Beruflich Dokumente

Kultur Dokumente

An Algorithm For Three-Phase Equilibrium Calculations

Hochgeladen von

José Arturo Tlapaltotoli PanecatlOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

An Algorithm For Three-Phase Equilibrium Calculations

Hochgeladen von

José Arturo Tlapaltotoli PanecatlCopyright:

Verfügbare Formate

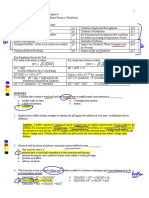

Computers cl Chemical Enginffring, Vol. 10, No.3, pp.

269-276, 1986

Printed in Great Britain. All rights reserved

0098-1354/86 $3.00 + 0.00

Copyright

1986 Pergamon Journals Ltd

AN ALGORITHM FOR THREE-PHASE

EQUILIBRIUM CALCULATIONS

J.-S. Wut and P. R. BISHNOIt

Department of Chemical and Petroleum Engineering, University of Calgary, Calgary,

Alberta T2N IN4, Canada

(Received 11 February 1985; revision received I October 1985;

received for publication 13 November 1985)

Abstract-A new algorithm is developed for performing liquid-liquid equilibrium, three-phase bubblepoint and three-phase equilibrium flash calculations. Material-balance and equilibrium equations are

rearranged suitably and solved by the Newton-Raphson method. The method of Shah [1] is used for

testing liquid stability and for generating initial values of the component moles required in the

liquid-liquid equilibrium calculation. A procedure for producing initial values of the variables required

in three-phase equilibrium flash is proposed. The partial derivatives of vapor-liquid K -factors required

in the method are calculated using the procedure proposed by Wu and Bishnoi [2]. The reliability and

efficiency of the proposed algorithm are illustrated by solving a number of example problems. The liquid

solution properties are calculated using the UNIQUAC model and the vapor-phase properties are

calculated using the virial equation of state.

Scope-A reliable and efficientalgorithm to perform equilibrium calculations for coexisting three phases

is required in the design and simulation of processes in the chemical and petroleum industry. Heidemann

[3], Gautam and Seider [4], Soares et al. [5] and Mehra [6] have developed calculation methods based on

the minimization of total Gibbs free energy with material-balance constraints. Alternatively, solution of

material-balance and equilibrium equations using iterative schemes has been suggested by Fournier and

Boston [7], Michelsen [8] and Nghiem and Heidemann [9]. Since the equilibrium and material-balance

equations are highly nonlinear, the reliability and efficiency of a solution method depend on the

arrangement of the equations and selection and the "good" initial values of iterative variables.

The algorithm proposed in this paper combines, in a suitable manner, the material-balance and

equilibrium equations and solves the resulting equations and the summation equations for component

moles using the Newton-Raphson method. The partial derivatives of vapor-liquid K-factors required in

the method are calculated by expressing the K -factor as a product of three functions to separate the effects

of temperature, composition and volatility characteristics, as suggested by Wu and Bishnoi [2]. Schemes

are presented to perform liquid-liquid equilibrium, three-phase bubble-point and three-phase equilibrium

flash calculations. A phase is tested for thermodynamic stability before performing the phase equilibrium

calculations. Heidemann [3], Gautam and Seider [4], Shah [1] and Michelsen [10] have discussed the

problem of phase stability. The stability test of Shah [I], when applied to liquid mixtures, produces

estimates of split factor and component mole fractions for the two liquid phases. Hence in the proposed

algorithm the method of Shah [I] is used for the stability test of the liquid phase and for generating initial

values of the component moles required in the liquid-liquid equilibrium calculation. The vapor-phase

stability is tested by performing vapor-liquid isobaric-isothermal flash calculations. For three-phase

calculations, a procedure is formulated to determine whether phases are present or absent and to generate

good initial guesses for the Newton-Raphson method.

The proposed algorithm is used to solve a wide variety of problems. The liquid solution properties are

calculated using the UNIQUAC model [II] and the vapor-phase properties are calculated using the virial

equation of state truncated after the second virial coefficient.

CondusioDs aDd Signiftcaaee-An algorithm is developed for liquid-liquid equilibrium and three-phase

bubble-point and flash calculations. The algorithm solves the material-balance and equilibrium equations

by the Newton-Raphson method and it is found to be reliable and efficienteven when the liquid mixture

is near its plait point or near the liquid-liquid equilibrium boundary curve. A procedure is formulated

for generating initial values for the three-phase equilibrium calculations. The procedure determines

whether phases are present or absent. This allows the Newton-Raphson method to be used advantageously to solve the equations for known combinations of coexisting phases, with good initial guesses,

and without the difficulties caused by disappearing phases. The algorithm and the procedure were found

to be reliable and efficient in solving a wide variety of problems.

following equations:

Component material-balance equations

LIQUID-LIQUID EQUILIBRIUM

Model equations

Liquid-liquid equilibrium can be described by the

1'+W-I/=O (i=l,c);

tVisiting Scholar from the East China Institute of Chemical

Technology, Shanghai, China.

tTo whom all correspondence should be addressed.

269

(I)

Total material-balance equation

L1+LII-L =0;

(2)

270

J.-S. Wu and P. R. BISHNOI

aMI

-L

il

aLI = (LI)2KII7;

Equilibrium relationships

W l}

LII = KnLI

(i

= 1, c),

(3)

where [11L I and l}1/L II represent mole fractions xl and

xP, respectively;

Mole-fraction summation equation

~ (21- i~l) = O.

(4)

Combining equations (I}-(3) to eliminate

dividing by [I gives

Mi=(I+L~ILIKn)i-I=O

ill and

(aKa)

I aP

aif=-VL I 2J

k

,

i

k

(k

= I,e)

(11)

and

aSI

-1 ~

aLI = (L I)2

7 (1 -

Kn)[1

S.

