Beruflich Dokumente

Kultur Dokumente

Valveworks USA 7-1/16

Hochgeladen von

LeandroOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Valveworks USA 7-1/16

Hochgeladen von

LeandroCopyright:

Verfügbare Formate

VALVEWORKS USA

OPERATION AND SERVICE MANUAL FOR 7-1/16

INCH MODEL FM1 GATE VALVES

7-1/16 Model FM1 Studded

Outlet 10,000-20,000 W.P

7-1/16 Model FM1 Flanged

Outlet 10,000 W.P

VALVEWORKS USA

Model FM1 Operation Manual

INTRODUCTION

In appreciation to our customer for purchasing our product, we have prepared this Operation Manual to assist

you in the Operation, Maintenance, Assembly and Installation of the Valveworks USA API 6A 7-1/16 inch

FM1 Gate Valve. We encourage you to follow recommendations in this booklet to attain the best possible

service from our product, which is designed and proven to offer the service one can expect of a quality product.

If you need to contact a representative for more specific information pertaining to a special problem, you should

contact:

EMAIL:

WEBSITE:

VALVEWORKS USA

1650 SWAN LAKE RD.

BOSSIER CITY, LA 71111

PHONE: 318-425-0266

FAX# 318-425-0934

TOLL FREE: 888-425-0266

SALES@VALVEWORKSUSA.COM

WWW.VALVEWORKSUSA.COM

CONTENTS

APPLICATIONS ...............................................................................................................................................3

TEMPERATURE RATING ....................................................................................................................................... 3

TRIM CHART ............................................................................................................................................................. 3

ORDERING INFORMATION .................................................................................................................................. 4

OPERATION ...............................................................................................................................................................4

ASSEMBLY DRAWING ............................................................................................................................................5

BILL OF MATERIALS ..............................................................................................................................................7

ASSEMBLY INSTRUCTIONS .................................................................................................................................. 9

UPPER/LOWER BONNET SUB-ASSEMBLY ......................................................................................... 9

BALL SCREW PREPARATION .......................................................................................................... 11

GATE SUB ASSEMBLY .................................................................................................................... 12

BODY SUB ASSEMBLY ................................................................................................................... 13

BALL SCREW SUB ASSEMBLY ........................................................................................................ 15

FINAL ASSEMBLY .......................................................................................................................... 17

PERIODIC MAINTENANCE.................................................................................................................................. 21

BALL SCREW LUBRICATION ........................................................................................................... 21

VENTING/ DRAINING A VALVE ...................................................................................................... 22

TROUBLESHOOTING ............................................................................................................................................23

MAINTAINANCE INTERVALS.............................................................................................................................24

TEST PROCEDURE.................................................................................................................................................24

HYDROSTATIC BODY TEST ............................................................................................................. 25

HYDROSTATIC SEAT TEST .............................................................................................................. 26

STUDDED OUTLET INSTALLATION/ TESTING .............................................................................................27

VISUAL INSPECTION ............................................................................................................................................29

FIELD HOOK UP INSTRUCTIONS ......................................................................................................................30

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

APPLICATIONS

Valveworks USA 7-1/16 FM1 gate valve unit can be applied to the following sizes and working pressures.

APPLICATION

OPTIONS AVAILABLE

Gate valve size

Valve working pressure

Temperature range

7-1/16

10,000 - 20,000 psi

-60C to 121C (-75F to 250 F)

The flanged outlet gate valve is rated for 10,000 psi work pressure and the studded outlet gate valve of this

product line is rated for 10,000 psi, 15,000 psi and 20,000 psi.

TEMPERATURE RATING

Temperature

classification

K

L

N

P

S

T

U

V

Operating Range

Min.

C

Max.

Min.

(F)

Max.

-60

-46

-46

-29

-18

-18

-18

2

82

82

60

82

60

82

121

121

-75

-50

-50

-20

0

0

0

35

180

180

140

180

140

180

250

250

TRIM CHART

Material class

AA - General service

BB - General service

CC - General service

DD - Sour service a

EE - Sour service a

FF - Sour service a

HH - Sour service a

Minimum Material Requirements

Pressure-controlling

Body, bonnet, end and

parts, stems and mandrel

outlet connections

hangers

Carbon or low-alloy steel

Carbon or low-alloy steel

Stainless steel

Carbon or low-alloy steel b

Carbon or low-alloy steel b

Stainless steel b

CRAs b

As defined by NACE MR 0175.

In compliance with NACE MR 0175.

Carbon or low-alloy steel

Stainless steel

Stainless steel

Carbon or low-alloy steel b

Stainless steel b

Stainless steel b

CRAs b

As shown by API-6A. For specific details, consult Valveworks USA.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

ORDERING INFORMATION

The following information should be provided with any request for quote or order placement of Valveworks

USA 7-1/16 FM1 Gate Valves:

API 6A Requirements (PR-PSL)

Temperature Rating (API 6A)

Material (API 6A)

Any Special Test Requirements

Any Special Material Requirements

Any Special Coating or Protection Requirements

Other Specifications and/or Certifications

OPERATION

The Valveworks USA Model FM1 gate valves are Ball Screw operated valves. The gate of the MODEL FM1

Valve is a one piece slab gate that uses two floating seats to generate a highly reliable seal. The slab gate

eliminates the chance of trapping pressure within the body cavity which can cause pressure locking.

Fully open the valve before installing or shipping. The sealing area of the gates, in the full open position, is

protected by the body and is less likely to be damaged.

Do not remove the molybdenum disulfide coating from internal parts. This coating serves as a lubricant and

corrosion inhibitor.

To hydrostatically test the valve body to full API test pressure, the valve must be in a partially open

position. When testing the valve in the closed position (seat test) do not exceed the working pressure

stamped on the valve identification plate.

During storage always leave the valve in the fully opened or fully closed position. This will tightly wedge

the gate against the seats and prevent damage to the sealing area of both the gate and seats.

