sigma PhasesDokument3 SeitenOverview Six Sigma Phaseshans_106Noch keine Bewertungen

- 9 Reporting of Channel State Information under AWGN ConditionsDokument233 Seiten9 Reporting of Channel State Information under AWGN ConditionspzernikNoch keine Bewertungen

- Singh Surender - Biostatistics & Research MethodolgyDokument18 SeitenSingh Surender - Biostatistics & Research MethodolgynamrataNoch keine Bewertungen

- Group3-Mas202 CompressDokument19 SeitenGroup3-Mas202 CompressNgọc YếnNoch keine Bewertungen

- Researchinma 130216121756 Phpapp01Dokument288 SeitenResearchinma 130216121756 Phpapp01Saharsh SaraogiNoch keine Bewertungen

- Fitting statistical models and calculating momentsDokument7 SeitenFitting statistical models and calculating momentsHitika TeckaniNoch keine Bewertungen

- Achievement StatDokument7 SeitenAchievement StatFRECY MARZANNoch keine Bewertungen

- Cambridge Secondary Checkpoint Mathematics (1112) Mark Scheme Part1: 2022-2015Dokument325 SeitenCambridge Secondary Checkpoint Mathematics (1112) Mark Scheme Part1: 2022-2015mal95% (19)

- Margin of Conservatism Framework for IRB PD, LGD and CCF EstimationDokument29 SeitenMargin of Conservatism Framework for IRB PD, LGD and CCF EstimationVeeresh KumarNoch keine Bewertungen

- Minitab Intro PDFDokument60 SeitenMinitab Intro PDFDo van QuanNoch keine Bewertungen

- 2007 - Tu - Et - Al - 2007 - Revisiting The Relation Between Change and Initial ValueDokument15 Seiten2007 - Tu - Et - Al - 2007 - Revisiting The Relation Between Change and Initial ValueDanilo MoggiaNoch keine Bewertungen

- Elementary StatistikDokument9 SeitenElementary Statistikcikgu_ishmaelNoch keine Bewertungen

- MATLAB Course at TU MunichDokument39 SeitenMATLAB Course at TU MunichNikhil AgarwalNoch keine Bewertungen

- Reviewer in MathstatDokument21 SeitenReviewer in MathstatJulian James LajomNoch keine Bewertungen

- Regulation of TimelinessDokument21 SeitenRegulation of TimelinessSusan KuncoroNoch keine Bewertungen

- Computer and Machine Vision 4e - Solution ManualDokument44 SeitenComputer and Machine Vision 4e - Solution Manualdekas_guitarhero3616Noch keine Bewertungen

- Measures of Central Tendency and Variability in Descriptive StatisticsDokument52 SeitenMeasures of Central Tendency and Variability in Descriptive StatisticsAnjali YadavNoch keine Bewertungen

- Heaney - Morris 1Dokument57 SeitenHeaney - Morris 1api-255415003Noch keine Bewertungen

- Chapter 2Dokument19 SeitenChapter 2Roha CbcNoch keine Bewertungen

- Background SubtractionDokument4 SeitenBackground SubtractionlatecNoch keine Bewertungen

- Measures of Central Tendency for Ungrouped DataDokument18 SeitenMeasures of Central Tendency for Ungrouped DataLee DokyeomNoch keine Bewertungen

- January 2012 QP - S1 EdexcelDokument13 SeitenJanuary 2012 QP - S1 EdexcelWambui KahendeNoch keine Bewertungen

- Tutorial Week 10 Statistics AnswersDokument10 SeitenTutorial Week 10 Statistics AnswersChristie BudiatmantoNoch keine Bewertungen

- Newbold Sbe8 Tif ch05 PDFDokument58 SeitenNewbold Sbe8 Tif ch05 PDFak100% (1)

- Skwarchuk Sowinski LeFevre2014.Dokument22 SeitenSkwarchuk Sowinski LeFevre2014.Anonymous Y0jxrlENoch keine Bewertungen

- Experimentation An Introduction To Measurement Theory and Experiment Design DC BairdDokument210 SeitenExperimentation An Introduction To Measurement Theory and Experiment Design DC BairdEpilefSantiago100% (3)

- Datascience With AnswersDokument36 SeitenDatascience With AnswersSudheer Redus100% (1)

- Course Outline BUSN-225Dokument10 SeitenCourse Outline BUSN-225Kevin KooblallNoch keine Bewertungen

- Terms 2Dokument11 SeitenTerms 2jlayambotNoch keine Bewertungen

- StatisticsDokument26 SeitenStatisticscherryNoch keine Bewertungen