Beruflich Dokumente

Kultur Dokumente

Night Stand: Online Extras

Hochgeladen von

sorix2005Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Night Stand: Online Extras

Hochgeladen von

sorix2005Copyright:

Verfügbare Formate

w041_online.

night stand

2/6/2005

4:05 PM

Page 26

Online Extras

Night Stand

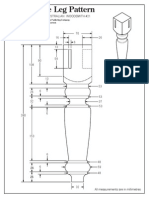

change the style with a cove

moulding top and pedestal base

By simply making a new top and

base, you can give the night stand a

more classic look. And then, adding

a few edge treatments to the base

and top will make them stand out to

complete the change. I finished both

assemblies the same as the case. By

the way, the knobs on the drawer

and door are also finished this way.

BUILT UP TOP . Instead of a single

top panel shown in the magazine, I

went with a built-up style by

adding a frame beneath it, as you

can see in the drawing below. The

frame is mitred at the front and

then has a 12.7mm-radius cove

routed into the front and sides, as

you can see in

detail a.

The new top

panel is the same

size as the original, but instead of

a crisp chamfer, I

routed a 6.35mm

roundover on the

bottom edges of the top (except the

back edge) to complement the cove

moulding below it. On the top

edges, simply ease the sharp edges

with some sandpaper.

When it comes time to attach the

new top to the case, youll have to

add an additional step. First, the

cove frame needs to be screwed to

the top panel. I drilled oversize

holes and used washers and

roundhead screws to allow the top

to expand and contract, as illustrated in detail a.

This assembly can then be

screwed to the case.

507

482

18

Drill and

countersink from

below for

8g x 32 c/s

woodscrews

TOP

222

476

400

FRAME

FILLER

90

90

315

25

16

25

a.

6.35

TOP

A

37

18

B

8g x 32 Rh

woodscrews

with washers

(through cove

frame into top)

8g x 32 c/s

woodscrews

COVE FRAME FRONT

(495 x 90)

6.35

roundover

B C

18

8g x 32 Rh

woodscrews with

washers (through case top

into cove frame)

8mm-dia. through

holes with

25mm-dia. x 6mm-deep

counterbore

COVE

FRAME

SIDE

NOTE: Cove frame sides,

cove frame front, and

frame filler are

18mm-thick hardwood

Australian Woodsmith No. 41 Online Extras

12.7 cove

Case

top

8g x 32mm

Rh woodscrews

with washers

FRONT

SECTION

VIEW

2005 August Home Publishing

w041_online.night stand

a.

2/6/2005

4:05 PM

Page 27

Drill and countersink

holes from bottom for

8g x 32 c/s woodscrews

Case

side

8g x 32 c/s

woodscrew

Case

bottom

6

1.5

50

445

18

BASE

PANEL

(18mm plywood)

50

453

6.35

roundover

FRONT

SECTION

VIEW

H

F

BASE

SIDE

b.

8g x 32 c/s

woodscrews

18

453

G

BASE

BACK

BASE

SIDE

18

109

6

G

18

Edge of

panel

is flush with

outside

face of back

BASE

SIDE

BASE

BACK

109

CORNER

GLUE

BLOCK

127

457

18

75

BASE

FRONT

BASE PANEL

TOP VIEW

477

18

BASE

SIDE

25

75

MITRED BASE. The base is pretty straight-

forward, as you can see in the drawing at

right. It consists of a mitred frame holding a plywood panel that is used to attach

the base to the case. There are just a few

details on the base that I should mention.

First, a roundover is routed along the

top edge of the front and sides to create a

moulded edge. I left a small shoulder, as

you can see in detail a above, to create a

45

NOTE: Base sides, front, and back

are18mm-thick hardwood

shadow line. Second, I cut an arch in the

front and sides to lighten up the base.

Finally, I wanted to beef up the frame

joints between the front (E), sides (F) and

back (G). So I added an 18mm-square

hardwood glue blocks to the inside of all

four of the corner joints.

Before gluing the base frame together, I

cut a rebate on the top inside edges of

each part (except the back) to hold the

18mm plywood panel, shown in detail b.