Always remove the valve from service before work is performed on the stem bearings.

When lubricating the body do not exceed the maximum API working pressure stamped on the identification

plate.

The valve should be fully closed or fully opened during lubrication of the body or seats. Seat lubrication

pressures should not exceed the maximum allowable API test pressure.

This method of operation will prevent damage to the sealing surfaces of the gate and seats, and will increase the

life of the valve.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

ASSEMBLY DRAWING OF MODEL FM1 GATE VALVE

FLANGED END

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

STUDDED END

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

BILL OF MATERIALS

FLANGED OUTLET

ITEM

PART NO

DESCRIPTION

QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

290-FM1-77XY

291-FM1-77XY

380-FM1-7700

313-FM1-77XY

340-FM1-77XY

341-FM1-77XY

356-FM1-7700

351-FM1-7700

352-FM1-7700

353-FM1-7700

306-FM1-77XY

354-FM1-77XY

321-FM1-77XY

334-FM1-77XY

343-FM1-7700

155-FM1-7700

397-7700

377-FM1-7700

374-FM1-7700

345-FM1-7700

346-FM1-77XY

387-FM1-77XY

381-FM1-7700

373-77XY

369-77XY

348-77XY

349-77XY

347-7700

096-7700

101-0000

109-0001

1173261

1173303

1173462

64313

400-0002

BODY, FLANGED

BONNET

HANDWHEEL

BONNET SEAL RING

STEM, OPERATING

STEM, BALANCING

GATE NUT

PACKING

PACKING RETAINER NUT

PACKING RETAINER LOCKNUT

GATE, SLAB

GATE GUIDE

SEAT, FLOATING RC

SEAT SEAL, FLOATING RC

STEM PROTECTOR

HOUSING, BALL SCREW

BALL SCREW, LH THREAD

BAERING SPACER, LOWER

BEARING SPACER, UPPER

COVER PLATE

STEM ADAPTER

GLAND, BACKSEAT

HANDWHEEL NUT

BEARING INTERNAL- NHTA-5280

BEARING, EXTERNAL

SNAP RING, SPIROLOX

ROD WIPER

O-RING

STUD W/ NUT, B7

BODY GREASE FITTING

ALEMITE GREASE FITTING

SET SCREW, 1/4 X 3/4 LG.

SET SCREW, 3/8 X 3/4 LG.

CAP SCREW, 1/4 X 1 LG.

PIN SPRING

GREASE

1

2

1

2

1

1

2

2

2

2

1

2

2

2

1

1

1

1

1

1

1

1

1

2

1

1

1

2

24

2

3

3

4

4

1

25 LBS

The last two digits in the part nos vary with X - Material Type and Y Coating. The table below gives the

different available material types and coatings. Please refer to the valve tag to know the material type and

coating on the valve parts.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

STUDDED OUTLET

ITEM

PART NO

DESCRIPTION

QTY

1

2

30

298-FM1-87XY

291-FM1-87XY

103-0000

BODY, STUDDED

BONNET

AUTOCLAVE FITTING

1

2

2

The Bill of Material for the flanged outlet and the studded outlet is the same except the ones tabulated above.

The body and bonnet vary for the tow products and the studded outlet valve uses Autoclave Fittings instead of

Body Grease Fittings.

1

1A

1B

1C

1D

1E

1F

2

2A

3

3A

4

4A

4B

5

6

6A

6B

7

8

8A

8B

8C

8D

8E

9

9A

9B

MATERIAL

TYPE

COATING

4130

4140

1040

1018

1020

SA285-C

1026

410SS FORGED

S42400

174SS

NITRONIC 50

316SS

316/304SS

304SS

BRONZE

INCONEL 718

INCONEL 725

INCONEL X750

MONEL

A487-4D

A487-4C

CA15

CF8M

CF3M

CA6NM

STELLITE #6

PLASTIC

STELLITE #3

NONE;

PHOSPHATE,

MOLY, STANDARD

PAINT/COATING,

POWDER COAT

NITRIDE QPQPHOSPHATE;

EXCEPTION - FC

BODY BUSHING DO NOT NITRIDE

HARDFACESTELLITE #6

SPRAY & FUSE

HARDFACE TUNGSTEN

CARBIDE

HARDFACE COLMONOY #5

ELECTROLIS

NICKEL

WELD ON

HARDFACE

ZINC PLATE

XYLAN COATING

(4130) INCONEL

625 CLAD

(4130)SS-316-RING

GROOVE

4

5

6

7

8

9

9A

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

ASSEMBLY INSTRUCTIONS

The following steps have to be followed before assembly of any component of the FM1 gate valves.

Assembly work area must be clean and free of dirt, metallic shavings and wood particles.

Surface preparation of work area should be metallic or covered with a layer of corrugated cardboard.

All lubricants and utensils used in assembly must be clean.

All tools used in assembly must be clean and in good working order.

Clean all components (metallic) prior to assembly.

Keep all elastomers and plastic base materials in bags or boxes until needed for assembly.

Inspect all components for burrs, dings, marks, scrapes, nicks, and etc. prior to assembly.

UPPER / LOWER BONNET SUB-ASSEMBLY

7 1/16 10/15M FM1 bonnet before assembly

Apply anti-seize compound to the inner threads

of the bonnet.

Tighten the packing retainer with an expanding wrench.

Insert a packing set into the bonnet as shown,

and push it down.

Screw in the packing retainer.

Screw in the packing retainer locknut.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FM1 Operation Manual

Tighten the packing retainer locknut with an

expanding wrench as well.

The next step is to insert the studs into the

bottom of the valve body.

Coat the threads of the body/bonnet stud holes

with anti-seize compound and screw in the studs.

Tighten the studs using a certified impact wrench.

Insert the bonnet seal ring as shown.

Place the bonnet on the body over the studs

and screw a hex nut onto each stud.

