Beruflich Dokumente

Kultur Dokumente

036-Nitrogen Purging Procedure PDF

Hochgeladen von

Köksal PatanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

036-Nitrogen Purging Procedure PDF

Hochgeladen von

Köksal PatanCopyright:

Verfügbare Formate

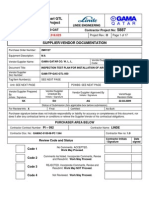

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.250.929

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: B

Page 2 of 9

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

09.10.08

Company Comments Incorporated

SK

EO

AG

CCI

17.09.08

Issued For Review

SK

EO

AG

IFR

24.04.08

Ready for Construction

BR

UA

ZG

RFC

05.12..07

Issued for Company comments

BR

AU/MC

ZG

ICC

27.11.07

Issued for Review

BR

AU/MC

ZG

IFR

22.11.07

Issued for Internal Review

BR

AU/MC

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

PROCEDURE FOR EQUIPMENT NITROGEN

PURGING

LINDE ENGINEERING AG

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

PRO

QAC

GTL

036

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.250.929

Vendor Code

Rev No: B

Q A T A R

Doc. Title

Doc No

PROCEDURE FOR EQUIPMENT NITROGEN PURGING

GAM-PRO-QAC-GTL-036 Rev. F

DATE:

09.10.08

TABLE OF CONTENTS

1.

SCOPE ________________________________________________________________________ 5

2.

PURPOSE _____________________________________________________________________ 5

3.

HSSE _________________________________________________________________________ 5

4.

REFERENCE __________________________________________________________________ 5

5.

DEFINITIONS _________________________________________________________________ 6

6.

RESPONSIBILITIES ____________________________________________________________ 6

7.

GENERAL _____________________________________________________________________ 7

8.

SAFETY REQUIREMENTS _______________________________________________________ 7

9.

PROCEDURE __________________________________________________________________ 7

10.

QUALITY ASSURANCE ________________________________________________________ 8

11.

ATTACHMENTS ______________________________________________________________ 8

T-4.250.929 REV-F

Page 4 of 9

Q A T A R

Doc. Title

Doc No

PROCEDURE FOR EQUIPMENT NITROGEN PURGING

GAM-PRO-QAC-GTL-036 Rev. F

DATE:

09.10.08

1. SCOPE

This procedure applies to the Preservation by Nitrogen purging of equipments to be

installed in C2 ASU PEARL GTL PROJECT by Gama Qatar

2. PURPOSE

The main purpose of this procedure is to describe the minimum requirements applicable

to the Preservation of equipments by Nitrogen purging and to determine the

preservation activities in compliance with the contract and manufacturer/Vendor

requirements.

3. HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan

Industrial City and International standards, codes, LINDE ENGINEERING AG and QSGTL

and/or its PMC requirements and instructions.

In addition all employees and GAMA subcontractor employees on site will have through

LINDE ENGINEERING AG Site Safety Induction and GAMA Qatar Safety induction for site

safety, health, environmental and security prior to work activities. Other training courses will

be attended as required by LINDE ENGINEERING AG or QSGTL and/or its PMC as

required.

4. REFERENCE

DEP 31.29.00.10

Installation of Rotating Equipment

DEP 70.08.10.11

Equipment & Tools for Maintenance (Mechanical

Maintenance Equipment, Tools and Bolt Tensioning)

DEP 70.10.70.11

the preservation of Old and New Equipment and Pipe

Standing Idle

T-4.250.927

Material Handling and Storage

T-4.250.932

Preservation of Equipment

T-4.234.542

Project Quality Plan

T-4.250.929 REV-F

Page 5 of 9

Q A T A R

Doc. Title

Doc No

PROCEDURE FOR EQUIPMENT NITROGEN PURGING

GAM-PRO-QAC-GTL-036 Rev. F

DATE:

