Beruflich Dokumente

Kultur Dokumente

Eliminator Eoe M 00005 en

Hochgeladen von

Shivananda PatraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Eliminator Eoe M 00005 en

Hochgeladen von

Shivananda PatraCopyright:

Verfügbare Formate

Eliminator CCU

Combined cleaning unit for lube oil treatment

The Eliminator.

The Eliminator is an optimized lube oil treatment

solution, combining two high performance Alfa Laval

technologies:

Both components can be built into the same housing

(Eliminator patented by Alfa Laval) or installed separately but

operating in combination. For example:

Full-flow automatic filter for collecting abrasive particles.

Mounted directly on the engine (for high speed engines),

the housing being specifically designed for the engine

block, and the unit promoted with the engine by the engine

manufacturer.

High efficiency disc stack centrifuge removing particles

from the backflush oil before returning to sump.

Remote mounted apart from the engine by means of

flexible or rigid connexions.

The filter and centrifuge installed as separate components

for larger installations or where the flow-rates are higher,

and connected by suitable pipework.

Advantages and benefits

Eliminates full-flow and bypass

cartridge filters, and all the costs

associated with the cartridge filters:

purchasing, transport, handling,

stocking, administration, oil losses,

disposal of used cartridges.

Increased engine availibility no

engine stop for filter cartridge

change.

No filter bypass the engine has

100% protection. In case of failure of

one engine component, the remaining engine parts are protected from

any resulting contamination returning

through the LO system, by the full

flow filter.

Sealed lube oil circuit the lube oil

circuit remains sealed: no risk of

contamination entering the system,

or of oil leakage and spillage occurring.

speed engine-builder customers has

shown that it is possible to double

the lifetime of the lube oil, through

close oil sample analysis.

The filter requiring service during

the normal engine service interval

and overhaul. At this time only a

set of O-rings is required.

Reduced maintenance costs.

The centrifuge requires cleaning up

to every 2500 hours by the

replacement of a paper insert.

Increased oil life-time the high efficiency of the centrifuge compared to

cartridges, keeps the lube oil cleaner,

hence increasing its operational life.

Our experience with some high-

Environmentally-friendly solution due

to no oil loss, no cartridge disposal,

reduced risk of oil spillage and the

possible extended operating life of

the engine lube oil.

Full-flow

filter

From lube

oil pump

Q1

Q2

To engine

Return from

hydraulic

motor

Q3

Centrifuge

Sump

Flow diagram of the Eliminator.

Full-flow automatic filter (A)

The automatic filter is made up of a

number of filter disc elements, each

element composed of two identical

halves. The number of elements

required is defined to meet each

application.

The stainless steel filtering mesh is

contained inside two supporting mesh,

giving an element with a long operating

life-time. This is one key part to the low

life-cycle cost of the unit.

The rigid frame of each element is

made in die-cast aluminium. This frame

has a number of radial ribs separating

each element into 8 or 12 sectors

depending on the element size.

The oil passes through the element

from the inside to outside, via the holes

on the inside edge of the element. The

particles are stopped and are trapped

on the mesh.

The elements are stacked on top of

each other, and hence the ribs form a

collection of independent sectors or

columns.

A rotating distributor set inside the disc

stack assures the backflushing of each

sector in turn by clean oil and is driven

by a hydraulic motor (B). This motor

itself is driven by oil pressure and slowly

rotates the distributor, ensuring the

complete and continuous backflushing

of the filtering surface area.

The rate of backflushing flow is regulated by the centrifuge (35% of the

LO flow-rate).

Centrifuge (C)

The centrifuge is made up of a rotor

(or bowl) spinning on a shaft, driven

by the pressure of oil which is forced

from two nozzles which are at 180

positions around the body. This rotation

is achieved due to the pressure difference from the inlet to outlet sides of

the centrifuge.