Tighten the hex nuts onto the studs using

an impact wrench.

Coat a 5/8 set screw with anti-seize coat and screw

into 6 gear attachment holes around the bonnet.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

10

VALVEWORKS USA

Tighten each of the set screws with a

5/8 Allen wrench.

Model FM1 Operation Manual

Coat the outer threads and screw the balance

stem protector down until tight.

NOTE: PLACE THE LOWER BONNET WHERE THE GREASE FITTING POINTS

TOWARDS ONE OF THE NON-CONNECTED SIDES OF THE VALVE.

BALL SCREW PREPARATION

Screw the operating stem into the travel

screw of the ball screw assembly.

The shoulder of the stem should make contact with the

bottom of the travel screw similar to the sample above.

CAUTION: Do not allow the travel screw to unscrew from the ball screw nut in either

direction. This will cause the ball screw to de-ball itself.

When assembling more than one valve, it is a good

idea to label or number the travel screw and its

specific operating stem to ensure that the two will

assemble correctly.

Mark the location of 2 socket set screw holes

with a hammer and transfer punch.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

11

VALVEWORKS USA

The transfer punch will leave an

indentation in two places like the one

shown above.

Model FM1 Operation Manual

Unscrew the operating stem from the ball screw

assembly, and drill 2 drill point depth holes at the

marked locations with a 0.25 drill. The finished

stem should appear similar to the one shown

above.

GATE SUB ASSEMBLY

Coat the outer threads with anti-seize coating.

Align the balance stem into the slot of the

gate, screw on the gate nut and tighten it

with an oil filter wrench.

Insert the balance stem into the gate nut.

Insert 4 -20UNC socket screws

around the gate nut and tighten them

with an allen wrench.

NOTE: The placement of balance stem depends on whether the valve will be direct operating

or reverse acting.

REPEAT THE STEPS FOR ASSEMBLY OF OPERATING STEM.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

12

VALVEWORKS USA

Model FM1 Operation Manual

The completed gate assembly should

appear similar to the one above.

BODY SUB ASSEMBLY

Coat the threads of the body/bonnet stud holes.

Insert the studs into the top of the valve body.

Tighten the studs onto the body using a studtightening bolt and a certified impact wrench.

Grease the back and backside of the seats, grease

and insert the external seal rings into the seal ring

grove of each of the seats.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

13

VALVEWORKS USA

Insert the greased end of the seat into the seat

pockets as shown.

Insert the bonnet seal ring.

Lower the gate assembly into the body. It should fit

between the seats and gate guides while the balance

stem travels thru the hole in the lower bonnet.

Model FM1 Operation Manual

Insert the gate guides on top of the seats as shown.

NOTE: The flat side should be on the top.

The body cavity should appear as shown with

the seats, gate guides and the bonnet seal ring.

The operating stem should stand up as shown above.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

14

VALVEWORKS USA

Model FM1 Operation Manual

BALL SCREW SUB ASSEMBLY

Raise the gate up until the stem is back seated.

Then, lay the valve down. The operating stem

should protrude as shown above.

Place the snap ring onto the other side

of the lower bearing spacer.

Place the upper bearing spacer on the ball

screw as shown above.

Place a bearing-race set over the travel screw

and onto the upper bearing spacer.

Place a 350 o-ring on the lower bearing

spacer as shown above.

Place the lower bearing spacer (snap ring end first) over

the operating stem. Be careful not to scratch the stem.

The ball screw should rest in the recess

area on the spacer as shown.

Screw the travel screw onto the top threads

of the operating stem as shown above.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

15

VALVEWORKS USA

If it is not already, unscrew the ball screw, with the

upper bearing spacer and bearing-race set, to reveal 2

holes for socket set screws as shown above.

Model FM1 Operation Manual

Adjust Lower Bearing Spacer where milled slot

is in line with spring pin. Use a 3/8 spring pin to

hold it in place.

Roll the ball screw nut, upper bearing spacer, and

bearing-race set back onto the lower bearing spacer.

Then, apply anti-seize compound to the threads of

the ball screw nut as shown above.

Screw the stem adapter onto the ball

screw nut as shown above.

Wipe any excess anti-seize compound from

underneath the stem adapter and cover the upper

bearing spacer and bearing-race set.

Weld the stem adapter to the

ball screw nut as shown.

Place a bearing-race set onto the stem

adapter as shown above.

Grease the lower bearing-race set that is

between the upper and lower bearing spacers.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

16

VALVEWORKS USA

Grease the upper bearing-race set that is

resting on the stem adapter.

Model FM1 Operation Manual

The greased ball screw assembly should appear

very similar to the one shown above.

CAUTION: Do not allow the travel screw to unscrew from the ball screw nut in either

direction. This can cause the ball screw to de-ball.

FINAL ASSEMBLY

Unscrew the ball screw assembly until there is

approximately a 4.25 space between the bottom of

the lower bearing spacer and the top of the upper

bonnet. Use a jack-bolt to secure the space.

Insert and tighten 3 Alemite grease fittings into the 3

holes along the outside of the ball screw housing.

Coat the outer threads of the upper

bonnet with anti-seize compound.

The top of the ball screw housing

should appear as shown.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

17

VALVEWORKS USA

Grease and insert the XLS bearing into

the top of the ball screw housing.

Model FM1 Operation Manual

Grease the inner surface of the ball screw housing

and place the cover plate onto the greased surface.

Align the holes on the cover plate with the holes on the top of the ball screw housing, insert & tighten

(4) -20UNC socket head cap screws thru the cover plate into the ball screw housing.

Place the ball screw housing over the stem

adapter as shown above, and push the housing

down until it rests on the bearing-race set.

Insert a snap ring into the snap ring groove which

is located about 2 7/8 inches inside the ball screw

housing.

Remove the jack-bolt, and the final assembly

should appear similar to the assembly above.