After drilling and countersinking some

mounting holes, the base can be glued

and screwed in place from below. W

Materials, Supplies, & Cutting Diagram

A

B

C

D

E

F

Top (1)

Cove Frame Front (1)

Cove Frame Sides (2)

Frame Filler (1)

Base Front (1)

Base Sides (2)

507 x 482 x 18

495 x 90 x 18

476 x 90 x 18

315 x 90 x 18

477 x 127 x 18

457 x 127 x 18

G

H

I

Base Back (1)

453 x 109 x 18

Corner Glue Blocks (4)

109 x 18 x 18

Base Panel (1)

453 x 445 x 18 - ply

(10) 8g x 32mm Rh Woodscrews w/Washers

(12) 8g x 32mm c/s Woodscrews

2400 x 150 x 25 Cherry

A

2400 x 125 x 25 Cherry

C

1500 x 150 x 25 Cherry

F

Australian Woodsmith No. 41 Online Extras

ALSO NEEDED: One 600 x 600 sheet

of 18mm cherry plywood

2004 August Home Publishing

Das könnte Ihnen auch gefallen

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideVon EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNoch keine Bewertungen

- Coffe TableDokument15 SeitenCoffe TableJun Vargas100% (1)

- 39 Pencil Post BedDokument1 Seite39 Pencil Post BedDavid TuaineNoch keine Bewertungen

- Materials, Supplies & Cutting Diagram: Classic Oak Tool Cabinet - Chest of Drawers OptionDokument1 SeiteMaterials, Supplies & Cutting Diagram: Classic Oak Tool Cabinet - Chest of Drawers OptionDavid TuaineNoch keine Bewertungen

- Free Heirloom TablesDokument18 SeitenFree Heirloom TablesDG100% (1)

- Cove CalculationsDokument1 SeiteCove CalculationsflerziNoch keine Bewertungen

- Z3083 CurlymapledesktoporganizerDokument0 SeitenZ3083 Curlymapledesktoporganizerroose1Noch keine Bewertungen

- 5hop Notes n128 PDFDokument57 Seiten5hop Notes n128 PDFpiedrahecNoch keine Bewertungen

- EZPine Wall ShelfDokument3 SeitenEZPine Wall ShelfBSulliNoch keine Bewertungen

- Pine Cabinet: Project 11142EZDokument5 SeitenPine Cabinet: Project 11142EZBSulliNoch keine Bewertungen

- Fast FixesDokument3 SeitenFast FixesGsmHelpNoch keine Bewertungen

- Materials, Supplies, & Cutting Diagram: Large Craftsman TableDokument1 SeiteMaterials, Supplies, & Cutting Diagram: Large Craftsman TableDavid TuaineNoch keine Bewertungen

- SN 100 - Reducing Rod DiameterDokument1 SeiteSN 100 - Reducing Rod DiameterHomerSimsonnakisNoch keine Bewertungen

- Adega ModularDokument15 SeitenAdega ModularJairoViolinistaNoch keine Bewertungen

- 94 Shooting-BoardDokument6 Seiten94 Shooting-Boardbjørn vidar andersenNoch keine Bewertungen

- 2 - Woodworking Plans - OakplateDokument6 Seiten2 - Woodworking Plans - OakplatemacpatorNoch keine Bewertungen

- Deluxe Router TableDokument27 SeitenDeluxe Router Tableiacob_gilberto6473100% (1)

- Jig For Threaded Inserts: Nline XtrasDokument1 SeiteJig For Threaded Inserts: Nline XtrasJd Diaz100% (1)

- Plansnow MilkpaintDokument3 SeitenPlansnow MilkpaintTa JavoNoch keine Bewertungen

- Cherry ConsoleDokument11 SeitenCherry ConsolekathmartinNoch keine Bewertungen

- Creating A Ring HolderDokument3 SeitenCreating A Ring Holderapi-522254901Noch keine Bewertungen

- Finger Joints: Fast and EasyDokument4 SeitenFinger Joints: Fast and EasyIlberto FortunaNoch keine Bewertungen

- Country Curio Clock: Project 12231EZDokument7 SeitenCountry Curio Clock: Project 12231EZBSulliNoch keine Bewertungen

- Build Your Own French Doors - Popular Woodworking Magazine PDFDokument1 SeiteBuild Your Own French Doors - Popular Woodworking Magazine PDFNei Souza100% (1)

- Woodcraft Magazine - April-May 2009 (Malestrom) PDFDokument84 SeitenWoodcraft Magazine - April-May 2009 (Malestrom) PDFSammy NgussieNoch keine Bewertungen

- Shop Drawings: Modern Power Tool BenchDokument9 SeitenShop Drawings: Modern Power Tool Benchn1856390Noch keine Bewertungen

- wb294 Booknook PDFDokument14 Seitenwb294 Booknook PDFDougNew100% (1)

- Wall MirrorDokument4 SeitenWall Mirrorrayane ouzmihNoch keine Bewertungen

- Cordless Tool ShelfDokument1 SeiteCordless Tool ShelfjuiceNoch keine Bewertungen

- Wall Hung Magazine and Book Rack: Project 14211EZDokument3 SeitenWall Hung Magazine and Book Rack: Project 14211EZBSulliNoch keine Bewertungen

- Garden Bench: Woodworks: Intermediate ProjectDokument9 SeitenGarden Bench: Woodworks: Intermediate ProjectRenos Konstantinou100% (1)

