Beruflich Dokumente

Kultur Dokumente

Bhavikatti Ijest 2010 02

Hochgeladen von

Рикардо Мендоса РодрігесCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bhavikatti Ijest 2010 02

Hochgeladen von

Рикардо Мендоса РодрігесCopyright:

Verfügbare Formate

A.M.Bhavikatti et. al.

/ International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

CHARACTERIZATION AND

ELECTROMAGNETIC STUDIES OF

NANO-SIZED BARIUM FERRITE

A.M.BHAVIKATTI*

Rural Engineering College, Bhalki585328, INDIA

DR.SUBHASH KULKARNI

Jaypraksh Narayan College of Engineering, Mahaboobnagar - 509001, INDIA

DR. ARUNKUMAR. LAGASHETTY

Appa Institute of Engineering and Technology, Gulbarga 580102, INDIA.

Abstract

The present article reports some of the interesting and important electromagnetic and impedance studies of

nanostructured barium ferrite. Here, the nano-sized barium ferrite (BaFe2O4) was synthesized by using

microwave route. The sample was characterized by X-ray diffraction, SEM and IR studies. Electrical

resistance(R) measurements of the sample revealed a very high resistivity and the results indicated a fall in

resistivity with the rise in temperature. The obtained dc conductivity is found to be very low of the order of 10-8

S/cm .The dc conductivity follows the Arrhenius law. The hysteresis M-H loops for this sample was traced

using the Vibrating Sample Magnetometer (VSM) to study the parameters coercivity (Hc), saturation

magnetization (Ms) , remanence (Mr) and squareness ratio( SQR). The complex impedance spectroscopy (CIS)

technique was used to study the electrical response of the nanostructured sample in a wide range of frequencies

(1 KHz to 1MHz) at different temperatures (07000 C).

Key words: Microwave synthesis, nano-sized barium ferrite, resistivity, conductivity, impedance studies

1. Introduction

Ferrites have continued to attract attention over the years. As magnetic materials, ferrites cannot be replaced by

any other magnetic material because they are relatively inexpensive, stable and have a wide range of

technological applications in transformer core, high quality filters, high and very high frequency circuits and

operating devices. The physical properties of ferrites are controlled by the preparation conditions, chemical

composition, sintering temperature and time, type and amount of substitutions [1].

In recent years, nanostructured materials have drawn outstanding attention due to the unique mechanical,

electrical, optical, and magnetic properties. The unique properties of nanostructured materials are due to their

changed electronic structure, close to that of an isolated atom or molecule. Among the nanoscale inorganic

materials, the magnetic metal oxides and their composites are of particular interest due to their exciting

applications in the areas of quantum computing, information storage media, magnetic resonance imaging,

sensors, refrigeration, electromagnetic wave absorption and modulation [2].

Recent studies have shown that, physical properties of nano particles are influenced significantly by the

processing techniques .Since crystalline size, distribution of particle sizes and inter particle spacing have the

greatest impact on magnetic particles, the ideal synthesis techniques must provide superior control over these

parameters .A variety of techniques have been employed for the synthesis of nano particles with definite shapes

and sizes [3].

Nanocrystalline barium ferrites are very interesting because of its chemical properties and thermal studies [4].

These materials are technologically important and have been used in many applications such as magnetic

recording media [5]. Recently, nanocrystalline magnetic materials have been receiving more and more attention

due to their novel material properties, which are significantly different from those of their bulk counterparts [6].

ISSN: 0975-5462

6532

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

Microwave firing of ceramics is a technology that has attracted much scientific interest as a technology for

ceramic manufacturing [7-9]. Microwave firing could be an interesting firing technology for crystalline

magnetic ceramics, such as barium ferrite, for the following reasons,

Microwave firing can be considered as direct heating method and is therefore expected to be more

economic. The energy consumption should be reduced because the ferrite materials are heated directly

and less energy is wasted to heat the kiln.

Higher densities are desired for all magnetic properties such as saturation magnetization, magnetic

permeability, etc

Microwave firing allows the achievement of high heating rates that cannot be achieved by conventional

furnaces and this may lead to significant reduction of the firing cycles times.

Earlier, we have presented the microwave synthesis of nano-sized barium ferrite [10].Recently, we have

presented electrical studies of nano sized barium ferrite [11].In the present article, we investigate the dc

conductivity, resistivity, magnetic properties, real and imaginary part of impedance of the nano-sized barium

ferrite.

Barium ferrite, which is a well-known ferric-magnetic material with superior chemical stability and anti-erosion

properties, attracted extensive attention in recent years .Owing to its high anisotropy property; this material has

been widely used in the fabrication of magnetic and magneto-optic devices. Applications are also found in

microwave devices mainly because of its high resistivity and permittivity at high frequency [12]

2. Experimental Procedure

2.1.1

Materials and Methods

Barium chloride, ferrous ammonium sulphate, oxalic acid and urea used were AR grade. Microwave method is

used for the synthesis of barium ferrite materials using urea as a fuel for the combustion reaction.

