Beruflich Dokumente

Kultur Dokumente

Water-tube Boilers: Types, Advantages & Combined Heat Power Systems

Hochgeladen von

hafidhrahadiyan2Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Water-tube Boilers: Types, Advantages & Combined Heat Power Systems

Hochgeladen von

hafidhrahadiyan2Copyright:

Verfügbare Formate

Water-tube Boilers Module 3.

Block 3 The Boiler House

Module 3.3

Water-tube Boilers

The Steam and Condensate Loop

3.3.1

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Water-tube Boilers

Pendant superheater

Steam drum

Convection bank

Gas baffles

Economiser

Burners

Fig. 3.3.1 Water-tube boiler

Water-tube boilers differ from shell type boilers in that the water is circulated inside the tubes,

with the heat source surrounding them. Referring back to the equation for hoop stress

(Equation 3.2.1), it is easy to see that because the tube diameter is significantly smaller, much

higher pressures can be tolerated for the same stress.

Water-tube boilers are used in power station applications that require:

o

A high steam output (up to 500 kg /s).

High pressure steam (up to 160 bar).

Superheated steam (up to 550C).

However, water-tube boilers are also manufactured in sizes to compete with shell boilers.

Small water-tube boilers may be manufactured and assembled into a single unit, just like packaged

shell boilers, whereas large units are usually manufactured in sections for assembly on site.

Many water-tube boilers operate on the principle of natural water circulation (also known

as thermo-siphoning). This is a subject that is worth covering before looking at the different

types of water-tube boilers that are available. Figure 3.3.2 helps to explain this principle:

o

Cooler feedwater is introduced into the steam

drum behind a baffle where, because the

density of the cold water is greater, it

descends in the downcomer towards the

lower or mud drum, displacing the warmer

water up into the front tubes.

Continued heating creates steam bubbles in

the front tubes, which are naturally separated

from the hot water in the steam drum, and

are taken off.

However, when the pressure in the water-tube

boiler is increased, the difference between the

densities of the water and saturated steam falls,

consequently less circulation occurs. To keep

the same level of steam output at higher design

pressures, the distance between the lower

drum and the steam drum must be increased,

or some means of forced circulation must

be introduced.

3.3.2

Steam

Boiler or

steam drum

Feedwater

Heat

Riser

Downcomer

Lower or mud drum

Fig. 3.3.2

Natural water circulation in a water-tube boiler

The Steam and Condensate Loop

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Water-tube boiler sections

The energy from the heat source may be extracted as either radiant or convection and conduction.

The furnace or radiant section

This is an open area accommodating the flame(s) from the burner(s). If the flames were allowed

to come into contact with the boiler tubes, serious erosion and finally tube failure would occur.

The walls of the furnace section are lined with finned tubes called membrane panels, which are

designed to absorb the radiant heat from the flame.

Insulation material

Boiler

tubes

Fins

Furnace flame

Fig. 3.3.3 Heat transfer in the furnace or radiant section

Convection section

This part is designed to absorb the heat from the hot gases by conduction and convection.

Large boilers may have several tube banks (also called pendants) in series, in order to gain

maximum energy from the hot gases.

Steam drum

Hot gases

Tubes

Water drum

Fig. 3.3.4 Heat transfer in the convection section

Water-tube boiler designation

Water-tube boilers are usually classified according to certain characteristics, see Table 3.3.1.

Table 3.3.1 Water-tube boiler classifications

Reservoir drum position

Water circulation

Number of drums

Capacity

The Steam and Condensate Loop

For example, longitudinal or cross drum

For example, natural or forced

For example, two, three

For example, 25 500 kg / h, 7 kg / s, 55 000 lb / h

3.3.3

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Alternative water-tube boiler layouts

The following layouts work on the same principles as other water-tube boilers, and are available

with capacities from 5 000 kg /h to 180 000 kg/h.

Longitudinal drum boiler

The longitudinal drum boiler was the original type of water-tube boiler that operated on the

thermo-siphon principle (see Figure 3.3.5).

