Beruflich Dokumente

Kultur Dokumente

Packaging Supplier Requirements PDF

Hochgeladen von

Sarfraz AliOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Packaging Supplier Requirements PDF

Hochgeladen von

Sarfraz AliCopyright:

Verfügbare Formate

Supplier Requirements Packaging

Purpose

To ensure packaging suppliers are aware of The Coca-Cola Company requirements for

quality and food safety. These requirements support the Coca-Cola supplier authorization

process, including facility audits, and are in addition to the general supplier requirements

defined in Supplier Requirements General (SU-RQ-005), the relevant category

requirements and specifications.

Scope

Applies to packaging suppliers to the Coca-Cola system.

Requirements

Management System

Establish, document, implement, maintain and continually improve the quality and food

safety management system in accordance with the requirements of

The Coca-Cola Company that covers products and packaging materials supplied to the

Coca-Cola system. Appoint a designated person to ensure the management system is

effectively implemented and maintained, and that performance is reported to senior

management.

Management System Policy

Implement a policy that demonstrates its commitment to producing quality products that

are safe and suitable for contact with foodstuffs. The policy is communicated to and

understood by personnel.

Planning

Risk Assessment

Use a risk assessment process to determine quality control points and food safety

risks (based on the HACCP seven-principle, twelve-step model described in the

Annex to Codex Alimentarius General Principles of Food Hygiene CAC/RCP 11969), which allows any identified risks to be reduced or eliminated.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 1 of 12

Classified - Internal use

Supplier Requirements Packaging

Specified Requirements

General

Meet the specified requirements defined by The Coca-Cola Company and any

specific additional local needs. Refer to Supplier Requirements General (SU-RQ005) for requirements for authorization purposes, category-specific requirements,

specifications and other relevant documents.

Food Safety

Primary packaging suppliers must obtain certification to one of the GFSI-recognized

food safety management schemes (refer to www.mygfsi.com).

NOTE: New primary packaging suppliers have 12 months to gain

certification to a GFSI-recognized scheme once they gain conditional

authorization from The Coca-Cola Company. Implement a detailed

plan to achieve certification.

Regulations

Implement a process to ensure compliance to applicable regulatory requirements to

where the packaging materials are manufactured as well as delivered.

Facilities and Equipment Design

Design facilities and equipment used to manufacture, handle or store materials (raw

materials, intermediate and finished products, auxiliary materials, processing aids,

and packaging materials) that are suitable for their intended use.

Maintain facilities and equipment to preclude potential contamination by or exposure

to outside elements, odorous substances, pests, hazardous materials, microbial

contaminants.

Validate the capability of new or changed equipment, new technology, or process

changes.

Objectives

Define and measure quality and food safety objectives in accordance with the

quality and food safety policy and the requirements of this document.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 2 of 12

Classified - Internal use

Supplier Requirements Packaging

Outsourcing

Ensure control over outsourced processes that may affect quality and food safety.

Change Control Management Process

Document and implement a change control management process that ensures

changes that impact product quality and food safety are reviewed, verified and

approved before implementation. Maintain records of the changes.

Notify The Coca-Cola Company when any changes occur to the following:

Manufacture process (outside of normal operating conditions)

Manufacture location

Packaging or material specifications

Company/facility ownership

Equipment related to a critical control point or has a substantial impact on the

quality of the package or package material

Raw material supply

How packaging or material is packed for delivery

Status in the certification to a GFSI recognized scheme (for primary

packaging suppliers)

Incident Management

Implement a program to manage unplanned events, potential emergencies or

disasters. Conduct a post-incident review to prevent recurrence and improve

processes, mitigating the consequences of such incidents.

Effectively manage issues that will or potentially will impact the quality, food safety

or supply of materials to the Coca-Cola system. Communicate any issues that could

result in a recall or withdrawal to the appropriate business unit immediately.

Implementation and Operation

Purchased Materials and Services

Implement a program to approve and monitor the suppliers of purchased materials

that includes the following:

Written specifications for purchased materials.

A process to ensure materials or services purchased from upstream

suppliers meet the specifications.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 3 of 12

Classified - Internal use

Supplier Requirements Packaging

A system to prevent the use of purchased materials that do not meet

specifications.

Design

Where applicable, plan and control the design and development of the products,

including inputs, outputs, review, verification and validation.

Process Monitoring and Control

General

Clearly define the process used to convert raw materials into the finished product.

This must include the identification of inputs, outputs, and control points and critical

control points (including monitoring frequencies, accept/reject criteria and

responsibilities) for each process.

Monitor processes to ensure they are operating properly and are under control, for

example: use of monitoring and recording devices, use of statistical process control

tools, etc.