2.1.2 Preparation of pellet

The powders were crushed and ground finally to reduce it to small crystallites of uniform size. The mixture was

dried and a small amount of PVA binder was added to the powder .The resulting powders were pressed by

applying a pressure of 70Mpa in a stainless steel die to make pellets of 1cm diameter and 1cm thickness. The

pellet samples were well polished to remove any roughness present on the surface of pellets. .For the dielectric

and conductivity measurements; silver paint was applied on the polished surfaces of the pellets and air-dried to

have good ohmic contacts. The binder burn off was carried out by a slow heating rate and soaking time being an

hour.

2.1.3 Instrumentation

D c conductivity measurements were carried out with Keithly 2010 electrometer using two probe methods. The

resistance R was measured for different temperatures and the conductivity was calculated. The impedance

spectroscopy was carried out to find the variation of real and imaginary part of impedance with temperature at

different frequencies using HP-4192A Impedance analyzer.

2.1.2 Synthesis of nanosized BaFe2O4

Barium oxalate and iron oxalate precursors was prepared by dissolving equimolar quantities of barium chloride

and ferrous ammonium sulphate with oxalic acid and was stirred well in a separate beakers. The precipitates of

barium and iron oxalate obtained was filtered through sintered glass crucible and was washed with distilled

water till free from chloride ions and oxalic acid, finally with dry acetone and was then dried under vacuum.

The barium oxalate, iron oxalate and urea were mixed in weight ratio 1:1:5 and ground well in a pestle and

mortar. Resultant solid was placed in a crucible and ignited in microwave oven. The reaction was found to be

completed in about ten minutes at high power level and forms a brown crystalline BaFe2O4 material. On cooling

to room temperature no trace of carbon impurities was observed in the final residue of nano-sized barium ferrite.

2.2Characterization:

The powder X-ray diffraction pattern was obtained from GEOL JDX-8P or SEIMEN (Japan) X-ray

diffractometer using CuK radiation. The morphology of the maghemite sample was obtained from Leica

Cambridge-440 scanning electron microscopy. Bonding in as prepared nano-sized barium ferrite was obtained

from Perkin-Elmer FTIR spectrophotometer (Model-1000).

ISSN: 0975-5462

6533

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

3 Results and Discussion

3.1X-ray diffraction

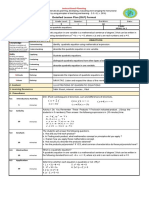

Table-1 shows observed 2 values as well as literature 2 values of the as prepared barium ferrite obtained from

XRD tool. This table also shows the indexing of the XRD peaks of the prepared sample. Observation of

literature 2 values and observed 2 shows the formation of BaFe2O4 sample. Unit cell parameters were

obtained by least square refinement of the powder XRD data. The lattice parameters are in agreement with the

data reported in literature (JCPDS-46-0113). The color of the as synthesized barium ferrite is brown which is

similar to the one which is mentioned in the literature. The average crystalline size was found to be about 74nm

and was calculated using equation (1).

The Average grain size has been calculated using Debye Scherrers equation (1) as shown below

D = 0.9 / 1/2 cos

-------------------- (1)

Where = wave length of the x- ray beam

1/2 = Angular width at the half max intensity

= Braggs angle

Table-1

Indexed XRD data of BaFe2O4 sample

Hkl

2obs

2lit

Iobs

402

28.240

28.235

60

212

28.435

28.428

100

610

32.720

32.716

50

020

33.269

33.266

30

802

43.610

43.604

10

422

44.172

44.164

23

2obs = Observed 2 values, 2lit = literature 2 values Iobs = Observed intensity

Table-2

Vibrational Frequencies of BaFe2O4 sample

Peak No.

1

2

3

4

5

6

7

8

9

10

3.2

Vibrational

Frequencies (cm-1|)

3100

1075

530

475

445

440

250

230

210

200

Scanning Electron Micrograph

Figure-1 shows SEM image of as prepared barium ferrite sample. The particles are irregular in shape with

compact arrangement. In some particles flakes of agglomerates are also observed. Needle shaped particles

forms globular arrangement with self assembled blocks.

ISSN: 0975-5462

6534

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

Figure-1: SEM image of as BaFe2O4 sample

3.3Infrared studies

The infrared study was performed aiming to ascertain the metal-oxygen and metal-metal bond in the prepared

ferrite sample. Table-2 gives the vibrational frequencies of the as synthesized BaFe2O4. The ferrite sample

shows the absorption in the region 3100, 1075, 530, 475, 445, 440, 250, 230, 210 and 200 cm-1. The peak at

3100 cm-1 corresponds to water of adsorption and the peak at1075cm-1 is due to the presence of some overtones.

The peaks at 530, 475, 445 and 440cm-1 correspond to the metal-oxygen vibrational modes of the spinel

compound [13]. The peaks at around 250, 230, 210 and 200cm-1 is observed is due to metal-metal (Ba-Fe)

vibration frequency range. This confirms the formation of BaFe2O4.

3.4 Resistivity

High dc resistivity of 1.75 109 Ohm-cm is obtained at room temperature and it decreases with increase of

temperature according to the Arrhenius equation. Increasing temperature leads to decrease in resistivity, which

is the normal behavior of semiconducting material. Increase in temperature of the sample will help the trapped

charges to be liberated and participate in the conduction process, with the result of decreasing the resistivity.