The combined filter and

centrifuge product

The full-flow filter and the centrifuge can

be installed in combination in a shared

housing (as shown below), the backflush flow of the filter feeding the centrifuge, where it is cleaned prior to

returning to the engine sump.

Depending on the engine, the Eliminator

housing can be adapted for direct

engine-mounting in place of the existing

filters, or installed separately from the

engine itself and connected through

suitable pipework.

The rotor contains an Alfa Laval disc

stack which enhances the performance

of the centrifuge by between 68 times

compared to a similar centrifuge with

no discs.

Particles down to 2 m and below in

size are retained on the rotor wall, when

the relative specific density of the particles to that of the oil allows. A paper

insert allows for simple removal of the

contaminants collected on the wall of

the centrifuge rotor.

B

A

The Eliminator filter.

Height

Option: Eliminator with clutchable

centrifuge, allowing cleaning or

replacement of the centrifuge,

without stopping the engine.

Leng

th

th

id

W

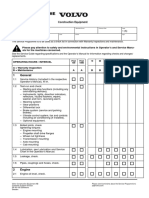

Technical data

Product range

Model

180-14

180-20

240-12

240-18

240-24

240-30

240-36

Q m3/h

to 30

to 35

to 45

to 65

to 85

to 90

to 90

L W H (mm)

884 252 393

956 252 393

904 340 422

988 340 422

1072 340 422

1156 340 422

1240 340 422

Applications

Products suitable for lube oil treatment for engines

burning HFO, DO, distillate or gas fuels. Suitable for

retro-fit installation.

Technical documentation

Complete information and documentation for the main

components and the installation, operation and maintenance

of the filter is contained in the Instruction Book that accompanies delivery of each Alfa Laval filter. Your local Alfa Laval

company will be able to provide more details on the application and sizing of Alfa Laval automatic filters.

EOEM00005EN 0504

How to contact Alfa Laval

Contact details for all countries are

continually updated on our web site.

Please visit www.alfalaval.com to

access the information direct.

Data

Max. filter inlet pressure

Min. filter outlet pressure

Normal filter outlet pressure

No counter pressure allowed

on centrifuge

Max. viscosity in the filter

at normal operation

Max. continuous temperature

in the filter

Normal P (inlet to outlet)

Alarm P

Back-flushing flow

(% of pump capacity)

Mounting position

Test pressure

Housing material

Value

12 bar

3 bar

3.56 bar

75 cSt

120C

0.20.5 bar

0.8 bar

35%

Horizontal

18 bar

Aluminium

Alfa Laval reserves the right to change specifications without prior notification.

ELIMINATOR is a trademark owned by Alfa Laval Corporate AB. ALFA LAVAL is a trademark registered and owned by Alfa Laval Corporate AB.

Eliminator filter with centrifuge.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Naval Architecture DigestDokument19 SeitenNaval Architecture DigestShivananda PatraNoch keine Bewertungen

- Classification Note RSV 3 4 Main Rules DM Aug 2013Dokument26 SeitenClassification Note RSV 3 4 Main Rules DM Aug 2013Shivananda PatraNoch keine Bewertungen

- Aalborg WHR-TG DatasheetDokument1 SeiteAalborg WHR-TG DatasheetShivananda PatraNoch keine Bewertungen

- Ebola Virus Disease: Occupational Safety and HealthDokument5 SeitenEbola Virus Disease: Occupational Safety and HealthShivananda PatraNoch keine Bewertungen

- Carriage of Liquefied GasesDokument7 SeitenCarriage of Liquefied GasessizwehNoch keine Bewertungen

- Bunker ConventionDokument20 SeitenBunker ConventionemailpawarNoch keine Bewertungen

- White Paper o Env 2014 Exhaust GasDokument8 SeitenWhite Paper o Env 2014 Exhaust GasShivananda PatraNoch keine Bewertungen

- Shipping Abbreviations PDFDokument7 SeitenShipping Abbreviations PDFTausif HussainNoch keine Bewertungen

