Beruflich Dokumente

Kultur Dokumente

RAJAMANE Full - Catalog - 09 PDF

Hochgeladen von

chidambaram kasiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RAJAMANE Full - Catalog - 09 PDF

Hochgeladen von

chidambaram kasiCopyright:

Verfügbare Formate

R

CE

ISO 9001 : 2000

Certificate: 041009396

NORD

COOLANT PUMPS FOR . . .

Machining . . .

Flooding

Circulating Ink / Varnish

Grinding

Chip Conveyer

Filtration . . .

. . . High Pressure Cooling

Through Tool

Washing

Filtration . . .

Refrigeration/

Temperature Control . . .

Printing

Packing

Welding . . .

. . . Oil Skimming

Belt

Disc . . .

Product Of Proven Performance

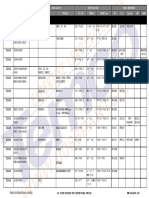

COOLANT PUMPS

RECOMMENDATION CHART

SEMI OPEN

X X

X X X X / X X

X X

RK3.5.7, RMS400-800

X X

X X X X / X X

X X

RKC100.500

X X

X X X X / X X

X X

RKM200

RKM300,RKM400

X X

X X / X / X X

RKM100,RKM250

RMS400-800

X X

X X X X / X X

RR50

X X

X X X X / X X

RMB-V-50..100

X X

X X / X / X X

RKM060

X X

X X X X X X X

10

RMH 060, 0250

X X

X X X X X X X

11

RK 060

X X

X X X X

12

RKM 0250, 050

X / X X

13

RPP

14

RTH45

X

X - USABLE

NOTE :

POLLUTION

/ /

/ / / X /

X X

X X / X X X X

X

/

X

X

/ - PLEASE ASK BEFORE SELECTING

POLLN. LEVEL

COARSE

> 1MM

MEDIUM

0.5 TO 1 MM

FEW

< 0.5

X

X

X

X

TYPE

SHEET METAL

FABRICATED.

FEW

RK275..800

CASTED

MEDIUM

CLOSED

SOLVENTS

COARSE

DE IONISED WATER

CHEMICALS

WATER

EMULSIONS

WASHING

CIRCULATING

GRINDING

X X X X X X X

TURNING

X X

RV25.250

MILLING

SAWING

BORING

IMPELLER TYPE

30-40%

20%

10-20%

PERIPHERAL

POLLUTION

MEDIUM

CHILING

HIGH TEMPERATURE

APPLICATION

COOLANT & LBRCTS

SERIES

SNo

COOLANT PUMPS

CATALOG INDEX

PAGE

NO.IN

CAT.

MODEL/SERIES

SALIENT FEATURES

(FOR DETAILED SELECTION CHART REFER

RECOMMENDATION CHART)

4

5

RV25.... RV250

RKC & RSM

SINGLE STAGE COOLANT PUMPS FOR CONVENTIONAL MACHINES, HIGHLY

EFFICIENT, UPTO 1 MTR. IMMERSION DEPTH

RK275....800

SINGLE STAGE, HIGH FLOW COOLANT PUMP, FOR GRINDING MACHINES,

FILTRATION SYSTEMS.

RK3.5......RK7

RKC & RSM

BOTTOM OUTLET, SINGLE STAGE & COUPLED TYPE PUMPS FOR FILTRATION

APPLICATION.

RPP

ALL POLY-PROPELENE PUMPS FOR SPECIAL APPLICATION

10

RMB-V

TANK TOP MOUNTING TYPE, IMPORT SUBSTITUTE PUMPS FOR CNC MACHINES.

11

RR50

COMPACT, LOW IMMERSION, HIGH PRESSURE PUMPS FOR CNC LATHES,

TEMPERATURE CONTROL EQUIPMENTS

12

RKM0250

RKM050

MULTISTAGE, COMPACT PUMPS FOR CLEAN LIQUIDS FOR WATER, COOLANT

EMULSIONS FOR CHILLERS / REFRIGIRATION / SPINDLE COOLING

13

RMH0250

HORIZONTAL PUMPS, FOR SPECIAL APPLICATIONS. FOR CHILLERS /

REFRIGIRATION / SPINDLE COOLING

14

RKM060

ALL STAINLESS STEEL PUMP PARTS, EFFICIENT PUMPS FOR CNC HIGH PRESSURE

APPLICATIONS.

15

RTH45

BRINKMANN PUMPS, GERMANY PUMP PORTION, COUPLED WITH RAJAMANE

MOTORS FOR HIGH PRESSURE APPLICATIONS. THROUGH COOLANT APPLICATION

16

RMH060

HORIZONTAL, ALL STAINLESS STEEL PUMP PARTS FOR SPECIAL APPLICATIONS.