This decrease in resistivity could be related to the increase in the drift mobility of the thermally activated

electrons according to the hopping conduction mechanism and not to thermally creation of the charge carriers.

[14].

1 .8 0 E + 0 0 9

1 .6 0 E + 0 0 9

1 .4 0 E + 0 0 9

Resistivity

1 .2 0 E + 0 0 9

1 .0 0 E + 0 0 9

8 .0 0 E + 0 0 8

6 .0 0 E + 0 0 8

4 .0 0 E + 0 0 8

2 .0 0 E + 0 0 8

0 .0 0 E + 0 0 0

-2 .0 0 E + 0 0 8

-5 0

50

100

150

200

250

300

350

400

T e m p e ra tu re

Figure-2: Resistivity of BaFe2O4 sample

ISSN: 0975-5462

6535

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

3.5 DC Conductivity

dc S/cm

DC conductivity increases with increasing temperature indicating a semiconducting behavior. The conductivity

obtained here is very less and the maximum conductivity obtained here is 410-8 S/cm at a temperature of 4000

C. The temperature variation of conductivity in this sample studied in the present work confirm to the Arrhenius

law [15] as shown in equation (2),

0 exp(- Edc /KT) -------(2)

Where, Edc activation energy required for the hopping process.

4.0x10

-8

3.0x10

-8

2.0x10

-8

1.0x10

-8

conductivity

0.0

50

100

150

200

250

300

350

400

450

Temperature C

Figure-3: Conductivity of BaFe2O4 sample

3.6 Magnetic studies

The hysteresis loop gives the relation between the magnetization M and the applied field H. The parameters

extracted from the hysteresis loop that are most often used to characterize the magnetic properties of magnetic

media include; the saturation magnetization Ms, the remanence Mr, the coercivity Hc, the squareness ratio SQR,

which is related to the slope at Hc .The squareness ratio is given by the ratio of (Mr/Ms) and is essentially a

measure of how square the hysteresis loop is. In general large SQR values are desired for recording medium

[16].

Magnetic parameters were determined for the sample by using a vibrating sample magnetometer at room

temperature at a maximum applied field of 81 KOe. Saturation magnetization, remanence magnetization and

coercivity were determined from the hysteresis loop and were found to be21.59 emu/gm, 4.55emu/gm and

438.02 Oe, respectively. The squareness ratio is found to be very low i.e.0.2107.Values for both coercivity and

saturation magnetization are found to be lower when as compared to reported bulk values. This could be due to

presence of minor amounts of phases other than barium ferrite.

The hysteresis curves are used to check the difference between the soft magnetic materials and the hard

magnetic materials. For a hard magnetic material, the area inside the hysteresis loop should be large because it

represents the amount of useful magnetic energy that can be made available to do work. But for a soft magnetic

material, it represents undesirable core loss .Materials having properties between hard and soft materials are

referred to as semi-hard magnetic materials.

ISSN: 0975-5462

6536

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

Figure-4: M-H Hysteresis curve of BaFe2O4 sample

3.7. Impedance studies

The complex impedance spectroscopy (CIS) technique was used to analyze the electrical response of the sample

in a wide range of frequencies (1 KHz to 1MHz) at different temperatures (07000 C). The dielectrical

properties of a material are often represented in terms of complex dielectric permittivity *, complex impedance

Z* and electric modulus M*, which are related to each other as: Z*=Z jZ; M*=1/*() = j(C0)Z*=M +

jM, where (Z,M) and (Z,M) are the real and imaginary components of impedance and modulus,

respectively, j = -1 the imaginary factor and is the angular frequency, = 2f[1]. Due to the large amount of

results obtained (five types of samples), we present the results associated only to the present sample, and

however, we claim that the results obtained in all the remaining four samples have similar behavior [17].

3.5x10

4x10

Z'

Z'

3.0x10

2.5x10

3x10

2.0x10

Z'

Z'

1.5x10

2x10

1.0x10

1x10

5

5.0x10

0.0

-5.0x10

(a)

100

200

300

400

500

600

700

(b)

Temperature C

100

200

300

400

500

600

700

Temperature C

500

Z'

2500

Z'

400

2000

300

Z'

Z'

1500

1000

500

200

100

100

200

300

400

500

600

700

100

200

300

400

500

600

700

Temperature C

(c)

(d)

Temperature C

Fig (5) Variation of real part of impedance (Z) with temperature at four different frequencies(a) 1KHz (b) 10KHz (c) 100KHz and (d)

1MHz

ISSN: 0975-5462

6537

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

3.7.1. Variation of real part of impedance (Z)- The variation of real part of impedance (Z) at selected

temperatures and different frequencies is shown in Figs (5). It indicates that the real part of impedance (i.e.,

resistance) decreases with the rise in frequency and temperature. A decrease in Z with the rise in frequency

indicates a possibility of increase in the ac conductivity with the increase in frequency [1].The maximum Z

value obtained is 3.5106 Ohms at a frequency of 1 KHz and a temperature of 3500 C. The minimum value of Z

obtained is 450 Ohms at 1MHz frequency and a temperature of 500C. Due to the large amount of results

obtained (five types of samples are under investigation), we present the results associated only to the present

sample, and however, we claim that the results obtained in all the remaining four samples have similar behavior

[17].