09.10.08

5. DEFINITIONS

Company

: QSGTL/or its PMC

Contractor

: LINDE ENGINEERING AG

Sub Contractor

: GAMA QATAR

Contract

: QSGTL Pearl Plant - C2 ASU Project

QCR

: Quality Control Record

QCP

: Quality Control Procedure

QCE

: Quality Control Engineer

QCI

: Quality Control Inspector

QA/QC

: Quality Assurance / Quality Control

TPI

: Third Party Inspection

6. RESPONSIBILITIES

1. GAMA Construction Manager or his designee shall be responsible to eliminate

the leaks and to restore the pressure at the value of minimum 0.2 barg in

accordance with this procedure and Contractors dispositions

2. GAMA QA/QC Mechanical Superintendent shall be responsible, to ensure a

check of the nitrogen pressure, damages to the valves, gauges and the external

surface protection is conducted once a week

3. HSSE Engineer- shall be responsible for monitoring safety performance & where

necessary Initiating corrective action through line management.

T-4.250.929 REV-F

Page 6 of 9

Q A T A R

Doc. Title

Doc No

PROCEDURE FOR EQUIPMENT NITROGEN PURGING

GAM-PRO-QAC-GTL-036 Rev. F

DATE:

09.10.08

7. GENERAL

Source of Nitrogen.

1.

Nitrogen which is shipped with equipment.

2.

Nitrogen should be pure (99.9 % of purity)

NB: Nitrogen purging requirements are in accordance with Manufacturers instructions

8. SAFETY REQUIREMENTS

Nitrogen cylinders shall be secured to a wall or post so they will not tip over or fall.

Gas regulators and cylinder must be checked for damaged threads, dirt, dust, oil or

grease. Dust and dirt must be removed with a clean cloth, while regulators/cylinder with

damage thread replaced.

9. PROCEDURE

Upon receipt from Contractor the Quality Control Inspector shall check the

equipment for nitrogen purging requirement and prepare the Nitrogen purging

report (Attachment ).

the pressure gauges shall be properly protected

The shell side and tube side of the equipment shall be filled with nitrogen at

high purity grade (99.9) and pressurized at a 0.2 barg or as specified by

manufacturer / Vendor.

The equipment shall be protected to avoid damage to the valves, gauges, etc. as

specified by the equipment Manufacturer.

The nitrogen pressure shall be checked once a month and pressure of shell side

shall be recorded on the report.

In case of pressure loss the nitrogen pressure shall be restored using the

nitrogen bottle attached to the equipment.

T-4.250.929 REV-F

Page 7 of 9

Q A T A R

Doc. Title

Doc No

PROCEDURE FOR EQUIPMENT NITROGEN PURGING

GAM-PRO-QAC-GTL-036 Rev. F

DATE:

09.10.08

If any leaks are found, the inspector shall inform the supervisor / Contractor to

take corrective action and shall investigate cause of leaks. The pressure restored

immediately.

The leaks shall be eliminated in accordance with the disposition of Contractor and

the pressure restored with nitrogen at the value of a minimum 0.2 barg and as

specified by manufacturer / Vendor.

If a small drop in nitrogen pressure is noticed, connect the nitrogen hose and the

equipment, open nitrogen regulator and pressure up the equipment as per the

vendor instruction manual.

If a complete drop in pressure is noticed, then prior to re-pressurising with

nitrogen, all air in the equipment shall be removed by flushing the equipment with

nitrogen. This is achieved by introducing nitrogen through the inlet valve while

keeping the outlet valve open to allow the escape of air from the equipment.

This shall continue until all entrapped air is removed, and verified by measuring

the oxygen content of escaping gas. Such incident shall be informed to

Contractor prior to depressurising the equipment.

10. QUALITY ASSURANCE

A Quality Assurance System shall be operated conforming to related standards.

Controls and checks shall be established and documented.

11. ATTACHMENTS

GAM-QCR-QAC-GTL-069

T-4.250.929 REV-F

Page 8 of 9

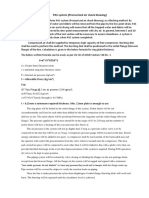

FORM NO:

STORAGE, PRESERVATION AND NITROGEN PURGING REPORT

SHT:

PROJECT: C2 ASU PEARL GTL PROJECT, RAS LAFFAN INDUSTRIAL CITY

EQUIP. TAG.NO.:

DESCRIPTION:

LOCATION:

MANUFACTURER:

DRG.NO.:

RFI NO:

MONTH

ACTIVITY

1

Month

Date Checked

Check all internal and accessories

storage is acceptable

Visual Check : Is there any damage

Check for protective covers on all the

openings

Check all warning labels, like N2

warning plate are existent

Check Purge Pressure level

If Re-purge is required, indicate

pressure level

GAMA SIGN WITH DATE

LINDE SIGN WITH DATE

QSGTL or its PMC

GAM-QCR-QAC-GTL-069

10

11

12

Das könnte Ihnen auch gefallen

- 016-CIVIL - MS Anchor Bolt Installation PDFDokument14 Seiten016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 1.hydrostatic Test and Flushing (R2)Dokument19 Seiten1.hydrostatic Test and Flushing (R2)sethu1091100% (8)

- Procedure For Piping Hydrostatic Pressure Test - 15124-MS-M-006 Rev-1Dokument17 SeitenProcedure For Piping Hydrostatic Pressure Test - 15124-MS-M-006 Rev-1Midhun K Chandrabose100% (3)

- Drying and Nitrogen ProcedureDokument5 SeitenDrying and Nitrogen ProcedureAdaghara67% (3)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDokument23 Seiten014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNoch keine Bewertungen

- 015-MS For Night Works PDFDokument16 Seiten015-MS For Night Works PDFKöksal Patan80% (5)

- Method Statement of Steel FabricationDokument15 SeitenMethod Statement of Steel Fabricationjohney290% (10)

- Hydrotest and Flushing ProcedureDokument16 SeitenHydrotest and Flushing Procedureคุณพ่อน้อง บิ๊กบอส100% (8)

- Pneumatic TestDokument3 SeitenPneumatic Testpuneethkumarr100% (1)

- 041 - ITP For Painting (Building) PDFDokument12 Seiten041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- Pneumatic TestDokument10 SeitenPneumatic Testchitobarba19726762100% (3)

- MS Casting Concrete For Box Culvert 20feb2016Dokument7 SeitenMS Casting Concrete For Box Culvert 20feb2016Joel AlcantaraNoch keine Bewertungen

- A Pocket Guide To CGMP SamplingDokument36 SeitenA Pocket Guide To CGMP Samplinganilpharma102275% (4)

- Air Leak TestingDokument5 SeitenAir Leak Testingkusdiyanta100% (2)

- 011-Method Statement For Repair of Concrete Works PDFDokument25 Seiten011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- High Pressure CleaningDokument8 SeitenHigh Pressure Cleaningmc chesterNoch keine Bewertungen

- Hydrotest Procedure For PipingDokument17 SeitenHydrotest Procedure For PipingMohammad RizwanNoch keine Bewertungen

- Machinery Component Maintenance and RepairVon EverandMachinery Component Maintenance and RepairBewertung: 5 von 5 Sternen5/5 (1)

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Dokument7 SeitenINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Tank Erection Itp & Org ChartDokument34 SeitenTank Erection Itp & Org Charthasan_676489616100% (2)

- Work Method Statement For Piping PrefabricationDokument11 SeitenWork Method Statement For Piping Prefabricationsoumaya yahyaoui100% (3)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDokument25 Seiten007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNoch keine Bewertungen

- Kcsa Construction Qms Induction Rev 01Dokument117 SeitenKcsa Construction Qms Induction Rev 01Adam MulengaNoch keine Bewertungen

- Installation Tray Method StatementDokument5 SeitenInstallation Tray Method StatementMohd FadzleNoch keine Bewertungen

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Dokument7 SeitenWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarNoch keine Bewertungen

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDokument23 Seiten008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNoch keine Bewertungen

- Test Package AttachmentDokument3 SeitenTest Package AttachmentFrancis Mayowa Ezekiel100% (1)

- Hydrotest Procedure For PipelineDokument12 SeitenHydrotest Procedure For Pipelineaike_577% (13)

- 013-MS For Mass Concrete Works PDFDokument26 Seiten013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- PED HelpDokument77 SeitenPED HelpShane Hancock100% (1)

- Method of Statement For Hydrostatic TestingDokument6 SeitenMethod of Statement For Hydrostatic TestingHalil GüneyNoch keine Bewertungen