(12)

= - LI'

where aKn/all are calculated as

xli "II

=xl "IP

(13)

and

all -

(6)

Equations (5) and (6) are model equations for

liquid-liquid equilibrium calculations; l} and L I are

selected as (e + 1) iterative variables; M I and SI are

(e + 1) residual functions and they are driven to zero

when the solution is reached.

Method of solution

The model equations (5) and (6) are solved simultaneously by the Newton-Raphson method, namely

= _~m

Xu.

(10)

aK11_ Ka(ln "II-In "IP)

Similarly, combining equations (2}-(4) gives

J1m~Zm+1

1-

= 1, c),

Ku =-

(i-I,e). (5)

1

SI = LI~(1-Ku)il-O.

aS I

(i

(7)

all

_ (0 In "11

aIn "Ill)

x; ~+ a[f

(14)

The partial derivatives

aIn "II

~ and

aIn "IP

0111

may be calculated from a suitable model describing

the activity coefficient. In this paper the UNIQUAC

model is chosen and the equation for the partial

derivative is given by Wu and Bishnoi [2J.

Computation procedure

The computation procedure is outlined as follows:

and

zm+.

= Zm + "~Zm+I,

(8)

where ~ is a vector of the residual functions,

~

= [M I , M 2, , M., SIJT,

and Z is a vector of the variables,

Z = [[~, [!, ... ,[~, LlJT.

The Jacobian matrix JI of the Newton-Raphson

method is as follows:

1. Perform a stability test on the liquid mixture

using the method developed by Shah [IJ. If the

liquid mixture is stable, only one liquid phase

exists, and hence skip the rest of the calculations. If the liquid mixture is unstable, the

test produces the values of split factor fl, xl

and xp. Using these values calculate L I and [1

and use them as initial values for the subsequent calculations.

2. Using xl and xp calculate "I:, "IP and

K u( = "Il1"1p).

3. Calculate residual functions. If

err J1=

oM.

a[~

oM. oM.

... a[~ aLI

as.

a[~

...

as.

OSI

a[~

aLI

The partial derivatives in the Jacobian matrix are

calculated by the following equations:

I

aMI [

L-L

all = 011< +

KnOll<

-u

+ (L

-LI)il(aKII)J!

LI

0[1 [I (i, k - I, c),

(9)

[~I"'II JI (e + 1) EO 10-

6

,

the calculations are completed. Otherwise go

on.

4. Form the Jacobian matrix, and solve equation

(7) by the Gauss elimination method with

column pivoting. Then update the variables L I

and l} using equation (8) and taking e = 1. If

err" +1 > 2 err", the value of " is halved and

enm+ is recalculated. The reduction of e is

continued until enm+1 EO err". A maximum of

six attempts are allowed to satisfy this criterion. In addition, the step size of every variable

is restricted so that I~X7'+11 EO 0.9x7', and every

variable is kept within its physical limit, i.e.

oE; LIE; Land 0 EO il EO [I'

Three-phase equilibrium. calculations

5. Update I}I, xl and x? using the relations

1=1/-1},

11

xI=II/~1}

and

and then return to Step 2.

mE mREE-PHASE BUBBLE-POINT CALCULATION

Model equations

The three-phase bubble-point calculation can be

described by the following equations:

Component material-balance combined

liquid-liquid equilibrium relationships

L-LI

)1}

with

M/= ( 1 +----v-KIt 1;-1 =0 (I = l,c); (15)

Vapour-liquid equilibrium relationships

II

Yt=KI ~I (i

= I,c);

=iL

(1- KIt)/1 = 0;

L /

(16)

(17)

Mole-fraction summation equation for vapor and

liquid phases

I

8 2 = LI~(I-KDI}=O.

Model equations

Three-phase equilibrium flash is described by the

following equations:

Component material-balance combined

vapor-liquid equilibrium relationships

I

I

II

F - L - L" III)

M/= (I /+1/ +

LI

K/ /

I

Method of solution

The model equations are rearranged into two

groups. First, equations (15) and (17) are solved

simultaneously by the Newton-Raphson method for

the variables II and L I. Then, equations (16) and (18)

are solved for the variables Y/ and T (if P is specified)

or P (if T is specified). The computation procedure

for the bubble-point calculations is outlined as

follows:

I. Assume P (if T is specified) or T (if P is

specified). The initial values of P or T can be

chosen by assuming only two phases and carrying out the bubble-point calculations.

2. Solve equations (15) and (17) by following the

procedure given previously for liquid-liquid

equilibrium calculations for the variables II and

Xlt-1=0 (1=I,c);

(18)

Thus, there are 2c + 2 equations and 2c + 3 independent variables: I}, Y/, L I , T and P; if P is specified,

it is a bubble-point temperature calculation; otherwise if T is specified, it is a bubble-point pressure

calculation.

L I.

3. Solve equations (16) and (18) for the variables

y/ and T or P. The solution is achieved by

following the procedure of two-phase bubblepoint calculations. The variable T or P is

calculated using the secant method applied to

equation (18)and the variables Y/ are calculated

using equation (16).

4. For the bubble-point pressure calculations, the

value of pressure obtained in Step 3 is the

desired solution because the activity

coefficients given by the UNIQUAC model are

independent of pressure. For the bubble-point

temperature calculations, check to see if the

absolute difference between the T calculated in

Step 3 and its assumed value is less than the

tolerance level of 10- 2 If the tolerance criterion is satisfied the calculations are completed.

Otherwise, assume the value of T to be equal

to that calculated in Step 3, and go to Step 2.

Since Kit are very weak functions of temperature, only a small number of iterations of

Steps 2-4 is expected to meet the criterion.

mREE-PHASE EQUILIBRIUM FLASH

Mole-fraction summation equation for liquid phases

8.