- Lumber Grading ChartDokument2 SeitenLumber Grading ChartKeith BibelhausenNoch keine Bewertungen

- DTC Drawer Slide Jig PDFDokument1 SeiteDTC Drawer Slide Jig PDFJohnNoch keine Bewertungen

- Cabriole Leg PatternDokument4 SeitenCabriole Leg PatternDalmatinoNoch keine Bewertungen

- Portable Sandpaper StorageDokument3 SeitenPortable Sandpaper Storagegmand68100% (1)

- 5 Drawer DeskDokument13 Seiten5 Drawer DeskĠëǿřge PètrǿpoũloŝNoch keine Bewertungen

- FinishDokument4 SeitenFinishGsmHelpNoch keine Bewertungen

- Digital Patterns: Designed by Steve GoodDokument5 SeitenDigital Patterns: Designed by Steve GoodticleanulNoch keine Bewertungen

- 03 PDFDokument68 Seiten03 PDFGeorge Vlad AndronicNoch keine Bewertungen

- SIX-CANDLE CENTERPIECE - Woodsmith ShopDokument5 SeitenSIX-CANDLE CENTERPIECE - Woodsmith ShopEricsNoch keine Bewertungen

- Wooden Puzzle Box PDFDokument18 SeitenWooden Puzzle Box PDFBen GerezNoch keine Bewertungen

- Woodworker's Journal - Vol 34 # 4 - 2010-07-08Dokument75 SeitenWoodworker's Journal - Vol 34 # 4 - 2010-07-08Tomas Tom MlNoch keine Bewertungen

- U-Bild: China SideboardDokument8 SeitenU-Bild: China SideboardEmilian BalutaNoch keine Bewertungen

- Sea ChestDokument2 SeitenSea ChestAnninha Sud AlvesNoch keine Bewertungen

- Adirondack ChairDokument10 SeitenAdirondack ChairNiltonNoch keine Bewertungen

- Arched Aurora NightstandDokument7 SeitenArched Aurora NightstandRoberto LandaNoch keine Bewertungen

- A Choice of Three BookcasesDokument8 SeitenA Choice of Three Bookcasescaballo_blanco_2100% (1)

- SN05216 - Knock Down Workbench PDFDokument10 SeitenSN05216 - Knock Down Workbench PDFtaxmacNoch keine Bewertungen

- Digital Patterns: Designed by Steve GoodDokument12 SeitenDigital Patterns: Designed by Steve GoodRichard PerezNoch keine Bewertungen

- 77 - Cutting Diagram - Pegboard Storage CabinetDokument2 Seiten77 - Cutting Diagram - Pegboard Storage CabinetGsmHelpNoch keine Bewertungen

- Disc Sander Circle JigDokument1 SeiteDisc Sander Circle JigFrancois VaaltynNoch keine Bewertungen

- Milling Machine Patterns and Setup PDFDokument7 SeitenMilling Machine Patterns and Setup PDFpepgoteNoch keine Bewertungen

- ParquetDokument4 SeitenParquetFernando FrayreNoch keine Bewertungen

- 41 Bench Top BookcaseDokument3 Seiten41 Bench Top BookcaseDavid Tuaine100% (1)

- 43two Tiered ChestDokument1 Seite43two Tiered ChestDavid TuaineNoch keine Bewertungen

- 38 Low Base ChestDokument1 Seite38 Low Base ChestDavid TuaineNoch keine Bewertungen

- 21sofatablenotes PDFDokument2 Seiten21sofatablenotes PDFsorix2005Noch keine Bewertungen

- The Best Fee Proposal - ToDokument5 SeitenThe Best Fee Proposal - ToDavid TuaineNoch keine Bewertungen

- Bondor Metecno Roof Guide Tech and InstallDokument2 SeitenBondor Metecno Roof Guide Tech and InstallDavid TuaineNoch keine Bewertungen

- Cyclone Ties SDokument2 SeitenCyclone Ties SDavid TuaineNoch keine Bewertungen

- Side Profile Pattern: Australian Woodsmith No.25 - Letter & Key RackDokument1 SeiteSide Profile Pattern: Australian Woodsmith No.25 - Letter & Key RackDavid TuaineNoch keine Bewertungen

- Guide FormworkDokument13 SeitenGuide FormworkFathimaRiznaAroozNoch keine Bewertungen

- Oval Jewellery Box TemplateDokument1 SeiteOval Jewellery Box Templatepyrrhus56100% (1)

- 43turned Legs PatternDokument1 Seite43turned Legs PatternDavid TuaineNoch keine Bewertungen

- 21 Coffe Table Leg PatternDokument1 Seite21 Coffe Table Leg PatternDavid TuaineNoch keine Bewertungen