6

3.0x10

1.8x10

(a)

2.5x10

Z''

Z''

(b)

1.6x10

1.4x10

6

2.0x10

1.2x10

1.0x10

Z''

Z''

1.5x10

8.0x10

1.0x10

6.0x10

4.0x10

5.0x10

2.0x10

0.0

0.0

100

200

300

400

500

600

-2.0x10

700

100

200

300

400

Temperature C

1.8x10

1.6x10

(d)

1600

1400

1200

1000

1.4x10

1.2x10

1.0x10

8.0x10

Z''

Z''

600

700

1800

Z''

(c)

500

Temperature C

6.0x10

Z''

800

600

4.0x10

400

2.0x10

200

0.0

-2.0x10

100

200

300

400

500

600

700

Temperature C

-200

0

100

200

300

400

500

600

700

Temerature C

Fig (6) Variation of imaginary part of impedance (Z) with temperature at four different frequencies(a) 1KHz (b) 10KHz (c) 100KHz and

(d) 1MHz

3.7.2. Variation of imaginary part of impedance (Z)

Fig (6) represents the variation of imaginary part of impedance (Z) with different temperatures at different

frequencies. This plot is suitable for evaluation of the relaxation frequency of the most resistive component. The

loss spectrum has some important features: (a) the appearance of two peaks. (b) the value of (Z) decreases and

shifts to the higher frequency side as temperature increases, (c) the first peak, typical peak broadening and the

second peak, typical peak symmetric and a decrease in the height of the peaks with increasing temperature[1].

4. Conclusions

In summary, we have successfully synthesized nanostructured barium ferrite by using microwave synthesis.

Microwave route for metal oxide materials is very simple, energy efficient technique and easy to scale up. Urea

is used as a fuel for the reaction and this fuel can be used for synthesis of other oxide materials. Temperature

dependent DC resistivity decreases with increase in temperature ensuring the semiconductor like nature of the

nanostructured sample.High value of dc resistivity, of the order of 109 cm, makes this ferrite suitable for the

ISSN: 0975-5462

6538

A.M.Bhavikatti et. al. / International Journal of Engineering Science and Technology

Vol. 2(11), 2010, 6532-6539

high frequency applications where eddy current losses are significant. The observation of magnetic hysteresis

loop at room temperature confirms existence of magnetic ordering at room temperature in this sample.

Acknowledgements

The authors are thankful to Prof. A Venkataraman, Department of Materials Science, Gulbarga University,

Gulbarga for helping in XRD analysis. Authors acknowledge Dr. Shashidhar Reddy, IISc,, Bangalore for

providing XRD pattern and SEM images .One of the authors(AMB) would like to thank, Dr.B.B.Lal, principal

REC Bhalki for his constant encouragement.

5. References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

M.M. Costa, G.F.M. Pires Junior, A.S.B. Sombra, Dielectric and impedance properties Studies of the lead doped (PbO)-Co2Y type

hexaferrite (Ba2Co2Fe12O22 (Co2Y)), International Journal of Materials Chemistry and Physics, 123, pp 3539, 2010.

Manish Srivastavaa, Animesh K. Ojha, S. Chaubey, Prashant K. Sharma, Avinash C. Pandey, Influence of calcinations temperature

on physical properties of the nanocomposites containing spinel and CuO phases ,Journal of Alloys and Compounds 494,pp 275

284,2010.

D.Bahadur, S.Rajkumar, Ankit kumar, Influence of Fuel ratios on auto combustion synthesis of barium ferrite nano particles,

Intl.J.Chem .Sci.,Vol, 118, No 1,pp15,2006.

S. Maensiri, C. Masingboon, B. Boonchom and S. seraphin, Scipt. Mater,.56 , pp797, 2007.

M. Sugimoto, J.Am. Ceram. Soc. 1999, 82, 269.

A Lagashetty, S. Kalyani and S.Omprakash. J.Mater. Sci. Res. Ind. 2005, 3(2), 145

Harish Bhat, M., Chakravarthy, B P., Ramakrishnan, P. A., Levasseur, A., and Rao, K. J., Bull. Mater. Sci, 23(6), 461, (2000).

Ramesh, P. D., and Rao, K. J., Adv. Mater. 7,177, (1995)

A. Lagashetty, V. Havanoor, S. Basavaraja, S. D. Balaji and A. venkataraman. Sci. & Tech. Adv. Mater. , 2008.

A.M.Bhavikatti ,Subhash.kulkarni, Arunkumar.Lagashetty, Microwave synthesis of Nano sized Barium Ferrite, at 2nd International

Symposium on advanced materials and Polymers for aerospace and defence applications.(SAMPADA-2008 ) at University of Pune, on

DEC-08th to 12th, 2008

A.M.Bhavikatti ,Subhash.kulkarni, Arunkumar.Lagashetty, Electrical studies of Nano-sized Barium ferrite, International Journal of

Materials Science, ISSN 0973-4589, Volume 4, No4, pp485-492, 2009.