271

with

(19)

Liquid-liquid equilibrium relationships

I II

II I}I

/="1/ L I-"It LII=O (i= l,c);

(20)

Mole.jraction summation equation for liquid phases

1

8 1 = 1 - I i I? = 0;

L /

(21)

Mole-fraction summation equation for vapor and

liquid phases

~ (1 - K I/) II/=0.

(22)

8 2 = i 1 L..

L /

Two types of flash calculations are discussed here,

i.e, the isothermal-isobaric flash and the isobaric

specified V IF flash.

Method of solution

There are 2c + 2 model equations. Hence, the

following 2c + 2 variables are chosen as independent:

Z = [Ii, I~, ... , I~, If, If, ... , I~I, L I, ,,]T

where " is L II for the isothermal-isobaric flash, and

" is T for the isobaric specified V IF flash. The model

272

J.-8. Wu and P. R.

equations (I9}-(22) are solved simultaneously by the

Newton-Raphson method. The corresponding residual functions are

oMc

all

J=

(i

= I, c),

(32)

=0

(k

= 1, e ),

(33)

aT

OSI

all

The Jacobian matrix is

oM. aMI

allc 01~1

es, ~ 0

'" = [M I , M 2, .. , M c' E I, E2, . . . , Ee> SI' S2]T.

aMI

01

BISHNOI

aMI aMI aMI

ol~ aLI

01/

OSI

oIP=-L II (k=l,e),

(34)

OSI

OLI=O,

(35)

OSI

aLII

oM eu,

... eu, eu,

. .. c aLI

01~1

alII

ol~

oEI

all

oEI

ol~

oEI

alII

oEI

ani

oEI

aLI

oMc

es,

es, ee, es,

ol~

01~1

01~1

es,

OSI

OSI

ol~

01~1

OS2

OS2

all ... ol~

OS2

olf

ol~

...

(37)

7'

aS2

alP = 0 (k

es, es,

= I, c),

(40)

OSI

es,

01~1

aLI

OSI

01/

OS2 =0

aLII

(41)

OS2

OS2

aLI

OS2

01/

ol~

and

OS2

= _-.!..-I ~ II (OK})

L 7' I er .

(23)

(26)

(i

= 1, c),

(i, k

(I,k=l,e),

y}l}.

(LI)2 (I = 1, c),

oEI

y}IW .

aLII = (LII)2 (I=l,e),

= 1, c),

oK I

a In y?

alP

oKl

o~ and OIl'

the suggestion of Wu and Bishnoi [2] is used to

express the K -factors as a product of three functions

separating the effects of temperature, composition

and apparent volatility as follows:

(27)

(28)

and

required in equations (28) and (29) is discussed

previously under the section Liquid-Liquid Equilibrium. In order to calculate the partial derivatives

(24)

(25)

(42)

In deriving equation (32), oyl/oT and fjyll/oT are

neglected. The calculation of the partial derivatives

al"l

(39)

OS2

1 ~

I I

S2

aLI = - (L I)2 7' (1 - K;)li = - LI'

a In yl

oEI

aLI =

(38)

01/

The partial derivatives in the Jacobian matrix are

calculated by the following equations:

I'll) .

(k = I,e),

aLI

et

0 In

x ( alP

(36)

OS2 = 1 - Kl_ -.!..- ~ II (OK})

all

LI

LI

I

all

011

all '"

II

OSI

aT =0,

01/

es;

= (L II)2L/i'

(43)

where Kb is primarily a function of temperature, 1'1 is

the activity coefficient, influenced primarily by composition, and !XI is an apparent volatility of the

component and it may be considered independent of

temperature and composition. Thus,

(29)

(30)

(31)

and

(45)

Three-phase equilibrium calculations

As recommended by Boston and Britt (12] the

factor K b is defined as

s; = exp[~ (yt'ln KD

(46)

and may be approximated as follows:

(47)

The coefficients PI and P2 are constants, only weakly

dependent on composition.

From equation (47),

oKb _

/G

oT -

P2

(48)

T2"

Combining equations (45) and (48) gives

oKI

oT

I P2

= K 1 ' T2"

(49)

Computation procedure

The computation procedure is outlined below:

l. Establish whether three phases exist by following the procedure given in the next section

Production ofinitial values. If three phases exist

the procedure would generate the initial values

of 11,111, L I and '1 and the values of K1. 1'1, I'~,

K/I and Yi'

2. The factors Kt, and al are calculated from

equations (46) and (43). For the isobaric

specified V/F flash P2 is calculated from equation (47).

3. Calculate the residual functions M/, E/, 8 1 and

8 2 , If

err

= [~I"'dJ!(2C +

2) ~

10-

the calculation is completed. Otherwise go on.

4. Form the Jacobian matrix JJ. Calculate ~Xm+1

and update the X variables following the procedure given in Step 4 of the computation

procedure for liquid-liquid equilibrium. The

step size for temperature in specified V /F flash

calculations is restricted so that ~T ~ 10 K.

5. Using the thermodynamic models calculate KI,

1'1 and I'll. Then return to Step 2.

Production of initial values

It is quite important, for the Newton-Raphson

method, to produce good initial values, especially for

highly nonlinear objective functions. The following

procedure is proposed to establish whether three

phases exist and to generate the initial values for the

isothermal-isobaric calculations:

l. Perform a three-phase bubble-point temperature calculation for the feed mixture. If the

specified temperature T is less than the bubblepoint temperature Tb , only liquid phases could

exist.

273

2. Perform a two-phase dew-point temperature

calculation for the feed mixture using an iterative scheme. The equilibrium equations are

solved for the mole fractions in the liquid phase

and the mole-fraction summation equation is

solved for Td using the secant method. If the

specified temperature T is larger than the dewpoint temperature Td , only a vapor phase could

exist.

