Beruflich Dokumente

Kultur Dokumente

Syn Aspartame PDF

Hochgeladen von

Alexiaaaa12Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Syn Aspartame PDF

Hochgeladen von

Alexiaaaa12Copyright:

Verfügbare Formate

A Convenient Synthesis of Aspartame

Gunnar Llndebergl

institute of Biochemistry, University of Uppsala. Box 576. S-751 23 Uppsala, Sweden

Pentide svnthesis, desvite its growing field of annlication

and r~crntlya(:knowledgedimp~~tanre;~usually

iinneglected sublect in chemistrv/biochemistr.v roursos. Onecan think

of several reasons forthis lack of popularity: the chemical

synthesis of peptides, as it is generally exercised, is a timeconsuming and laborious undertaking. Already the preparation of a small peptide is a multi-step procedure where the

total time required cannot be substantially reduced since

reactions and purifications cannot he speeded up beyond

certain limits. Although the synthesis of a simple di- or

tripeptide demonstrates the use of blocking groups and coupling methods, the peptide as such is rarely of particular

interest and can he characterized by physical and chemical

methods only (NMR, IR, end-group determination, chromatographic and electrophoretic behavior, etc.). Small peptides with easily measurable biological effects are few. Larger peptides can-he iynthesized hy ihe solid-phase proredure

111 in what may be judged a reasonahly short periud uf time.

'I'h~rcarr st:vmd hidoyically active peptides in the decapeptide range, for example, hormones; yet considerably

more timeand effort is needed ior their synthesis and puritication than is the case fur di- and tripeprides. In addition,

one is faced with the problem of setting up rather sophisticated assav systems,and there isa risk that the finalemphasisof theexiwriment will lir in r>hvsiolorvrather than rhemistry. 0the; factors, such as the iatheibigh cost of amino

acid derivatives and other reagents, the lack of suitable

equipment for organic chemistr; in many biochemistry laboratories-not to mention special equipment for solid-phase

synthesis-and the handling of aggressive or hazardous

chemicals by inexperienced persons also need consideration.

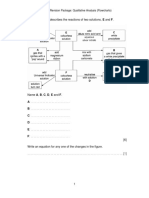

The submitted exveriment. an enzvmatic svnthesis of the

dipeptide sweetener aspartake (2) -that has found widespread use as a sucrose substitute, is an attempt to circumvent most of the objections mentioned above. The application of modern concents in neotide chemistry, such as enzyme-catalyzed coidensakon and catalitic transfer

hvdroaenation, makes the procedure simnle and straightforward @ig. 1).The one-tube synthesis or aspartamecan be

accomplishedeasily in a couple of days and requires a minimum of equipment. The testing of biological activity is also

simple: the threshold value, that is, the lowest concentration

a t which the (sweet) taste can still be detected, is determined

with a dilution series and related to that of a reference

substance (sucrose). The simnle design of the exveriment

also makesit possible to includeone or more analogues in the

synthesis, which allows some conclusions to be drawn about

structural requirements for the hiological effect. The progress of the reactions and the purity of the intermediates can

he conveniently monitored by TLC (Fig. 2 ) or by HPLC (Fig.

3) if such equipment is available.

Methods

The use of proteolytic enzymes as catalysts for synthetic

reactions has found increasing applications in the last few

years, particularly in semi-synthesis of proteins. The elegant

trypsiu-mediated conversion of porcine insulin into the hu-

HCOONH4. PdlC

MeOH

1

Figure 1. Synthesis of aspartame

An excerpt of this paper was presented at the 19th European

Peptide Symposium. Porto Carras, Greece. August 31-September 5.

1986.

I Present address: Institute of Immunology, University of Uppsala,

Box 582.5-751 23 Uppsala, Sweden.

The 1984 Nobel Prize in Chemistry was awarded to R. 6.

Merrifield for the development of solid-phase peptide synthesis.

1062

Journal of Chemical

ducati ion

Figure 2. n C of aspartame and intermediates. (a) Z-Asp-Phe-0Me.H-PheOMe. (b) Z-Asp-Phe-OMe, (c) crude, (d) purified H-Asp-Pha-OMe. (el a

mixture of Z-Asp-OH and H-Phe-OMe. Silica gel in BBuOH:AcOH:H20

(3:t:t).Visualization by UV at 254 nm and ninhydrin (hatched).

man form (3, 4) can be mentioned as an example of that

approach. However, imnll or medium-sized peitidrs have

alio I w n prepared by a ct)mhination of enzymatic and

chemical methods. The reader is referred to one of therecent

reviews in this field, such as the one by Jakubke (5), for

further details. Not surprisingly, aspartame has also been

the subject of enzymatic approaches, and so the first step of

this experiment is patterned on the procedure of Isowa et al.

