Beruflich Dokumente

Kultur Dokumente

Fast Construction Precast Concrete Bridges

Hochgeladen von

rizkyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fast Construction Precast Concrete Bridges

Hochgeladen von

rizkyCopyright:

Verfügbare Formate

Totally Precast

Concrete

Bridges

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Is it possible to design

an Instant Bridge?

Almost! There are

many ways to put a

bridge together

quickly with precast

concrete products.

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

The speed and

variety of precast

prestressed

products and

methods give

designers many

options. Consider

these advantages

of an

all-precast

bridge

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Benefits to Owner Agencies:

Reduction in the duration of

work zones

Reduced traffic handling costs

Reduced accident exposure risks

Less inconvenience to the

traveling public

Fewer motorist complaints

BACK

Fast construction benefits

owner agencies by reducing the

duration of the work zone. Fast

construction reduces traffic

handling costs and accident

exposure risks. Theres less

inconvenience to the traveling

public, fewer delays, and fewer

motorist complaints. According

to a report by the Texas

Transportation Institute, costs

incurred by drivers passing

through a work zone (along with

engineering costs) can be $10,000

to $20,000 per day. A recent

Federal report indicates user

costs of $50,000 per day for work

zones in urban areas.

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Benefits to Contractors:

Reduced exposure to hazards

More work -- less time

Contractors benefit from

reduced exposure to

traffic hazards. More

work can be accomplished

in less time, with fewer

weather delays.

Costs are lower for forms,

skilled field labor,

scaffolding and shoring,

and cranes.

Fewer weather delays

Lower costs

Less skilled labor

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

After foundations have

been completed,

scheduling can be

controlled by a single

contractor working with a

familiar material.

Scheduling Control

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Precast concrete

structural elements

should always be plant

produced under carefully

controlled conditionsby

plants that are Certified

by PCI.

Plant-produced Elements

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

so all structural

elements benefit from

the excellent quality and

corrosion resistance of

prestressed concrete.

Quality and Corrosion Resistance

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Fully-cured precast

concrete structural

elements can be

stockpiled in advance of

need

Stockpiled in Advance

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

and can be scheduled

for just-in-time

delivery and erection

Immediate Delivery and Erection

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Theres no curing time

required at the jobsite, as

with cast-in-place

concrete. Bridge piers

can be erected in a day,

and beams can follow

immediately.

No Curing Time

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

The following photos

illustrate the many

products and construction

methods that enable very

rapid project completion.

In addition to the oftenused superstructure

elements of girders and

deck slabs, substructure

components such as these

piers can also be precast.

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Precast concrete piles are

quite popular in much of

the country. They come

in different sizes and

shapes, ranging from 10inch square piles to 66inch diameter hollow

cylinder piles.

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Pile caps also can be

precast concrete,

reducing exposure,

forming and curing in

the field.

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Piers can be made of

precast concrete pieces

quickly assembled in

the field.

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Abutments can also be

made of precast.

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

The Sucker Creek Bridge

in Hague, New York,

consists of precast

concrete box beams

supported on precast

concrete abutments

assembled into a

jointless, rigid frame.

Sucker Creek Bridge in Hague

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

In San Juan, Puerto Rico,

the totally precast

concrete Baldorioty de

Castro Avenue bridges

were built in recordsetting time, attractively,

and economically.

Puerto Rico

MAIN

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Puerto Rico A totally

precast bridge

BACK

Each of four bridges,

ranging in length from 700

to 900 feet, was erected

in about 24 hours. This

was well within the

owners construction

allowance of 72 hours per

bridge, a condition

established to minimize

disruption to one of the

citys highly traveled

corridors.

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

In addition to speed, the

bridges also met the

citys budgetary needs.

The four box-beam

bridges were constructed

for $2 million less than

the next lowest bid for

another material.

Puerto Rico

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Totally precast bridge

systems may be the only

viable solution in harsh field

conditions.

The Confederation Bridge

connecting Canadas Prince

Edward Island to mainland

New Brunswick is such

an example.

The bridge spanned the

eight-mile-wide

Northumberland strait,

which experiences severe

winters and is covered with

ice floes for five months of

the year.

Confederation Bridge

New Brunswick, Canada

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Even in such harsh

conditions, precast

concrete was able to

meet the owners

requirements of a

100-year service life,

a 3-year construction

period, and

attractiveness.

Confederation Bridge

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

It just makes economic

sense to evaluate

conversion of cast-inplace to precast

concrete. This was done

for the Edison Bridge in

Florida. Precast piers and

beams were spliced to

produce tall pier bents.

Edison Bridge

Florida

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

The state of Texas has

constructed several

bridges with segmental

precast concrete piers.

The attractive piers and

pier caps are hollow

members. Some are made

of high-performance

concrete. Such segments

may be match-cast,

similar to segmental box

girder bridges, or

separated by a thin

mortar bed, much like

giant masonry units.

Texas - Precast Piers

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

In Houston, the Louetta

Road Overpass utilized

precast concrete matchcast piers, as well as

precast, prestressed Ubeams and stay-in-place

deck panels.