- 43dining Table Drawer OptionDokument1 Seite43dining Table Drawer OptionDavid Tuaine100% (1)

- 43locking RebatesDokument1 Seite43locking RebatesDavid TuaineNoch keine Bewertungen

- Anelled Lanket Hest: Nline XtrasDokument2 SeitenAnelled Lanket Hest: Nline XtrasDavid TuaineNoch keine Bewertungen

- 43two Tiered ChestDokument1 Seite43two Tiered ChestDavid TuaineNoch keine Bewertungen

- 42 Oval Jewellery Box LidDokument1 Seite42 Oval Jewellery Box Lidpyrrhus56Noch keine Bewertungen

- Wall Shelf CDDokument1 SeiteWall Shelf CDssixxpacNoch keine Bewertungen

- Materials, Supplies, & Cutting Diagram: Traditional Corner Media Cabinet - Upper CabinetDokument2 SeitenMaterials, Supplies, & Cutting Diagram: Traditional Corner Media Cabinet - Upper CabinetDavid TuaineNoch keine Bewertungen

- 41 Bench Top BookcaseDokument3 Seiten41 Bench Top BookcaseDavid Tuaine100% (1)

- Materials, Supplies, & Cutting Diagram: Large Craftsman TableDokument1 SeiteMaterials, Supplies, & Cutting Diagram: Large Craftsman TableDavid TuaineNoch keine Bewertungen

- 38 Low Base ChestDokument1 Seite38 Low Base ChestDavid TuaineNoch keine Bewertungen

- 39 Bookshelf OptionDokument1 Seite39 Bookshelf OptionDavid TuaineNoch keine Bewertungen

- 34 Storage Bench CDDokument1 Seite34 Storage Bench CDDavid TuaineNoch keine Bewertungen

- Lassic Uffet: Nline XtrasDokument1 SeiteLassic Uffet: Nline XtrasDavid TuaineNoch keine Bewertungen

- 33 Arch Top HeadboardDokument1 Seite33 Arch Top HeadboardDavid TuaineNoch keine Bewertungen

- 32 Insert Jig Raised PanelsDokument1 Seite32 Insert Jig Raised PanelsDavid TuaineNoch keine Bewertungen

- 30 Tool HoldersDokument3 Seiten30 Tool HoldersDavid Tuaine100% (1)

- Haunched Mortise & Tenon: AustralianDokument2 SeitenHaunched Mortise & Tenon: AustralianDavid TuaineNoch keine Bewertungen

- Australian: Drill Bit Speed ChartDokument1 SeiteAustralian: Drill Bit Speed ChartDavid TuaineNoch keine Bewertungen

- House Rules: How to Decorate for Every Home, Style, and BudgetVon EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNoch keine Bewertungen

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiVon EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiBewertung: 4 von 5 Sternen4/5 (3)

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeVon EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeBewertung: 5 von 5 Sternen5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsVon EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (10)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesVon EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNoch keine Bewertungen

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastVon EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastBewertung: 5 von 5 Sternen5/5 (1)

- Timeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersVon EverandTimeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersNoch keine Bewertungen

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysVon EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysBewertung: 4.5 von 5 Sternen4.5/5 (7)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallVon EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallBewertung: 4 von 5 Sternen4/5 (24)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsVon EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsVon EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsBewertung: 5 von 5 Sternen5/5 (1)

- Celtic Line Drawing - Simplified InstructionsVon EverandCeltic Line Drawing - Simplified InstructionsBewertung: 5 von 5 Sternen5/5 (4)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Von EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Noch keine Bewertungen

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreVon EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreBewertung: 5 von 5 Sternen5/5 (5)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestVon EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestBewertung: 5 von 5 Sternen5/5 (2)

- Friends: The One with the Crochet: The Official Crochet Pattern BookVon EverandFriends: The One with the Crochet: The Official Crochet Pattern BookBewertung: 5 von 5 Sternen5/5 (1)

- Tunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Von EverandTunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Bewertung: 5 von 5 Sternen5/5 (3)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionVon EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionBewertung: 4.5 von 5 Sternen4.5/5 (23)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchVon EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchBewertung: 5 von 5 Sternen5/5 (1)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Von EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Bewertung: 3 von 5 Sternen3/5 (2)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreVon EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Creative Watercolor: A Step-by-Step Guide for BeginnersVon EverandCreative Watercolor: A Step-by-Step Guide for BeginnersBewertung: 4 von 5 Sternen4/5 (8)

- Knit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyVon EverandKnit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Crochet Lace: Techniques, Patterns, and ProjectsVon EverandCrochet Lace: Techniques, Patterns, and ProjectsBewertung: 3.5 von 5 Sternen3.5/5 (3)