- Defrost Control TypesDokument2 SeitenDefrost Control TypesShivananda PatraNoch keine Bewertungen

- Refrigeration CyclesDokument17 SeitenRefrigeration CyclesKhairatun NisaNoch keine Bewertungen

- البخاخات PDFDokument22 Seitenالبخاخات PDFMarranNoch keine Bewertungen

- WP DistillateFuelOilTreatmentDokument8 SeitenWP DistillateFuelOilTreatmentShivananda PatraNoch keine Bewertungen

- 6.5 Simple Vapor Compression Refrigeration System:: CompresorDokument8 Seiten6.5 Simple Vapor Compression Refrigeration System:: CompresorJay ShuklaNoch keine Bewertungen

- Rubber Tube Sheet Shell-And-tubeDokument2 SeitenRubber Tube Sheet Shell-And-tubeKishore KuttyNoch keine Bewertungen

- PureVent Centrifugal Oil Mist Separator Cleaning Crankcase Gas - 1009Dokument4 SeitenPureVent Centrifugal Oil Mist Separator Cleaning Crankcase Gas - 1009Shivananda PatraNoch keine Bewertungen

- BVI Fin Stabi Z 7-2012Dokument2 SeitenBVI Fin Stabi Z 7-2012Shivananda PatraNoch keine Bewertungen

- Air Compressor Condition ReportDokument1 SeiteAir Compressor Condition ReportShivananda PatraNoch keine Bewertungen

- BVI-Fin Stabi Type S 7 2013Dokument8 SeitenBVI-Fin Stabi Type S 7 2013Shivananda PatraNoch keine Bewertungen

- Brazed Shell-And-tube Heat ExchangersDokument2 SeitenBrazed Shell-And-tube Heat ExchangersShivananda PatraNoch keine Bewertungen

- Flex Separation Systems, S-Separators 921-987 - EMD00233ENDokument6 SeitenFlex Separation Systems, S-Separators 921-987 - EMD00233ENRogerio Salvagni0% (1)

- Flex Separation Systems, S-Separators 921-987 - EMD00233ENDokument6 SeitenFlex Separation Systems, S-Separators 921-987 - EMD00233ENRogerio Salvagni0% (1)

- Alfa Laval s815 ManDokument4 SeitenAlfa Laval s815 ManAbid Lakhani67% (3)

- Alfa Laval s815 ManDokument4 SeitenAlfa Laval s815 ManAbid Lakhani67% (3)

- EMD00062EN LowresDokument2 SeitenEMD00062EN LowresShivananda PatraNoch keine Bewertungen

- Flex Separation Systems, P-Separators 626636 - EMD00232ENDokument6 SeitenFlex Separation Systems, P-Separators 626636 - EMD00232ENShivananda PatraNoch keine Bewertungen

- EMD00056EN LowresDokument2 SeitenEMD00056EN LowresShivananda PatraNoch keine Bewertungen

- Fuel Oil FilterDokument4 SeitenFuel Oil FilterTrișcă Cristian AndreiNoch keine Bewertungen

- EMD00284EN - Lube Oil Filter 350Dokument3 SeitenEMD00284EN - Lube Oil Filter 350Shivananda PatraNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- NAFA Guide To Air FiltrationDokument20 SeitenNAFA Guide To Air Filtrationkesavaganesan58Noch keine Bewertungen

- FAT Protocol PDFDokument2 SeitenFAT Protocol PDFvinodNoch keine Bewertungen

- XAS136Dokument6 SeitenXAS136CarlosNoch keine Bewertungen

- O&m BW211 BW212Dokument124 SeitenO&m BW211 BW212Ricardo Portal70% (10)

- GM Say NO To FlushDokument5 SeitenGM Say NO To FlushRobert MoreauNoch keine Bewertungen

- AAI - Fire AlarmDokument23 SeitenAAI - Fire AlarmGirish Mohan KaulNoch keine Bewertungen