- Pneumatic Test ProcedureDokument12 SeitenPneumatic Test ProcedurePower Power100% (4)

- Flushing Procedure Final 11Dokument4 SeitenFlushing Procedure Final 11Hamada ELaraby50% (2)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDokument10 Seiten045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 043-ITP FOR Water Proofing (Buildings) PDFDokument13 Seiten043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 048-Itp For Installation of Hvac Unit PDFDokument8 Seiten048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- Air Blowing ProcedureDokument5 SeitenAir Blowing ProcedureArslan NisarNoch keine Bewertungen

- Method Statemant HydroDokument8 SeitenMethod Statemant Hydrojay_rajeshirkeNoch keine Bewertungen

- Sampling PlanDokument3 SeitenSampling PlanGanesh KashinathNoch keine Bewertungen

- Document Ref: Date: 05/08/2020 Psb/Pqp/Qap Rev. No: Project Quality Manual Quality Assurance PlanDokument3 SeitenDocument Ref: Date: 05/08/2020 Psb/Pqp/Qap Rev. No: Project Quality Manual Quality Assurance PlanNizam PodNoch keine Bewertungen

- 6.method Statement For Concrete Repairs Rev. 1Dokument14 Seiten6.method Statement For Concrete Repairs Rev. 1mohsin100% (5)

- 010 - ITP For Hydro TestDokument5 Seiten010 - ITP For Hydro TestSam Jose0% (2)

- Pressure Testing and Purging CalculatorDokument2 SeitenPressure Testing and Purging Calculatoramacathot06100% (5)

- Cable Engineering: Advaris C2Dokument4 SeitenCable Engineering: Advaris C2MeryL AngNoch keine Bewertungen

- 049-Itp For Lighting and Small Power (Building) PDFDokument15 Seiten049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- KSB CurveDokument92 SeitenKSB CurveRagvendra BistNoch keine Bewertungen

- Pneumatic Testing Procedure For PipelinesDokument3 SeitenPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinNoch keine Bewertungen

- 050-Itp For Installation of Air Intake Filter PDFDokument17 Seiten050-Itp For Installation of Air Intake Filter PDFKöksal PatanNoch keine Bewertungen

- Job Hazard Analysis Worksheet: Cold Cutting in Open AreaDokument2 SeitenJob Hazard Analysis Worksheet: Cold Cutting in Open AreaAbdul Hakam Mohamed Yusof0% (1)

- Quality Policy Manual QSM Rev IDokument27 SeitenQuality Policy Manual QSM Rev ISunit MishraNoch keine Bewertungen

- Hydrotest ProcedureDokument6 SeitenHydrotest Procedurebagusu_6Noch keine Bewertungen

- 039-Itp For Embedded Plate PDFDokument7 Seiten039-Itp For Embedded Plate PDFKöksal PatanNoch keine Bewertungen

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDokument16 Seiten012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- Engineering Standard: IPS-E-PR-260Dokument66 SeitenEngineering Standard: IPS-E-PR-260davoodsalimiNoch keine Bewertungen

- Valve ReplacementDokument7 SeitenValve ReplacementKamarularifin Kamel100% (2)

- Istqb Guru Study Guide: Latest ISTQB Questions With AnswersDokument78 SeitenIstqb Guru Study Guide: Latest ISTQB Questions With AnswersErdoğan Hizan100% (1)

- 014-MS For General Scaffolding PDFDokument33 Seiten014-MS For General Scaffolding PDFKöksal Patan100% (2)

- SOP Granulation, CoatingDokument6 SeitenSOP Granulation, CoatingDSP PVCNoch keine Bewertungen

- Nitrogen Purging PDFDokument17 SeitenNitrogen Purging PDFgshdavid100% (2)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDokument17 Seiten010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNoch keine Bewertungen

- Leak Test Procedure InstrumentDokument10 SeitenLeak Test Procedure InstrumentNAVANEETHNoch keine Bewertungen

- FM-QA-044 Rev 02 Supplier Evaluation QuestionnaireDokument6 SeitenFM-QA-044 Rev 02 Supplier Evaluation QuestionnaireAvoor KhanNoch keine Bewertungen