Louetta Road Bridge

Texas

BACK

FORWARD

TOTALLY PRECAST BRIDGES -- CASE STUDIES

Another famous bridge is

the Sunshine Skyway

Bridge over Tampa Bay in

Florida. The piles, piers

and pier caps were

constructed of precast

concrete elements

connected together with

post-tensioning

threadbars.

Sunshine Skyway Bridge

Florida

BACK

FORWARD

Thank You for

Your Attention

BACK

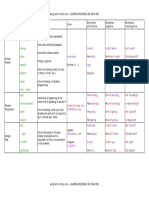

Das könnte Ihnen auch gefallen

- Rehabilitation of Concrete Structures with Fiber-Reinforced PolymerVon EverandRehabilitation of Concrete Structures with Fiber-Reinforced PolymerNoch keine Bewertungen

- Royle S A - Islands Nature and Culture - Earth Series - 2014Dokument226 SeitenRoyle S A - Islands Nature and Culture - Earth Series - 2014Simón Simón100% (1)

- Precast Concrete AnchorsDokument11 SeitenPrecast Concrete AnchorskurtainNoch keine Bewertungen

- MOVABLE BRIDGESDokument92 SeitenMOVABLE BRIDGESJoe AndrewsNoch keine Bewertungen

- M50 - Design of Integral BridgesDokument7 SeitenM50 - Design of Integral BridgeslovehackinggalsNoch keine Bewertungen

- Amazing Feats of Civil Engineering (Great Achievements in Engineering)Dokument114 SeitenAmazing Feats of Civil Engineering (Great Achievements in Engineering)Fouad Kehila100% (3)

- Precast Concrete Connections With Embedded Steel MebersDokument28 SeitenPrecast Concrete Connections With Embedded Steel Mebersbaharfka7423100% (2)

- Precast 1 Concepts PDFDokument111 SeitenPrecast 1 Concepts PDFRaymond Chan100% (5)

- Precast SectionsDokument16 SeitenPrecast SectionsRigid JointNoch keine Bewertungen

- Precast Concrete For Low-RiseDokument62 SeitenPrecast Concrete For Low-RiseJune Suriyawanakul100% (4)

- Precast Concrete Joint DesignDokument17 SeitenPrecast Concrete Joint Designkam_kevin5185100% (8)

- Precast ConcreteDokument69 SeitenPrecast Concretecapriciouskash70% (10)

- Deck ExampleDokument100 SeitenDeck ExampleDenis100% (1)

- BCA - Composite Concrete Bridge SuperstructuresDokument49 SeitenBCA - Composite Concrete Bridge Superstructuresshiva_cvl100% (3)

- ConcreteBasements 1 PDFDokument184 SeitenConcreteBasements 1 PDFMaiz NetoNoch keine Bewertungen

- Precast Concrete Wall Panel PresentationDokument21 SeitenPrecast Concrete Wall Panel PresentationBoonme Chinnaboon100% (1)

- Strut-And-Tie Modeling Provisions - What When and HowDokument54 SeitenStrut-And-Tie Modeling Provisions - What When and HowHildebrando Santos100% (1)

- Project Reference Catalogue: Balanced Cantilever BridgesDokument26 SeitenProject Reference Catalogue: Balanced Cantilever BridgesRaymond Sent75% (4)

- Tendon Grouting - VSLDokument46 SeitenTendon Grouting - VSLIrshadYasinNoch keine Bewertungen

- Topic 6 - Bridge SubstructureDokument62 SeitenTopic 6 - Bridge SubstructureAisyah NadhirahNoch keine Bewertungen

- CPCI Designing With Precast Concrete Structural Solutions PDFDokument44 SeitenCPCI Designing With Precast Concrete Structural Solutions PDFMarie Fe Fortuno Bermido100% (1)

- Short Span Steel Bridges-Cost Effective DesignDokument37 SeitenShort Span Steel Bridges-Cost Effective Designshakirhamid6687100% (1)

- Bridge Deck DesignDokument32 SeitenBridge Deck DesignChukwuma Ogbonna100% (2)

- Precast Concrete Frames GuideDokument58 SeitenPrecast Concrete Frames GuideHari Amudhan Ilanchezhian100% (9)

- Precast Concrete Applications & General OverviewDokument60 SeitenPrecast Concrete Applications & General Overviewcrabbysya100% (1)

- Concrete: A Guide To One Hundred AdvantagesDokument59 SeitenConcrete: A Guide To One Hundred Advantageskannanperiyanan100% (4)

- Precast Segmental Concrete BridgesDokument2 SeitenPrecast Segmental Concrete BridgesmemomsmNoch keine Bewertungen

- 2011 Bridge SarkadyDokument17 Seiten2011 Bridge SarkadyTan Duy LeNoch keine Bewertungen

- Precast FlooringDokument20 SeitenPrecast FlooringantonamxNoch keine Bewertungen

- Pre Stressed Concrete Is A Method For Overcoming The ConcreteDokument7 SeitenPre Stressed Concrete Is A Method For Overcoming The ConcreteNurhamizah MeskamNoch keine Bewertungen