After inserting the snap ring, push the ball screw housing

onto the outer threads of the upper bonnet. Then, screw the

ball screw housing onto the upper bonnet.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

18

VALVEWORKS USA

Once the housing is on the threads, you can use

a strap wrench to tighten it down. Again, you

will periodically rotate the stem adapter

counterclockwise to allow the housing to move.

Lightly coat a NPT grease fitting (or 9/16

Autoclave for 15 kpsi) with anti-seize compound,

and insert it into the upper bonnet.

Model FM1 Operation Manual

Insert a -20 UNC tap bolt into the ball

screw housing, and tighten it with a

crescent wrench.

Tighten the grease fitting with an impact

wrench.

NOTE: Periodically, turn the stem adapter counterclockwise to loosen the ball screw nut

to allow the ball screw housing to screw on completely.

The finished upper bonnet assembly should appear as shown.

REPEAT THE STEPS FOR THE LOWER BONNET TOO.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

19

VALVEWORKS USA

Place the hand wheel onto the stem adapter.

Place a 222 o-ring onto the gland backseat.

Turn the hand wheel counterclockwise until it stops.

Measure the gap between the gland backseat

and stem adapter with a Feeler gauge.

Model FM1 Operation Manual

Tighten the hand wheel onto the stem

adapter with a handwheel nut.

Screw the gland backseat into the stem adapter.

Leave the stem adapter unscrewed about 0.500.

Screw the gland backseat into the stem

adapter the rest of the way.

Unscrew the gland backseat and have the distance

of the gap trimmed off the thread side of it.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

20

VALVEWORKS USA

Coat the trimmed gland backseat with

anti-seize compound.

Model FM1 Operation Manual

Screw it back into the stem adapter

completely.

PERIODIC MAINTAINANCE

The Model FM1 gate valves are non-lubricated valves, in that they do not require the injection of lubricants or

sealants to effectively seal. However, to prevent corrosion and excessive wear a normal amount of lubrication is

recommended to extend the life and serviceability of the valve.

Maintenance Tools

To perform normal maintenance and lubrication, the following tools are recommended:

Grease pump with adapter and coupling

Safety pressure releasing tool

Valveworks USA API Gate Valves at 15,000 PSI W.P. are supplied with 9/16" 17-4SS autoclave fitting

connections.

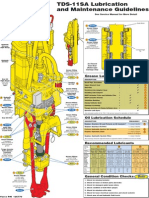

BALL SCREW BEARING LUBRICATION

Valveworks USA FM1 valves are equipped with alemite hydraulic type 1/8" NPT bonnet grease fittings. Ball

Screw bearing lubrication is accomplished through this fitting using a standard type grease gun. Any good grade

No. 3 grease is recommended for this lubrication. Ball screw bearings normally do not require great amounts of

grease. If too much lubrication should occur, excess grease will flow around the stem to the atmosphere.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

21

VALVEWORKS USA

Model FM1 Operation Manual

CAUTION: If bearings should need to be changed, the valve must be removed from service. During

pressurized valve body lubrication, pressure applied to the valve body with the grease gun must not exceed the

maximum working pressure of the valve being lubricated.

VENTING OR DRAINING A VALVE

Most products contain a certain amount of water, line scale, sediment and other foreign matter which tend to

accumulate in the valve body. A regular draining program will increase the life of a valve against damage

caused by:

Water freezing in the body cavity, causing damage to the body.

An accumulation of foreign matter in the lower part of the body, which could prevent the valve from fully

closing, resulting in a throttling action which may cause inefficient sealing.

Foreign matter trapped in the body may become lodged between the sealing surfaces of the gate and seats,

resulting in scored or damaged sealed.

Venting a Model FM1 valve is a positive method of checking the sealing ability of the gate and seats. If the

body vents down to zero pressure with the valve in fully closed position, this is definite indication that

sealing surfaces are in good condition.

PROCEDURE TO VENT OR DRAIN

Place the valve gate in a fully opened or fully closed position.

Remove the safety cap from either

body grease fitting

Attach the pressure release tool.

CAUTION: Remove the safety cap slowly to allow the ball check to sufficiently seal and avoid

uncontrolled venting. Should the ball check fail to seal properly, pressure will continue to blow through

the safety cap orifices. You should then retighten the safety cap screw and vent through the other body

grease fitting. Once the body pressure is bled to zero you should then attempt to repair the leaking ball

check.

Screw the stem of the releasing tool into the fitting forcing the ball check off its seat. The valve will vent

and drain once the ball check is unseated.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

22

VALVEWORKS USA

Model FM1 Operation Manual

A program of regular draining and body venting is the most positive way to prevent problems caused by foreign

matter in the valve. However, if a regular draining program cannot be followed, it is recommended that valves

be drained after the following operations:

After a well has come in and has been cleaned up.

After a mudding operation.

After a cementing operation.

Anytime the valve seems hard to operate by hand and will not fully open or close by the required number of

hand wheel turns.

When the valve is hard to operate from the fully open or fully closed position because it is "pressure locked"

or "Iced-up".

"Pressure locked" is a condition that may exist with any dual seat expanding type gate valve when body

pressure greatly exceeds line pressure. It occurs only in fully closed position and is a positive indication that

sealing surfaces are in good condition.

"Iced-up" is a condition caused by a restriction in the flow or a differential in the pressure of gas flow at high

pressure, which produces extremely low temperatures.

These restrictions or differentials in pressure may be caused by throttling through a valve, by leakage of a

closed valve or by Leakage through the stem packing. Valves in service on gas containing hydrates or in fresh

water service, exposed to low external temperatures may also "iced-up". In this case it is advisable to inject

alcohol or glycol into the valve body through the drain fitting to combat these conditions.

The same procedures are used for injecting alcohol or glycol as are used for valve body lubrication. Do not

operate the valve immediately after injecting as these fluids should be retained in the body to perform the

Antifreeze effect.