Cooler feedwater is fed into a drum, which is placed longitudinally above the heat source. The

cooler water falls down a rear circulation header into several inclined heated tubes. As the water

temperature increases as it passes up through the inclined tubes, it boils and its density decreases,

therefore circulating hot water and steam up the inclined tubes into the front circulation header

which feeds back to the drum. In the drum, the steam bubbles separate from the water and the

steam can be taken off.

Typical capacities for longitudinal drum boilers range from 2 250 kg /h to 36 000 kg /h.

Steam off-take

Steam

Water

Feedwater

Waste

gases to

stack

Heat

Fig. 3.3.5 Longitudinal drum boiler

Cross drum boiler

The cross drum boiler is a variant of the longitudinal drum boiler in that the drum is placed cross

ways to the heat source as shown in Figure 3.3.6. The cross drum operates on the same principle

as the longitudinal drum except that it achieves a more uniform temperature across the drum.

However it does risk damage due to faulty circulation at high steam loads; if the upper tubes

become dry, they can overheat and eventually fail.

The cross drum boiler also has the added advantage of being able to serve a larger number of

inclined tubes due to its cross ways position.

Typical capacities for a cross drum boiler range from 700 kg / h to 240 000 kg /h.

3.3.4

The Steam and Condensate Loop

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Steam

Feedwater

Heat

Waste gases to stack

Fig. 3.3.6 Cross drum boiler

Bent tube or Stirling boiler

A further development of the water-tube boiler is the bent tube or Stirling boiler shown in

Figure 3.3.7. Again this operates on the principle of the temperature and density of water, but

utilises four drums in the following configuration.

Cooler feedwater enters the left upper drum, where it falls due to greater density, towards the

lower, or water drum. The water within the water drum, and the connecting pipes to the other

two upper drums, are heated, and the steam bubbles produced rise into the upper drums where

the steam is then taken off.

The bent tube or Stirling boiler allows for a large surface heat transfer area, as well as promoting

natural water circulation.

Steam off-take

Feedwater

Waste gases to stack

Mud drum

Heat

Fig. 3.3.7 Bent tube or Stirling boiler

The Steam and Condensate Loop

3.3.5

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Advantages of water-tube boilers:

o

They have a small water content, and therefore respond rapidly to load change and heat

input.

The small diameter tubes and steam drum mean that much higher steam pressures can be

tolerated, and up to 160 bar may be used in power stations.

The design may include many burners in any of the walls, giving horizontal, or vertical firing

options, and the facility of control of temperature in various parts of the boiler. This is particularly

important if the boiler has an integral superheater, and the temperature of the superheated

steam needs to be controlled.

Disadvantages of water-tube boilers:

o

They are not as simple to make in the packaged form as shell boilers, which means that more

work is required on site.

The option of multiple burners may give flexibility, but the 30 or more burners used in power

stations means that complex control systems are necessary.

Combined heat and power (CHP) plant

The water-tube boilers described above are usually of a large capacity. However, small, special

purpose, smaller waste heat boilers to be used in conjunction with land based gas turbine plants

are in increasing demand.

Several types of steam generating land based gas turbine plant are used:

o

Combined heat and power - These systems direct the hot exhaust gases from a gas turbine

(approximately 500C) through a boiler, where saturated steam is generated and used as a

plant utility.

Typical applications for these systems are on plant or sites where the demands for electricity

and steam are in step and of proportions which can be matched to a CHP system.

Efficiencies can reach 90%.

Enclosure

Generator

Gearbox

Air intake

plenum

Gas turbine

Exhaust

Fig. 3.3.8 Gas turbine / alternator set

3.3.6

The Steam and Condensate Loop

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Combined cycle plant - These are extensions to CHP systems, and the saturated steam is

taken through a superheater to produce superheated steam. The superheater may be separately

fired because of the comparatively low temperature of the gas turbine exhaust. The superheated

steam produced is directed to steam turbines which drive additional alternators, and

generate electricity.

The turndown ratio of these plants is poor, because of the need for the turbine to rotate at a

speed synchronised to the electrical frequency. This means that it is only practical to run these

plants at full-load, providing the base load of steam to the plant.