(6):ZAsp-OH3 is condensed with H-Phe-OMe in the presence of thermolysin to yield the partially protected dipeptide ZAspPhe-OMe. In the presence of excess amine component a sparingly soluble salt is formed that precipitates

. .

f n m the r~actionmixture. Consequently. the equilihrium is

shifted toward synthesis, and therea~tionisdrivenalmvst to

completion. The salt is washed free from enzyme and unreacted material, and treated with aqueous HC1. The m i n e

component, which is acid soluble, is then removed by repeat-

ed centrifugations and washings. The 8-carboxyl in the Asp

residue need not he protected, a fact that considerably facilitates the preparation of starting materials. The peptide

bond is selectively formed between the a-carhoxyl of the

aspartic acid and the amino arouu of the ~henvlalanine

. .

ester. As a matter of fact, thesp&ifieity of the enzyme can he

further exploited: even if one or both of the amino acids is

used as the less expensive DL-derivative, Z-L-Asp-L-PheOMe is still the sole product of the condensation reaction,

and the yield remains essentially unchanged. The dipeptide

salt (Fig. 1) is preferentially formed with H-D-Phe-OMe if

both stereoisomers of that component are present.

Removal of the benzyloxycarbonyl group, the remaining

step of the synthesis, is usually accomplished by acidolysis

(HBrlAcOH) or catalytic hydrogenation. Treatment with

HBrIAcOH must be done under anhvdrous conditions in

order to avoid hydrolysis of peptide and ester bonds and

would in this case reauire an additional d ~ n a s t e nCatalvt.

ic hydrogenation ns"ally proceeds smoothlyiut sometimes

needs considerable time for complete reaction. Since gaseous hydrogen is used, the deprotection has to be carried out

in a well-ventilated hood, a fact that, together with the

problems of hydrogen supply, makes the procedure unsuited

for use in a student laboratory. However, transfer hydrogenation, where the reducing ability is supplied by a hydrogen

donor rather than molecular hydrogen, provides a rapid and

experimentallv s i m ~ l emeans for removal of benzvl-tvoe

prbtecting

'A comprehensive review of catalytic

transfer hvdroaenation was recentlv ~ublishedbv Johnstone

et al. ( 7 ) : ~ i i h the use of two eqiivalents ofammonium

formate as hvdroaen donor (8) and 0.1-0.2 Darts hv

" weight

"

(theoretical values) of 5% PdIC as catalyst, the deblockingof

2-AspPhe-OMe in MeOH is complete in less than 5 min.

The use of the 5% catalyst is recommended because of its

lower tendency for spontaneous ignition once i t has been

activated. The rate of deprotection is not significantly increased with the 10% catalyst originally suaaested ( 8 ) .The

crude product, after removal of caialys<and&vent, is redissolved in water and lyophilized in order to reduce the

amount of volatile salts.

Solutions of aspartame have limited stability, especially

outside the DH reaion 3-5 andlor a t elevated temoeratnre.

Primary dec&npokion products are the free peptiie, which

is formed bv hvdrolvsis of the ester bond a t low DH values.

and the dikftopiper&ne otltained by ring closure mainly at

neutral or alkaline ronditions. The vhvsioloplical effects of

the latter compound in particular, b u i alsovof aspartame

itself, have been questioned on several occasions and, for

some years, caused the withdrawal of aspartame as a food

additive. However, extensive investigations have not confirmed the suspicion that aspartame would be unsuitable for

human consumption. A joint FAOIWHO expert committee

msl

established accentabledailv intake levelsof40.0and 7.5 ---.

kg body weight for aspartame and diketopiperazine, respectivelv (9). In the Dresent exneriment diketoninerazine and

other negatively charged impurities, if present, are removed

bv ion-exchanae chromatoaranhv

- . . immediatelv before dilution and tasting.

A large number of analogues to aspartame have been synthesized in the search for still sweeter substances and with

the aim to explain taste properties

in terms of chemical

. .

structure. The effect of some atrtlctural modifications may

bestudied also in thisexperiment: the influence of the iizeof

the ester group is illustrated by substitution of H-Phe-OEt

for H-Phe-OMe, a change that reduces sweetness potency

to less than half the original value. Elongation of the sidechain carrying the free carboxyl group, accomplished by

