Beruflich Dokumente

Kultur Dokumente

TankTech UTI

Hochgeladen von

etchegarayfCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TankTech UTI

Hochgeladen von

etchegarayfCopyright:

Verfügbare Formate

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

Portable Oil / Water Interface Detector (PMS)

( Technical Service Manual )

z APPLICABLE RULE

: MARPOL 73/78 Chapter II Reg.15 (3) (b)

IMO MEPC.5(XIII) Annex 4

z APPLICABLE MODEL

: T2000-TFC-01 (CLOSED TYPE)

T2000-TFC-02 (CLOSED TYPE)

T2000-TFS-01 (RESTRICTED TYPE)

C-1

07.July.2006

Issued for training

B. C. Park

J. O. Lee

H. Jin

06.Jan. 2006

Issued for training

B. C. Park

J. O. Lee

H. Jin

04.Oct. 2005

Issued for training

J. O. Lee

H. Jin

09 Mar. 2005

Issued for training

J. M. Kang

J. O. Lee

H. Jin

Doc. No.

TKT-PMS-TSM-001

Page

1/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

Rev.

Date

Description

Prepared

Checked

2006.07.07

Rev. C-1

Approved

CONTENTS

Part 1 : Temperature Calibration........................................... 3

Part 2 : Replacement of sensor probe ................................. 7

Part 3 : Change of battery ................................................... 10

Part 4 : Change of tape ........................................................ 11

Doc. No.

TKT-PMS-TSM-001

Page

2/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

2006.07.07

Portable Oil / Water Interface Detector

Technical Service Manual

Rev. C-1

Part 1 : Temperature Calibration

The equipment required to do a RACEABLE

CALIBRATION

Thermometer

are

and

Precision

fine

tuned

Digital

controlled

temperature water bath.

This thermometer has to be sent to a National

Institute

for

calibration

against

their

higher

standard of accuracy, which is what it meant by

traceable.

The accuracy of the F250 is 500 ppm or parts per

million. The PT100 probe is a 4-wire thermometer

of Laboratory grade.

Fig. 1 PRECISION DIGITAL THERMOMETER

The sensor probe is immersed into the water bath along with the F250 probe.

The temperature points are at: 20C, 40C and 60C.

VR2 : TEMPERATURE ZERO ADJUST POTENTIO-METER

VR1 : TEMPERATURE GAIN ADJUST POTENTIO-METER

VR3 : ULTRASONIC SENSITIVE ADJUST POTENTIO-METER

Fig. 2 TFC-01 SENSOR PROBE VIEW FROM THE TOP

Doc. No.

TKT-PMS-TSM-001

Page

3/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

VR2 : TEMPERATURE ZERO ADJUST POTENTIO-METER

VR1 : TEMPERATURE GAIN ADJUST POTENTIO-METER

VR3 : ULTRASONIC SENSITIVE ADJUST POTENTIO-METER

VR4 : WATER SENSITIVE ADJUST POTENTIO-METER

Fig. 3 TFC-02/TFS-01 SENSOR PROBE VIEW FROM THE TOP

This analogue, linear signal is amplified by a LM2904 Op. amp. with the facilities to adjust and offset the

zero point and the gain or slope.

Preliminary adjustments are made at two points (20C and 60C) before calibration. Therefore the probes

are firstly immersed in cold water (lower end of the temperature range) and the ZERO adjustable PotentioMeter is adjusted to correct the error reading. Secondly, both probes are transferred to a hot water bath at

the higher end of the temperature range and the GAIN Potentio-Meter is adjusted to correct the error

reading. After the final stage, where the probes are transferred to and from hot to cold water and no

corrections are necessary, then the probes are placed in the hot water temperature regulated bath for the

full calibration range.

Doc. No.

TKT-PMS-TSM-001

Page

4/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

GAIN OR SLOPE ADJUST

ZERO ADJUST

Fig. 4 THE ZERO AND SLOPE ADJUSTABLE RESISTORS

Calibration procedure for 3 points: 20C, 40C, and 60C with temperature regulating water bath, precision

thermometer and sensor probe.