3. Perform an L-V isothermal flash calculation

for the feed mixture to produce a new vapor

phase V' and liquid phase L ',

4. Test the stability of vapor V' by performing an

L-Visothermal flash calculation again for V'.

Ifno liquid is generated, V' is stable. Otherwise

the vapor V' is unstable and the new vapor

phase V" and liquid phase L" are produced.

5. Perform liquid-liquid equilibrium calculations

for the liquid mixture L m obtained by combining L' and L". If the liquid mixture L m is

stable (possible only when L" = 0 and L' is

stable), the calculation is an L-V isothermal

flash and it is completed. Otherwise the initial

two liquid phases are produced. The amounts

and compositions of these two liquids are used

as initial values.

It is worth noting that in our findings both or either

of the vapor V' and the liquid L' could be unstable.

We found that the objective function for the isobaric specified V/F flash calculation has a wider

convergence

domain

than

that

of

the

isothermal-isobaric flash. Hence the requirement of

having good initial values is not very strict. Initial

values can be obtained by the following procedure:

l. Perform a two-phase isobaric specified V/F

flash calculation for the feed mixture and generate vapor phase V' and liquid phase L'.

2. Perform a three-phase bubble-point temperature calculation for the liquid L' and

generate P, xl, xii, T, K/I and KI. The initial

values of II, 111, L I and T are thus obtained.

EXAMPLE PROBLEMS

The application of the algorithm is demonstrated

by solving a variety of problems. The specifications

and results of the problems are given in Tables I and

2 for bubble-point and flash calculations, respectively. The UNIQUAC parameters used in the

calculations are taken from Ref. [II] and the second

virial coefficients are calculated using the Hayden and

O'Connell correlation [13]. The computations were

performed on a Honeywell DPS 8/70M computer.

In Table I first the temperature is specified and the

bubble-point pressure is calculated. Then, for every

example the pressure is specified and the bubble-point

temperature is calculated. The two results are found

to be the same as expected. The number of iterations

in the table are those required for Step 2 of the

Table I. Specifications and results for bubble-point calculations

Mole fractions

Case

No.

2

3

7

8

9

10

11

12

13

14

Temp

(K)

Pressure

(bar)

Mole fractions

of feed

333

0.592

333

0.605

333

0.707

298

0.119

298

0.098

298

0.099

298

0.083

298

0.089

298

0.089

318.15

0.425

298.15

0.181

298.15

0.181

370.46

1.013

370.46

1.013

0.6000

0.1300

0.2700

0.6000

0.1500

0.2500

0.6000

0.3500

0.0500

0.1000

0.3000

0.4000

0.2000

0.3000

0.4000

0.2000

0.1000

0.3000

0.4000

0.3000

0.4000

0.4000

0.2000

0.2700

0.4000

0.3300

0.2500

0.4000

0.3500

0.5000

0.3000

0.2000

0.4000

0.3000

0.3000

0.4000

0.4000

0.2000

0.9000

0.1000

0.2500

0.7500

Components

Water

Acrylonitrile

Acetonitrile

Water

Acrylonitrile

Acetonitrile

Water

Acrylonitrile

Acetonitrile

2,2,4-TMP"

Furfural

Cyclohexane

Benzene

2,2,4-TMP

Furfural

Cyclohexane

Benzene

2,2,4-TMP

Furfural

Cyclohexane

2,2,4-TMP

Furfural

Benzene

2,2,4-TMP

Furfural

Benzene

2,2,4-TMP

Furfural

Benzene

Acetonitrile

a-Heptane

Benzene

Benzene

Water

Ethanol

Benzene

Water

Ethanol

Water

Furfural

Water

Furfural

fJ

Liquid I

Liquid II

Vapor

0.2863

0.8082

0.0463

0.1455

0.8368

0.0431

0.1201

0.9520

0.0341

0.0139

0.0314

0.6044

0.1770

0.1872

0.0435

0.8139

0.0545

0.0881

0.0276

0.9141

0.0583

0.0794

0.7399

0.1807

0.1439

0.5368

0.3193

0.1644

0.4930

0.3426

0.6337

0.1851

0.1812

0.6765

0.0872

0.2363

0.8201

0.0443

0.1356

0.9445

0.0555

0.9444

0.0556

0.5165

0.1636

0.3199

0.4689

0.2092

0.3219

0.2140

0.6964

0.0896

0.1315

0.1603

0.5023

0.2059

0.4945

0.0862

0.3103

0.1090

0.4816

0.0573

0.4611

0.6719

0.1117

0.2164

0.4575

0.1966

0.3459

0.4145

0.2212

0.3643

0.3497

0.4292

0.2211

0.0798

0.5464

0.3738

0.0305

0.7129

0.2566

0.2038

0.7962

0.2037

0.7963

0.3082

0.3497

0.3421

0.3039

0.3847

0.3114

0.2727

0.6709

0.0564

0.0970

0.0313

0.6621

0.2096

0.3617

0.0426

0.4414

0.1543

0.3325

0.0454

0.6221

0.6040

0.0473

0.3487

0.4866

0.0395

0.4739

0.4724

0.0385

0.4891

0.5860

0.2622

0.1518

0.6664

0.1516

0.1820

0.6738

0.1562

0.1670

0.8889

0.1111

0.8889

0.1111

0.3563

0.5231

0.3146

0.4312

0.4000

0.4589

0.5979

0.6577

0.5293

0.5366

0.4680

0.9399

0.0625

No. of

iteration

5

5

5

6

3

5

6

6

7

5

5

5

2,2,4-TMP = 2,2,4-trimethyl-pentane.

Table 2. Specifications and results for flash calculations

No. of iterations

specified

Mole fractions

Case

No.