exchanging Asp by Glu, yields an inactive (tasteless) prod-

~~~~~~

A.

~~

..

Figure 3. HPLC of aspartame and intermediates. Notations as in Figure 2.

Support: Spherisorb S10 ODs. 4.6 X 150 mm. Buffer A: 0.1 M Jodium

phosphate, pH 3.0. Buffer 8: 0.1 M sodium phosphate, pH 3.0, in 50% EtOH.

Gradient: 5-90% B in 20 min, then isocratic. Flow rate: 1 mL1min. Detection:

UV at 210 nm.

2 = benzyloxycarbonyl(carbobenzoxy).

Volume 64 Number 12 December 1967

1063

uct, whereas deletion of t h e side-chain carhoxvl, that is.

replacement of Asp w i t h Ala, brings a b o u t a conv&ion from

sweet to hitter taste. T h e analogues a r e synthesized essentially b y t h e s a m e methods as t h e p a r e n t compound. Z G l u Phe-OEt, d u e to its higher solubility, is n o t isolated b y

centrifugation h u t is extracted into EtOAc after acidification. T h e simple chromatographic procedure used for aspart a m e a n d t h e other analoeues c a n n o t h e anolied for H-AlaPhe-OMe because t h e drketopiperazine *this case is uncharged. Crvstallization from water is also n o t feasible. since

rapid c y c l i ~ a t i o nis observed when t h e solution is hkated.

However, a homogeneous product is recovered b y extraction

with ice water followed h y lyophilizatiou i n order to remove

volatile salts.

Experimental Procedure

%Asp-OH, ZAla-OH, ZGlu-OH, H-Phe-OMe.HC1 and HPhe-OEt.HC1 were prepared according to published procedures but

are also commerciallv available. Thermolvsin (-40 Ulme) was obtained from ~ o e h r i n- e e~ r l~~ a n, n h e i,m

~ . ~- ~ k n h n from

d e.

Phnrmnx

cia, and 5% palladium on charcoal from Fluka. TLC was run on

Qrecoated silica gel plates (Merck) in n-BuOH:AcOH:H1O (3:l:l). A

solvent migration of 5-10 cm beyond the application line was adequate

~