Because of the relatively low temperature of the gas turbine exhaust, compared to the burner

flame in a conventional boiler, a much greater boiler heat transfer area is required for a given

heat load. Also, there is no need to provide accommodation for burners. For these reasons,

water-tube boilers tend to provide a better and more compact solution. Because efficiency is

a major factor with CHP decision-makers, the design of these boilers may well incorporate an

economiser (feedwater heater).

If the plant is combined cycle the design may also include a superheater. However, the

relatively low temperatures may mean that additional burners are required to bring the steam

up to the specification required for the steam turbines.

Feedwater

Economiser

Superheater

Superheated

steam

outlet

Steam and

water drum

Evaporator

Circulation pump

Heat from gas turbine exhaust

Fig. 3.3.9 A forced circulation water-tube boiler as used on CHP plant

The Steam and Condensate Loop

3.3.7

Water-tube Boilers Module 3.3

Block 3 The Boiler House

Questions

1. Why can higher pressure steam be produced in a water-tube boiler compared with a

shell boiler ?

a| A superheater is incorporated in a water-tube boiler

b| Water-tube boilers incorporate a radiant and convection section

c| In a water-tube boiler the water is in tubes and a higher stress

and pressure can be accepted

d| Water-tube boilers have a greater heat transfer surface

2. Which of the following is a disadvantage of a water-tube boiler compared to a shell

boiler ?

a| They have a lower water content

b| They are more difficult to control because of the number of burners

c| They are physically much larger

d| It is more difficult to produce superheated steam in a water-tube boiler

3. Why are water-tube boilers typically used in power stations ?

a| Ease of temperature turndown as load changes

b| They are flexible to rapid load changes

c| Because of their pressure, capacity and the degree of superheat

d| Because the body of a water-tube boiler can accept a higher stress than a shell boiler

4. Which of the following is a disadvantage of a cross drum boiler ?

a| It does not permit superheating

b| It doesnt incorporate a mud drum

c| Due to having an external steam drum steam quality can be poor

d| Faulty circulation can occur at high steam loads

5. What is the advantage of a CHP system ?

a| Saturated steam is produced from waste gases

b| The system is at least 90% efficient

c| The steam produced is a by-product of power generation

d| All of the above

6. Which of the following is a disadvantage of a gas turbine / alternator set ?

a| The turndown ratio is poor

b| The superheater always needs separate firing

c| Because of the low gas temperature only low pressure steam can be produced

d| The superheated steam produced is unsuitable for driving another generator

Answers

1: c, 2: b, 3: c, 4: d, 5: d, 6: a

3.3.8

The Steam and Condensate Loop

Das könnte Ihnen auch gefallen

- Water-Tube Boilers - International Site For Spirax SarcoDokument7 SeitenWater-Tube Boilers - International Site For Spirax SarcotahirNoch keine Bewertungen

- Boiler and Steam SystemDokument33 SeitenBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Boiler Efficiency and CombustionDokument12 SeitenBoiler Efficiency and Combustionhafidhrahadiyan2Noch keine Bewertungen

- Boiler Fittings and Mountings GuideDokument14 SeitenBoiler Fittings and Mountings GuideSarah Frazier100% (2)

- Condensate Manual - Gestra PDFDokument176 SeitenCondensate Manual - Gestra PDFtrpac100% (1)

- Chapter 2 - Boiler & Thermal Fluid HeaterDokument62 SeitenChapter 2 - Boiler & Thermal Fluid HeaterFaisal FarabiNoch keine Bewertungen

- Boiler Handbook GuideDokument287 SeitenBoiler Handbook Guidevenus energy94% (18)

- Steam Boilers Guide - Types, Parts & MountingsDokument26 SeitenSteam Boilers Guide - Types, Parts & MountingsAnkit bohra0% (1)

- DeaeratorDokument18 SeitenDeaeratorSouvik DeNoch keine Bewertungen

- SteamDokument36 SeitenSteamsalilm31100% (2)

- Boiler Code Study GuideDokument104 SeitenBoiler Code Study Guidearmstrong323590% (10)

