Beruflich Dokumente

Kultur Dokumente

Rowad Debugging Machine

Hochgeladen von

Ronnie De Joya AguirreCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rowad Debugging Machine

Hochgeladen von

Ronnie De Joya AguirreCopyright:

Verfügbare Formate

Profis Anchor 2.5.

www.hilti.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

STL

|

1

ROWAD FACTORY

DEBUGGING MACHINE

4/25/2015

Specifier's comments:

1 Input data

Anchor type and diameter:

HIT-HY 200 + HIT-Z M10

Effective embedment depth:

hef,act = 70 mm (hef,limit = - mm)

Material:

DIN EN ISO 4042

Evaluation Service Report:

ESR-3187

Issued I Valid:

1/1/2015 | 3/1/2016

Proof:

Design method ACI 318-08 / Chem

Stand-off installation:

eb = 0 mm (no stand-off); t = 10 mm

Anchor plate:

lx x ly x t = 140 mm x 200 mm x 10 mm; (Recommended plate thickness: not calculated)

Profile:

no profile

Base material:

cracked concrete, C30/37, fc' = 4351 psi; h = 250 mm, Temp. short/long: 40/24 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

tension: condition B, shear: condition B; no supplemental splitting reinforcement present

Seismic loads (cat. C, D, E, or F)

edge reinforcement: none or < No. 4 bar

no

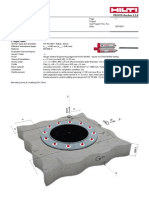

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

2

ROWAD FACTORY

DEBUGGING MACHINE

4/25/2015

Page:

Project:

Sub-Project I Pos. No.:

Date:

STL

|

2 Load case/Resulting anchor forces

Load case: Design loads

y

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Anchor

1

0.000

5.000

2

0.000

5.000

max. concrete compressive strain:

- []

max. concrete compressive stress:

- [N/mm2]

resulting tension force in (x/y)=(0/0):

0.000 [kN]

resulting compression force in (x/y)=(0/0): 0.000 [kN]

2

Shear force x

0.000

0.000

Shear force y

5.000

5.000

3 Tension load

Load Nua [kN]

N/A

Capacity fNn [kN]

N/A

Utilization bN = Nua/fNn

N/A

Status

N/A

Pullout Strength*

N/A

N/A

N/A

N/A

Sustained Tension Load Bond Strength*

N/A

N/A

N/A

N/A

Concrete Breakout Strength**

N/A

N/A

N/A

N/A

Steel Strength*

* anchor having the highest loading

**anchor group (anchors in tension)

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com

3

ROWAD FACTORY

DEBUGGING MACHINE

4/25/2015

Page:

Project:

Sub-Project I Pos. No.:

Date:

STL

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

4 Shear load

Load Vua [kN]

5.000

Steel Strength*

Steel failure (with lever arm)*

Pryout Strength (Concrete Breakout

Strength controls)**

Concrete edge failure in direction x+**

* anchor having the highest loading

Capacity fVn [kN]

9.960

Utilization bV = Vua/fVn

51

Status

OK

N/A

N/A

N/A

N/A

10.000

47.163

22

OK

10.000

46.992

22

OK

**anchor group (relevant anchors)

4.1 Steel Strength

Vsa

= (n 0.6 Ase,V futa)

f Vsteel Vua

refer to ICC-ES ESR-3187

ACI 318-08 Eq. (D-2)

Variables

n

1

Ase,V [mm2]

58

futa [N/mm2]

650.00

(n 0.6 Ase,V futa) [kN]

fsteel

0.600

f Vsa [kN]

9.960

Vua [kN]

5.000

16.600

Calculations

Vsa [kN]

16.600

Results

Vsa [kN]

16.600

4.2 Pryout Strength (Concrete Breakout Strength controls)

Vcpg

= kcp

[(AA ) y

Nc

ec,N

Nc0

yed,N yc,N ycp,N Nb

ACI 318-08 Eq. (D-31)

f Vcpg Vua

ANc see ACI 318-08, Part D.5.2.1, Fig. RD.5.2.1(b)

ANc0 = 9 h2ef

1

2 e'N 1.0

yec,N =

1+

3 hef

ca,min

1.0

yed,N = 0.7 + 0.3 1.5h

ef

ca,min 1.5hef

1.0

ycp,N = MAX c , c

ac

ac

1.5

'

Nb

= kc l fc hef

)

)

ACI 318-08 Eq. (D-2)

ACI 318-08 Eq. (D-6)