( CAUTION ! ) The immersion depths of both sensor probe and precision thermometer must be the same

for a homogeneous reading.

A calibration certificate will be issued after the test and adjustments and the readings error tolerance must

be within the specification limits.

Picture on the left shows the Precision PID Temperature

controller water bath for the Calibration Laboratory Standard.

TANKTECH calibrates every single piece of temperature

sensor and issue a calibration certificate before dispatching

the Tape.

Doc. No.

TKT-PMS-TSM-001

Page

5/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

<Procedure for temperature calibration>

Following is brief information for the calibration which can be done at ON-BOARD

* Normal Temperature(20) , High Temperature(60) : carry out temperature calibration at 2

points

1. Regulate VR2 at Normal Temperature and set the temperature to a standard temperature.

2. Regulate VR1 at High Temperature and set the temperature to a standard temperature.

3. Check Normal Temperature(20), and High Temperature(60).

Repeat the procedure again in case the deviation between Detector LCD temperature and

standard temperature exceeds more than 0.2.

( NOTE )

1. TFC-01 Temperature Calibration.

- VR2 : Turn the Volume to left and temperature will rise

- VR1 : Turn the Volume to right and temperature will rise

2. TFC-02 Temperature Calibration.

- VR2 : Turn the Volume to right and temperature will rise

- VR1 : Turn the Volume to right and temperature will rise

( CAUTION !) Please note that Temperature Calibration can be done only by adjusting VR1, and VR2.

Do not turn other volumes like VR3, VR4.

Doc. No.

TKT-PMS-TSM-001

Page

6/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

Part 2 : Replacement of sensor probe

1. Disconnection of sensor probe

SENSOR UNIT

SET SCREW

O-RING

THREAD

3P TERMINAL

PROBE BARREL

Fig. 1

Fig. 2

Fig. 3

DISCONNECTION PROCEDURE

1. Carefully separate the sensor unit from the probe barrel with monkey spanner by grapping

probe barrel tightly.

In order to unfasten these two items, rotate 2~3 times the sensor unit toward counterclockwise with monkey spanner. Refer to Fig. 1

( CAUTION ! ) Do not loose the set screw when separating the sensor unit

2. After separate the sensor unit from probe barrel, three electric wire have to disconnect from

the 3P terminal by a small (-) screw driver. Refer to Fig. 2

3. Make be in good shape the 3P Terminal with three electric wires of Sensor Unit.

Refer to Fig. 3

Doc. No.

TKT-PMS-TSM-001

Page

7/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

Step

1

Description

2006.07.07

Rev. C-1

Illustration

Carefully separate the sensor unit from the probe barrel with

monkey spanner by grapping probe barrel tightly.

After separate the sensor unit from probe barrel, three electric

wire have to disconnect from the 3P terminal by a small (-) screw

driver.

2. Reconnection of sensor probe

PROBE BARREL

THREAD

3P TERMINAL

TERMINAL CONNECTOR

PROBE BARREL

FOUNDATION VIEW OF PROBE BRREL

Fig. 5

Fig. 4

Doc. No.

TKT-PMS-TSM-001

Page

8/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

CONNECTION PROCEDURE

1. Connect the 3P Terminal at the sensor unit with the terminal connector at the probe barrel.

Refer to Fig.4

Before assembly it, please coat some heavy grease on the screw thread and O-rings.

2. Make be in good shape the 3 electric wires into spiral at one edge inside barrel as shown on

below picture, so that they cannot be damaged by screw thread. Refer to Fig.5

3. Connect the probe barrel to the sensor unit vertically with both hands.

4. To tighten the sensor unit with the probe barrel, please rotate the sensor unit with monkey

spanner 2~3 times in clockwise rotation.

Turn 1~2 rounds clockwise first to lessen the cable twisting inside.

(Fig. 1)

Note> Please do not be tighten over 3 rotations. Wires which located in the probe barrel could

be damaged by excessive twist.

( CAUTION ! ) Do not let the cable get in between the tape header and the probe threads.

Otherwise the header may cut the cable insulations and cause a short circuit.

3. Tool or Kit

Monkey Spanner(12inch), (-)Screw driver, Rubber coated Globes

Doc. No.