TROUBLESHOOTING

PROBLEM

Leakage when closed

CAUSE

Seats

Leakage when open through

body/bonnet connection

Leakage when partially open

thru top of bonnet

Leakage at flange

Bonnet Seal

Ring

Packing

Flange Seal

Ring

SOLUTION

Disconnect from service and check for

the condition of the seats.

Disconnect from service and replace

the bonnet seal ring

Disconnect from service and replace

the packing

Disconnect from service and replace

the flange seal ring.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

23

VALVEWORKS USA

Model FM1 Operation Manual

MAINTAINANCE INTERVALS

Procedure

Vent or Drain

Cycle Open to Close

Disconnect and Test

Recommended Interval

See Page

Semi-Annually

Annually

TEST PROCEDURE

Grease and insert a BX156 ring joint into one of

the body flanges. Note: Refer to the end of the

manual for studded outlet to prepare for testing.

Be sure that the test flange has a tightened grease

fitting, all of its studs, and a nut on each with all

of the nuts on the grease fitting side as shown.

Align the test flange studs with the body flange

holes. Then, push the test flanges, its studs, and

their hex nuts onto the body flange.

Screw the each hex nut on the vacant side of a

stud as shown until all of the studs have a nut on

the test flange and the valve flange.

Tighten the hex nuts on the test flange side

with an impact wrench until they are tight.

A finished flange should appear as shown.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

24

VALVEWORKS USA

Model FM1 Operation Manual

NOTE: Repeat the above steps for the opposite flange.

Remove the grease fitting cap from one test flange

and attach a pressure release tool as shown above.

Remove the grease fitting cap from the opposite

test flange and attach the flow line as shown above.

Hydrostatic Body Test

With the pressure release tool and flow line connection tight, open the valve partially, and apply the test

pressure for at least three (3) minutes.

Bleed off the pressure until its reduced to

zero, and close the pressure release tool.

Raise the pressure back up to the test pressure for the secondary pressure-holding period of at least three (3)

minutes.

Bleed off the pressure until its reduced to zero. Then, close the pressure release tool and the valve.

The hydrostatic body test pressure shall be determined by the rated working pressure of the equipment.

Hydrostatic test pressures shall be as given as tabulated below.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

25

VALVEWORKS USA

Model FM1 Operation Manual

HYDROSTATIC BODY TEST PRESSURE, PSI (MPa)

Working

Pressure

Rating - PSI (Mpa)

2,000

3,000

5,000

10,000

15,000

20,000

(13,8)

(20,7)

(34,5)

(69,0)

(103,4)

(138,0)

End and

Outlet

Connections - PSI (Mpa)

4,000

6,000

7,500

15,000

22,500

30,000`

(27,6)

(41,4)

(51,7)

(103,4)

(155,2)

(207,0)

Line Pipe

and Tubing

Threads - PSI (Mpa)

4,000

6,000

7,500

15,000

-

(27,6)

(41,4)

(51,7)

(103,4)

-

Hydrostatic Seat Test

With the valve closed, apply the rated working pressure.

Hold and monitor at that pressure for at least three (3) minutes.

Open the valve, and bleed off the pressure until its reduced to zero. Then, close the valve and the pressure

release tool.

Repeat the steps above.

Switch the sides of your flow and pressure release connections, bleed off the new pressure release side, and

repeat steps above to perform a seat test on the new flow side.

The valve is acceptable if no leakage is visible during the holding period.

While holding the hex nuts on the body flange,

loosen each of the test flange hex nuts.

After removing the body flange hex nuts, you can

remove the test flange, its studs, and their hex nuts.

Pass a drift mandrel through the valve bore after

the valve has been assembled, operated, and

pressure tested.

Remove the upper bonnet grease fitting cap, and

attach a flow line from the grease pump to the

grease fitting as shown above.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

26

VALVEWORKS USA

Remove the lower bonnet grease fitting cap, and

attach a pressure release tool as shown above.

Model FM1 Operation Manual

After the valve is accepted, it is tagged with a

green or blue tag before being painted.

STUDDED OUTLET INSTALLATION/ TESTING

Coat the threads of each hole with antiseize compound.

Grease and insert the BX156 ring joint

into the valve ring groove.

Screw the 1.50 thread length side of each pad

stud into an empty, coated hole.

Tighten each stud with a pipe wrench.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

27

VALVEWORKS USA

Model FM1 Operation Manual

Place a test flange, with a grease fitting

installed, onto the studs.

Lightly coat the exposed threads of the pad

stud with anti-seize compound.

Screw a hex nut onto each of the exposed

pad studs.

Tighten the hex nuts with a certified

impact wrench.

Repeat the above steps to install the other test flange.

NOTE: A test flange is shown in this manual, but the service flange will use the same nuts

and bolt circle.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

28

VALVEWORKS USA

Model FM1 Operation Manual

VISUAL INSPECTION

Before installing a Valveworks USA Model FM1 valve in the field, here are a few items to visually inspect:

Be sure the upper bonnet grease

fitting cap is on and tight.

Be sure the upper bonnet grease

fitting cap is on and tight.

Be sure the Alemite fittings are on

and tight.

Be sure the Hand wheel Nut is

tight

Be sure the gate is in the fully open

or fully closed position

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

29

VALVEWORKS USA

Model FM1 Operation Manual

FIELD HOOK UP INSTRUCTIONS

Grease and insert ring joint into the

valve flange.

Align the service flange holes with the body flange

holes. Push a stud thru each aligned hole until there is a

stud thru each hole. Screw a hex nut on both sides of

each stud by hand.

Torque the service flange hex nuts with a

certified torque gun until they are tight.