- Sellers .005 Pressurized Deaerator Model DescriptionDokument9 SeitenSellers .005 Pressurized Deaerator Model DescriptionarjmandquestNoch keine Bewertungen

- Basic Parts of A BoilerDokument9 SeitenBasic Parts of A Boilermessi107Noch keine Bewertungen

- Boiler Powerpoint 2003Dokument70 SeitenBoiler Powerpoint 2003Sahil Mishra100% (1)

- 1.1 Background of The Project 1.2 Problem Statement 1.3 Objectives of The Project 1.4 Project ScopeDokument21 Seiten1.1 Background of The Project 1.2 Problem Statement 1.3 Objectives of The Project 1.4 Project ScopeAbdi samad MohamedNoch keine Bewertungen

- Boiler BasicsDokument61 SeitenBoiler Basicsfferla100% (1)

- SCHROEDAHL Automatic Recirculation ValveDokument12 SeitenSCHROEDAHL Automatic Recirculation ValveJaebeom YiNoch keine Bewertungen

- (A) 03.16 The Boiler House - Methods of Detecting Water Level in Steam Boilers (Spirax-Sarco, 2005)Dokument16 Seiten(A) 03.16 The Boiler House - Methods of Detecting Water Level in Steam Boilers (Spirax-Sarco, 2005)Abdul Hamid100% (2)

- Boiler FundamentalsDokument73 SeitenBoiler Fundamentalsmasoodism100% (1)

- Efficient Industrial Heat Exchangers - Seminar ReportDokument67 SeitenEfficient Industrial Heat Exchangers - Seminar ReportdaemonohNoch keine Bewertungen

- Boiler FundamentalsDokument63 SeitenBoiler Fundamentalsakrverma2011100% (1)

- BoilerpptDokument11 SeitenBoilerpptFarhan SiddiquiNoch keine Bewertungen

- The Boiler DesignDokument154 SeitenThe Boiler DesignAyman Esa100% (2)

- SpiraxSarco-B14-Condensate RecoveryDokument80 SeitenSpiraxSarco-B14-Condensate Recoverydanenic100% (5)

- Boiler SystemDokument22 SeitenBoiler SystemMuhammad AfifuddinNoch keine Bewertungen

- Industrial Watertube BrochureDokument12 SeitenIndustrial Watertube Brochuregonzaracing84Noch keine Bewertungen

- Gestra: Condensate ManualDokument172 SeitenGestra: Condensate ManualNavneet PandeyNoch keine Bewertungen

- SpiraxSarco-B10-Steam DistributionDokument56 SeitenSpiraxSarco-B10-Steam Distributiondanenic100% (3)

- Steam Source Book PDFDokument108 SeitenSteam Source Book PDFJose Levican A100% (1)

- 15 TPH FBC Boiler Technical DetailsDokument348 Seiten15 TPH FBC Boiler Technical DetailsMuttappa T JainapurNoch keine Bewertungen

- Thermal Power Plants: Assignment No 1 Boilers 17-MS-PT-PE (T) - 20 Muneeb Ur Rehman KhanDokument8 SeitenThermal Power Plants: Assignment No 1 Boilers 17-MS-PT-PE (T) - 20 Muneeb Ur Rehman KhanSuper SiangohanNoch keine Bewertungen

- SpiraxSarco-B5-Basic Control TheoryDokument74 SeitenSpiraxSarco-B5-Basic Control Theorydanenic100% (2)

- Bosch Steam Boilers UKDokument24 SeitenBosch Steam Boilers UKAnonymous fopfQn4J6D100% (1)

- Boiler CalculationsDokument16 SeitenBoiler CalculationshuliplayNoch keine Bewertungen

- Combustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsVon EverandCombustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsBewertung: 3 von 5 Sternen3/5 (1)

- Boiler Control Systems Engineering, Second EditionVon EverandBoiler Control Systems Engineering, Second EditionBewertung: 4.5 von 5 Sternen4.5/5 (15)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshVon EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNoch keine Bewertungen

- Theory and Calculation of Heat Transfer in FurnacesVon EverandTheory and Calculation of Heat Transfer in FurnacesBewertung: 3 von 5 Sternen3/5 (4)