~~~~~~

~~~

~.

2-Asp-Phe-OMe-H-Phe-OMe

Z-Asp-OH (267 mg, 1mmol) and H-Phe-OMe.HC1 (431 mg, 2

mmol) were weighed into a centrifuge tube of -10 mL capacity and

suspended in HzO (3 mL). The pH was adjusted to 7 (indicator

paper) by portion-wise addition of 4 M NaOH (-700 pL) while the

mixture was being stirred on a vortex mixer. Thermolysin (2 mg in

200 fiL H 2 0 ) was added to the resulting clear solution, which was

then kept in a water bath at 40 'C overnight. Occasionally, the

product precipitated as an oil but this could be brought to crystallize

by repeated caollng and stirring. The precipitate was broken up with

a glass rod, centrifuged and washed by centrifugation with 5 X 4 mL

H20.A sample was collected for TLC.

2-Asp-Phe-OMe

The peptide salt was decomposed by trituration in an ice bath

with a mixture of Hz0 (3mL) and 1M HCI (1mL). A glass rod rather

than a vortex mixer was used for stirring, since the product at this

stage tended to stick to the walls of the tube. After -10 min the

precipitate had changed appearance and gave the impression of

being more compact. I t was centrifuged and washed with 5 X 4 mL

ice water. A sample was saved for TLC.

H-Asp-Phe-OMe, Aspartame

>Asp-Phe-OMe (still moist product above, <1 rnmol) and

HCOONHd (126 mg, 2 mmol) were dissolved in MeOH (2mL). A

sample of the solution was applied onto s TLC plate. The catalyst,

5% PdIC (50 mg), was added and washed down with MeOH (0.5

mL). The suspension was kept at room temperature in the open test

tuhe until gas evolution had ceased (-20 min). Samples were withdrawn and spotted onto the TLC plate after 2,5, and 10 min. The

catalyst was then removed by centrifugation and filtration of the

supernate through a tightly packed plug (5-10 mm) of cotton wool in

a Pasteur pipet. Catalyst and filter were washed with MeOH (0.5

1064

Journal

of Chemical Education

mL). The filtrate was collected in a small beaker and taken to

dryness in a stream of nitrogen with gentle heating (hair dryer). The

residue was dissolved in a small amount af warm water (3-5 mL) and

lyophilized.

H-Asp-Phe-OEt

This substance was prepared according to the above procedure

starting with Z-Asp-OH (267 mg, 1 mmol) and H-Phe-OEt.HCL

(460 mg, 2 mmol).

H-Glu-Phe-OEt

ZGlu-OH (281 mg, 1 mmol) and H-Phe-OEt.HC1 (460 mg, 2

mmol) were condensed as described above. EtOAe (2.5 mL) and 1M

HCI (2 mL) were then added to the reaction mixture, which was

shaken vigorously in order to dissolve the precipitate. The phases

were separated (centrifugation), and the aqueous phase was transferred toa second test tube with the aid of a disposablesyringe fitted

with a short length of polyethylene tubing, and extracted in the

same manner with more EtOAc (2 X 2 mL). The combined organic

extracts were washed with H 2 0 (5 X 2 mL) and sat. NaCL (2 mL)

and then evaporated to dryness in a stream of nitrogen with gentle

heating. The residue was dissolved in MeOH and deprotected as

described above.

~

H-Ala-Phe-OMe

ZAla-OH (446 mg, 2 mmol) and H-Phe-OMe.HC1 (431 mg, 2

mmol) were condensed in the presence of thermolysin (2 mg) after

neutralization with 4 M NaOH (700 pL). The product was collected

by centrifugation and washed with H20 (5 X 4 mL). Deproteetion

was performed in MeOH (4 mL) as described above, hut using 252

mg (4 mmol) of HCOONH4. The residue obtained after evaporation

of the filtrate was extracted in the cold with ice water (2 X 2 mL,

centrifugation). The extract was filtered, lyophilized, and used

without further purification in the sweetness evaluation.

Purification a n d Testing

An aqueous solution of crude lyophilized aspartame (50 mg dissolved in 5 mL of HzO) was neutralized with 2 M NaOH and passed

through a small column (5 X 40 mm, Pasteur pipet) of QAE-Sephadex A-25 (acetate form, packed in H20). The product was eluted

with H20 (2 mL), and its concentration in the eluate was determined

from the UV absorbance (qS7= 200). The solution was diluted to

cover the range 0.003-0.3% and tasted, starting with the lowest

concentration, in order to establish the threshold value. Dilution

series of analogues and sucrose (0.2-490) were treated accordingly.

The sweetness was expressed as the quotient,

=

rhreihuld w l u r (sucrose)

rhreshdd value rpeptidel

I . Merriiiold. R.H. J. Am. ChsmSoc. 1963.85, 2149.

2. Mamr.R. H.;Schlatter, J. M.: Goldkamp,A.H. J.Arn. Cham. Soe 1969,91,2684.

doncsyk, A.; Gattner, H.-G. Hoppp-Seylpr>Z Ph?,>hl.

Chem. 1981.382.M91.