Good Manufacturing Practices (GMP)

Plant personnel, visitors and outside contractors must comply with the GMP

requirements as set forth by applicable regulations. Refer to Codex General

Principles of Food Hygiene (CAC/RCP 1) as a minimum (for those suppliers who

are not yet certified to a GFSI-recognized scheme).

Good Laboratory Practices (GLP)

Plant or contract laboratories and laboratory personnel must implement GLP

principals.

The laboratory must use published, recognized and validated testing methods.

Where published test methods are not available, internally developed methods must

be validated for their intended use consistent with GLP requirements. The

laboratory design, equipment and processes must ensure the test results are

consistent and reliable.

Pest Control

Implement a documented pest control program to effectively prevent pest activity in

the facility and the surrounding area. Assign a trained plant personnel or an

approved external contractor to manage this program. Assign certified pest control

operators or personnel with equivalent training to perform pest control activities.

Use insecticides, fungicides or rodenticides in accordance with current applicable

regulations where products are manufactured as well as with the regulations to

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 4 of 12

Classified - Internal use

Supplier Requirements Packaging

where products are delivered. Technical supplements from the pest control supplier

may specify other requirements.

Housekeeping and Sanitation Controls

Implement a sanitation program that ensures the cleanliness of the handling

equipment and the facility.

The program must also ensure raw materials, packaging, in-process components

and finished goods storage areas, shipping trailers, cars and containers are clean

and pest-free.

Only cleaning chemicals suitable for use in food packaging manufacturing facilities

are permitted for the specific purpose intended. Programs for managing facility

housekeeping must be included in the suppliers plant sanitation controls. A

system for verifying and documenting the effectiveness of the sanitation program

must be in place.

Weight Controls

Where applicable, the supplier must have a weight control program compliant with

applicable regulations. Establish operating limits and quality monitoring procedures

to achieve tolerances documented in the specifications or purchase contract.

Foreign and Extraneous Material Control

Implement controls, procedures and equipment in place to prevent foreign and

extraneous material from entering the products. Examples include the use of metal

detectors, magnets, screens and filtration systems.

Chemical Residue and Contamination Control

Document controls for the storage, handling and use of chemicals.

Traceability

Implement a system that enables the supplier to trace the entire history of a specific

lot through lot records (forward and backward traceability). This includes

identification of materials (including any rework added), processing conditions, test

results and the customers to whom the lot was distributed.

Identify each lot individually. Validate the traceability process periodically through a

mock recall system to verify effectiveness and use the results to improve the

process.

Finished Goods

Pack primary packaging components using suitable secondary packaging material

as agreed with the delivery location.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 5 of 12

Classified - Internal use

Supplier Requirements Packaging

Deliver packaging materials in a manner that enables the easy identification of

tampering. If tamper evident packaging or locks are used the storage and handling

of the tamper evident devices or locks must be controlled to prevent unauthorized

use.

Palletize finished goods unless otherwise specified. Pallets must be made of

suitable material and must be clean, dry and free from contaminants. Do not use

untreated wooden pallets.

It is preferred that wooden pallets be heat treated and not be treated with

chemicals, such as fungicides, pesticides, or wood preservatives, that could

contaminate the packaging material or finished goods.

Where local regulatory authorities require the chemical treatment of wooden pallets,

ensure the pallets do not contaminate package materials during shipment and

storage. If pallets are chemically treated, declare the treatment to

the Coca-Cola system. The following restrictions apply:

o No use of chlorinated or brominated phenolic compounds;

o No use of halogenated phenols; or

o Conformity with applicable heavy metal regulations.

Transportation

Implement processes to ensure transportation conditions do not affect the

packaging and to prevent the shipment of nonconforming packaging.

Inspect transportation vehicles for structural integrity, cleanliness, security and

suitability prior to loading.

Control the security of the trailer/container/tanker to prevent tampering. The

supplier must demonstrate the security of the delivery container.

Calibration Controls

Identify critical processing and testing equipment and design and implement a

calibration program for that equipment that ensures the accuracy and validity of

results. The program must include procedures for monitoring the performance of

processing and testing equipment to ensure that equipment continues to perform

between calibrations. Where applicable, calibration standards must be traceable to

National or International Standards.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 6 of 12

Classified - Internal use

Supplier Requirements Packaging

Training

Ensure personnel (includes permanent, contract and temporary employees) working

for or on behalf of the supplier are competent on the basis of appropriate education,

training, skills and experience for the tasks assigned to them.

Documentation

Document the quality and food safety management system to ensure compliance

with The Coca-Cola Company policies, programs, specifications, and regulatory

requirements as defined in this document, SU-RQ-005, and any category

requirements. Establish, implement and maintain any documented procedures to

define the controls needed, ensuring documents are current.