Wen-Tsang Liu , Jyh-Fu Lee , Jenn-Ming Wu , X-ray absorption spectroscopic study of barium ferrite thin films synthesized by sol

gel method, Materials Chemistry and Physics, 69 ,pp8994,2001

C. N .R. Rao, Chemical applications of infrared spectoscopy, Academic Press, New York and London 1963.

J.Chand, M.Singh, Electric and dielectric properties of Mg Gd0.1Fe1.9O4 ferrite, Journal of Alloys & Compounds, 2009-Article in

press

N.R.Reddy, M.Venkataramana, K.Krishnaveni, K.V.Shivakumar, V.R.K.Murthy, Dielectric, elastic, anelastic and conductivity

behavior of ferromagnetic composites Ni0.5Zn0.5Fe1.95O4- +Ba0.8Pb0.2TiO3, Bull. Mater .Sci. Vol.30, No4,pp 357-363,2007.

B. C. Dodrill, Magnetic Media Measurements with a VSM, Lake Shore Cryotronics, Ohio.

A.M.Bhavikatti, Subhash kulkarni, Arunkumar Lagashetty, Impedance Spectroscopy and dc studies of Nano-sized Magnesium

ferrite, International Journal of Materials Science, ISSN 0973-4589, Volume 5, Number 3, pp 351-359, 2010.

Biographies of authors

A M Bhavikatti received a degree in Electronics & communication in 1985, has completed ME in

power electronics in 1991 and is a research scholar in Electronic materials .Till date, he has more

than 35 publications in International and National journals and Conferences .Presently he is a

Professor and Head of Electronics and Communication Engineering Dept at Rural Engineering

College, Bhalki, Karnataka state

Dr.Subhash.S.Kulkarni completed BE in Electronics and Communication Engg in 1988 and

Masters program in Electronic Design & Technology from Indian Institute of Science, Bangalore

in 1995.He was awarded PhD from IIT, Kharagpur in 2002 in the area Geometric Deformable

Models for Image Segmentation .Presently he is working as Principal in Jayaprakash Narayan

College of Engineering, Mahabubnagar, Andhra Pradesh. Till date he has more than 30

publications in International & National journals and Conferences and is guiding 8 research

scholars.

Dr.Arunkumar.Lagashetty completed M.Sc in 2000 and M.phil in 2001 from Gulbarga

University, Gulbarga. He was awarded PhD from Gulbarga University in 2004 in the area of

Physical chemistry .He was a Junior Research fellow for an UGC Project. Till date he has more

than 28 publications in International and National journals and more than 30 publications in

conferences. Presently, he is working as a Head of department of Chemistry at Appa Institute of

Engineering and Technology, Gulbarga, Karnataka state.

ISSN: 0975-5462

6539

Das könnte Ihnen auch gefallen

- Electromagnetic Studies of Nickel Ferrite Synthesized by Microwave RouteDokument9 SeitenElectromagnetic Studies of Nickel Ferrite Synthesized by Microwave RouteFatma MaharaniNoch keine Bewertungen

- Synthesis, Sintering and Dielectric Properties of A Batio - Ni CompositeDokument7 SeitenSynthesis, Sintering and Dielectric Properties of A Batio - Ni CompositeArmando MonteNoch keine Bewertungen

- Synthesis and Characterization of Magnesium Borate Via Sol Gel Method and Electrospinning MethodDokument6 SeitenSynthesis and Characterization of Magnesium Borate Via Sol Gel Method and Electrospinning MethodEditor IJTSRDNoch keine Bewertungen

- Investigation On Barium Zirconate Nanocomposite For Dielectric PropertiesDokument16 SeitenInvestigation On Barium Zirconate Nanocomposite For Dielectric Propertiesazkayounas74Noch keine Bewertungen

- Structural, Magnetic and Electrochemical Properties of Coxzn1-X Fe2O4 Nanoparticles Synthesized by Co-Precipitat..Dokument10 SeitenStructural, Magnetic and Electrochemical Properties of Coxzn1-X Fe2O4 Nanoparticles Synthesized by Co-Precipitat..vijayamathubalan pandyNoch keine Bewertungen

- Ceramics International: Swapnil A. Jadhav, Mangesh V. Khedkar, Sandeep B. Somvanshi, K.M. JadhavDokument11 SeitenCeramics International: Swapnil A. Jadhav, Mangesh V. Khedkar, Sandeep B. Somvanshi, K.M. JadhavJuancho PachonNoch keine Bewertungen

- Materials Letters: Min Lu, Yang Lu, Kangwen Qiu, Jinbing Cheng, Hailong Yan, Yongsong LuoDokument4 SeitenMaterials Letters: Min Lu, Yang Lu, Kangwen Qiu, Jinbing Cheng, Hailong Yan, Yongsong LuoDary LorenaNoch keine Bewertungen

- 181-Mariam Fatima-Ceramic InternationalDokument7 Seiten181-Mariam Fatima-Ceramic InternationalShahid RamayNoch keine Bewertungen

- Structural Dielectric Impedance and Electric ModulDokument15 SeitenStructural Dielectric Impedance and Electric ModulIshfaqNoch keine Bewertungen