4. Marku.ren.J.I1.K Patent ApplicatinnGB 2069502A. 1981.

6. lakohke, H:D; Kuhl, P.;Konnecke, A.An8eia. Cham. 1ni.Ed. E n d 1985,24,86.

6. Imwa. Y ; Ohmori. M.; lchikawa. T.: Mori, K.; Nonaka, 7.;Kihara. K.; Oyama, K.

Tetrohedmn Lett. 1979.28,2611.

7. dohnrtm~e,R.A. W.; Wi1by.A. H.;Entwistle,I.D. Chem. Re". 1985,8.5, 129.

8. Anwer. M. K.; Spatu1a.A. KSynlhesir 1980.829.

9. Joint FAOiWHO Exwrt Committee on Fond Additives. In WHO Food Addiliues

Serir*: WHO: Geneva, 1982: Vol. 16.pp28-12.

Das könnte Ihnen auch gefallen

- Sucrose DerivativesDokument6 SeitenSucrose DerivativesMuhammadTalalNooriNoch keine Bewertungen

- Sulfonation and Sulfation ProcessesDokument37 SeitenSulfonation and Sulfation Processesanandram100% (1)

- Analysis and Stability of The Sweetener Sucralose in Beverages - M.E. Quinlan - 1990Dokument3 SeitenAnalysis and Stability of The Sweetener Sucralose in Beverages - M.E. Quinlan - 1990Jose M. Gomez RuedaNoch keine Bewertungen

- Mitsunobu and Related Reactions - Advances and ApplicationsDokument101 SeitenMitsunobu and Related Reactions - Advances and ApplicationsSuresh BabuNoch keine Bewertungen

- Organic Polyelectrolytes in Water TreatmentDokument24 SeitenOrganic Polyelectrolytes in Water TreatmentCamille Nunes LeiteNoch keine Bewertungen

- The Diels-Alder Reaction: PROBLEM 22.10Dokument8 SeitenThe Diels-Alder Reaction: PROBLEM 22.10Sandipan Saha100% (1)

- Friedel Crafts ReactionsDokument6 SeitenFriedel Crafts ReactionsjanmanchiNoch keine Bewertungen

- Quanti NST BookDokument178 SeitenQuanti NST BookIffatul Muna100% (1)

- Chalcone Synthesis, Structure DiversityDokument13 SeitenChalcone Synthesis, Structure DiversityDini Elsi ANoch keine Bewertungen

- Modern Chemistry of Aromatic Heterocycles Their Synthesis and Bio-Synthesis and Their Role in LifeDokument25 SeitenModern Chemistry of Aromatic Heterocycles Their Synthesis and Bio-Synthesis and Their Role in LifeAustin Macauley Publishers Ltd.0% (1)

- The Benefits of Industrial SymbiosisDokument33 SeitenThe Benefits of Industrial Symbiosisrobotrobot13Noch keine Bewertungen

- Nobuo Shiraishi, Hiromu Kajita and Misato Norimoto (Eds.) - Recent Research On Wood and Wood-Based Materials. Current Japanese Materials Research (1993)Dokument248 SeitenNobuo Shiraishi, Hiromu Kajita and Misato Norimoto (Eds.) - Recent Research On Wood and Wood-Based Materials. Current Japanese Materials Research (1993)Gr Madong ParhusipNoch keine Bewertungen

- English2as Project-Noble PriceDokument23 SeitenEnglish2as Project-Noble Priceالتداوي بالاعشاب الطبية ببراقيNoch keine Bewertungen

- Linear Combination of Atomic OrbitalsDokument11 SeitenLinear Combination of Atomic OrbitalsAnonymous gUjimJKNoch keine Bewertungen

- Organic Reactions 63 (2004) eDokument366 SeitenOrganic Reactions 63 (2004) emarkiza07Noch keine Bewertungen

- Molinspiration ChembioinformaticsDokument6 SeitenMolinspiration ChembioinformaticsbedibediNoch keine Bewertungen

- Thermal AnalysisDokument28 SeitenThermal AnalysisYuppie RajNoch keine Bewertungen

- Oxidation ReactionDokument32 SeitenOxidation ReactionDeepak PradhanNoch keine Bewertungen

- 0469 PDFDokument477 Seiten0469 PDFyui765Noch keine Bewertungen

- 5991-5411EN Agilent LC Theory EnglishDokument36 Seiten5991-5411EN Agilent LC Theory EnglishBalanMihaelaNoch keine Bewertungen

- Absolute EPR Spin Echo #69A PDFDokument15 SeitenAbsolute EPR Spin Echo #69A PDFchaparalNoch keine Bewertungen

- Modern Aldol Reactions, Part2Dokument346 SeitenModern Aldol Reactions, Part2Kybernetikum100% (1)

- HPLC DetectorsDokument18 SeitenHPLC DetectorssouvenirsouvenirNoch keine Bewertungen

- Experiment 3Dokument3 SeitenExperiment 3Madhu KhanNoch keine Bewertungen

- Thrombolyzer Compact: X Proven. Tough. ReliableDokument2 SeitenThrombolyzer Compact: X Proven. Tough. ReliableRenato DesideriNoch keine Bewertungen

- NEW Annex 7 Qualification of Mass Spectrometers PDFDokument11 SeitenNEW Annex 7 Qualification of Mass Spectrometers PDFParkhomyukNoch keine Bewertungen

- Toxicophores: Groups and Metabolic Routes Associated With Increased Safety RiskDokument13 SeitenToxicophores: Groups and Metabolic Routes Associated With Increased Safety RiskMercedes ArmijosNoch keine Bewertungen

- Azipine PDFDokument58 SeitenAzipine PDFGanesamoorthy Thirunarayanan67% (3)

- Perkin ReactionDokument2 SeitenPerkin Reactionrajaraghuramvarma100% (1)

- Nickel ComplexesDokument6 SeitenNickel ComplexesJugoslavKrstic50% (2)

- Selective Oxidation of Secondary AlcoholsDokument24 SeitenSelective Oxidation of Secondary AlcoholsFernando Silva BetimNoch keine Bewertungen