Records

Establish, document and maintain records to provide evidence of conformity to

requirements and of the effective operation of the management system.

Establish, implement and maintain documented procedures to define the controls

needed for the identification, storage, protection, retrieval, retention and disposal of

records. This applies to both electronic and paper records.

Communication

Ensure effective communication within the organization with regard to the quality

and food safety management requirements.

Scientific and Regulatory Affairs

Materials used in the manufacturing of packaging must meet both corporate and

local business unit requirements and performance criteria.

Materials that have a potential for direct contact with The Coca-Cola Company

products must comply with regulatory requirements for food contact use in the

country where the finished product will be distributed.

Materials must be approved by the Company Scientific and Regulatory Affairs

(SRA) and additionally, if required, by the groups SRA.

Suppliers must provide complete and accurate information for components of

materials used for contact with The Coca-Cola Company product.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 7 of 12

Classified - Internal use

Supplier Requirements Packaging

Security

Supply Chain Security

Document a security policy and designate an individual who is responsible to

satisfactorily demonstrate compliance to the policy.

Secure manufacture and storage areas with no unauthorized personnel allowed.

Trademarked Protection

Maintain control of The Coca-Cola Companys trademarked materials/promotional

materials and/or graphics (Intellectual Property) until point of delivery. This

requirement includes the control, use and destruction of scrap and/or obsolete

materials.

Acknowledge and comply with requirements pertaining to

The Coca-Cola Companys intellectual property ownership rights as outlined in the

Supplier Authorization Agreement.

Information

Secure access to information that pertains to the Coca-Cola system.

Performance Assessment

Internal Audit

Document and implement an internal audit program that includes the following:

A schedule based on risk, status and importance, that covers all aspects of

the quality and food safety management program;

Audit procedures and reporting requirements;

Linkage to corrective action (see Improvement below) and management

review (see Management Review below); and

Auditors that are independent of the area being audited.

Handling of Nonconformities

Nonconforming material (raw material, intermediate material, finished good, etc.)

must be segregated or identified by a suitable means to ensure the prevention of its

use in production and/or dispatch.

Procedures for rework, disposal and/or change of final use of the nonconforming

materials must be in place and records for full traceability must be maintained.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 8 of 12

Classified - Internal use

Supplier Requirements Packaging

Where nonconformities are identified they must be corrected and action taken to

mitigate their impact (see Improvement below).

Improvement

Document and implement an improvement program that addresses corrective,

preventive and improvement actions. Inputs must be from internally generated data

(nonconformities, internal audit results) and external data (customer complaints,

customer satisfaction surveys, external audit results).

Management Review

Records of management reviews must demonstrate the following aspects have

been covered:

Results of audits;

Feedback from customers and stakeholders;

Status of preventive and corrective actions;

Follow-up actions from previous management reviews;

Changing circumstances, including developments in legal and other

requirements, related to the suppliers aspects and associated risks;

Recommendations for improvement;

Data and information on the suppliers performance;

Results of the evaluation of compliance with legal and other requirements;

and

Review of the quality and food safety policy.

Records of reviews will also include actions to perform the following:

Improve the effectiveness of the management system;

Improve supplier performance; and

Ensure resources are available to improve the management system and its

processes.

Definitions

Auxiliary Material: Materials used in manufacturing processes, storage and product

delivery that come into intentional contact with equipment, packaging, or surfaces, or

unintentional contact with raw materials, intermediate or finished products. Examples:

cleaning and sanitizing agents, container cleaning agents (including bottle washer

additives), lubricants, solvents, glues, date code ink.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 9 of 12

Classified - Internal use

Supplier Requirements Packaging

Coca-Cola Trademark Brand Products: Products bearing the Coca-Cola trademark in

their name; such as Coca-Cola, Coca-Cola classic, cherry Coke, Diet Coke, Coca-Cola

light.

Extraneous Material: Any undesirable material that is a natural portion of the product,

such as stems, leaves, and seeds.

Finished Product: Product, equipment, packaging material or ingredient created by a

suppliers manufacturing process for use by the Coca-Cola system.

Foreign Material: Any material which is not natural to the product, such as metal, wood,

glass, plastic, rock, paper or cloth.

Good Laboratory Practice (GLP): Embodies a set of principles that provides a

framework in which laboratory tests are planned, performed, monitored, recorded, reported

and archived. These tests are undertaken to generate data so the hazards and risks to

users, consumers and third parties (including the environment) of exposure to

pharmaceuticals, agrochemicals, cosmetics, food and feed additives and contaminants,

novel foods and biocides. GLP helps assure regulatory authorities that the data submitted

is a true reflection of the results obtained during the testing and can therefore be relied

upon when making risk/safety assessments.