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewVon EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNoch keine Bewertungen

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AVon EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANoch keine Bewertungen

- Energy and Process Optimization for the Process IndustriesVon EverandEnergy and Process Optimization for the Process IndustriesNoch keine Bewertungen

- Steam BoilerDokument7 SeitenSteam BoilerVishnu VardhanNoch keine Bewertungen

- Water Tube BoilerDokument8 SeitenWater Tube Boilersandeep kumarNoch keine Bewertungen

- Chapter Three: Steam Generators 3.1 DefinitionDokument43 SeitenChapter Three: Steam Generators 3.1 DefinitionHeber Farid Fabrica Quispe100% (1)

- Materials: Pressure Vessel Steel Wrought Iron Stainless Steel Live Steam Copper Brass Fireboxes Steam LocomotivesDokument10 SeitenMaterials: Pressure Vessel Steel Wrought Iron Stainless Steel Live Steam Copper Brass Fireboxes Steam LocomotivesVelampalli AshokNoch keine Bewertungen

- Boiller Types Sabic PDFDokument40 SeitenBoiller Types Sabic PDFMuhammad Hamza NaveedNoch keine Bewertungen

- Tugas Util (Boiler)Dokument4 SeitenTugas Util (Boiler)AkhmadSumarnoNoch keine Bewertungen

- Module 3Dokument62 SeitenModule 3AshishNoch keine Bewertungen

- 3 Lecture 4 Steam Generator and ConditionarDokument19 Seiten3 Lecture 4 Steam Generator and ConditionarHasib RyanNoch keine Bewertungen

- #Lecture 3 - Steam GeneratorsDokument22 Seiten#Lecture 3 - Steam Generatorsmohamed EldesokyNoch keine Bewertungen

- Lecture 7 - Steam Generators: Mechanics of Steam BoilersDokument7 SeitenLecture 7 - Steam Generators: Mechanics of Steam BoilersIjazzzAliNoch keine Bewertungen

- Boilers - Types and ClassificationDokument4 SeitenBoilers - Types and ClassificationSharif Muhammad HossainNoch keine Bewertungen

- 9what Is A Boiler?Dokument59 Seiten9what Is A Boiler?Ali MuradNoch keine Bewertungen

- Lecture 7 - Steam GeneratorsDokument6 SeitenLecture 7 - Steam GeneratorsHussain Abbas100% (1)

- Materials: Vessel Water FluidDokument8 SeitenMaterials: Vessel Water FluidJinith MahajanNoch keine Bewertungen

- Introduction To Boiler: Fire Tube BoilersDokument34 SeitenIntroduction To Boiler: Fire Tube BoilersSandhya NaveenNoch keine Bewertungen

- Boiler: MaterialsDokument10 SeitenBoiler: MaterialssarojpapuNoch keine Bewertungen

- Chapter Two Steam Power PlantDokument42 SeitenChapter Two Steam Power PlantPercy Aduviri FloresNoch keine Bewertungen

- Current Efforts in Ports and Supply Chains RiskDokument6 SeitenCurrent Efforts in Ports and Supply Chains Riskhafidhrahadiyan2Noch keine Bewertungen

- Probing Questions To Help Students Think Critically About Reading (May Be Used As Tasks) Questions Which Probe Basic Understanding and PreparationDokument2 SeitenProbing Questions To Help Students Think Critically About Reading (May Be Used As Tasks) Questions Which Probe Basic Understanding and Preparationhafidhrahadiyan2Noch keine Bewertungen

- Testing Requirements in The Boiler HouseDokument6 SeitenTesting Requirements in The Boiler Househafidhrahadiyan2Noch keine Bewertungen

- The Effect of Back Pressure On The Operation of A Diesel EngineDokument37 SeitenThe Effect of Back Pressure On The Operation of A Diesel Enginehafidhrahadiyan2Noch keine Bewertungen

- Boiler RatingsDokument6 SeitenBoiler Ratingshafidhrahadiyan2Noch keine Bewertungen