3

4

6

7

Components

Water

Acrylonitrile

Acetonitrile

Water

Acrylonitrile

Acetonitrile

Water

Acrylonitrile

Acetonitrile

2,2,4-TMP"

Furfural

Cyclohexane

Benzene

2,2,4-TMP

Furfural

Benzene

2,2,4-TMP

Furfural

Benzene

2,2,4-TMP

Furfural

Cyclohexane

Benzene

Water

Ethanol

Benzene

Water

Ethanol

Pressure

(bar)

Mole fractions

of feed

Temp

(K)

fJ

Liquid I

Liquid II

Vapor

VjF

1.013

0.3004

0.5923

0.1073

0.6000

0.2500

0.1500

0.6000

0.3500

0.0500

0.3000

0.4000

0.2000

0.1000

0.4000

0.4000

0.2000

0.2700

0.4000

0.3300

0.3000

0.4000

0.3000

0.4500

0.5000

0.0500

0.4000

0.5000

0.1000

343.15

0.6167

0.9286

0.9873

339.65

0.4605

0.8885

300.05

0.5542

0.9728

299.00

0.5291

0.9686

298.30

0.2158

0.7899

300.20

0.5992

0.9934

298.80

0.4238

0.2383

14

298.30

0.3702

0.2314

0.2969

0.6112

0.0919

0.2921

0.4773

0.2306

0.2889

0.6376

0.0735

0.4919

0.0487

0.3303

0.1291

0.6789

0.0525

0.2686

0.5070

0.0409

0.4521

0.4754

0.0516

0.4730

0.7267

0.1932

0.0801

0.6975

0.1692

0.1333

0.4773

0.9375

0.0374

0.0251

0.3701

0.3422

0.2877

0.2358

0.6493

0.1149

0.6288

0.0768

0.2135

0.0809

0.7573

0.0901

0.1526

0.5067

0.1725

0.3208

0.6259

0.0582

0.3519

0.0042

0.9631

0.0327

0.0075

0.9009

0.0916

332.60

0.2555

0.6040

0.1405

0.8877

0.0386

0.0737

0.9447

0.0360

0.0193

0.0456

0.8580

0.0331

0.0633

0.0649

0.8132

0.1219

0.1246

0.5856

0.2898

0.0339

0.9270

0.0391

0.9798

0.0048

0.0154

0.9408

0.0137

0.0455

0.627

0.90

0.098

0.083

0.089

0.099

0.176

0.179

2,2,4-TMP = 2,2,4-trimethyl-pentane.

VjF

274

Three-phase equilibrium calculations

275

computation procedure outlined for the three-phase

K, = Liquid-liquid K-factor

L = Total moles of liquid

bubble-point calculations. For the bubble-point temI = Component moles of liquid

perature calculations the number of iterations of

M = Residual function of the component material

Steps 2-4 of the procedure is found to be only two.

balance

This number is small, as expected, because the activP = Pressure

S, = Residual function of the mole-fraction sumity coefficients are very weak functions of temmation for liquid phases

perature. Cases 2-8 are taken from the examples of

S2 = Residual function of the mole-fraction sumliquid-liquid equilibrium given by Prausnitz et al.

mation for vapor and liquid phases

[11]. The split factor p and the compositions of the

T = Temperature

two liquid phases are the same as those reported by

V = Total moles of vapor

x = Mole fraction of liquid

Prausnitz et al. [11]. These authors have reported that

y = Mole fraction of vapor

the number of iterations required in their method

increases substantially for the feed mixtures near their Greek letters

plait points. However, in our method the number of

IX = "Apparent" volatility

P = Split factor, ratio of moles of liquid I to total

iterations is nearly the same for any feed mixture as

moles of liquids

illustrated by Cases 1, 2, 8, 9, 10 and 11 which are

P" P2 = Coefficient in equation (47)

close to the plait points. Cases 13 and 14 are binary

y = Activity coefficient

systems and the calculated results are close to the

~Ik = Kronecker delta, ~ii = I, ~Ik = 0 (i k)

experimental data measured by Mains and reported

e = Damping factor

'1 = Variable, T or P

by Gmehling and Onken [14]. The computation times

X = Independent variable

for the examples ranged from 0.45 to 0.82 s.

z = Vector of independent variables

The examples given in Table 2 are solved first by

'" = Vector of residual functions

specifying temperature and calculating V IF. The

Subscripts

examples are then solved by specifying VIF and

b = Bubble point

calculating temperature. As expected the results are

d=Dew point

the same in both the solutions. The three phases

i, k = Component number

generated by the calculations are tested for stability

and found to be stable. For most of the examples the Supercripts

I, II = Liquid phase number

three phases occur in a narrow range of temperature.

m = Iteration number

For example in Case 3 the three-phase bubble-point

temperature of the feed is 339.40K, and when the

REFERENCFS

mixture is flashed at 339.70K only one liquid phase

is found to be present. The computation times for the

I. V. B. Shah, Ph.D. Thesis, Univ. of Toledo, Toledo,

Ohio (1980).

problems ranged from 2.15 to 3.40s for the

2. J.-S. Wu and P. R. Bishnoi, Comput, chem. Engng

isobaric-isothermal flash calculations and from 1.41 s

(1986).

to 2.21 s for the isobaric specified VIF flash calcu3. R. A. Heidemann, AIChE JI20, 847 (1974).

lations except for Case 8 which required 6.04 s.

4. R. Gautam and W. D. Seider, AIChE JI25, 999 (1979).

Acknowledgements-The authors wish to express their sincere appreciations to Dr R. A. Heidemann for his valuable

suggestions. The financial assistance provided by the Ministry of Education, China and the University of Calgary is

greatly appreciated.