- Retrosynthetic AnalysisDokument3 SeitenRetrosynthetic AnalysismmiliyasNoch keine Bewertungen

- 7 - 17-156 P - 451-464Dokument14 Seiten7 - 17-156 P - 451-464Selenia ReyesNoch keine Bewertungen

- Converted - Organic Chemistry-Named ReactionsDokument9 SeitenConverted - Organic Chemistry-Named ReactionsTedoh RajNoch keine Bewertungen

- Phosphoric Acids and PhosphatesDokument9 SeitenPhosphoric Acids and PhosphatesIrma Juan AndreasNoch keine Bewertungen

- Functionalization of Indole and Pyrrole Cores Via Michael - Type AdditionsDokument61 SeitenFunctionalization of Indole and Pyrrole Cores Via Michael - Type AdditionsSilvina CancianNoch keine Bewertungen

- Lab BiodieselDokument7 SeitenLab Biodieselskb89Noch keine Bewertungen

- ChemistryResearchandApplicationsColeLynwood Polystyrene - SynthesisCharacteristicsandApplications NovaSciencePubInc2014 PDFDokument320 SeitenChemistryResearchandApplicationsColeLynwood Polystyrene - SynthesisCharacteristicsandApplications NovaSciencePubInc2014 PDFMestviaNoch keine Bewertungen

- Nucleophilic Substitution ReactionDokument17 SeitenNucleophilic Substitution ReactionRojo JohnNoch keine Bewertungen

- Preparation of Nitrobenzene (Nitration of Benzene) : Example On (Electrophilic Aromatic Substitution)Dokument8 SeitenPreparation of Nitrobenzene (Nitration of Benzene) : Example On (Electrophilic Aromatic Substitution)Akhwat Mujahidah100% (1)

- Heterocyclic Chemistry: Parts 2 and 3: Year 3, Semester 1 DR Boa, C301, A.n.boa@hull - Ac.ukDokument26 SeitenHeterocyclic Chemistry: Parts 2 and 3: Year 3, Semester 1 DR Boa, C301, A.n.boa@hull - Ac.ukMohini BajajNoch keine Bewertungen

- Electrophoresis and Capillary Electrophoresis PDFDokument21 SeitenElectrophoresis and Capillary Electrophoresis PDFVinay kumarNoch keine Bewertungen

- Photocatalytic Degradation of Congo Red Dye On Thermally Activated Zinc OxideDokument13 SeitenPhotocatalytic Degradation of Congo Red Dye On Thermally Activated Zinc OxideAmin MojiriNoch keine Bewertungen

- Sodium Phosphate: Volume (ML) of 1 M Nah Po Volume (ML) of 1 M Na Hpo Final PHDokument2 SeitenSodium Phosphate: Volume (ML) of 1 M Nah Po Volume (ML) of 1 M Na Hpo Final PHAkash Pagare0% (1)

- GlycerolDokument10 SeitenGlycerolAshwani KumarNoch keine Bewertungen

- A-Level Chemistry Investigation - Methyl OrangeDokument32 SeitenA-Level Chemistry Investigation - Methyl Orangemattr01100% (3)

- ,MMNBGDokument6 Seiten,MMNBGAnonymous FW5PVUp100% (1)

- Abstract-Volume-last Version PDFDokument121 SeitenAbstract-Volume-last Version PDFClaudio Andres Suarez AuthievreNoch keine Bewertungen

- 16 Cellulose Acetate ElectrophoresisDokument5 Seiten16 Cellulose Acetate ElectrophoresisLeonard BowenNoch keine Bewertungen

- HydrolysisH PDFDokument12 SeitenHydrolysisH PDFEuwan Tyrone PriasNoch keine Bewertungen

- Synthesis Characterization and Biological Evaluation of Somethiazolidinone Derivatives As Antimicrobial AgentsDokument8 SeitenSynthesis Characterization and Biological Evaluation of Somethiazolidinone Derivatives As Antimicrobial Agentssunaina agarwalNoch keine Bewertungen

- Esterification ReactionDokument3 SeitenEsterification ReactionIvenksNoch keine Bewertungen

- Nomenclature of Heterocyclic CompoundsDokument43 SeitenNomenclature of Heterocyclic CompoundsgfdgdghNoch keine Bewertungen

- Heterocycles PDFDokument8 SeitenHeterocycles PDFSiddarth PalletiNoch keine Bewertungen

- Ch1b Ps3 Key SerDokument7 SeitenCh1b Ps3 Key SerRichard ZhuNoch keine Bewertungen

- Atomic SpectrosDokument28 SeitenAtomic SpectrosJorge Rios RNoch keine Bewertungen

- Adv Retrosynthesis PDFDokument29 SeitenAdv Retrosynthesis PDFericaNoch keine Bewertungen

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDokument12 SeitenSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosTheo DianiarikaNoch keine Bewertungen

- 1 s2.0 S0734975005000480 Main PDFDokument10 Seiten1 s2.0 S0734975005000480 Main PDFAlexiaaaa12Noch keine Bewertungen

- 1 s2.0 S0927775714000533 Main PDFDokument7 Seiten1 s2.0 S0927775714000533 Main PDFAlexiaaaa12Noch keine Bewertungen

- 1 s2.0 S1570023206009512 Main PDFDokument16 Seiten1 s2.0 S1570023206009512 Main PDFAlexiaaaa12Noch keine Bewertungen

- 1 s2.0 S0734975005000480 Main PDFDokument10 Seiten1 s2.0 S0734975005000480 Main PDFAlexiaaaa12Noch keine Bewertungen

- 1 s2.0 S0167732215000410 Main PDFDokument8 Seiten1 s2.0 S0167732215000410 Main PDFAlexiaaaa12Noch keine Bewertungen

- 1 s2.0 S104659281500100X Main PDFDokument7 Seiten1 s2.0 S104659281500100X Main PDFAlexiaaaa12Noch keine Bewertungen