TKT-PMS-TSM-001

Page

9/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

Part 3 : Change of battery

Step

Description

Illustration

Unfasten four screws from the hub ring by using M4 hex key.

Detach the hub ring from the drum.

Lift carefully the display PCB from the drum

Replace old battery with new one.

Put back the display PCB into its original location.

Doc. No.

TKT-PMS-TSM-001

Page

10/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

Step

Description

2006.07.07

Rev. C-1

Illustration

Put back the hub ring with gasket.

Tighten four hex screws with M4 hex key.

Check the PMS by switching on.

Part 4 : Change of tape

1. Removing the faulty tape

1) Preparatory step

A.

Remove the Storage barrel and them Tape protection device from the Tape body assembly.

B.

Remove the sensor probe from the connecting head with 19mm monkey spanner.

( CAUTION ! ) This procedure has to be done out of the hazardous zones.

2) Remove the 4 cover screws with 6 mm Hex key and place screws and washers in a cup.

3) Remove the Tape plate screws with + screwdriver.

4) Release and pull out the faulty tape from the reel, coil the tape outside of the body.

( CAUTION ! ) to unwind tape while it is resting on the Display side, to avoid the tape falling off the

reel.)

5) Remove the bracket screws inside the Hub core.

6) Cut open the cable insulations (shrinking tubes) and unsolder the wires from the tape.

7) Remove the bracket from the tape with + screwdriver and 5.5mm socket wrench.

8) Clean up the core from solder wastes and the Hub and associated parts from Silicone Sealant.

Doc. No.

TKT-PMS-TSM-001

Page

11/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

< REMOVAL PROCEDURE >

Step

Description

Illustration

Unfasten four screws of cover with 6mm hex key.

Unfasten four screws of Tape plate.

Release the tape from the hub core in order to easily remove the

tape.

Unfasten screws of the mounting bracket which located in hub

core.

Remove the bracket from the tape with socket wrench and (+)

driver.

Doc. No.

TKT-PMS-TSM-001

Page

12/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

Step

Description

2006.07.07

Rev. C-1

Illustration

Unsolder the wires and connections to the tape.

Remove the tape and clean up the core.

2. Fixing a new tape

1) Preparatory step

A.

Place the new tape besides the tape body (CAUTION! Do not uncoil the tape).

B.

CAUTION! Position of the tape should be Header inside and open end outside.

C. Remove the wiper assembly (this is optional, as it will be easier to push the new tape in without

the wiper getting in the way.)

2) Push the tape (Scale side facing window) through the indicator bar,

pulley roller and into the Hub core through the slot. Allow about

100 mm lead head.

3) Splice the tape with 50mm length 13mm dia. shrinking tube before

the mounting bracket.

4) Sleeve the cables with 3 mm dia. 25mm length shrinking tubes (red color for the red cable and

black sleeve for the yellow cable). Short 22mm length, 13mm dia. to the tape end, after the bracket.

5) Fix back the mounting bracket onto the tape and apply Silicone Sealant to the nuts and screws.

Doc. No.

TKT-PMS-TSM-001

Page

13/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

6) Solder the wires to the tape connections. Tape Scale facing: Red wire on top, black in middle and

yellow on bottom.

7) Shrink the small tubes of the cables and the short larger one over all the joints. Shrink the 50mm

length 13mm dia tube at about 40 mm away from the bracket.

8) Coil the tape inside the hub and screw the bracket to hub with + screwdriver.

9) Connect the sensor probe to test the connection integrity. If the connection is right then proceed on

to the next step. But if the Display shows ERROR then there is communication error, check the

connections again.

10) Apply silicone sealant to the hub slot and the bracket mounting screws and close the Tape plate,

screw with + screwdriver.

11) Close back the cover of tape body screw with 6mm HEX key.

12) Rewind the new tape to the reel.

13) Fix back Tape protection device and then Storage baarel.

14) Fix back the sensor probe. ( CAUTION ! )

A.

Do not twist the cables excessively. Turn head assembly 2 to 3 turns anti-clockwise and screw

in clockwise.

B.