Good Manufacturing Practice (GMP): Relates to the manufacturing, processing, and

storing of food materials that assure the food materials are safe for human consumption

and have been prepared, packed and stored under sanitary conditions. This includes the

prevention of any type of contamination. Good Manufacturing Practice requires correctly

designed and constructed buildings and equipment, adequate training of personnel to

produce quality food materials, and properly maintained plant conditions.

HACCP: (Hazard Analysis Critical Control Point) A broadly recognized preventive and

systematic approach for the identification, evaluation and control of food safety hazards.

Hazard: A biological, chemical or physical agent or factor with the potential to cause an

adverse health effect that is likely to occur in the production process if control is not

exercised.

Lot Record: A collection of records\data that identifies a complete history of a lot. This

includes procurement, manufacturing, test and shipping information to enable traceability

(another term for batch record)

Lot: A defined quantity of a product (another term for batch).

Mock Recall or Simulated Product Recovery: A simulated recall of the manufactured

product or item, including the tracing of manufacturing records, shipping records and a full

reconciliation of quantities received, manufactured, stored, destroyed and shipped.

Nonconforming: A product, packaging material or ingredient that fails to meet

specification or regulatory requirements.

Primary Packaging: Packaging component that touches the product.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 10 of 12

Classified - Internal use

Supplier Requirements Packaging

Processing Aid: Materials added or coming into intentional contact with the processing of

raw materials, intermediate and finished products to fulfill a technological purpose relating

to processing or treatment, but which do not perform a technological function in the final

product. Examples: water treatment chemicals, water and sugar treatment materials,

packaging gases, ozone, anti-foaming agent.

Product Recovery: Any voluntary or involuntary retrieval of a product that has been

released for distribution.

Purchased Materials/Services: Materials or services purchased by suppliers for use in

production of their finished products.

Regulatory Action: The seizure, holding or recall of any product by a regulatory

authority. Also includes any findings resulting in prosecution, injunction, or regulatory

letter.

Regulatory Authority: Any duly authorized agent or employee of any government

agency empowered to enforce laws.

Secondary Packaging: A uniform covering or wrapping for one or more primary

containers for the purposes of market distribution. Any packaging, packaging component

or materials in direct contact with the primary packaging but not in contact with the product

Tamper Evident: A feature(s) of a package or container that allows customers or

consumers, under ordinary conditions of use, to determine whether unauthorized

opening or tampering has occurred.

Tamper-Evident Seal: Seals or sealing mechanisms that are unique to the supplier, and

are non-toxic and designed to readily show any violation or attempted violation of the

integrity of the seal or a change in status of the package or object on which they are

placed; such as containers or valves. For suppliers, seals should be unique and

identifiable to that specific supplier. The design and strength of the seals used depend on

specific use of the seal and the risk inherent with inadvertent damage or violation of the

seals integrity: for example plants bulk-shipping Company products should select stronger

high-tensile strength numbered seals for protection.

The Coca-Cola Company: The legal entity entitled The Coca-Cola Company and its

consolidated affiliates. It includes internal business units, such as company operating

groups, divisions, regions, and consolidated bottling operations, and all further subsets of

these units.

The Coca-Cola system: The Coca-Cola Company and its bottling partners.

Trademarked Materials: Business related articles, including packaging materials, labels,

seals and closures that bear the trademarked logos of The Coca-Cola Company.

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 11 of 12

Classified - Internal use

Supplier Requirements Packaging

References

Codex Alimentarius General Principles

http://www.codexalimentarius.org/standards/en/

of Food Hygiene (CAC/RCP 1-1969)

Supplier Requirements - General

SU-RQ-005

Global Food Safety Initiative (GFSI)

www.mygfsi.com

Revision History

Revision Date

Summary of Change

14-Jun-2013

New KORE document, based on original SU-RQ-010, with scope

limited to packaging suppliers

Requirement

Revision: 14-Jun-2013

SU-RQ-020

Page 12 of 12

Classified - Internal use

Das könnte Ihnen auch gefallen

- Cleaning and disinfection of food factories: a practical guideVon EverandCleaning and disinfection of food factories: a practical guideNoch keine Bewertungen

- 2-3 Bioreactor SOPDokument2 Seiten2-3 Bioreactor SOPxavikxavikNoch keine Bewertungen

- Corrective And Preventative Action A Complete Guide - 2020 EditionVon EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNoch keine Bewertungen

- Detergent Flushing of Pre Boiler System-Procedure 250Dokument11 SeitenDetergent Flushing of Pre Boiler System-Procedure 250Sara LopezNoch keine Bewertungen