- 1 s2.0 S0301462207002359 Main PDFDokument10 Seiten1 s2.0 S0301462207002359 Main PDFAlexiaaaa12Noch keine Bewertungen

- Food and Chemical Toxicology: Marina Marinovich, Corrado L. Galli, Cristina Bosetti, Silvano Gallus, Carlo La VecchiaDokument7 SeitenFood and Chemical Toxicology: Marina Marinovich, Corrado L. Galli, Cristina Bosetti, Silvano Gallus, Carlo La VecchiaDiana Agustini RaharjaNoch keine Bewertungen

- Classes of Antibiotics SummaryDokument1 SeiteClasses of Antibiotics Summaryhanzukik100% (1)

- 1 s2.0 S0021979713000805 Main PDFDokument9 Seiten1 s2.0 S0021979713000805 Main PDFAlexiaaaa12Noch keine Bewertungen

- Syn Aspartame PDFDokument3 SeitenSyn Aspartame PDFAlexiaaaa12Noch keine Bewertungen

- Edulcorantes-The Potential Toxicity of Artificial SweetenersDokument9 SeitenEdulcorantes-The Potential Toxicity of Artificial SweetenersRaul KimNoch keine Bewertungen

- 1 s2.0 S0022283611002324 Main PDFDokument15 Seiten1 s2.0 S0022283611002324 Main PDFAlexiaaaa12Noch keine Bewertungen

- Amsterdam For Website UvA PDFDokument31 SeitenAmsterdam For Website UvA PDFAlexiaaaa12Noch keine Bewertungen

- Effects of Aspartame Metabolites On Astrocytes and NeuronsDokument8 SeitenEffects of Aspartame Metabolites On Astrocytes and NeuronsAlexiaaaa12Noch keine Bewertungen

- Penicillin Fermentation Mechanisms and Models PDFDokument15 SeitenPenicillin Fermentation Mechanisms and Models PDFAlexiaaaa12Noch keine Bewertungen

- Antibiotics 2Dokument4 SeitenAntibiotics 2amatoryfictionliteraNoch keine Bewertungen

- Medicinal Outline 11-4-04Dokument24 SeitenMedicinal Outline 11-4-04Hassan NaqviNoch keine Bewertungen

- Alexander Fleming's Miraculous Discovery of PenicillinDokument5 SeitenAlexander Fleming's Miraculous Discovery of PenicillinZulhasri WahapNoch keine Bewertungen

- 1 Classification of The AntibioticsDokument5 Seiten1 Classification of The AntibioticsMiguelNoch keine Bewertungen

- J. Antimicrob. Chemother.-2003-Kümmerer-5-7 PDFDokument3 SeitenJ. Antimicrob. Chemother.-2003-Kümmerer-5-7 PDFAlexiaaaa12Noch keine Bewertungen

- PenicillinDokument5 SeitenPenicillinAlexiaaaa12Noch keine Bewertungen

- bph0163 0184 PDFDokument11 Seitenbph0163 0184 PDFAlexiaaaa12Noch keine Bewertungen

- Antibiotics in EndodonticsDokument10 SeitenAntibiotics in EndodonticstarekrabiNoch keine Bewertungen

- 1 s2.0 S1319016415000882 Main PDFDokument5 Seiten1 s2.0 S1319016415000882 Main PDFAlexiaaaa12Noch keine Bewertungen

- Antibiotics 1106Dokument2 SeitenAntibiotics 1106MagesssNoch keine Bewertungen

- AntibioticsDokument4 SeitenAntibioticsAnnisa Chaerani BurhanuddinNoch keine Bewertungen

- Analysis of Three Penicillin Antibiotics (Ampicillin, Amoxicillin and Cloxacillin) of Several Iranian Pharmaceutical Companies by HPLCDokument11 SeitenAnalysis of Three Penicillin Antibiotics (Ampicillin, Amoxicillin and Cloxacillin) of Several Iranian Pharmaceutical Companies by HPLCbeletristicliteraturNoch keine Bewertungen

- ANTIBIOTICSDokument18 SeitenANTIBIOTICSNisha Pillai100% (1)

- Mass SpectrometryDokument27 SeitenMass Spectrometryciborg1978Noch keine Bewertungen

- Chapter 2 QuizDokument4 SeitenChapter 2 Quizapi-296550987Noch keine Bewertungen

- 1E7 Rehabilitation AD 2Dokument111 Seiten1E7 Rehabilitation AD 2alexrodriguezabcNoch keine Bewertungen

- Objectives Chemical Effects of Electric - 1Dokument3 SeitenObjectives Chemical Effects of Electric - 1VinodNoch keine Bewertungen

- Chlorination Mass Balance Calculation: Legend Overall Reactions (Mol/Hr)Dokument2 SeitenChlorination Mass Balance Calculation: Legend Overall Reactions (Mol/Hr)Husni RadiyanNoch keine Bewertungen

- A Review of Graphene Based Nanostructural Materials For Both Catalyst Supports and Metal Free Catalysts in PEM Fuel Cell Cxygen Reduction ReactionsDokument25 SeitenA Review of Graphene Based Nanostructural Materials For Both Catalyst Supports and Metal Free Catalysts in PEM Fuel Cell Cxygen Reduction ReactionsoceanforestNoch keine Bewertungen

- 17-7 Material PDFDokument5 Seiten17-7 Material PDFJothi ManiNoch keine Bewertungen

- TDS BM66Dokument1 SeiteTDS BM66hatemNoch keine Bewertungen

- Corrosion and Degradation of MaterialsDokument25 SeitenCorrosion and Degradation of MaterialsNexan Delos AngelesNoch keine Bewertungen

- Course Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)Dokument8 SeitenCourse Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)SanthaKumar Muthu ThankaveluNoch keine Bewertungen