NOMENCLATURE

c = Number of components

E = Residual function of the liquid-liquid equi-

librium relation

F = Total moles of feed

/ = Component moles of feed

JJ = Jacobian matrix

K = Vapor-liquid K-factor

Kb = Base vapor-liquid K-factor function

5. M. E. Soares et al., Chem. Engng Sci. 37, 521 (1982).

6. R. K. Mehra, Ph.D. Dissertation, Univ. of Calgary,

Calgary, Alberta (1981).

7. R. L. Fournier and J. F. Boston, Chem. Engng Commun. 8, 305 (1981).

8. M. L. Michelsen, Fluid Phase Equil. 9, 21 (1982).

9. L. X. Nghiem and R. A. Heidemann, Paper presented

at the 2nd Eur. Symp. on EnhancedOil Recovery, Paris

(1982).

10. M. L. Michelsen, Fluid Phase Equi/. 9, 1 (1982).

II. J. M. Prausnitz et al.; Computer Calculations/or Multicomponent Vapor-Liquid and Liquid-Liquid Equilibria.

Prentice-Hall, New York (1980).

,

12. J. F. Boston and H. I. Britt, Comput, chem.Engng 2, 109

(1978).

13. J. G. Hayden and J, P. O'Connell, Ind. Engng Chem.,

Process Des. Dev. 14, 209 (1975).

14. J. Gmehling and U. Onken, Chemistry Data Series,

Vol. I, Part I. DECHEMA, Frankfurt, F.R.G. (1977).

About tbe autbors-JUN-SHENG Wu: graduated in chemical engineering from East China Institute of

Chemical Technology in 1960. He has been a lecturer at the institute since 1960. During the period

1982-1984 he was a Visiting Scholar at the University of Calgary. He has returned to China, taking up

his previous position with the institute. His major interests include simulation of separation processes and

mass transfer operations.

P. R. BISHNOI: received his B. Chern. Eng. and M.Sc. (Tech.) in Chemical Engineering from the

C.A.C.E. IO/}-Q

276

J.-S. Wu and P. R. BISHNOI

University of Bombay, India and Ph.D. in Chemical Engineering from the University of Alberta,

Edmonton, Alberta, Canada. After having worked as Senior Process Engineer with Ralph M. Parsons

Co. and Fluor Canada Ltd. he is presently Professor of Chemical Engineering at the University of Calgary.

His major research interests are chemical engineering thermodynamics, simulation and design of chemical

processes and natural gas hydrates.

Das könnte Ihnen auch gefallen

- Notes On Diffy QsDokument252 SeitenNotes On Diffy Qsarachno85Noch keine Bewertungen

- Flash Calc 1flash Calc 185Dokument18 SeitenFlash Calc 1flash Calc 185Mohamed MamdouhNoch keine Bewertungen

- Computation of Phase and Chemical Equilibrium IDokument9 SeitenComputation of Phase and Chemical Equilibrium IThou KanshieNoch keine Bewertungen

- A Quasi-Newton Algorithm For Solving Multi Phase Equilibrium Flash ProblemsDokument22 SeitenA Quasi-Newton Algorithm For Solving Multi Phase Equilibrium Flash ProblemsDaniel MedeirosNoch keine Bewertungen

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodVon EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodNoch keine Bewertungen

- Naphtali & Sandholm - Multicomponent Separation Calculations by Linearization PDFDokument6 SeitenNaphtali & Sandholm - Multicomponent Separation Calculations by Linearization PDFCarlos PlazasNoch keine Bewertungen

- Reactive DistillationDokument8 SeitenReactive DistillationSalim ChohanNoch keine Bewertungen

- Twu, C. H. " An Internally Consistent Correlation For PredictingDokument14 SeitenTwu, C. H. " An Internally Consistent Correlation For PredictinglucasNoch keine Bewertungen

- Hydraulic FluidsDokument20 SeitenHydraulic FluidsRamirez Indeleble100% (1)

- Application of UNIQUAC Equation to Calculate Multicomponent Phase EquilibriaDokument10 SeitenApplication of UNIQUAC Equation to Calculate Multicomponent Phase EquilibriaGiovanni Ospino AlvaradoNoch keine Bewertungen

- Calculation of Vapor-Liquid-Liquid Equilibria For The Fischer-Tropsch Reactor Effluents Using Modified Peng-Robinson Equation of StateDokument31 SeitenCalculation of Vapor-Liquid-Liquid Equilibria For The Fischer-Tropsch Reactor Effluents Using Modified Peng-Robinson Equation of StatekenymorenoNoch keine Bewertungen

- Calculation of Phase Envelopes and Critical Points For Multicomponent MixturesDokument10 SeitenCalculation of Phase Envelopes and Critical Points For Multicomponent Mixturesflavio_cordero_1Noch keine Bewertungen

- Extension of Peng-Robinson For Complex MixturesDokument18 SeitenExtension of Peng-Robinson For Complex MixturesMandy NelsonNoch keine Bewertungen

- RRKM TheoryDokument4 SeitenRRKM TheoryjainankitmumNoch keine Bewertungen

- Test3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Dokument18 SeitenTest3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Anas SaadNoch keine Bewertungen

- Thermodynamic Model SelectionDokument11 SeitenThermodynamic Model SelectionKuldeep28883100% (1)

- Batch Drying With Vacuum Contact DryersDokument7 SeitenBatch Drying With Vacuum Contact DryersBramJanssen76Noch keine Bewertungen

- Multiphase Equilibria Calculation by Direct MinimizationDokument23 SeitenMultiphase Equilibria Calculation by Direct MinimizationAloisio NunesNoch keine Bewertungen

- Flash Calc 3Dokument16 SeitenFlash Calc 3Mohamed MamdouhNoch keine Bewertungen

- Phase Stability Analysis of Liquid Liquid EquilibriumDokument15 SeitenPhase Stability Analysis of Liquid Liquid EquilibriumJosemarPereiradaSilvaNoch keine Bewertungen