Watch out for the cables that they do not get in between the threads.

C. Do not use pipe wrench to grip the sensor probe, as this may cause deep scratch marks on it.

Use hand gloves or belt-wrench if needed to.

15) Switch on the set to test. If ERROR message displayed, remove the sensor probe again to check

the connecting cables. If any of the cable insulation is cut, pull out the cable from the

connector with mini screwdriver pushing the lock pin and apply shrinking tube (3mm dia.)

on it and shrink with cigarette lighter. Push back the cable and test again before screwing

in the sensor probe to the header assembly.

16) Changing of tape is completed.

Doc. No.

TKT-PMS-TSM-001

Page

14/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

2006.07.07

Rev. C-1

< FIXING PROCEDURE >

Step

Description

Picture

Push new tape (scale facing window) through the bar and slot.

Sleeve in the 50mm length x 13mm dia shrinking tube.

Fix the bracket to the tape. Place shrinking tubes to wires and

tape.

Solder wires to tape (Red, black, Yellow scale face)

Shrink the smaller tubes and then the bigger with cigarette lighter.

Doc. No.

TKT-PMS-TSM-001

Page

15/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Portable Oil / Water Interface Detector

Technical Service Manual

Step

Description

Fix back the bracket to the mounting point. Apply silicone sealant.

Cover back the hub cap and guide reel.

Fix back the cover of tape body screw with 6mm HEX key.

Fix back Tape protection device.

10

Fix back Storage barrel.

TKT-PMS-TSM-001

Rev. C-1

Picture

Doc. No.

2006.07.07

Page

16/16

File

Tech Service PMS(ALL-RC-1).doc

TANKTECH reserves the right to change the specification and design at any time without prior notice.

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- VDR HyundaiDokument28 SeitenVDR HyundaiDIPIN PNoch keine Bewertungen

- ODME ExplainationDokument36 SeitenODME ExplainationRachit Srivastava100% (2)

- Furuno Ecdis 1 PDFDokument309 SeitenFuruno Ecdis 1 PDFJayesh SolaskarNoch keine Bewertungen

- PR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Dokument50 SeitenPR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Mooi Pang Ng100% (2)

- Simrad RadarDokument4 SeitenSimrad RadarNesil Abiera100% (2)

- Bnwas BW-800Dokument26 SeitenBnwas BW-800etchegarayf100% (3)

- KTMS 2500Dokument127 SeitenKTMS 2500etchegarayfNoch keine Bewertungen

- Marine Track SafeGuard Installation V3.3Dokument28 SeitenMarine Track SafeGuard Installation V3.3BeneDict Ben DNoch keine Bewertungen

- 7000 108-011, G, Installation Manual R4 AIS Shipborne Class A Transponder SystemDokument83 Seiten7000 108-011, G, Installation Manual R4 AIS Shipborne Class A Transponder SystemetchegarayfNoch keine Bewertungen

- 190-ECDIS JRC JAN-7201S-9201S Instruct Manual Reference 27-7-2020Dokument350 Seiten190-ECDIS JRC JAN-7201S-9201S Instruct Manual Reference 27-7-2020dorgNoch keine Bewertungen

- SAFE RC Design ForDokument425 SeitenSAFE RC Design ForMarlon Braggian Burgos FloresNoch keine Bewertungen

- JHS 32BInstruction ManualDokument152 SeitenJHS 32BInstruction Manualnavyeye100% (1)

- Enrico Fermi Pioneer of The at Ted GottfriedDokument156 SeitenEnrico Fermi Pioneer of The at Ted GottfriedRobert Pérez MartinezNoch keine Bewertungen

- CleanTrack1000B Ver209 PDFDokument181 SeitenCleanTrack1000B Ver209 PDFIvaylo IvanovNoch keine Bewertungen

- DR S GurusamyDokument15 SeitenDR S Gurusamybhanu.chanduNoch keine Bewertungen

- OdmeDokument10 SeitenOdmeHarshit Nanda100% (1)

- Dukane DK100 ULDDokument25 SeitenDukane DK100 ULDetchegarayfNoch keine Bewertungen