- Afrox Megapac: Welding Consumables Carbon SteelsDokument3 SeitenAfrox Megapac: Welding Consumables Carbon SteelsBranko FerenčakNoch keine Bewertungen

- Fundamental Studies of Copper Anode Passivation During Electrorefining: Part I. Development of TechniquesDokument7 SeitenFundamental Studies of Copper Anode Passivation During Electrorefining: Part I. Development of TechniquesLeandro GuzmánNoch keine Bewertungen

- SHS ELS Module 3Dokument23 SeitenSHS ELS Module 3sei gosa0% (1)

- Molar Mass Activity For Grade 11 ChemistryDokument2 SeitenMolar Mass Activity For Grade 11 ChemistryMatthew GreesonNoch keine Bewertungen

- Study of Holding Time, Fade Effect and Microstructure in Ductile IronDokument14 SeitenStudy of Holding Time, Fade Effect and Microstructure in Ductile Irondemiancito06Noch keine Bewertungen

- Comparative Life Cycle Environmental Assessment of CCS TechnologiesDokument11 SeitenComparative Life Cycle Environmental Assessment of CCS Technologiesmiguel_jose123Noch keine Bewertungen

- 4E5N Science (Chemistry) : Revision Package: Qualitative Analysis (Flowcharts)Dokument11 Seiten4E5N Science (Chemistry) : Revision Package: Qualitative Analysis (Flowcharts)RizXNoch keine Bewertungen

- RPS22 Iss 10 Chromating of Magnesium AlloysDokument20 SeitenRPS22 Iss 10 Chromating of Magnesium AlloysshaggerukNoch keine Bewertungen

- Narancsos SzappanDokument1 SeiteNarancsos SzappanEmőke BarabásNoch keine Bewertungen

- Astm B21Dokument5 SeitenAstm B21caop217Noch keine Bewertungen

- HiPrep Q - HP Q - FF SP - HP 16 - 10 Litdoc28941323 - 20130114100615Dokument19 SeitenHiPrep Q - HP Q - FF SP - HP 16 - 10 Litdoc28941323 - 20130114100615Ana SmolkoNoch keine Bewertungen

- Friction of CeramicsDokument37 SeitenFriction of CeramicsChandrika LakhanpalNoch keine Bewertungen

- 2D Nanomaterials As LubricantDokument14 Seiten2D Nanomaterials As LubricantwhutecompressorNoch keine Bewertungen

- Iso 8502-9Dokument13 SeitenIso 8502-9DARYONO sudaryonoNoch keine Bewertungen

- Glass To Metal JointsDokument11 SeitenGlass To Metal JointsNeilNoch keine Bewertungen

- Activity 4 BiomoleculesDokument3 SeitenActivity 4 Biomoleculeseva palattaoNoch keine Bewertungen

- SART For Copper Control in Cyanide Heap Leaching: by M. Stewart, and D. KappesDokument7 SeitenSART For Copper Control in Cyanide Heap Leaching: by M. Stewart, and D. KappesVasily ShapovalenkoNoch keine Bewertungen

- Bonding, Structure and Periodicity TestDokument9 SeitenBonding, Structure and Periodicity TestMišel VuittonNoch keine Bewertungen

- Unit 4.7 - Spectroscopy and Chromatography - TestDokument15 SeitenUnit 4.7 - Spectroscopy and Chromatography - TestSan SiddzNoch keine Bewertungen

- IB Chemistry IA Eggshell LabDokument8 SeitenIB Chemistry IA Eggshell LabNour Makarem0% (3)

- Revuelta 2011Dokument115 SeitenRevuelta 2011Simona ScutarasuNoch keine Bewertungen

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesVon EverandA New Approach to HAZOP of Complex Chemical ProcessesNoch keine Bewertungen

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Physical and Chemical Equilibrium for Chemical EngineersVon EverandPhysical and Chemical Equilibrium for Chemical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Phase Equilibria in Chemical EngineeringVon EverandPhase Equilibria in Chemical EngineeringBewertung: 4 von 5 Sternen4/5 (11)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- Principles and Case Studies of Simultaneous DesignVon EverandPrinciples and Case Studies of Simultaneous DesignNoch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesVon EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNoch keine Bewertungen

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesVon EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNoch keine Bewertungen

- Distillation Design and Control Using Aspen SimulationVon EverandDistillation Design and Control Using Aspen SimulationBewertung: 5 von 5 Sternen5/5 (2)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Von EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Noch keine Bewertungen

- Fundamentals of Risk Management for Process Industry EngineersVon EverandFundamentals of Risk Management for Process Industry EngineersNoch keine Bewertungen

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- Biotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsVon EverandBiotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringVon EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesVon EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNoch keine Bewertungen