- N2 PurgingDokument5 SeitenN2 PurgingSubbarayan SaravanakumarNoch keine Bewertungen

- 017-CIVIL-MS For Installation of Fence & Gate PDFDokument18 Seiten017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 165 - 2015 - Pavement Design For CT PDFDokument162 Seiten165 - 2015 - Pavement Design For CT PDFattiori fabrice100% (6)

- Tie in Procedure Rev. BDokument8 SeitenTie in Procedure Rev. BgenjiNoch keine Bewertungen

- Pipeline Hydrotest PlanDokument16 SeitenPipeline Hydrotest PlanSunday Paul0% (1)

- 2-MS. Cleaning and Flushing of PipeworkDokument7 Seiten2-MS. Cleaning and Flushing of PipeworkBaha'a F. AbdulhadiNoch keine Bewertungen

- Pressure TestingDokument9 SeitenPressure TestingSanjay SinghNoch keine Bewertungen

- 035-Procedure For Material Traceability and Marking PDFDokument16 Seiten035-Procedure For Material Traceability and Marking PDFKöksal Patan100% (10)

- Integrated Offshore Constr Work-Instruction To Tenderers (Final)Dokument74 SeitenIntegrated Offshore Constr Work-Instruction To Tenderers (Final)Idara Okopido0% (1)

- Shutdown Tie in Procedure 1075 Well 22 Nov 2017Dokument12 SeitenShutdown Tie in Procedure 1075 Well 22 Nov 2017Sumanth Reddy100% (2)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDokument10 Seiten044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- LEAK TEST Method Statement Ponticelli & Total Petroleum.Dokument7 SeitenLEAK TEST Method Statement Ponticelli & Total Petroleum.Fasola Lawal100% (4)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDokument18 Seiten012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNoch keine Bewertungen

- AB-522 Standard Pneumatic Test Procedure RequirementsDokument16 SeitenAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNoch keine Bewertungen

- 009-Civil-Ms Concrete Works PDFDokument27 Seiten009-Civil-Ms Concrete Works PDFKöksal PatanNoch keine Bewertungen

- Calculation Sheet For PurgingDokument7 SeitenCalculation Sheet For PurgingAkintoye Asaolu100% (1)

- 010-MS For Grouting PDFDokument33 Seiten010-MS For Grouting PDFKöksal PatanNoch keine Bewertungen

- Pipeline Drying ProceduresDokument6 SeitenPipeline Drying Proceduresronald rodrigoNoch keine Bewertungen

- 008 - Field Hydrotest ProcedureDokument17 Seiten008 - Field Hydrotest Procedurekaruna346100% (2)

- 031-Procedure For Hydro and Pneumatic Testing PDFDokument36 Seiten031-Procedure For Hydro and Pneumatic Testing PDFKöksal PatanNoch keine Bewertungen

- Quality Assurance and Quality ControlDokument44 SeitenQuality Assurance and Quality ControlArshad AliNoch keine Bewertungen

- Method Statement of Pipeline Pigging Services: Polmaz LimitedDokument10 SeitenMethod Statement of Pipeline Pigging Services: Polmaz LimitedVineet Agrawal100% (1)

- Nitrogen Purging ProcedureDokument17 SeitenNitrogen Purging ProcedureTanver Ali100% (2)

- 008-CIVIL-MS Backfilling Works PDFDokument16 Seiten008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 038-Itp For Coldboxes PDFDokument25 Seiten038-Itp For Coldboxes PDFKöksal PatanNoch keine Bewertungen

- Hydrotest Procedure For PipingDokument4 SeitenHydrotest Procedure For Pipingsuria qaqcNoch keine Bewertungen

- 037-Procedure For Cleanliness PDFDokument21 Seiten037-Procedure For Cleanliness PDFKöksal PatanNoch keine Bewertungen

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDokument28 Seiten047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNoch keine Bewertungen

- Pipe and Vessel PurgingDokument4 SeitenPipe and Vessel PurgingAnonymous v5uipH100% (2)

- Hydrotest Method Statement 12th Mar 2012 1Dokument21 SeitenHydrotest Method Statement 12th Mar 2012 1Saut Maruli Tua Samosir100% (1)