- Omd 24 eDokument30 SeitenOmd 24 eabuzer1981Noch keine Bewertungen

- Marine Controller: User ManualDokument44 SeitenMarine Controller: User ManualIbnu Sanusi92% (12)

- Westfalia Separator Visco Booster Unit en 9997 0787 030Dokument16 SeitenWestfalia Separator Visco Booster Unit en 9997 0787 030etchegarayfNoch keine Bewertungen

- Handbook of Magnetic Compass AdjustmentDokument46 SeitenHandbook of Magnetic Compass AdjustmentRoderick EstrellaNoch keine Bewertungen

- GMDSS Pre Survey ChecklistDokument2 SeitenGMDSS Pre Survey ChecklistBetül Gündoğdu100% (1)

- Scan2000 GyrocompassDokument51 SeitenScan2000 GyrocompassetchegarayfNoch keine Bewertungen

- JRC Discontinued Parts Supply Status 2018-12 EngDokument4 SeitenJRC Discontinued Parts Supply Status 2018-12 EngPrashant S NagwekarNoch keine Bewertungen

- Manufacturers With Type Approved Certificates For BNWASDokument1 SeiteManufacturers With Type Approved Certificates For BNWASAndrey100% (1)

- NW4000-60 VDR Authority Access Manual V1.4Dokument19 SeitenNW4000-60 VDR Authority Access Manual V1.4Drago Dragic100% (1)

- Dmlib-#97915-V1-Lok Oil Discharge Monitoring & Control SysDokument238 SeitenDmlib-#97915-V1-Lok Oil Discharge Monitoring & Control SysravipedapudiNoch keine Bewertungen

- SW2020 Users Manual V10Dokument81 SeitenSW2020 Users Manual V10Antonio Antonio100% (2)

- 15PPM Ocd CM PDFDokument4 Seiten15PPM Ocd CM PDFTrần Quang Tuyên100% (1)

- Motorola Gp328 338 Service ManualDokument272 SeitenMotorola Gp328 338 Service Manualhankruan86% (7)

- Cleantrack1000 Manual en 20060906Dokument195 SeitenCleantrack1000 Manual en 20060906CRIS SEDANTONoch keine Bewertungen

- Vapour Drop CalculationsDokument11 SeitenVapour Drop Calculationskneller100% (1)

- Instructional Manual For Riken Combustible Gas MonitorDokument50 SeitenInstructional Manual For Riken Combustible Gas MonitorMichaelcef Miranda0% (1)

- VDR C.O.C. Requirements - 2018.02.27Dokument17 SeitenVDR C.O.C. Requirements - 2018.02.27Macro Love100% (2)

- Marsen Catalog v6.0Dokument26 SeitenMarsen Catalog v6.0seckin80100% (1)

- Guideline - Research ProposalDokument38 SeitenGuideline - Research ProposalRASNoch keine Bewertungen

- Furuno SC-50 - 110Dokument30 SeitenFuruno SC-50 - 110etchegarayf100% (1)

- Laz 5000 ElacDokument75 SeitenLaz 5000 ElacMorseNoch keine Bewertungen

- Alcoscan Alcohol Tester - Al 7000Dokument4 SeitenAlcoscan Alcohol Tester - Al 7000Shanmugamoorthy100% (1)

- Headway User Manual 2.6.5.0 - DianellaDokument189 SeitenHeadway User Manual 2.6.5.0 - Dianellamotor tankerNoch keine Bewertungen

- Operator Manual: E5024 ECDIS SystemDokument80 SeitenOperator Manual: E5024 ECDIS SystemEduard PrikhodkoNoch keine Bewertungen

- Salwico 2020 Manual-130524Dokument141 SeitenSalwico 2020 Manual-130524Mayan De la CruzNoch keine Bewertungen

- Navigator PDFDokument19 SeitenNavigator PDFetchegarayfNoch keine Bewertungen

- GPS JLR 7700 MK Ii PDFDokument112 SeitenGPS JLR 7700 MK Ii PDFVladimirNoch keine Bewertungen

- ODME Operation InstrDokument5 SeitenODME Operation InstrCelal BozdoganNoch keine Bewertungen