- Waste Heat Boiler and Steam DrumDokument9 SeitenWaste Heat Boiler and Steam Drumhafidhrahadiyan2Noch keine Bewertungen

- Reported SpeechDokument4 SeitenReported SpeechkiritosamaNoch keine Bewertungen

- Guidance Document For Fuel Burning Equipments and Air Pollution Control SystemsDokument95 SeitenGuidance Document For Fuel Burning Equipments and Air Pollution Control Systemshafidhrahadiyan2Noch keine Bewertungen

- Conversion Factors Natural GasDokument1 SeiteConversion Factors Natural Gashafidhrahadiyan2Noch keine Bewertungen

- Water Treatment, Storage and Blowdown For Steam BoilersDokument8 SeitenWater Treatment, Storage and Blowdown For Steam Boilershafidhrahadiyan2100% (1)

- Automatic Level Control SystemsDokument10 SeitenAutomatic Level Control Systemshafidhrahadiyan2100% (1)

- Shell BoilersDokument12 SeitenShell Boilershafidhrahadiyan2Noch keine Bewertungen

- Boiler TypeDokument6 SeitenBoiler TypeMochamad Fajar RamdaniNoch keine Bewertungen

- Engineering Design Guidelines - Compressors Rev02 KLM Technology GroupDokument32 SeitenEngineering Design Guidelines - Compressors Rev02 KLM Technology GroupAhmed Fgt Kaasehg0% (1)

- WE Inlastek 05A Visual ExaminationDokument30 SeitenWE Inlastek 05A Visual Examinationhafidhrahadiyan2100% (1)

- Circulation Control CalculationDokument26 SeitenCirculation Control Calculationhafidhrahadiyan2Noch keine Bewertungen

- Steam - The Energy FluidDokument32 SeitenSteam - The Energy FluidIamPedroNoch keine Bewertungen

- Efficiency DefinitionDokument16 SeitenEfficiency DefinitionsimplynehaNoch keine Bewertungen

- Cost of SteamDokument13 SeitenCost of SteamAlouis MutimboNoch keine Bewertungen

- MTU High Speed Diesel For WorkboatDokument3 SeitenMTU High Speed Diesel For Workboathafidhrahadiyan2Noch keine Bewertungen

- Lambda Presentation 2Dokument19 SeitenLambda Presentation 2cossatotNoch keine Bewertungen

- 5.7 Hazop V1.0Dokument14 Seiten5.7 Hazop V1.0hafidhrahadiyan2Noch keine Bewertungen

- Marine Accident ReportDokument12 SeitenMarine Accident Reporthafidhrahadiyan2Noch keine Bewertungen

- Hazard and Operability (HAZOP) Study: Dr. AADokument75 SeitenHazard and Operability (HAZOP) Study: Dr. AAjoenediath9345Noch keine Bewertungen

- Certification For ISM Code & ISPS Code: Safety Management System & Ship Security Management SystemDokument1 SeiteCertification For ISM Code & ISPS Code: Safety Management System & Ship Security Management Systemhafidhrahadiyan2Noch keine Bewertungen

- HAZOPSDokument21 SeitenHAZOPShafidhrahadiyan2Noch keine Bewertungen

- Formal Safety Assessment: Basic Glossary of TermsDokument7 SeitenFormal Safety Assessment: Basic Glossary of Termshafidhrahadiyan2Noch keine Bewertungen

- Tutorial Song 2014Dokument3 SeitenTutorial Song 2014hafidhrahadiyan2Noch keine Bewertungen

- CopelandDokument3 SeitenCopelandJesús R. Zárraga100% (1)

- Mitsubishi CompressorsDokument5 SeitenMitsubishi Compressorsstavros7100% (1)

- Maquet Compressor Mini PartsDokument9 SeitenMaquet Compressor Mini PartsAlexandar100% (1)

- Trane ChillerDokument14 SeitenTrane ChillerwesleyNoch keine Bewertungen

- 5TH UnitDokument2 Seiten5TH UnitHarsha Vardhan GuptaNoch keine Bewertungen

- WEEKLY MOTOR VIBRATION ChecklistDokument9 SeitenWEEKLY MOTOR VIBRATION ChecklistJoyanta Maity100% (1)