- Knief Chapter 1 FinalDokument32 SeitenKnief Chapter 1 FinalJohn W HollandNoch keine Bewertungen

- SPE 63158 Inflow Performance Relationships For Gas CondensatesDokument14 SeitenSPE 63158 Inflow Performance Relationships For Gas Condensatesabnou_223943920Noch keine Bewertungen

- A Improving Predictions of Equation of State by Modifying Its Parameters For Super Critical Components of Hydrocarbon Reservoir FluidsDokument17 SeitenA Improving Predictions of Equation of State by Modifying Its Parameters For Super Critical Components of Hydrocarbon Reservoir Fluids13670319Noch keine Bewertungen

- Phase Oil Equilibria of Oil-Water-Brine - Yaun Kun LiDokument11 SeitenPhase Oil Equilibria of Oil-Water-Brine - Yaun Kun LiRonald NgueleNoch keine Bewertungen

- Monte Carlo Statistical Methods IntroductionDokument289 SeitenMonte Carlo Statistical Methods IntroductioncasesilvaNoch keine Bewertungen

- Matrix Mathematics Chemical Problems: ApplicationsDokument9 SeitenMatrix Mathematics Chemical Problems: ApplicationsCarlosNoch keine Bewertungen

- Flash Calculation Stability PDFDokument12 SeitenFlash Calculation Stability PDFAndre BecNoch keine Bewertungen

- Semi Detailed Lesson Plan in Electricity g71Dokument6 SeitenSemi Detailed Lesson Plan in Electricity g71Edessa MasinasNoch keine Bewertungen

- Preservation of Boiler 1Dokument21 SeitenPreservation of Boiler 1DangolNoch keine Bewertungen

- A Modified UNIFAC ModelDokument16 SeitenA Modified UNIFAC Modelmappemaq100% (1)

- PB Lecture Notes 2017Dokument59 SeitenPB Lecture Notes 2017ganeshNoch keine Bewertungen

- Newton-Raphson Vs BroydenDokument6 SeitenNewton-Raphson Vs Broydencorreita77Noch keine Bewertungen

- Burgers Equation ViscousDokument18 SeitenBurgers Equation ViscousSakethBharadwajNoch keine Bewertungen

- Collocated FVMDokument17 SeitenCollocated FVMapoorvs75Noch keine Bewertungen

- 7-Ode Ivp1Dokument12 Seiten7-Ode Ivp1rahulNoch keine Bewertungen

- Maple Books and Ebook Study Guide From CSTDokument6 SeitenMaple Books and Ebook Study Guide From CSTbejewelNoch keine Bewertungen

- Thermodynamic Model SelectionDokument12 SeitenThermodynamic Model Selectionnarayana reddyNoch keine Bewertungen

- Flash ConceptsDokument2 SeitenFlash ConceptsJuan Camilo HenaoNoch keine Bewertungen

- MA3004 Part 3: Computational Fluid Dynamics (CFD) : Martin SkoteDokument46 SeitenMA3004 Part 3: Computational Fluid Dynamics (CFD) : Martin SkotedavidbehNoch keine Bewertungen

- Rachford Ride EquationDokument15 SeitenRachford Ride EquationEstuardo Javier Gan RodríguezNoch keine Bewertungen

- Cet 2Dokument2 SeitenCet 2Anonymous U4iBvF6Noch keine Bewertungen

- (E-Book) Physics - Nuclear Reactors Listing WWDokument70 Seiten(E-Book) Physics - Nuclear Reactors Listing WWKarthigeyan RameshKumar100% (1)

- Thermodynamics of Polymer Blends PDFDokument5 SeitenThermodynamics of Polymer Blends PDFpedroNoch keine Bewertungen

- Jacobian Matrix PDFDokument23 SeitenJacobian Matrix PDFRajesh MalikNoch keine Bewertungen

- Chapter 3b Fugacity and Fugacity Coefficient For MixtureDokument26 SeitenChapter 3b Fugacity and Fugacity Coefficient For MixtureSeptiana AyuningtiasNoch keine Bewertungen

- Solution of A Concentration Problem Using Numerical MethodsDokument59 SeitenSolution of A Concentration Problem Using Numerical MethodsSalma_Elgaili_5654Noch keine Bewertungen

- Module 6Dokument351 SeitenModule 6Chien NguyenNoch keine Bewertungen

- Equations of StateDokument11 SeitenEquations of StateaguswiadiNoch keine Bewertungen

- An Efficient Technique For The Point Reactor Kinetics Equations With Newtonian Temperature Feedback EffectsDokument8 SeitenAn Efficient Technique For The Point Reactor Kinetics Equations With Newtonian Temperature Feedback EffectsDebasmitSarkarNoch keine Bewertungen

- Keyword Manual PDFDokument953 SeitenKeyword Manual PDFYves-donald MakoumbouNoch keine Bewertungen

- An Iterative Sequence For Phase-Equilibria Calculations Incorporating The Redlich-Kwong Equation of StateDokument10 SeitenAn Iterative Sequence For Phase-Equilibria Calculations Incorporating The Redlich-Kwong Equation of Statethlim19078656Noch keine Bewertungen

- Mixing Rule For Cubic Equations of StateDokument9 SeitenMixing Rule For Cubic Equations of StateMundo LepalcaNoch keine Bewertungen

- Dr. Syeilendra Pramuditya - Lecture Notes On Thermal Hydraulics and Nuclear SafetyDokument105 SeitenDr. Syeilendra Pramuditya - Lecture Notes On Thermal Hydraulics and Nuclear SafetySyeilendra PramudityaNoch keine Bewertungen

- 03 Momentum Transport Flow of Falling FilmDokument25 Seiten03 Momentum Transport Flow of Falling FilmLucia Sii0% (1)