A finished flange should appear as

shown.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

30

Das könnte Ihnen auch gefallen

- Model fm4Dokument25 SeitenModel fm4LeandroNoch keine Bewertungen

- Stripper TOT 2.50 10M DS34 TechMan1146Dokument13 SeitenStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaNoch keine Bewertungen

- Bop1006 b73s33s-3r2l3l-35h-0Dokument1 SeiteBop1006 b73s33s-3r2l3l-35h-0api-513539506Noch keine Bewertungen

- Product Information Bulletin: Date: Bulletin Number: 1000059437-PIB Revision: 01Dokument7 SeitenProduct Information Bulletin: Date: Bulletin Number: 1000059437-PIB Revision: 01carlosorizabaNoch keine Bewertungen

- Maintenance Schedule For Adapter Flange - 5131086 - 01Dokument7 SeitenMaintenance Schedule For Adapter Flange - 5131086 - 01franko guddiNoch keine Bewertungen

- 1PackerSystem PackerAccessories&tools PDFDokument21 Seiten1PackerSystem PackerAccessories&tools PDFAnand aashishNoch keine Bewertungen

- CHAMP® XHP PackerDokument2 SeitenCHAMP® XHP PackerservicemenruNoch keine Bewertungen

- Introduction 15K H2S PCEDokument4 SeitenIntroduction 15K H2S PCEJuanNoch keine Bewertungen

- Parker HTR ActuatorDokument22 SeitenParker HTR ActuatorYorkistNoch keine Bewertungen

- M60eh44 Man 001Dokument40 SeitenM60eh44 Man 001Riski KurniawanNoch keine Bewertungen

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDokument34 SeitenTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopPastor VelasquezNoch keine Bewertungen

- Check Valve MS PDFDokument4 SeitenCheck Valve MS PDFazeazeazeNoch keine Bewertungen

- Os Gui Berson Product CatalogDokument61 SeitenOs Gui Berson Product CatalogDicky RKNoch keine Bewertungen

- Kline General CatalogDokument30 SeitenKline General CatalogservicemenruNoch keine Bewertungen

- DPC PDFDokument94 SeitenDPC PDFjquevedo8237Noch keine Bewertungen

- Te ValveDokument30 SeitenTe Valvecrni roko100% (2)

- Oilfield Union Color Code GuideDokument5 SeitenOilfield Union Color Code Guidelalberto96Noch keine Bewertungen

- DL Bop BrochureDokument4 SeitenDL Bop BrochureIRWIN_DSOUZANoch keine Bewertungen

- Jar Safety Clamps 2010Dokument21 SeitenJar Safety Clamps 2010Oswal Agusto Cabrera PantojaNoch keine Bewertungen

- TECH MANUAL FOR 3.06 10M "EKDokument25 SeitenTECH MANUAL FOR 3.06 10M "EKJose Leonardo Materano Perozo100% (1)

- 25k Bop FlyerDokument1 Seite25k Bop FlyersyedainahmadNoch keine Bewertungen

- Fabritech Globular® GBOP User Manual REV.1Dokument50 SeitenFabritech Globular® GBOP User Manual REV.1Joel S100% (1)

- FSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes ReliabilityDokument2 SeitenFSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes Reliabilitymehmet sait öztürkNoch keine Bewertungen

- Rupture Disk FUL-FLO Sampler: HalliburtonDokument2 SeitenRupture Disk FUL-FLO Sampler: Halliburtonsaeed65Noch keine Bewertungen

- Test Pump WindlassDokument40 SeitenTest Pump WindlassMd.farman Ali AhmedNoch keine Bewertungen

- National Oilwell Varco: Distributed by EESDokument2 SeitenNational Oilwell Varco: Distributed by EESG MahendraNoch keine Bewertungen

- Low Force Shear Ram Test Results SummaryDokument2 SeitenLow Force Shear Ram Test Results SummaryBala KrishnanNoch keine Bewertungen

- Design Overview: Basic Design and Maintenance InstructionsDokument5 SeitenDesign Overview: Basic Design and Maintenance Instructionsazze bouzNoch keine Bewertungen

- Wireline Pressure Control EquipmentDokument6 SeitenWireline Pressure Control EquipmentArielNoch keine Bewertungen

- TlbopDokument7 SeitenTlbopadvantage025Noch keine Bewertungen

- M60es54 Na549y QC Man 001Dokument29 SeitenM60es54 Na549y QC Man 001Riski Kurniawan67% (3)

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDokument6 SeitenCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- DSQ4 10M SidedoorDokument15 SeitenDSQ4 10M SidedoorДудла СтаніславNoch keine Bewertungen

- 1522 FZ54-35U Ram BOPDokument42 Seiten1522 FZ54-35U Ram BOPAsif JalgaonkarNoch keine Bewertungen

- 003 Casing & Tubing Hanger PDFDokument4 Seiten003 Casing & Tubing Hanger PDFalaliali88Noch keine Bewertungen

- Operating and Service Manual For Hyd. Act. Series 4000,5000,6500Dokument24 SeitenOperating and Service Manual For Hyd. Act. Series 4000,5000,6500Mehdi Norouzi100% (1)

- COS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronDokument5 SeitenCOS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronYudaNoch keine Bewertungen

- Anson Gate Valves, Manifolds, and TreesDokument9 SeitenAnson Gate Valves, Manifolds, and TreesBala KrishnanNoch keine Bewertungen

- CT WKM Powrseal GateDokument28 SeitenCT WKM Powrseal GatemoonanbuNoch keine Bewertungen

- Equipment FlyerDokument7 SeitenEquipment FlyerCatalin StoicescuNoch keine Bewertungen

- Trex 03168Dokument1 SeiteTrex 03168OSDocs2012Noch keine Bewertungen

- Maintain & operate Regan Type K BOPDokument4 SeitenMaintain & operate Regan Type K BOPAshok SureshNoch keine Bewertungen

- 3in BOP Inner & Outer SealsDokument1 Seite3in BOP Inner & Outer SealsusamakhattakNoch keine Bewertungen