- $RG5W35IDokument16 Seiten$RG5W35IipostkastNoch keine Bewertungen

- Precast Concrete StructuresDokument31 SeitenPrecast Concrete Structuresjack thomasNoch keine Bewertungen

- Precast Concrete Solutions HumesDokument83 SeitenPrecast Concrete Solutions Humespandeshantanu100% (4)

- Week 6 - Magnel Dia. & Tendon ProfileDokument27 SeitenWeek 6 - Magnel Dia. & Tendon ProfileAlif Akhmizan100% (1)

- Concrete Products: Product GuideDokument16 SeitenConcrete Products: Product GuideRisa AiNoch keine Bewertungen

- Post Tensioning Tendon Installation and Grouting Manual PDFDokument172 SeitenPost Tensioning Tendon Installation and Grouting Manual PDFJohnnie StrydomNoch keine Bewertungen

- PCI ch3 Precast Concrete PDFDokument86 SeitenPCI ch3 Precast Concrete PDFBhuidhar Verma100% (1)

- How To Disproportionate CollapseDokument8 SeitenHow To Disproportionate CollapseccapotaNoch keine Bewertungen

- Investigation of the Chirajara Bridge CollapseVon EverandInvestigation of the Chirajara Bridge CollapseNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Totally Precast Concrete Bridges: ForwardDokument27 SeitenTotally Precast Concrete Bridges: ForwardPECMURUGANNoch keine Bewertungen

- Advantages of Prestressed Concrete BridgesDokument44 SeitenAdvantages of Prestressed Concrete Bridgeskavya1811Noch keine Bewertungen

- Advantages of Prestressed Concrete BridgesDokument44 SeitenAdvantages of Prestressed Concrete BridgesVivek PremjiNoch keine Bewertungen

- The Books On The BottomDokument53 SeitenThe Books On The BottomJr BongabongNoch keine Bewertungen

- Precast Prestressed Concrete Short Span BridgesDokument41 SeitenPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Reducing Time For Steel Bridge ConstructionDokument9 SeitenReducing Time For Steel Bridge ConstructionMario Guevara Ubidia- IngenieroCivilNoch keine Bewertungen

- AspireBook Win14 WebDokument48 SeitenAspireBook Win14 Webjrobert123321Noch keine Bewertungen

- Tac 2006Dokument21 SeitenTac 2006Chewfy1Noch keine Bewertungen

- CHAPTER IDokument4 SeitenCHAPTER Imaddih gayeNoch keine Bewertungen

- Bridge DissertationDokument6 SeitenBridge DissertationPaperWritingServicesBestCanada100% (1)

- 500-Word ProposalDokument2 Seiten500-Word Proposalsahar mokhtariNoch keine Bewertungen

- Roller Compacted Concrete PDFDokument34 SeitenRoller Compacted Concrete PDFAdrian Luis Hernandez Garcia67% (3)

- Arti - IngDokument9 SeitenArti - IngNIVANET DEL CARMEN SOSA CORREANoch keine Bewertungen

- Accelerated Brideg Construction in Washington StateDokument16 SeitenAccelerated Brideg Construction in Washington StatesyedabdulhannanNoch keine Bewertungen

- Innovative Deployment of Reinforced Concrete Bridge DecksDokument5 SeitenInnovative Deployment of Reinforced Concrete Bridge DecksIqbal AhmadNoch keine Bewertungen

- Techbrief: Slide-In Bridge ConstructionDokument7 SeitenTechbrief: Slide-In Bridge ConstructionAhmad Yassine KouacheNoch keine Bewertungen

- Guide to Pedestrian Bridges Under 40 CharactersDokument4 SeitenGuide to Pedestrian Bridges Under 40 CharactersJuan AlayoNoch keine Bewertungen

- 210040117-Roller Compacted ConcreteDokument5 Seiten210040117-Roller Compacted Concretesahilbarbade.ee101Noch keine Bewertungen

- Civil Strcutres - BridgesDokument26 SeitenCivil Strcutres - BridgesSina Hafezi Masoomi100% (1)

- PPBBI (Peraturan An Bangunan Baja Indonesia) 1984Dokument87 SeitenPPBBI (Peraturan An Bangunan Baja Indonesia) 1984allabout_civil100% (6)

- PhrasesDokument19 SeitenPhrasesrizkyNoch keine Bewertungen

- Pemanfaatan Limbah Kertas Koran-Sapti MartaliaDokument10 SeitenPemanfaatan Limbah Kertas Koran-Sapti Martaliaseptyn_1Noch keine Bewertungen

- Tenses Table PDFDokument5 SeitenTenses Table PDFAlejandra Neira GonzálezNoch keine Bewertungen

- Totally Precast Concrete Bridges: ForwardDokument27 SeitenTotally Precast Concrete Bridges: ForwardPECMURUGANNoch keine Bewertungen

- PPP in PrisonDokument31 SeitenPPP in PrisonAmellliaNoch keine Bewertungen

- Fast Construction Precast Concrete BridgesDokument27 SeitenFast Construction Precast Concrete Bridgesrizky100% (1)