- Tar Acids in Creosote-Coal Tar Solutions: Standard Test Method ForDokument3 SeitenTar Acids in Creosote-Coal Tar Solutions: Standard Test Method ForCasey RybackNoch keine Bewertungen

- Purified-Water QuDokument127 SeitenPurified-Water Qujay patelNoch keine Bewertungen

- Technical Service Bulletin: Commissioning Procedure For HydracapDokument10 SeitenTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisNoch keine Bewertungen

- Biobench BioreactorDokument7 SeitenBiobench BioreactorCristobal BusseniusNoch keine Bewertungen

- Section 01 91 00 - General Commissioning Requirements Part 1 - GeneralDokument20 SeitenSection 01 91 00 - General Commissioning Requirements Part 1 - GeneralJim WoodNoch keine Bewertungen

- Commissioning Qualification Validation Blue PaperDokument12 SeitenCommissioning Qualification Validation Blue PaperVarun ZotaNoch keine Bewertungen

- Clean RoomDokument24 SeitenClean RoomTran Thanh Tuan100% (1)

- Monitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPADokument17 SeitenMonitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPAAna M VrrNoch keine Bewertungen

- CORESYF T2 VVR VVP01 E R Verification and Validation Plan Framework V1 0Dokument31 SeitenCORESYF T2 VVR VVP01 E R Verification and Validation Plan Framework V1 0designselvaNoch keine Bewertungen

- SAT Plan & Procedure VMSDokument47 SeitenSAT Plan & Procedure VMSMGHIRBI HAYKELNoch keine Bewertungen

- Materials ManagementDokument17 SeitenMaterials ManagementAkash SahaNoch keine Bewertungen

- PQ FBDDokument6 SeitenPQ FBDAjay GuptaNoch keine Bewertungen

- QSP-006 R0 QSP For Non-Conformance Product ControlDokument13 SeitenQSP-006 R0 QSP For Non-Conformance Product ControljennyNoch keine Bewertungen

- Water Quality ManualDokument9 SeitenWater Quality ManualRavii Curtis100% (1)

- Professional SummaryDokument3 SeitenProfessional SummaryVijay LS SolutionsNoch keine Bewertungen

- Full Proposal Template - Tech Tranfer Simple FormatDokument15 SeitenFull Proposal Template - Tech Tranfer Simple FormatSaddam Ali KhanNoch keine Bewertungen

- Commissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Dokument20 SeitenCommissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Venkataramanan SNoch keine Bewertungen

- SAT Sample For BoilerDokument15 SeitenSAT Sample For Boilerjpmaurya77Noch keine Bewertungen

- MWC Testing and CommissioningDokument8 SeitenMWC Testing and CommissioningladaojmNoch keine Bewertungen

- FAT & SAT For Electrical System in Utility EndDokument16 SeitenFAT & SAT For Electrical System in Utility EndBabuNoch keine Bewertungen

- Factory Acceptance Test Procedure For DCS - Page 1Dokument2 SeitenFactory Acceptance Test Procedure For DCS - Page 1kapsarcNoch keine Bewertungen

- Delivery Report: Delivering DealerDokument2 SeitenDelivery Report: Delivering DealerBrayan Calcina BellotNoch keine Bewertungen

- Complete Magnetic Filtration Mini-CatalogDokument19 SeitenComplete Magnetic Filtration Mini-Catalog15 FFNoch keine Bewertungen

- 63 Leak TesterDokument6 Seiten63 Leak Testersystacare remediesNoch keine Bewertungen

- Temperature Mapping Protocol For RM QuarantineDokument20 SeitenTemperature Mapping Protocol For RM Quarantinemehrdarou.qaNoch keine Bewertungen

- Or RQ 101Dokument9 SeitenOr RQ 101Rosa Maria OrtegaNoch keine Bewertungen

- A Traceability System For Outgrower SchemesDokument157 SeitenA Traceability System For Outgrower SchemessebichondoNoch keine Bewertungen

- URS Contents: Blank TemplateDokument11 SeitenURS Contents: Blank TemplateBREWSKI100% (1)

- Performance Qualification Protocol For Blister Packing MachineDokument9 SeitenPerformance Qualification Protocol For Blister Packing Machinemehrdarou.qaNoch keine Bewertungen

- Technical Doc 1 - Technical Scope of Work Drs Eac181Dokument25 SeitenTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09Noch keine Bewertungen

- Quality Assurance Agreement 0 PDFDokument11 SeitenQuality Assurance Agreement 0 PDFMinyamir AsratNoch keine Bewertungen

- Sop For High Performance Liquid ChromatographyDokument3 SeitenSop For High Performance Liquid ChromatographyRainMan75100% (1)