- Completion 4Dokument36 SeitenCompletion 4AboZaidNoch keine Bewertungen

- Stripper Packer DSV4 3.06 1 VentanaDokument12 SeitenStripper Packer DSV4 3.06 1 VentanaValeria Sanchez100% (1)

- 5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SDokument2 Seiten5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SAbhinav KumarNoch keine Bewertungen

- Hydril Annular BOP1Dokument2 SeitenHydril Annular BOP1Abde EsselamNoch keine Bewertungen

- Shaffer Ram & Spherical Blowout Preventer PartsDokument5 SeitenShaffer Ram & Spherical Blowout Preventer PartsJIN WANGNoch keine Bewertungen

- Product Safety Alert: 22 February 2021Dokument4 SeitenProduct Safety Alert: 22 February 2021carlosorizabaNoch keine Bewertungen

- D392005428-MKT-001 6012 Bop PDFDokument2 SeitenD392005428-MKT-001 6012 Bop PDFMitul PatelNoch keine Bewertungen

- Cameron Dual Bore FLEXPACKERDokument1 SeiteCameron Dual Bore FLEXPACKERTitanBOPNoch keine Bewertungen

- Down Hole Assembly PDFDokument13 SeitenDown Hole Assembly PDFOvRrj AhmedNoch keine Bewertungen

- Quality Blowout Preventer SpecificationsDokument12 SeitenQuality Blowout Preventer SpecificationsLeonardo Alvarez100% (1)

- T-2 On/Off Tool Technical DatasheetDokument2 SeitenT-2 On/Off Tool Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Dokument21 SeitenTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNoch keine Bewertungen

- HP Auto Clave FittingsDokument1 SeiteHP Auto Clave FittingsRavi Chaitanya VelamarthyNoch keine Bewertungen

- Ds Shearing Blind Ram Tc1399Dokument2 SeitenDs Shearing Blind Ram Tc1399Gregory StewartNoch keine Bewertungen

- API 6A Valve Parts CatalogDokument144 SeitenAPI 6A Valve Parts CatalogAnggi SujiwoNoch keine Bewertungen

- Model FCDokument23 SeitenModel FCLeandroNoch keine Bewertungen

- Operation and Service Manual for Valveworks USA Model M and MSG Gate ValvesDokument26 SeitenOperation and Service Manual for Valveworks USA Model M and MSG Gate ValvesAshok SureshNoch keine Bewertungen

- 108 73000e Pump Down Cement FloatDokument2 Seiten108 73000e Pump Down Cement FloatLeandroNoch keine Bewertungen

- Well Service Pump Reference Guide - Weir SPMDokument55 SeitenWell Service Pump Reference Guide - Weir SPMGeorge Buitrago91% (11)

- OFD FEPP Prod Catalog Low ResDokument170 SeitenOFD FEPP Prod Catalog Low ResVictor Moises Vite SanchezNoch keine Bewertungen

- Omega 600S ManualDokument36 SeitenOmega 600S ManualLeandroNoch keine Bewertungen

- Pump Parts For All RIGsDokument1 SeitePump Parts For All RIGsLeandroNoch keine Bewertungen

- National Board Inspection Code (NBIC) R'Dokument2 SeitenNational Board Inspection Code (NBIC) R'Leandro0% (1)

- FA1300Dokument15 SeitenFA1300LeandroNoch keine Bewertungen

- FB1600 Part Numbers NatOilDokument1 SeiteFB1600 Part Numbers NatOilLeandroNoch keine Bewertungen

- MSC RD 19440 PDFDokument13 SeitenMSC RD 19440 PDFJairo WilchesNoch keine Bewertungen

- Stress Concentration Factors in T-HeadsDokument27 SeitenStress Concentration Factors in T-HeadsLeandroNoch keine Bewertungen

- Iso 9001 2008 Checklist Sample Rev 2-20-09usDokument8 SeitenIso 9001 2008 Checklist Sample Rev 2-20-09usRonaldSincheNoch keine Bewertungen

- API Spec q1 9th EditionDokument3 SeitenAPI Spec q1 9th Editionvtsusr fv80% (5)

- Webq2 140617151212 Phpapp02 PDFDokument21 SeitenWebq2 140617151212 Phpapp02 PDFLeandroNoch keine Bewertungen

- Webq1 140617150850 Phpapp01 PDFDokument20 SeitenWebq1 140617150850 Phpapp01 PDFLeandroNoch keine Bewertungen

- Gk11 5 (6609B)Dokument37 SeitenGk11 5 (6609B)LeandroNoch keine Bewertungen

- Catalog PDFDokument222 SeitenCatalog PDFLeandro100% (1)

- Shaffer LXT 7-5M-User ManualDokument75 SeitenShaffer LXT 7-5M-User ManualLeandroNoch keine Bewertungen

- Gate Valve Maintenance ManualDokument27 SeitenGate Valve Maintenance ManualLeandro100% (1)

- Optimal Shape Design of Shoulder Fillets For Flat and Round Bars Under Various LoadingsDokument14 SeitenOptimal Shape Design of Shoulder Fillets For Flat and Round Bars Under Various Loadingsstefan.vince536Noch keine Bewertungen

- NSK CAT E1102m B234-243Dokument5 SeitenNSK CAT E1102m B234-243LeandroNoch keine Bewertungen

- Optimal Shape Design of Shoulder Fillets For Flat and Round Bars Under Various LoadingsDokument14 SeitenOptimal Shape Design of Shoulder Fillets For Flat and Round Bars Under Various Loadingsstefan.vince536Noch keine Bewertungen

- Bolt Head Stress Concentration Factors in Cylindrical Pressure VesselsDokument6 SeitenBolt Head Stress Concentration Factors in Cylindrical Pressure VesselsLeandroNoch keine Bewertungen

- Model FCDokument23 SeitenModel FCLeandroNoch keine Bewertungen

- 10 HP M2a Right Angle ManualDokument21 Seiten10 HP M2a Right Angle ManualSonthiMNoch keine Bewertungen