ACI 318-08 Eq. (D-9)

ACI 318-08 Eq. (D-11)

ACI 318-08 Eq. (D-13)

ACI 318-08 Eq. (D-7)

Variables

kcp

2

hef [mm]

70

ec1,N [mm]

0

ec2,N [mm]

0

ca,min [mm]

140

yc,N

1.000

cac [mm]

105

kc

17

l

1

f'c [psi]

4351

ANc0 [mm2]

44100

yec1,N

1.000

yec2,N

1.000

yed,N

1.000

fconcrete

0.700

f Vcpg [kN]

47.163

Vua [kN]

10.000

Calculations

ANc [mm2]

65100

Results

Vcpg [kN]

67.376

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

ycp,N

1.000

Nb [kN]

22.821

Profis Anchor 2.5.2

www.hilti.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

STL

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

4

ROWAD FACTORY

DEBUGGING MACHINE

4/25/2015

4.3 Concrete edge failure in direction x+

Vcbg

(AA ) y

Vc

ec,V

Vc0

yed,V yc,V yh,V yparallel,V Vb

ACI 318-08 Eq. (D-22)

f Vcbg Vua

AVc see ACI 318-08, Part D.6.2.1, Fig. RD.6.2.1(b)

AVc0 = 4.5 c2a1

1

2e'v

1.0

yec,V =

1+

3ca1

ca2

1.0

yed,V = 0.7 + 0.3 1.5c

a1

1.5ca1

1.0

yh,V =

ha

0.2

l

1.5

Vb

= 7 e

da l f'c ca1

da

(( )

ACI 318-08 Eq. (D-2)

ACI 318-08 Eq. (D-23)

ACI 318-08 Eq. (D-26)

ACI 318-08 Eq. (D-28)

ACI 318-08 Eq. (D-29)

ACI 318-08 Eq. (D-24)

Variables

ca1 [mm]

190

ca2 [mm]

140

ecV [mm]

0

yc,V

1.000

ha [mm]

250

le [mm]

70

l

1.000

da [mm]

10

f'c [psi]

4351

yparallel,V

2.000

AVc0 [mm2]

162450

yec,V

1.000

yed,V

1.000

yh,V

1.068

fconcrete

0.700

f Vcbg [kN]

46.992

Vua [kN]

10.000

Calculations

AVc [mm2]

131250

Vb [kN]

38.911

Results

Vcbg [kN]

67.132

5 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Condition A applies when supplementary reinforcement is used. The factor is increased for non-steel Design Strengths except Pullout Strength

and Pryout strength. Condition B applies when supplementary reinforcement is not used and for Pullout Strength and Pryout Strength. Refer to

your local standard.

Design Strengths of adhesive anchor systems are influenced by the cleaning method. Refer to the INSTRUCTIONS FOR USE given in the

Evaluation Service Report for cleaning and installation instructions

The ACI 318-08 version of the software does not account for adhesive anchor special design provisions corresponding to overhead applications.

Checking the transfer of loads into the base material and the shear resistance are required in accordance with ACI 318 or the relevant standard!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

STL

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

5

ROWAD FACTORY

DEBUGGING MACHINE

4/25/2015

6 Installation data

Anchor plate, steel: Profile: no profile; 0 x 0 x 0 mm

Hole diameter in the fixture: df = 12 mm

Plate thickness (input): 10 mm

Recommended plate thickness: not calculated

Cleaning: No cleaning of the drilled hole is required

Anchor type and diameter: HIT-HY 200 + HIT-Z M10

Installation torque: 0.025 kNm

Hole diameter in the base material: 12 mm

Hole depth in the base material: 100 mm

Minimum thickness of the base material: 130 mm

Coordinates Anchor mm

Anchor

1

2

x

0

0

y

-50

50

c-x

-

c+x

190

190

c-y

140

240

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

STL

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

ROWAD FACTORY

DEBUGGING MACHINE

4/25/2015

7 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas and

security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be strictly

complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior to using

the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you put in.

Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by you.

Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard to

compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret norms

and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a specific

application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the

regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not use

the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in each case

by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or damaged data or

programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Das könnte Ihnen auch gefallen

- 1 Input Data: Profis Anchor 2.2.4Dokument6 Seiten1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNoch keine Bewertungen

- 1 Input Data: WWW - Hilti.inDokument5 Seiten1 Input Data: WWW - Hilti.inpudumaiNoch keine Bewertungen

- 1 Input Data: WWW - HiltiDokument5 Seiten1 Input Data: WWW - HiltiCibotaru MihaiNoch keine Bewertungen

- Connection d01 1Dokument6 SeitenConnection d01 1Win ThanNoch keine Bewertungen

- Canopy M16 HIT-RE500Dokument5 SeitenCanopy M16 HIT-RE500marchus09Noch keine Bewertungen

- PROFIS Anchor 2.2.6: WWW - Hilti.inDokument6 SeitenPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Noch keine Bewertungen

- Beam End Connection ReportDokument6 SeitenBeam End Connection ReportHibri HalimNoch keine Bewertungen

- Shaft B, Hb1 Kempinski 11-1-17.pa2Dokument7 SeitenShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNoch keine Bewertungen

- Machine RoomDokument6 SeitenMachine RoomRonnie De Joya AguirreNoch keine Bewertungen

- 290mm Thick Slab and 540mm EcenDokument6 Seiten290mm Thick Slab and 540mm EcenihpeterNoch keine Bewertungen

- PROFIS Anchor 2.4.6: WWW - Hilti.luDokument6 SeitenPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.5.2Dokument5 Seiten1 Input Data: Profis Anchor 2.5.2jasekan.dcNoch keine Bewertungen

- Hilti Bolt DesignDokument7 SeitenHilti Bolt Designcheligp1981Noch keine Bewertungen

- H 200mm Thick Slab - Pa2Dokument6 SeitenH 200mm Thick Slab - Pa2ihpeterNoch keine Bewertungen

- Pipe Rack Hilti Bolt CalculationsDokument6 SeitenPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNoch keine Bewertungen

- PROFIS Anchor 2.4.6: WWW - Hilti.luDokument6 SeitenPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNoch keine Bewertungen

- PROFIS Anchor 2.4.6: WWW - Hilti.luDokument6 SeitenPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNoch keine Bewertungen

- PROFIS Anchor 2.0.7Dokument4 SeitenPROFIS Anchor 2.0.7Miky CastenNoch keine Bewertungen

- Kempinski Hilti Rc-ODokument6 SeitenKempinski Hilti Rc-OsobhiNoch keine Bewertungen

- PROFIS Anchor 2.2.0: WWW - Hilti.deDokument6 SeitenPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNoch keine Bewertungen

- 1 Input Data: WWW - Hilti.co - UkDokument6 Seiten1 Input Data: WWW - Hilti.co - UkihpeterNoch keine Bewertungen

- Profis Anchor Design for KWIK HUS-EZ AnchorDokument6 SeitenProfis Anchor Design for KWIK HUS-EZ AnchorJester AbucayNoch keine Bewertungen

- PES Hilti M10 HSA Report RunnerDokument4 SeitenPES Hilti M10 HSA Report RunnerCollin NguNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.4.6Dokument6 Seiten1 Input Data: Profis Anchor 2.4.6Naresh KumarNoch keine Bewertungen

- Profis Anchor Calculation for Three-storey BuildingDokument6 SeitenProfis Anchor Calculation for Three-storey BuildingantonioNoch keine Bewertungen

- Hilti Anchor Design CalculationsDokument5 SeitenHilti Anchor Design CalculationsadelhelmiNoch keine Bewertungen

- Profis Anchor Design SoftwareDokument7 SeitenProfis Anchor Design SoftwareFrancisco BonillaNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.6.6Dokument6 Seiten1 Input Data: Profis Anchor 2.6.6Collin NguNoch keine Bewertungen

- Profis Anchor 2.6.1 Design SoftwareDokument5 SeitenProfis Anchor 2.6.1 Design SoftwareihpeterNoch keine Bewertungen

- 10m Ran Strut Base - Pa2Dokument8 Seiten10m Ran Strut Base - Pa2aikohapNoch keine Bewertungen

- Hilti AnchorDokument5 SeitenHilti AnchorGopi KrishnanNoch keine Bewertungen

- Anchor Design - Hilti (HP)Dokument6 SeitenAnchor Design - Hilti (HP)Harikrishnan PNoch keine Bewertungen

- PROFIS Anchor 2.1.4: WWW - Hilti.atDokument5 SeitenPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15Noch keine Bewertungen

- Hilti - Profis Anchor Design Report 594Dokument5 SeitenHilti - Profis Anchor Design Report 594Madhu GuptaNoch keine Bewertungen

- B3L01 - Detail 1Dokument7 SeitenB3L01 - Detail 1vikramjain66Noch keine Bewertungen