- 1 s2.0 S0272884213014090 MainDokument8 Seiten1 s2.0 S0272884213014090 MainAjit Kumar DhankaNoch keine Bewertungen

- Ceramics International: SciencedirectDokument14 SeitenCeramics International: SciencedirectYassine MOUHIBNoch keine Bewertungen

- Vijayan2020 Article MicrowaveCombustionSynthesisOfDokument8 SeitenVijayan2020 Article MicrowaveCombustionSynthesisOfDEPT EEENoch keine Bewertungen

- Dielectric and Magnetic Variance in Nico O Spinels Mediated by ZN Substitution For Efficient Data and Energy StorageDokument11 SeitenDielectric and Magnetic Variance in Nico O Spinels Mediated by ZN Substitution For Efficient Data and Energy StorageYassine MOUHIBNoch keine Bewertungen

- MN SR CoprecipitacionDokument10 SeitenMN SR CoprecipitacionLizbethNoch keine Bewertungen

- Facile Solvent Deficient Synthesis of Mesoporous Co O Nanoparticles For Electrochemical Energy StorageDokument11 SeitenFacile Solvent Deficient Synthesis of Mesoporous Co O Nanoparticles For Electrochemical Energy StorageRohan KoreNoch keine Bewertungen

- Research Article: Preparation and Characterization of Promoted Fe-V/Sio Nanocatalysts For Oxidation of AlcoholsDokument11 SeitenResearch Article: Preparation and Characterization of Promoted Fe-V/Sio Nanocatalysts For Oxidation of AlcoholsAhmed Fouad MusaNoch keine Bewertungen

- Author's Accepted ManuscriptDokument34 SeitenAuthor's Accepted ManuscriptjhaeldagNoch keine Bewertungen

- Synthesis and Characterization of Nickel Cobalt Ferrite Nanoparticles Via Heat Treatment MethodDokument5 SeitenSynthesis and Characterization of Nickel Cobalt Ferrite Nanoparticles Via Heat Treatment MethodyenijosefinasanchezNoch keine Bewertungen

- Ijcps Ijcps Ijcps Ijcps: International Journal of Chemical and Pharmaceutical Sciences 2014, Sep., Vol. 5Dokument7 SeitenIjcps Ijcps Ijcps Ijcps: International Journal of Chemical and Pharmaceutical Sciences 2014, Sep., Vol. 5briyan rhNoch keine Bewertungen

- BN Nanosheets In-Situ Mosaic On MOF-5 Derived Porous Carbon Skeleton For High-Performance Lithium-Ion BatteriesDokument9 SeitenBN Nanosheets In-Situ Mosaic On MOF-5 Derived Porous Carbon Skeleton For High-Performance Lithium-Ion BatteriesRizwan UllahNoch keine Bewertungen

- Polyhedron: Masoud Salavati-Niasari, Fatemeh Davar, Noshin MirDokument5 SeitenPolyhedron: Masoud Salavati-Niasari, Fatemeh Davar, Noshin MirNILTHON FRANCO POMA HUARINGANoch keine Bewertungen

- BFSZU-Volume 2022-Issue 1 - Page 30-36Dokument7 SeitenBFSZU-Volume 2022-Issue 1 - Page 30-36Siddu KLEITNoch keine Bewertungen

- Jurnal SuperkapasitorDokument5 SeitenJurnal Superkapasitorrolan smkn1Noch keine Bewertungen

- SEP1Xx-16-final Version PDFDokument8 SeitenSEP1Xx-16-final Version PDFijasrjournalNoch keine Bewertungen

- Synthesis and Characterizations of BNT - BT and BNT-BT-KNN Ceramics For Actuator and Energy Storage ApplicationsDokument7 SeitenSynthesis and Characterizations of BNT - BT and BNT-BT-KNN Ceramics For Actuator and Energy Storage ApplicationsM CHANDRASEKHARNoch keine Bewertungen

- Development of Multiferroic Polymer Nanocomposite From PVDF and (Bi Ba SR) (Fe Ti) ODokument12 SeitenDevelopment of Multiferroic Polymer Nanocomposite From PVDF and (Bi Ba SR) (Fe Ti) OSubham AdhikariNoch keine Bewertungen

- Characterization of Perovskite-Spinel Nanaocomposites by Chemical RouteDokument8 SeitenCharacterization of Perovskite-Spinel Nanaocomposites by Chemical RouteSoumya MukherjeeNoch keine Bewertungen

- Structural, Electrical and Magnetic Properties of Co-Cu Ferrite NanoparticlesDokument8 SeitenStructural, Electrical and Magnetic Properties of Co-Cu Ferrite Nanoparticlesehagar60Noch keine Bewertungen

- One Pot Synthesis, Characterization of ZN GO Nanocomposite For The Electrochemical Decoloration of A Textile DyeDokument7 SeitenOne Pot Synthesis, Characterization of ZN GO Nanocomposite For The Electrochemical Decoloration of A Textile DyeEditor IJTSRDNoch keine Bewertungen

- Nickel-Zinc Accordion-Fold Batteries With MicrofibrousDokument14 SeitenNickel-Zinc Accordion-Fold Batteries With MicrofibrousMarco Antonio Miranda RodriguezNoch keine Bewertungen