- MCM Oil Tools: 10422 W. Gulf Bank RD., Houston, Texas 77040Dokument29 SeitenMCM Oil Tools: 10422 W. Gulf Bank RD., Houston, Texas 77040LeandroNoch keine Bewertungen

- Gate Valve Parts CatalogueDokument12 SeitenGate Valve Parts CatalogueLeandroNoch keine Bewertungen

- ControlFlow GateValveDokument29 SeitenControlFlow GateValvehrh_pogcNoch keine Bewertungen

- Ad00912v Wkmsaf T SealDokument36 SeitenAd00912v Wkmsaf T SealJulia WadeNoch keine Bewertungen

- Manual: Original InstructionsDokument118 SeitenManual: Original InstructionsMelanie GerdesNoch keine Bewertungen

- Operation and Maintenance Manual 5 1/8" LT Full Bore Plug ValveDokument20 SeitenOperation and Maintenance Manual 5 1/8" LT Full Bore Plug ValveMustafa NaithelNoch keine Bewertungen

- CA250Dokument206 SeitenCA250Oscar Alejandro Marcano100% (1)

- Rotation Joint 1.5 - Forum N156RJ30N-REV0Dokument6 SeitenRotation Joint 1.5 - Forum N156RJ30N-REV0Владислав ВиршинитNoch keine Bewertungen

- Erskine Vibratory Packer Manual-Downloaded-2015-06-21Dokument24 SeitenErskine Vibratory Packer Manual-Downloaded-2015-06-21Luis Miguel Herrera CuartasNoch keine Bewertungen

- SJ Repacking Longsweep STDDokument2 SeitenSJ Repacking Longsweep STDVipul Shah100% (1)

- National General Service ManualDokument155 SeitenNational General Service Manualmarwa mahmoud100% (4)

- 1082019-1 CLA SIENZ (Frusan) PDFDokument19 Seiten1082019-1 CLA SIENZ (Frusan) PDFrodrigoNoch keine Bewertungen

- Maintenance Checklist - Foster Power TongDokument1 SeiteMaintenance Checklist - Foster Power TongKhaled MahranNoch keine Bewertungen

- Grease Gun THK M70Dokument1 SeiteGrease Gun THK M70ikhsanNoch keine Bewertungen

- Cameron FLs Gate ValvesDokument54 SeitenCameron FLs Gate Valveskrishnsgk100% (14)

- SKF BearingsDokument108 SeitenSKF BearingsAgg GlezNoch keine Bewertungen

- Tb2 SDC - vp101 00hfb M M1a Man 9033 Rev0 (Even Error Trang 200)Dokument512 SeitenTb2 SDC - vp101 00hfb M M1a Man 9033 Rev0 (Even Error Trang 200)nguyễn hữu trườngNoch keine Bewertungen

- Spinner Manual 950 PNEUMATIC Serial Numbers 1 To 80Dokument81 SeitenSpinner Manual 950 PNEUMATIC Serial Numbers 1 To 80Andres BernalNoch keine Bewertungen

- Operating Manual: LKH Centrifugal PumpDokument38 SeitenOperating Manual: LKH Centrifugal Pumppablo ortizNoch keine Bewertungen

- Bomba Amstrong Condensado PDFDokument30 SeitenBomba Amstrong Condensado PDFRuben Rafael Blanco RodriguezNoch keine Bewertungen

- Gearbox Parts ManualDokument57 SeitenGearbox Parts ManualRELOJERIANoch keine Bewertungen

- Bowie - Pump Maintence ManualDokument36 SeitenBowie - Pump Maintence ManualThiago OliveiraNoch keine Bewertungen

- 951-130-184 - US - KFGS Manaul - New SKF PDFDokument48 Seiten951-130-184 - US - KFGS Manaul - New SKF PDFZT350Noch keine Bewertungen

- Fag Split Plummer Block Housings of Series SNVDokument84 SeitenFag Split Plummer Block Housings of Series SNVKharimul Aziz0% (1)

- Orbit Parts List and Ordering InstructionsDokument24 SeitenOrbit Parts List and Ordering Instructionskeertiraj09Noch keine Bewertungen

- Sprider 817-18175Dokument72 SeitenSprider 817-18175Avotra RandriamisainaNoch keine Bewertungen

- Operational and Maintenance Manual PDFDokument19 SeitenOperational and Maintenance Manual PDFYuda100% (1)

- Model Impact Wrench: CP7748 Series EDokument1 SeiteModel Impact Wrench: CP7748 Series EJimmy K CerratoNoch keine Bewertungen

- PEN00651-01 JTHB Hydraulic Breaker Operation and Maintenance ManualDokument94 SeitenPEN00651-01 JTHB Hydraulic Breaker Operation and Maintenance ManualAlvaroValdebenitoValenzuela60% (5)

- LWE160Dokument288 SeitenLWE160aleksandar.stamenkovskiNoch keine Bewertungen

- T32 SERIES INSTRUCTION MANUAL TWO-STAGE HIGH PRESSURE INDUSTRIAL AIR COMPRESSORSDokument32 SeitenT32 SERIES INSTRUCTION MANUAL TWO-STAGE HIGH PRESSURE INDUSTRIAL AIR COMPRESSORSRaimundo GuevaraNoch keine Bewertungen

- Forging Machine Preventive MaintenanceDokument4 SeitenForging Machine Preventive Maintenancemr. kNoch keine Bewertungen

- Top Drive Varco TDS 11 Lubrication PDFDokument1 SeiteTop Drive Varco TDS 11 Lubrication PDFWilliam TuckerNoch keine Bewertungen

- Juntas Rotativas PACQUET - Distribuye VorKaufDokument32 SeitenJuntas Rotativas PACQUET - Distribuye VorKaufhexapodo2Noch keine Bewertungen