- Bilgmon488 Instruction Manual VCDokument23 SeitenBilgmon488 Instruction Manual VCLwin PhyoNoch keine Bewertungen

- Jowa Odme Cleantoil 9000Dokument6 SeitenJowa Odme Cleantoil 9000CRIS SEDANTO0% (1)

- Jlr-10 Instr. ManualDokument126 SeitenJlr-10 Instr. Manual'Egemen KayaNoch keine Bewertungen

- Manual G36 O2 Analyzer - V.2.04 July 2017Dokument46 SeitenManual G36 O2 Analyzer - V.2.04 July 2017Isidoros100% (3)

- ODMEDokument12 SeitenODMEAntonio Antonio100% (1)

- Rivertrace Manual 2015 - SseDokument44 SeitenRivertrace Manual 2015 - SseRomankoNoch keine Bewertungen

- tfc02 PDFDokument22 Seitentfc02 PDFAniigiselaNoch keine Bewertungen

- Instruction Manual For LEA-HPDokument76 SeitenInstruction Manual For LEA-HPRM Haroon100% (2)

- OdmeDokument18 SeitenOdmerajishrrr100% (1)

- Daiichi Nekken C-28C Manual v2.0Dokument23 SeitenDaiichi Nekken C-28C Manual v2.0giro roskyNoch keine Bewertungen

- Nakakita Seisakusho ValveDokument2 SeitenNakakita Seisakusho ValveMohd Faris Amzar Mat ZamNoch keine Bewertungen

- PT-500 CMZ-700SDokument41 SeitenPT-500 CMZ-700SВиктор НетребкоNoch keine Bewertungen

- 8402 Smart ODME Data SheetDokument4 Seiten8402 Smart ODME Data SheetPankajNoch keine Bewertungen

- GX 8000 Tips and CautionsDokument11 SeitenGX 8000 Tips and CautionsalexanderNoch keine Bewertungen

- Calibration Laboratories, Inc.: Portable Electronic Gauging Tapes For Petroleum and Chemical TanksDokument1 SeiteCalibration Laboratories, Inc.: Portable Electronic Gauging Tapes For Petroleum and Chemical TanksArmando SixtoNoch keine Bewertungen

- Operation and Service Manual For Hermetic Sampler GT-STRD: Portable Closed Sampling DeviceDokument40 SeitenOperation and Service Manual For Hermetic Sampler GT-STRD: Portable Closed Sampling DeviceGMNoch keine Bewertungen

- Dry Chemical PowderDokument1 SeiteDry Chemical PowderAbhinand LMNoch keine Bewertungen

- TRO Fault and SolutionDokument4 SeitenTRO Fault and SolutionIgor DoroshchukNoch keine Bewertungen

- 3060 - E - 012 - Pilotstar D Typ Ap02-S01Dokument166 Seiten3060 - E - 012 - Pilotstar D Typ Ap02-S01Gary GouveiaNoch keine Bewertungen

- Purging Routine For Framo Cargo Pumping System: Service Bulletin #47Dokument16 SeitenPurging Routine For Framo Cargo Pumping System: Service Bulletin #47MAKNoch keine Bewertungen

- JRC Jma 9132 S Band TXRX Azi Error ChecksDokument2 SeitenJRC Jma 9132 S Band TXRX Azi Error ChecksAkhil ViswanathanNoch keine Bewertungen

- JUE 251 501 Instruction ManualDokument394 SeitenJUE 251 501 Instruction ManualСергей БородинNoch keine Bewertungen

- Spectro Quick User GuideDokument20 SeitenSpectro Quick User Guidemoe_htwe_1100% (2)

- Technical Manual: Hydrocarbon Gas Sampling & Detection SystemDokument12 SeitenTechnical Manual: Hydrocarbon Gas Sampling & Detection SystemAleksandr Andreev100% (1)

- HTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Dokument4 SeitenHTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Riddhi DasNoch keine Bewertungen

- Seres Mk-II Start Stop InstructionsDokument3 SeitenSeres Mk-II Start Stop Instructionsdodoi_neelrNoch keine Bewertungen