- PES Hilti M10 HSA ReportDokument4 SeitenPES Hilti M10 HSA ReportCollin NguNoch keine Bewertungen

- 6x12 BaseDokument2 Seiten6x12 Basejmwalker90Noch keine Bewertungen

- 1 Input Data: Profis Anchor 2.6.0Dokument2 Seiten1 Input Data: Profis Anchor 2.6.0Collin NguNoch keine Bewertungen

- Anchor Calculations For Roof Top TowerDokument46 SeitenAnchor Calculations For Roof Top TowerRoseLockerNoch keine Bewertungen

- ReportDokument2 SeitenReportpravincs_007Noch keine Bewertungen

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDokument21 SeitenHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNoch keine Bewertungen

- Profis Rebar ReportDokument5 SeitenProfis Rebar ReportSowmya MajumderNoch keine Bewertungen

- 1 Input Data: WWW - Hilti.co - UkDokument3 Seiten1 Input Data: WWW - Hilti.co - UkshoebNoch keine Bewertungen

- Thermosorb Paint ThicknessDokument5 SeitenThermosorb Paint ThicknessKawser HossainNoch keine Bewertungen

- Hilti Monitor - Pa2Dokument2 SeitenHilti Monitor - Pa2Asaru DeenNoch keine Bewertungen

- Hilti Monitor - Pa2Dokument2 SeitenHilti Monitor - Pa2Asaru DeenNoch keine Bewertungen

- 1 Input Data: WWW - Hilti.co - UkDokument2 Seiten1 Input Data: WWW - Hilti.co - UkkarlrossmannNoch keine Bewertungen

- Hilti HST 1Dokument11 SeitenHilti HST 1Mihnea-Bogdan NicolaescuNoch keine Bewertungen

- Anchor Bolt PDFDokument7 SeitenAnchor Bolt PDFRonnie Albert MonteroNoch keine Bewertungen

- Base Plate Design by PROKON.: Input DataDokument4 SeitenBase Plate Design by PROKON.: Input DatainoNoch keine Bewertungen

- Hilti - Calculo Manual de Re500Dokument41 SeitenHilti - Calculo Manual de Re500James ClaytonNoch keine Bewertungen

- Base CHS X 10tDokument7 SeitenBase CHS X 10tCollin NguNoch keine Bewertungen

- Technical Glass - Top BaseplateDokument10 SeitenTechnical Glass - Top BaseplateShafeeq KTNoch keine Bewertungen

- Check For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)Dokument3 SeitenCheck For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)ARYANoch keine Bewertungen

- Re 500Dokument15 SeitenRe 500mazmamrefNoch keine Bewertungen

- Flupec Catalog Etansari Translatie PDFDokument446 SeitenFlupec Catalog Etansari Translatie PDFRadu VasileNoch keine Bewertungen

- IS - Steel Strengthening 8M20 I Profile - Aug 4, 2020Dokument7 SeitenIS - Steel Strengthening 8M20 I Profile - Aug 4, 2020noneNoch keine Bewertungen

- Channel at End of SlabDokument10 SeitenChannel at End of SlabOecoep IteemNoch keine Bewertungen

- Engineering Applications: A Project Resource BookVon EverandEngineering Applications: A Project Resource BookBewertung: 2.5 von 5 Sternen2.5/5 (1)

- Engineering Service Revenues World Summary: Market Values & Financials by CountryVon EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Eaton Busway Detail.Dokument1 SeiteEaton Busway Detail.Ronnie De Joya AguirreNoch keine Bewertungen

- Idges 1973Dokument506 SeitenIdges 1973hcabanillaspNoch keine Bewertungen

- ChainLinkGate Install PDFDokument11 SeitenChainLinkGate Install PDFRonnie De Joya AguirreNoch keine Bewertungen

- Design Manualfor Roads and BridgesDokument39 SeitenDesign Manualfor Roads and BridgesRonnie De Joya AguirreNoch keine Bewertungen

- Ready Mix Concrete Tips - Ready Mix Ordering TipsDokument2 SeitenReady Mix Concrete Tips - Ready Mix Ordering TipsRonnie De Joya AguirreNoch keine Bewertungen

- Machine RoomDokument6 SeitenMachine RoomRonnie De Joya AguirreNoch keine Bewertungen

- CE 48-Timber Design SyllabusDokument3 SeitenCE 48-Timber Design Syllabuspicefeati75% (4)

- Magnesium For AerospaceDokument13 SeitenMagnesium For Aerospacevikrant GarudNoch keine Bewertungen