- Dipti PaperDokument19 SeitenDipti PaperShreyaNoch keine Bewertungen

- Processing and Characterization of Charcoal Added Bulk MGB SuperconductorDokument7 SeitenProcessing and Characterization of Charcoal Added Bulk MGB SuperconductorJOSEPH LONGJI DADIELNoch keine Bewertungen

- Synthesis of Highly Magnetic Iron Oxide Nanomaterials From Waste Iron by One-Step ApproachDokument11 SeitenSynthesis of Highly Magnetic Iron Oxide Nanomaterials From Waste Iron by One-Step ApproachIgorCoreixasNoch keine Bewertungen

- V8I4 (13) Q. WeiDokument6 SeitenV8I4 (13) Q. WeiAsif Fareed QaisraniNoch keine Bewertungen

- Observation of Phonon Anharmonicity in SnO2 NanoparticlesDokument14 SeitenObservation of Phonon Anharmonicity in SnO2 NanoparticlesmohanNoch keine Bewertungen

- BN CharacterizationDokument7 SeitenBN CharacterizationSalehin AnamNoch keine Bewertungen

- Zhang 2021Dokument10 SeitenZhang 2021Spades Of BlueNoch keine Bewertungen

- Studies of Rare-Earth-Doped BiFeO3 CeramicsDokument8 SeitenStudies of Rare-Earth-Doped BiFeO3 CeramicsBojan StojadinovićNoch keine Bewertungen

- To DoDokument5 SeitenTo DoPn Linda Mohd KasimNoch keine Bewertungen

- ColloidalDokument24 SeitenColloidalUmair QaziNoch keine Bewertungen

- Phsv04i02p0069 PDFDokument5 SeitenPhsv04i02p0069 PDFphysicsjournalNoch keine Bewertungen

- Production and Characterization of Bio-Based (Bambusa Vulgaris) Porous Activated Carbon For Use As Electrode Material in SupercapacitorDokument15 SeitenProduction and Characterization of Bio-Based (Bambusa Vulgaris) Porous Activated Carbon For Use As Electrode Material in SupercapacitorockiyacliffcNoch keine Bewertungen

- 2021 ArticleDokument17 Seiten2021 ArticleKUMAR RAJASEKARNoch keine Bewertungen

- Magisetty2018Dokument17 SeitenMagisetty2018Riston SinagaNoch keine Bewertungen

- Microwave-Assisted Synthesis and Characterization of Cao NanoparticlesDokument7 SeitenMicrowave-Assisted Synthesis and Characterization of Cao NanoparticlesBeth JiménezNoch keine Bewertungen

- Electrochimica Acta 2 RMKDokument11 SeitenElectrochimica Acta 2 RMKRohan KoreNoch keine Bewertungen

- Superlattices and MicrostructuresDokument10 SeitenSuperlattices and MicrostructuresParmodDhandaNoch keine Bewertungen

- Microwave Sintering of W-18cu and W-7ni-3cu AlloysDokument5 SeitenMicrowave Sintering of W-18cu and W-7ni-3cu AlloysAvijit MondalNoch keine Bewertungen

- Polymer: Adil Sultan, Faiz MohammadDokument12 SeitenPolymer: Adil Sultan, Faiz MohammadenggsantuNoch keine Bewertungen

- S Sutradhar Publication Feb 2021Dokument10 SeitenS Sutradhar Publication Feb 2021Subham AdhikariNoch keine Bewertungen

- 1 s2.0 S0925838821018417 MainDokument11 Seiten1 s2.0 S0925838821018417 MainYassine MOUHIBNoch keine Bewertungen

- Research MaterialsDokument14 SeitenResearch MaterialsDr ADITYA VORANoch keine Bewertungen

- Self-Assembled Palladium Nanoparticles On Carbon NanofibersDokument6 SeitenSelf-Assembled Palladium Nanoparticles On Carbon NanofiberswwNoch keine Bewertungen

- Microwave Absorption Studies On Cobalt Iron Nano-Alloys: Vinod Kumar, R. P. Pant, Anu Rana, and Vikram KumarDokument4 SeitenMicrowave Absorption Studies On Cobalt Iron Nano-Alloys: Vinod Kumar, R. P. Pant, Anu Rana, and Vikram KumarRanu PathakNoch keine Bewertungen

- Journal of Alloys and CompoundsDokument10 SeitenJournal of Alloys and CompoundsHuckkey HuNoch keine Bewertungen

- J Mtener 2021 100774Dokument10 SeitenJ Mtener 2021 100774Hira FiazNoch keine Bewertungen

- Fabrication and Characterization of Silver nanoparticles/PVA Composites For Flexible Electronic ApplicationDokument8 SeitenFabrication and Characterization of Silver nanoparticles/PVA Composites For Flexible Electronic ApplicationYe Zar Ni HtweNoch keine Bewertungen

- 1.a Sonochemical MethodDokument5 Seiten1.a Sonochemical MethodAzadeh VahediNoch keine Bewertungen

- 10 1016@j Materresbull 2013 09 003Dokument8 Seiten10 1016@j Materresbull 2013 09 003Aliy Kanza Al GhiffariNoch keine Bewertungen