- Uae Tasneef GCC CodeDokument147 SeitenUae Tasneef GCC Codekoib789Noch keine Bewertungen

- Service Tips Chassis Icc9Dokument15 SeitenService Tips Chassis Icc9Zeko MekoNoch keine Bewertungen

- LG TV 29fu6rsd (RS) Chassis Cw62d, Service ManualDokument22 SeitenLG TV 29fu6rsd (RS) Chassis Cw62d, Service Manualjazjcl3269Noch keine Bewertungen

- compactNSX UserManual PDFDokument148 SeitencompactNSX UserManual PDFLuis JesusNoch keine Bewertungen

- Toshiba SM Rav SM SP 560 800 XT eDokument187 SeitenToshiba SM Rav SM SP 560 800 XT eetchegarayfNoch keine Bewertungen

- MX 400 GPS U ManualDokument231 SeitenMX 400 GPS U ManualetchegarayfNoch keine Bewertungen

- Omc-139 Wheather Station ManualDokument2 SeitenOmc-139 Wheather Station ManualetchegarayfNoch keine Bewertungen

- compactNSX UserManual PDFDokument148 SeitencompactNSX UserManual PDFLuis JesusNoch keine Bewertungen

- BACtrack S70 Manual 2 PDFDokument11 SeitenBACtrack S70 Manual 2 PDFetchegarayfNoch keine Bewertungen

- Commax IC-M36 - M35 ManualDokument8 SeitenCommax IC-M36 - M35 ManualetchegarayfNoch keine Bewertungen

- DCP2 Data Sheet 4921210105 UKDokument4 SeitenDCP2 Data Sheet 4921210105 UKLukas AlvesNoch keine Bewertungen

- GP 328 User GuideDokument23 SeitenGP 328 User GuideamrilsiregarNoch keine Bewertungen

- DP-6 (Refer To Service Manual) : Changing Answerback and ID CodesDokument2 SeitenDP-6 (Refer To Service Manual) : Changing Answerback and ID CodesetchegarayfNoch keine Bewertungen

- Wheather Fax Furuno FAX30Dokument122 SeitenWheather Fax Furuno FAX30etchegarayfNoch keine Bewertungen

- GST P-9910B Handheld ProgrammerDokument15 SeitenGST P-9910B Handheld ProgrammeretchegarayfNoch keine Bewertungen

- 6222 VHF DSC User ManualDokument92 Seiten6222 VHF DSC User ManualNicollePascalNoch keine Bewertungen

- GST100 Installation and Operation ManualDokument48 SeitenGST100 Installation and Operation Manualetchegarayf0% (1)

- 3-Cmlt-1004 Rev e Air X Owners ManualDokument32 Seiten3-Cmlt-1004 Rev e Air X Owners ManualCarlos LopesNoch keine Bewertungen

- Contactor Unit TK 75A / TK 80A TK 85A / TK 90A: For ELECTRO-TYFON® MT 150/-And MTX 150Dokument2 SeitenContactor Unit TK 75A / TK 80A TK 85A / TK 90A: For ELECTRO-TYFON® MT 150/-And MTX 150etchegarayfNoch keine Bewertungen

- WS-2815U-IT Wireless Professional Weather Center: Operations ManualDokument30 SeitenWS-2815U-IT Wireless Professional Weather Center: Operations ManualetchegarayfNoch keine Bewertungen

- 1622 Installation Manual F2 10-7-02Dokument24 Seiten1622 Installation Manual F2 10-7-02etchegarayfNoch keine Bewertungen

- Spring 2010 - CS604 - 1 - SolutionDokument2 SeitenSpring 2010 - CS604 - 1 - SolutionPower GirlsNoch keine Bewertungen

- Ti05001 PDFDokument1 SeiteTi05001 PDFanggieNoch keine Bewertungen

- Omnitron CatalogDokument180 SeitenOmnitron Catalogjamal AlawsuNoch keine Bewertungen

- Nutrition 2022 PIRDokument22 SeitenNutrition 2022 PIRAlmira LacasaNoch keine Bewertungen

- Animal Health ChecklistDokument4 SeitenAnimal Health ChecklistcapsfastNoch keine Bewertungen