- Accurately Calculate Nitrogen Requirement For Pressure PurgingDokument5 SeitenAccurately Calculate Nitrogen Requirement For Pressure PurgingSuleyman Halicioglu67% (3)

- 013-MS Utilization of Hilti DX 76 PDFDokument51 Seiten013-MS Utilization of Hilti DX 76 PDFKöksal PatanNoch keine Bewertungen

- Procedures For Pigging OperationsDokument5 SeitenProcedures For Pigging Operationsテレブリコ ジェファーソン78% (9)

- 027-PRO For MONITORING OF CONCRETE FOUNDATIONS PDFDokument9 Seiten027-PRO For MONITORING OF CONCRETE FOUNDATIONS PDFKöksal PatanNoch keine Bewertungen

- Execution Procedure For Pipe Connection Tie in and Hot TapzDokument7 SeitenExecution Procedure For Pipe Connection Tie in and Hot TapzyuwantoniNoch keine Bewertungen

- 16" Utue Ka-Ubit PP Gas Pipeline Nitrogen Purging ProcedureDokument17 Seiten16" Utue Ka-Ubit PP Gas Pipeline Nitrogen Purging ProcedureRichard Nwachukwu92% (12)

- 009-Method Statement - Main Erection Sequence For Acc PDFDokument68 Seiten009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 015-Method Statement For Painting Works (Building) PDFDokument21 Seiten015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- International Cyanide Management CodeDokument33 SeitenInternational Cyanide Management CodeRhama WijayaNoch keine Bewertungen

- Equipment Nitrogen Purging Procedure PDFDokument13 SeitenEquipment Nitrogen Purging Procedure PDFKUMAR100% (2)

- 025-Pro For Sewer & Drainage PDFDokument25 Seiten025-Pro For Sewer & Drainage PDFKöksal PatanNoch keine Bewertungen

- Hydrostatic Test Procedure Site RevDDokument23 SeitenHydrostatic Test Procedure Site RevDBhavani Prasad100% (8)

- Specification of Hydro Testing For OnshoreDokument19 SeitenSpecification of Hydro Testing For Onshoreamacathot0685% (13)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDokument18 Seiten046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNoch keine Bewertungen

- 040-ITP For Repair of Steam Distribution Manifold PDFDokument11 Seiten040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNoch keine Bewertungen

- Purging Hydrocarbon PipelinesDokument7 SeitenPurging Hydrocarbon Pipelinesgan_raoNoch keine Bewertungen

- Pressurized Air Shock BlowingDokument3 SeitenPressurized Air Shock BlowingEmir PayNoch keine Bewertungen

- Official ListDokument8 SeitenOfficial ListFrance CaparedaNoch keine Bewertungen

- Tle9 Q1 W2 CSSDokument39 SeitenTle9 Q1 W2 CSSJohn Carl VillarinNoch keine Bewertungen

- Quality Assurance PlanDokument1 SeiteQuality Assurance PlanRaj AcharyaNoch keine Bewertungen

- Project Report On Klaus Union EngineeringDokument37 SeitenProject Report On Klaus Union EngineeringsantoshNoch keine Bewertungen

- Guidance To Identify Barriers in Blood Services Using The Blood System Self-Assessment (BSS) ToolDokument73 SeitenGuidance To Identify Barriers in Blood Services Using The Blood System Self-Assessment (BSS) Toolpemastian mutuNoch keine Bewertungen

- Iecq 04-1-2010Dokument11 SeitenIecq 04-1-2010Martin AnsongNoch keine Bewertungen

- Quality Orientation GuideDokument25 SeitenQuality Orientation Guidethu duongNoch keine Bewertungen

- Astm A-880Dokument5 SeitenAstm A-880Felipe De la cruzNoch keine Bewertungen

- DNV Se 0477Dokument48 SeitenDNV Se 0477Ian HamiltonNoch keine Bewertungen

- Chapter 1 TQM Evolution Semis FinalDokument37 SeitenChapter 1 TQM Evolution Semis FinalDexter CanietaNoch keine Bewertungen

- NHPC Roles Responsibilities 2017Dokument35 SeitenNHPC Roles Responsibilities 2017pctmtstNoch keine Bewertungen