- Change Parts Capacity Control Hitachi Screw CompressorsDokument2 SeitenChange Parts Capacity Control Hitachi Screw Compressorsmarcyel Oliveira WoliveiraNoch keine Bewertungen

- Daftar Motor Mesin Kertas PTKPDokument29 SeitenDaftar Motor Mesin Kertas PTKPArdi Wahab RamadhanNoch keine Bewertungen

- Centrifugal Fan Blade Design and TheoryDokument18 SeitenCentrifugal Fan Blade Design and TheoryjbharghavNoch keine Bewertungen

- BSFilterForecast 22023Dokument1 SeiteBSFilterForecast 22023Gula-gula KapasNoch keine Bewertungen

- Renner Scroll LineDokument1 SeiteRenner Scroll LineAriantoNoch keine Bewertungen

- 1-6 Types of Pumps and FansDokument43 Seiten1-6 Types of Pumps and FansCirky NadleiNoch keine Bewertungen

- ATS Report OctoberDokument12 SeitenATS Report OctoberJay MarkNoch keine Bewertungen

- Chapter 2 Exercises 1 To 4Dokument14 SeitenChapter 2 Exercises 1 To 4Rahmasari Nur SetyonoNoch keine Bewertungen

- Analytical Determination of Radial Inflow Turbine Design Geometry For Maximum Efficiency by RohlikDokument39 SeitenAnalytical Determination of Radial Inflow Turbine Design Geometry For Maximum Efficiency by RohlikSyed Jiaul HoqueNoch keine Bewertungen

- Pump Types: Kinetic Pumps Positive Displacement PumpsDokument40 SeitenPump Types: Kinetic Pumps Positive Displacement PumpsAmos OchienoNoch keine Bewertungen

- Price List: Crompton Greaves Consumer Electricals LimitedDokument25 SeitenPrice List: Crompton Greaves Consumer Electricals LimitedNishanth GaneshNoch keine Bewertungen

- Muzamil Proficad Part 1Dokument1 SeiteMuzamil Proficad Part 1ijaz sajjadNoch keine Bewertungen

- Uniflair Water Cooled Chillers BCWCDokument8 SeitenUniflair Water Cooled Chillers BCWCraviNoch keine Bewertungen

- Hydraulic Institute Standards For Rotodynamic PumpsDokument5 SeitenHydraulic Institute Standards For Rotodynamic Pumpseduin100% (1)

- Compounding of Steam TurbinesDokument18 SeitenCompounding of Steam Turbinesarjmandquest100% (1)

- Barwa Equipment BoqDokument1 SeiteBarwa Equipment BoqHemant KaleNoch keine Bewertungen

- Cascade Refrigeration With Inverse Brayton CycleDokument21 SeitenCascade Refrigeration With Inverse Brayton CycleShubham Raj RajNoch keine Bewertungen

- Hydraulic Machines 1 12 OctDokument7 SeitenHydraulic Machines 1 12 OctViswanathan SrkNoch keine Bewertungen

- Web - DOW Industrial Reaction Engineering Course Flyer PDFDokument1 SeiteWeb - DOW Industrial Reaction Engineering Course Flyer PDFChintan Milan ShahNoch keine Bewertungen

- Pump ReportDokument12 SeitenPump ReportHesham Zaghloul100% (1)

- Calculator Centrifugal Fan - Google SearchDokument2 SeitenCalculator Centrifugal Fan - Google SearchJebDesNoch keine Bewertungen

- Advanced Heat Transfer PDFDokument4 SeitenAdvanced Heat Transfer PDFsachin chavanNoch keine Bewertungen

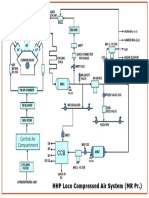

- HHP Compressed Air DrawingDokument1 SeiteHHP Compressed Air Drawingdhaneesh22Noch keine Bewertungen

- Air Preheater Washing ProtocolDokument3 SeitenAir Preheater Washing ProtocolSony Rama0% (1)