- Bridge Protective Ship CollisionDokument200 SeitenBridge Protective Ship CollisionJuniorJavier Olivo FarreraNoch keine Bewertungen

- Project Fea Crane HookDokument14 SeitenProject Fea Crane HookUtkarsh TrivediNoch keine Bewertungen

- Lihong Mao, Final Report of Term ProjectDokument42 SeitenLihong Mao, Final Report of Term ProjectApril MayNoch keine Bewertungen

- Nitowrap FRC: Constructive SolutionsDokument2 SeitenNitowrap FRC: Constructive SolutionsbinodNoch keine Bewertungen

- Mean Flange Thickness T Overall Depth DDokument3 SeitenMean Flange Thickness T Overall Depth DAkhil BabuNoch keine Bewertungen

- Uvce 2nd Sem B.e-Mech Syl Copy 2k11Dokument12 SeitenUvce 2nd Sem B.e-Mech Syl Copy 2k11hemanth kumar s gNoch keine Bewertungen

- Vibration Isolation - Mounting SystemsDokument67 SeitenVibration Isolation - Mounting Systemsnaveenmg201100% (1)

- Mmems 2 UDokument163 SeitenMmems 2 UHardeshkumar KumarNoch keine Bewertungen

- PP H2222 36Dokument2 SeitenPP H2222 36keyur1109Noch keine Bewertungen

- Section VIII DIV 2 IndexDokument12 SeitenSection VIII DIV 2 IndexArupendranarayan ThakurNoch keine Bewertungen

- ASME Section II Part A - Ferrous Material SpecificationsDokument44 SeitenASME Section II Part A - Ferrous Material SpecificationsGato SesaNoch keine Bewertungen

- ASTM D882 - 09 ChangesDokument11 SeitenASTM D882 - 09 ChangesMMFAWZYNoch keine Bewertungen

- Sydney Harbour Bridge walking tourDokument35 SeitenSydney Harbour Bridge walking tourMatthew LinNoch keine Bewertungen

- Axial - Loaded Pile PLAXIS 2dDokument4 SeitenAxial - Loaded Pile PLAXIS 2dMarko AdamovićNoch keine Bewertungen

- Capacity Design and Seismic Performance of Multi-SDokument18 SeitenCapacity Design and Seismic Performance of Multi-SclaudioNoch keine Bewertungen

- Echo Prestress Brochure Mar 2020 NewDokument8 SeitenEcho Prestress Brochure Mar 2020 NewAhmadNoch keine Bewertungen

- Devcon Plastic Putty A PDFDokument2 SeitenDevcon Plastic Putty A PDFbollidNoch keine Bewertungen

- SOM Question BankDokument8 SeitenSOM Question BankprakashmenmoliNoch keine Bewertungen

- Spe 114781 MSDokument16 SeitenSpe 114781 MSJessica KingNoch keine Bewertungen

- Analysis and Design of Shopping MallDokument84 SeitenAnalysis and Design of Shopping MallAarathi Lakshmipathy100% (1)

- F 564 - 00 RJU2NC1SRUQ - Emergency SupportDokument15 SeitenF 564 - 00 RJU2NC1SRUQ - Emergency Supportnica tamNoch keine Bewertungen

- Concrete Slab Analysis in ExcelDokument25 SeitenConcrete Slab Analysis in ExcelTuanQuachNoch keine Bewertungen

- Bondek Design & Construct ManualDokument131 SeitenBondek Design & Construct ManualAkuma.Gokai7328100% (12)

- Fatigue Behaviour of Thin Walled Cold Formed Steel ProfilesDokument11 SeitenFatigue Behaviour of Thin Walled Cold Formed Steel ProfilesFarhan DanishNoch keine Bewertungen

- Tir A9 XX - d4 - 9 13 13 - CleanDokument102 SeitenTir A9 XX - d4 - 9 13 13 - Cleany2kareinNoch keine Bewertungen

- Mechanical properties of engineering materials under tensile loadingDokument22 SeitenMechanical properties of engineering materials under tensile loadingKarl ToddNoch keine Bewertungen

- CivilBay Structural Engineering Spreadsheet Tutorial on Anchorage DesignDokument153 SeitenCivilBay Structural Engineering Spreadsheet Tutorial on Anchorage Designhatot100% (1)

- Strut and Tie Model (STM) IntroductionDokument8 SeitenStrut and Tie Model (STM) IntroductionsaharuiNoch keine Bewertungen