- RO/Water/Wastewater Treatment Supervisor/OperatorDokument3 SeitenRO/Water/Wastewater Treatment Supervisor/Operatorapi-72678201Noch keine Bewertungen

- GLP or Good Laboratory PracticesDokument35 SeitenGLP or Good Laboratory Practicesningsih rezekiNoch keine Bewertungen

- EIGA (2008) - Comparison of EP, USP & JP For Medicinal GasDokument21 SeitenEIGA (2008) - Comparison of EP, USP & JP For Medicinal GashuynhhaichauchauNoch keine Bewertungen

- Product Verification Protocol: Applies To Specification Ref(s) : Date of Origin: Date of Last RevisionDokument9 SeitenProduct Verification Protocol: Applies To Specification Ref(s) : Date of Origin: Date of Last RevisionMohamedRefaatMohamedNoch keine Bewertungen

- Packaging PDFDokument48 SeitenPackaging PDFDebasis Kumar SahaNoch keine Bewertungen

- SOP For Preparation of TrendsDokument2 SeitenSOP For Preparation of TrendsАнна ОрлеоглоNoch keine Bewertungen

- Validates PIABDokument2 SeitenValidates PIABltrevino1000% (1)

- Oxygen USPDokument2 SeitenOxygen USPMartha Lucia Roa FonsecaNoch keine Bewertungen

- Filtration Membranes in Cell CultureDokument12 SeitenFiltration Membranes in Cell CulturemailreemaNoch keine Bewertungen

- CIP Validating FormDokument4 SeitenCIP Validating FormCruz LheoNoch keine Bewertungen

- Allpax Factory Acceptance TestsDokument5 SeitenAllpax Factory Acceptance Testssaneie99Noch keine Bewertungen

- Sop Fume HoodDokument2 SeitenSop Fume HoodKoko AshourNoch keine Bewertungen

- Marcyrl 8662 (Offer)Dokument51 SeitenMarcyrl 8662 (Offer)Mina Maher MikhailNoch keine Bewertungen

- Aka GMP Audit FormDokument8 SeitenAka GMP Audit FormAlpian BosixNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05Dokument1 SeiteSaudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05philipyapNoch keine Bewertungen

- SOP in Use QualificationDokument4 SeitenSOP in Use QualificationDharmesh PatelNoch keine Bewertungen

- UNA620A-ADA Data Sheet 220317Dokument2 SeitenUNA620A-ADA Data Sheet 220317Raymund RascoNoch keine Bewertungen

- SHP Laboklav Manual PDFDokument35 SeitenSHP Laboklav Manual PDFAntoni Gandia100% (1)

- Documentation Required For Periodic GMP Compliance Inspection Annex 1 JPDokument5 SeitenDocumentation Required For Periodic GMP Compliance Inspection Annex 1 JPspam_discardNoch keine Bewertungen

- Validation Master Plan Example - LongDokument31 SeitenValidation Master Plan Example - LongJayesh kolheNoch keine Bewertungen

- Medevo Pharmaceuticals, Pvt. LTD Lahore. Title: Users Required Specifications For Document # Revisions: 00 Date: 20-Apr-20Dokument23 SeitenMedevo Pharmaceuticals, Pvt. LTD Lahore. Title: Users Required Specifications For Document # Revisions: 00 Date: 20-Apr-20zubair136100% (1)

- AACHC Emergency Shutdown Procedures Template 4-25-14Dokument9 SeitenAACHC Emergency Shutdown Procedures Template 4-25-14bertan dağıstanlıNoch keine Bewertungen

- MS For The Audio Intercom SystemDokument11 SeitenMS For The Audio Intercom Systemwaaji snapNoch keine Bewertungen

- Method Statement For Ultrasonic Testing: DCSM Project 2019Dokument5 SeitenMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenNoch keine Bewertungen

- EFE Matrix & Porter's Model: Strategic ManagementDokument5 SeitenEFE Matrix & Porter's Model: Strategic ManagementSarfraz Ali0% (1)

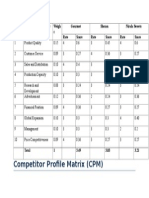

- Competitor Profile Matrix (CPM)Dokument1 SeiteCompetitor Profile Matrix (CPM)Sarfraz AliNoch keine Bewertungen

- Account Opening DepartmentDokument24 SeitenAccount Opening DepartmentSarfraz AliNoch keine Bewertungen

- Account Opening DepartmentDokument15 SeitenAccount Opening DepartmentSarfraz AliNoch keine Bewertungen

- What Is The Functionalist Perspective in SociologyDokument4 SeitenWhat Is The Functionalist Perspective in SociologySarfraz AliNoch keine Bewertungen