- Nanocrystalline Materials: Their Synthesis-Structure-Property Relationships and ApplicationsVon EverandNanocrystalline Materials: Their Synthesis-Structure-Property Relationships and ApplicationsNoch keine Bewertungen

- Predictors of Failure of Endoscopic Retrograde Cholangiography in Clearance of Bile Duct Stones On Initial Procedure: A Moroccan Retrospective StudyDokument4 SeitenPredictors of Failure of Endoscopic Retrograde Cholangiography in Clearance of Bile Duct Stones On Initial Procedure: A Moroccan Retrospective StudyIJAR JOURNALNoch keine Bewertungen

- Detailed Lesson Plan (DLP) Format: Nowledge ObjectivesDokument2 SeitenDetailed Lesson Plan (DLP) Format: Nowledge ObjectivesErwin B. NavarroNoch keine Bewertungen

- Mulligan Vs ART PDFDokument4 SeitenMulligan Vs ART PDFwernsickleNoch keine Bewertungen

- TomatoDokument19 SeitenTomatoaravind kishanNoch keine Bewertungen

- Taskkill To Unlock WindowsDokument3 SeitenTaskkill To Unlock WindowswebbizNoch keine Bewertungen

- Sorting in ALV Using CL - SALV - TABLE - SAP Fiori, SAP HANA, SAPUI5, SAP Netweaver Gateway Tutorials, Interview Questions - SAP LearnersDokument4 SeitenSorting in ALV Using CL - SALV - TABLE - SAP Fiori, SAP HANA, SAPUI5, SAP Netweaver Gateway Tutorials, Interview Questions - SAP LearnerssudhNoch keine Bewertungen

- IBM PVM Getting Started GuideDokument104 SeitenIBM PVM Getting Started GuideNoureddine OussouNoch keine Bewertungen

- NSSCO Chemistry SyllabusDokument52 SeitenNSSCO Chemistry SyllabusEbic GamerNoch keine Bewertungen

- Nutanix OverviewDokument33 SeitenNutanix OverviewDeepak JainNoch keine Bewertungen

- Calculus IIIvectorcalculus 2011Dokument82 SeitenCalculus IIIvectorcalculus 2011Alfi LouisNoch keine Bewertungen

- Solution To Q9 (Vii) Tut-Sheet 3 (By Professor Santanu Dey)Dokument1 SeiteSolution To Q9 (Vii) Tut-Sheet 3 (By Professor Santanu Dey)Prayas JainNoch keine Bewertungen

- gp2 Speed IncreaserDokument2 Seitengp2 Speed Increasermayur22785Noch keine Bewertungen

- Consumer Perception On MatrimonyDokument41 SeitenConsumer Perception On Matrimonydeepak1818Noch keine Bewertungen

- Maintenance Manual Training Presentation - R.ADokument232 SeitenMaintenance Manual Training Presentation - R.AYasir Ammar100% (3)

- Chapter 70 Multi Mooring Systems 2010Dokument135 SeitenChapter 70 Multi Mooring Systems 2010Araby Gamal GamalNoch keine Bewertungen

- Source of HeatDokument9 SeitenSource of HeatSreekumar RajendrababuNoch keine Bewertungen

- Gilian Gilibrator ManualDokument25 SeitenGilian Gilibrator ManualEvaavivahNoch keine Bewertungen

- Clavius' ElementaDokument818 SeitenClavius' Elementapenttila86Noch keine Bewertungen

- As Level Biology Summary Notes (2022-2024 Syllabus)Dokument5 SeitenAs Level Biology Summary Notes (2022-2024 Syllabus)ElisaNoch keine Bewertungen

- Exambank HigherDokument62 SeitenExambank HigherJust WadeNoch keine Bewertungen

- Reversi (Othello) - Game StrategyDokument11 SeitenReversi (Othello) - Game StrategysuperyoopyNoch keine Bewertungen

- Transformer Health IndicesDokument12 SeitenTransformer Health IndicesIngenieria APANoch keine Bewertungen

- Powernel1500 TDS EN 02152006Dokument1 SeitePowernel1500 TDS EN 02152006Magoge NgoashengNoch keine Bewertungen

- DV-08-UK (Oct-07)Dokument28 SeitenDV-08-UK (Oct-07)hepcomotionNoch keine Bewertungen

- 3tnv82a Bdsa2Dokument2 Seiten3tnv82a Bdsa2BaggerkingNoch keine Bewertungen

- Chapter - 20 3-6-05Dokument30 SeitenChapter - 20 3-6-05samandondonNoch keine Bewertungen

- AK TPM Overview TechnionDokument27 SeitenAK TPM Overview Techniongdfeiu dionwdnNoch keine Bewertungen

- Basics of Robotics 24.06.2020Dokument25 SeitenBasics of Robotics 24.06.2020prabhaNoch keine Bewertungen

- What Is Excel Swiss Knife - Excel Swiss KnifeDokument1 SeiteWhat Is Excel Swiss Knife - Excel Swiss KnifevaskoreNoch keine Bewertungen

- Condenser & Heater PerformanceDokument116 SeitenCondenser & Heater PerformanceGaurav Singh100% (2)