- 2004 Model Year Scheduled Maintenance GuideDokument48 Seiten2004 Model Year Scheduled Maintenance GuidejavierenriqueabadNoch keine Bewertungen

- Honda Hru215 Mower Manual - Wasp Bee Removal Call 0423688352 SydneyDokument87 SeitenHonda Hru215 Mower Manual - Wasp Bee Removal Call 0423688352 SydneyJosé Roberto Simões0% (1)

- Fast Moving Filter and VbeltDokument72 SeitenFast Moving Filter and Vbeltgreicel marianjas sihombingNoch keine Bewertungen

- Motor Nissan Hr16deDokument127 SeitenMotor Nissan Hr16deAdriánSchumm92% (12)

- B Check TrainingDokument3 SeitenB Check TrainingGIGINoch keine Bewertungen

- Master Plan Service 10 - 2022Dokument105 SeitenMaster Plan Service 10 - 2022Yoseph Freinademetz100% (1)

- Chapter 1 5 Modified Indoor Air Purifier With Monitoring SystemDokument118 SeitenChapter 1 5 Modified Indoor Air Purifier With Monitoring SystemDominicNoch keine Bewertungen

- Group 4 - Fuel SystemDokument222 SeitenGroup 4 - Fuel SystemTyler Lee100% (6)

- Guidelines For Fuel Gas Line Cleaning Using Compressed Air or NitrogenDokument74 SeitenGuidelines For Fuel Gas Line Cleaning Using Compressed Air or NitrogenPriyabrat100% (1)

- Iseki - Service Parts Guides PDFDokument35 SeitenIseki - Service Parts Guides PDF徐利斌Noch keine Bewertungen

- Iso 1585 2020 en PDFDokument11 SeitenIso 1585 2020 en PDFBraulio Gutierrez PimentaNoch keine Bewertungen

- Owners Manual Eh09-2d Rammer PDFDokument16 SeitenOwners Manual Eh09-2d Rammer PDFForge GarageNoch keine Bewertungen

- Infographic Fine Particulate Matter EngDokument1 SeiteInfographic Fine Particulate Matter EngBenBlackNoch keine Bewertungen

- Service Programme Backhoe Loaders: Construction EquipmentDokument5 SeitenService Programme Backhoe Loaders: Construction EquipmentMACHINERY101GEARNoch keine Bewertungen

- Owner'S Manual: New Type Cyclone Vacuum CleanerDokument24 SeitenOwner'S Manual: New Type Cyclone Vacuum CleanerniknikolNoch keine Bewertungen

- Cub Cadet Parts Manual For Model 2518 48 TractorDokument9 SeitenCub Cadet Parts Manual For Model 2518 48 Tractorlaura100% (46)

- 7000 EXL Generator Owners ManualDokument24 Seiten7000 EXL Generator Owners Manualabrote7114Noch keine Bewertungen

- Service Manual Aixam MotorDokument140 SeitenService Manual Aixam MotorAlexander Keresztely100% (4)

- NPI Ionizing-Air-Purifier 20210405Dokument8 SeitenNPI Ionizing-Air-Purifier 20210405Selena ThaliaNoch keine Bewertungen

- 3054C Industrial Engine - Maintenance IntervalsDokument34 Seiten3054C Industrial Engine - Maintenance IntervalsAlberto Migraña80% (5)

- Manual Motor Cat c9Dokument127 SeitenManual Motor Cat c9Victor Raul Osnayo Mamani95% (22)

- Doosan DX300LCA 7M SpecDokument28 SeitenDoosan DX300LCA 7M SpecAndrea T FilottoNoch keine Bewertungen

- Cummins K19 Maintainence ScheduleDokument13 SeitenCummins K19 Maintainence Schedulesxturbo100% (1)

- Wheel Excavator: Engine Bucket Specifications Working Ranges Weights DriveDokument36 SeitenWheel Excavator: Engine Bucket Specifications Working Ranges Weights DriveThiago SantosNoch keine Bewertungen