- TechnicalDataSheetTDS 0103000199393021448224 English 03012020Dokument43 SeitenTechnicalDataSheetTDS 0103000199393021448224 English 03012020lmimouni mostafaNoch keine Bewertungen

- GMP Requirements in Packaging Materials ScienceDokument40 SeitenGMP Requirements in Packaging Materials ScienceYub Raj NeupaneNoch keine Bewertungen

- Cell Phone Life CycleDokument1 SeiteCell Phone Life CycleNagaVenkat ChNoch keine Bewertungen

- Swot Analysis and Marketing StrategiesDokument20 SeitenSwot Analysis and Marketing Strategiesashwini373Noch keine Bewertungen

- Bubble Packing: Profile No.: 72 NIC Code:22203Dokument8 SeitenBubble Packing: Profile No.: 72 NIC Code:22203Sabhaya ChiragNoch keine Bewertungen

- D7425D7425M 13Dokument3 SeitenD7425D7425M 13diego rodriguez100% (1)

- F452 1207649-1Dokument2 SeitenF452 1207649-1Everton PizzioNoch keine Bewertungen

- Föreläsning 9Dokument41 SeitenFöreläsning 9Sara HasanicNoch keine Bewertungen

- BRC Issue 6 Audit ChecklistDokument11 SeitenBRC Issue 6 Audit Checklistsudar1477Noch keine Bewertungen

- Sustainable Innovation Through An Entrepreneurship Lens 2000Dokument14 SeitenSustainable Innovation Through An Entrepreneurship Lens 2000joedixon737100% (1)

- 5th - Product AdaptationDokument19 Seiten5th - Product AdaptationRestu Imada AryofikNoch keine Bewertungen

- StandardsforNonFoodSuppliers tcm137-70082Dokument12 SeitenStandardsforNonFoodSuppliers tcm137-70082joyrjaelNoch keine Bewertungen

- Volkswagen Group LogisticsDokument17 SeitenVolkswagen Group LogisticsVIPUL TUTEJA100% (1)

- Supply Chain Management Summer-2021 Assignment No.-2: Course Name: Distribution ManagementDokument8 SeitenSupply Chain Management Summer-2021 Assignment No.-2: Course Name: Distribution ManagementRohit SainiNoch keine Bewertungen

- UFLEX Investor - Presentation - FY21Dokument39 SeitenUFLEX Investor - Presentation - FY21Chirag GothiNoch keine Bewertungen

- Handout - Lesson 3 Marketing Household LinensDokument3 SeitenHandout - Lesson 3 Marketing Household LinensRhoda Bayacal Ynte100% (1)

- MarketingDokument28 SeitenMarketingSaksham ChhabraNoch keine Bewertungen

- Modified Jacket Proposal Modified Cost SheetDokument1 SeiteModified Jacket Proposal Modified Cost SheetabdullahNoch keine Bewertungen

- BS 03936-4-2007Dokument32 SeitenBS 03936-4-2007Ali RayyaNoch keine Bewertungen

- 4 Seco ULCDokument60 Seiten4 Seco ULCmscarreraNoch keine Bewertungen

- Iso 22716 2007 en PDFDokument11 SeitenIso 22716 2007 en PDFAdeel AhmedNoch keine Bewertungen

- Ba TW45C 08 12 enDokument64 SeitenBa TW45C 08 12 enangela1590100% (1)

- Bsi MD MDR Best Practice Documentation Submissions en gb1Dokument41 SeitenBsi MD MDR Best Practice Documentation Submissions en gb1Khushboo WarhadeNoch keine Bewertungen

- Unit 2 The Three Levels of Supply Chain ManagementDokument11 SeitenUnit 2 The Three Levels of Supply Chain ManagementSheela AngelNoch keine Bewertungen

- Exporting Moringa To EuropeDokument20 SeitenExporting Moringa To Europeswapnilrane03Noch keine Bewertungen

- 2023-03 Onboarding+PresentationDokument105 Seiten2023-03 Onboarding+Presentationducduydang36Noch keine Bewertungen

- Dell Precision M6700, P22F, P22F001, DeLL Regulatory and Environmental DatasheetDokument6 SeitenDell Precision M6700, P22F, P22F001, DeLL Regulatory and Environmental DatasheetRahul DubeyNoch keine Bewertungen

- Polymers Practical UseDokument1 SeitePolymers Practical UseRaajeswaran BaskaranNoch keine Bewertungen

- Food Traceability and RecallDokument15 SeitenFood Traceability and RecallPhạm Thanh Vấn100% (1)