- Literature Review of Service Quality in RestaurantsDokument7 SeitenLiterature Review of Service Quality in RestaurantsuifjzvrifNoch keine Bewertungen

- ইসলাম ও আধুনিকতা – মুফতি মুহম্মদ তকী উসমানীDokument118 Seitenইসলাম ও আধুনিকতা – মুফতি মুহম্মদ তকী উসমানীMd SallauddinNoch keine Bewertungen

- RSC Article Template-Mss - DaltonDokument15 SeitenRSC Article Template-Mss - DaltonIon BadeaNoch keine Bewertungen

- Benefits and Limitations of BEPDokument2 SeitenBenefits and Limitations of BEPAnishaAppuNoch keine Bewertungen

- Lancru hzj105 DieselDokument2 SeitenLancru hzj105 DieselMuhammad MasdukiNoch keine Bewertungen

- Consent Form: Republic of The Philippines Province of - Municipality ofDokument1 SeiteConsent Form: Republic of The Philippines Province of - Municipality ofLucette Legaspi EstrellaNoch keine Bewertungen

- MolnarDokument8 SeitenMolnarMaDzik MaDzikowskaNoch keine Bewertungen

- Low Speed Aerators PDFDokument13 SeitenLow Speed Aerators PDFDgk RajuNoch keine Bewertungen

- Angel C. Delos Santos: Personal DataDokument8 SeitenAngel C. Delos Santos: Personal DataAngel Cascayan Delos SantosNoch keine Bewertungen

- Case 3 SectionC Group 1 (Repaired)Dokument3 SeitenCase 3 SectionC Group 1 (Repaired)SANDEEP AGRAWALNoch keine Bewertungen

- Survivor's Guilt by Nancy ShermanDokument4 SeitenSurvivor's Guilt by Nancy ShermanGinnie Faustino-GalganaNoch keine Bewertungen

- Pedagogy MCQS 03Dokument54 SeitenPedagogy MCQS 03Nawab Ali MalikNoch keine Bewertungen

- Verniers Micrometers and Measurement Uncertainty and Digital2Dokument30 SeitenVerniers Micrometers and Measurement Uncertainty and Digital2Raymond ScottNoch keine Bewertungen

- 1.161000 702010 New Perspectives 2ndedDokument43 Seiten1.161000 702010 New Perspectives 2ndedbimobimoprabowoNoch keine Bewertungen

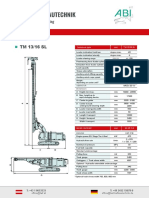

- ABI TM 13 16 SL - EngDokument1 SeiteABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNoch keine Bewertungen

- Marion Nicoll: Life & Work by Catharine MastinDokument147 SeitenMarion Nicoll: Life & Work by Catharine MastinArt Canada InstituteNoch keine Bewertungen

- Sap New GL: Document Splitting - Configuration: ChooseDokument3 SeitenSap New GL: Document Splitting - Configuration: ChooseChandra Sekhar PNoch keine Bewertungen

- Java Complete Collection FrameworkDokument28 SeitenJava Complete Collection FrameworkkhushivanshNoch keine Bewertungen

- Play ClawDokument2 SeitenPlay ClawFrenda SeivelunNoch keine Bewertungen

- [18476228 - Organization, Technology and Management in Construction_ an International Journal] Adaptive Reuse_ an Innovative Approach for Generating Sustainable Values for Historic Buildings in Developing CountriesDokument15 Seiten[18476228 - Organization, Technology and Management in Construction_ an International Journal] Adaptive Reuse_ an Innovative Approach for Generating Sustainable Values for Historic Buildings in Developing Countrieslohithsarath bethalaNoch keine Bewertungen

- SDN Van NotesDokument26 SeitenSDN Van Notesmjsmith11Noch keine Bewertungen

![[18476228 - Organization, Technology and Management in Construction_ an International Journal] Adaptive Reuse_ an Innovative Approach for Generating Sustainable Values for Historic Buildings in Developing Countries](https://imgv2-2-f.scribdassets.com/img/document/422064728/149x198/344a5742a7/1565947342?v=1)