- Equations of StateDokument42 SeitenEquations of StateEng MohammedNoch keine Bewertungen

- Cluster ExpansionsDokument38 SeitenCluster ExpansionsgrossogrossoNoch keine Bewertungen

- Rheology Notes Introduction To RheologyDokument30 SeitenRheology Notes Introduction To RheologyDoug AmatoNoch keine Bewertungen

- Ex05 SolDokument7 SeitenEx05 SolGerman ChiappeNoch keine Bewertungen

- Driving Forces For The Transport PhenomenaDokument10 SeitenDriving Forces For The Transport Phenomenadppriya1984Noch keine Bewertungen

- Solutions Hints 2Dokument6 SeitenSolutions Hints 2iftikhar4498929Noch keine Bewertungen

- Journal of Electroanalytical Chemistry 609 (2007) 17-26Dokument10 SeitenJournal of Electroanalytical Chemistry 609 (2007) 17-26Alex B-RomeroNoch keine Bewertungen

- Physics 715 HW 1Dokument13 SeitenPhysics 715 HW 1Antonildo PereiraNoch keine Bewertungen

- Flash CheguideDokument16 SeitenFlash Cheguidesok_splNoch keine Bewertungen

- Httpcpe Czasopisma Pan Plimagesdatacpewydaniano3201211calculationofvapourliquidliquidequilDokument15 SeitenHttpcpe Czasopisma Pan Plimagesdatacpewydaniano3201211calculationofvapourliquidliquidequilLeonardoNoch keine Bewertungen

- Prediction of Activity Coefficients For Mixed Aqueous Electrolyte Solutions The Data of Their Binary SolutionsDokument11 SeitenPrediction of Activity Coefficients For Mixed Aqueous Electrolyte Solutions The Data of Their Binary SolutionsWilo JaraNoch keine Bewertungen

- Chapter 18. Entropy, Free Energy, and EquilibriumDokument41 SeitenChapter 18. Entropy, Free Energy, and EquilibriumEUNAH LimNoch keine Bewertungen

- Atoms Molecules and IonsDokument78 SeitenAtoms Molecules and IonszulqarnainkhaliqNoch keine Bewertungen

- Inorganica Chimica Acta: Research PaperDokument7 SeitenInorganica Chimica Acta: Research Paperhenry martinez quiñonezNoch keine Bewertungen

- Electronic Excitation by UV/Vis SpectrosDokument34 SeitenElectronic Excitation by UV/Vis SpectrosAdjieAtjie Jie BillionerNoch keine Bewertungen

- Reaction Mechanism NotesDokument34 SeitenReaction Mechanism NotesDipesh kumarNoch keine Bewertungen

- CHEM 11 - Lesson 1 - Some Basic Concepts in ChemistryDokument8 SeitenCHEM 11 - Lesson 1 - Some Basic Concepts in ChemistryPrabhat Singh 11C 13Noch keine Bewertungen

- Thermal Degradation Kinetics and Structural Characterization of Sodium BentoniteDokument15 SeitenThermal Degradation Kinetics and Structural Characterization of Sodium BentonitedsfsfNoch keine Bewertungen

- Thermionic Emission: PurposesDokument3 SeitenThermionic Emission: Purposeskumar.arasu8717Noch keine Bewertungen

- Fountain SolutionDokument36 SeitenFountain SolutionallUddinNoch keine Bewertungen

- Chemical Bonding ExplainedDokument10 SeitenChemical Bonding ExplainedMYLENE B. ZABALLERONoch keine Bewertungen

- Ibong Tiririt Pipe 3Dokument29 SeitenIbong Tiririt Pipe 3Mc LesterNoch keine Bewertungen

- Liquid SolutionDokument11 SeitenLiquid SolutionBikashNoch keine Bewertungen

- Chapter - 3.1 - Finale External Forced ConvectionDokument18 SeitenChapter - 3.1 - Finale External Forced ConvectioneirinaNoch keine Bewertungen

- Drug DesignDokument28 SeitenDrug DesignRavi DesaiNoch keine Bewertungen

- Computational Chemistry: Semester Ii M.SC Chemistry M.G University KottayamDokument15 SeitenComputational Chemistry: Semester Ii M.SC Chemistry M.G University KottayamDr. Partha Sarathi SenguptaNoch keine Bewertungen

- Report On CondenserDokument5 SeitenReport On CondenserDheeraj Shukla100% (1)

- Design of Mini Compressor Less Powered Refrigerator: Project Report ONDokument37 SeitenDesign of Mini Compressor Less Powered Refrigerator: Project Report ONBhati Rdx SurajNoch keine Bewertungen

- Sounds Cool Q&AofcDokument2 SeitenSounds Cool Q&AofcSaik SikshaNoch keine Bewertungen

- Steam Cracker PFDDokument1 SeiteSteam Cracker PFDMUHAMMAD NUR KHAIRINoch keine Bewertungen

- ScriptDokument4 SeitenScriptJoel KhouriNoch keine Bewertungen

- CHM s2Dokument9 SeitenCHM s2kolapo feyisetanNoch keine Bewertungen

- 2023 Specimen Paper 3 Mark SchemeDokument10 Seiten2023 Specimen Paper 3 Mark SchemejamesNoch keine Bewertungen

- Sublimation and Melting Point Determination (Repaired)Dokument3 SeitenSublimation and Melting Point Determination (Repaired)MherizNoch keine Bewertungen

- ECE 3223 Separation Processes I: B. Eng (Hons.) Chemical EngineeringDokument19 SeitenECE 3223 Separation Processes I: B. Eng (Hons.) Chemical EngineeringJosh VatomNoch keine Bewertungen

- Heat Recovery Steam Generators PDFDokument34 SeitenHeat Recovery Steam Generators PDFahmed_2211896127100% (1)