- Course: Consumer Behaviour: Relaunching of Mecca Cola in PakistanDokument10 SeitenCourse: Consumer Behaviour: Relaunching of Mecca Cola in PakistanAnasAhmedNoch keine Bewertungen

- Working Backwards: Insights, Stories, and Secrets from Inside AmazonVon EverandWorking Backwards: Insights, Stories, and Secrets from Inside AmazonBewertung: 4.5 von 5 Sternen4.5/5 (44)

- The E-Myth Chief Financial Officer: Why Most Small Businesses Run Out of Money and What to Do About ItVon EverandThe E-Myth Chief Financial Officer: Why Most Small Businesses Run Out of Money and What to Do About ItBewertung: 4.5 von 5 Sternen4.5/5 (14)

- Design Thinking for Beginners: Innovation as a Factor for Entrepreneurial SuccessVon EverandDesign Thinking for Beginners: Innovation as a Factor for Entrepreneurial SuccessBewertung: 4.5 von 5 Sternen4.5/5 (7)

- The Goal: A Process of Ongoing Improvement - 30th Aniversary EditionVon EverandThe Goal: A Process of Ongoing Improvement - 30th Aniversary EditionBewertung: 4 von 5 Sternen4/5 (685)

- Revolutionizing Business Operations: How to Build Dynamic Processes for Enduring Competitive AdvantageVon EverandRevolutionizing Business Operations: How to Build Dynamic Processes for Enduring Competitive AdvantageNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Project Planning and SchedulingVon EverandProject Planning and SchedulingBewertung: 5 von 5 Sternen5/5 (6)

- The Influential Product Manager: How to Lead and Launch Successful Technology ProductsVon EverandThe Influential Product Manager: How to Lead and Launch Successful Technology ProductsBewertung: 5 von 5 Sternen5/5 (2)

- Working Backwards: Insights, Stories, and Secrets from Inside AmazonVon EverandWorking Backwards: Insights, Stories, and Secrets from Inside AmazonBewertung: 4.5 von 5 Sternen4.5/5 (14)

- The Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerVon EverandThe Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerBewertung: 4 von 5 Sternen4/5 (103)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneVon EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneBewertung: 4.5 von 5 Sternen4.5/5 (5)

- PMP Exam Prep: How to pass the PMP Exam on your First Attempt – Learn Faster, Retain More and Pass the PMP ExamVon EverandPMP Exam Prep: How to pass the PMP Exam on your First Attempt – Learn Faster, Retain More and Pass the PMP ExamBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Product Roadmaps Relaunched: How to Set Direction while Embracing UncertaintyVon EverandProduct Roadmaps Relaunched: How to Set Direction while Embracing UncertaintyBewertung: 4 von 5 Sternen4/5 (2)

- The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive WorldVon EverandThe Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive WorldNoch keine Bewertungen

- Materials Management: An Executive's Supply Chain GuideVon EverandMaterials Management: An Executive's Supply Chain GuideNoch keine Bewertungen

- Value Stream Mapping: How to Visualize Work and Align Leadership for Organizational Transformation: How to Visualize Work and Align Leadership for Organizational TransformationVon EverandValue Stream Mapping: How to Visualize Work and Align Leadership for Organizational Transformation: How to Visualize Work and Align Leadership for Organizational TransformationBewertung: 5 von 5 Sternen5/5 (34)

- Project Management: The Ultimate Guide to Help You Master and Innovate Projects with Lean Thinking, Including How to Dominate Agile, Scrum, Kanban, and Six SigmaVon EverandProject Management: The Ultimate Guide to Help You Master and Innovate Projects with Lean Thinking, Including How to Dominate Agile, Scrum, Kanban, and Six SigmaBewertung: 3 von 5 Sternen3/5 (1)

- Self-Discipline: The Ultimate Guide To Beat Procrastination, Achieve Your Goals, and Get What You Want In Your LifeVon EverandSelf-Discipline: The Ultimate Guide To Beat Procrastination, Achieve Your Goals, and Get What You Want In Your LifeBewertung: 4.5 von 5 Sternen4.5/5 (662)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityVon Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityBewertung: 5 von 5 Sternen5/5 (3)

- Spare Parts Inventory Management: A Complete Guide to SparesologyVon EverandSpare Parts Inventory Management: A Complete Guide to SparesologyBewertung: 4 von 5 Sternen4/5 (3)

- From Source to Sold: Stories of Leadership in Supply ChainVon EverandFrom Source to Sold: Stories of Leadership in Supply ChainNoch keine Bewertungen

- The Influential Product Manager: How to Lead and Launch Successful Technology ProductsVon EverandThe Influential Product Manager: How to Lead and Launch Successful Technology ProductsBewertung: 4.5 von 5 Sternen4.5/5 (11)