17

RKM100

MOST POPULAR, MEDIUM PRESSURE PUMPS FOR ALL CNC TURNING CENTRES &

MACHINING CENTRES

18

RKM200 & 300

MULTISTAGE PUMPS FOR MACHINING CENTRES

19

RKM250

MOST RUGGED, MULTISTAGE PUMPS WITH HIGHER CONTAMINATION

HANDLING CAPACITY. FOR CNC MACHINING CENTRES

20

RMS400....800

MULTISTAGE, HIGH PRESSURE & HIGH FLOW PUMPS FOR COOLANTS WITH

CONTAMINATION. COMPONENT WASHING.

21

ROS

OIL SKIMMENS FOR REMOVAL OF FLOATING OIL FROM COOLANT TANKS.

22

RSB

STIRRERS, IN COMPACT SIZES FOR CHILLER UNITS, FOR USE IN COOLANT

TANKS AND SIMILAR APPLICATIONS.

23

GENERAL INFORMATION ON OUR OTHER PRODUCTS.

24

BRINKMANN

PUMPS

SPECIAL BRINKMANN PUMPS FOR MACHINE TOOLS INDUSTRY.

TECHNICAL INFORMTION

COOLANT PUMPS

Technical Information

I.

ELECTRICAL:

1.

Always connect the 3 phase coolant pumps through suitable OLR or MPCB to avoid motor failures due to

overloading, voltage fluctuations, single phasing , etc.

2.

All standard coolant pumps are fitted with Induction motors having specifications as- 415V,50Hz, 3 Phase, S1 duty,

CL-F/B. ,2800 RPM. The power rating is given against the pump model. Other voltage, insulation Class & frequency

are available on request.

3.

Self cooling motors (TESC) are fitted for coolant pumps with upto 0.18kW rating. These motor body temperature

raise have been tested & are within the range specified in class of insulation section. The body temperature of these

motors will be within 80O C even when felt very hot by bare hand.

4.

Temperature raise: All motor temperature raise is as under, based on its class of insulation, in addition to the

ambient temperature (room temperature):

Class of Insulation

Temperature Raise

80o C

120o C

5.

OLR/MPCB setting: set the current in these at 10% higher than that on the nameplate, to avoid nuisance tripping

caused by variation in loads, voltages, supply frequency, etc. The motors are capable of taking this extra current.

6.

Frequency Drive: Most of the motors are suitable for operating through frequency drive, from 0-50 Hz. For

overloading with 60 Hz. ask factory.

7.

Connection diagrams:

Standard 3 leads, for direct online start

U

Dual speed-dhahlender winding:

FOR LOW SPEED:

FOR HIGH SPEED:

Supply

SUPPLY

OPEN

SUPPLY

SHORT

A2B2C2

A1B1C1

A1B1C1

A2B2C2

TO CHANGE THE DIRECTION

OF ROTATION INTERCHANGE

ANY TWO SUPPLY LEADS.

Dual voltage connection :

LOW VOLTAGE

A1

B1

C1

C2

A2

B2

FOR LOW VOLTG: SHORT

A1C2,B1A2,C1B2

SUPPLY A2,B2,C2

FOR HIGH VOLTG.:SHORT A1B1C1

SUPPLY A2B2C2

or

HIGH VOLTAGE

A1

B1

C1

A2

B2

C2

(colour coded)

Single phase Motor :

Star-delta connection-for 5.5kw & above:

U1

V1

W2 U 2

W1

U1

V1

A1M1

V1

For star/delta starter

SUPPLY

W1

For Direct online start

CAP

M2

For changing the direction, interchange

M1 & M2

(For D.O.L. starting connect in delta. For through starter, remove shorting leads.)

A2

COOLANT PUMPS

8.

II.

Current rating: the current ratings of the pump motors, against their kW is given below. This table is for 2 pole

(2800RPM) motors only. If the pump is fitted with special motor of other RPM, call factory for current details:

Power

in kW

Current

in A

Power

in kW

Current

in A

Power

in kW

Current

in A

Power

in kW

Current

in A

0.08

0.24

0.54

1.5

1.7

3.5

0.1

0.34

0.75

1.8

4.3

9.5

2.25

0.18

0.4

1.1

2.6

4.5

5.5

10.5

0.25

0.75

1.3

2.9

7.5

14

0.37

0.9

1.5

3.4

3.7

8.5

16

MECHANICAL/ HYDRAULIC:

1.

Coolant pump performance graphs shown in the catalog are for water as media, at room temperature only. Pump

performance varies +/- 15% on the flowrate & +/-10% on the head.

2.

For best performance of the pumps, maintain minimum & maximum levels as given in the catalog.

3.

For multistage coolant pumps, while mounting on the small immersion tanks, ensure that the minimum of two

impeller stages are immersed in the liquid. Balance portion of the pump can be mounted on a spacer like distance

piece.

4.

Suction gap: Maintain minimum suction gap depending on the flow rate being taken- 25 mm for upto 200 LPM flow

& 50 mm for upto 800 LPM flow.

5.

Effect of Viscocity & Specific Gravity of liquids: The raising viscocity needs more power. As such the standard

motors can be used for liquids having 5 CST viscocity & coolant emulsions. Similarly, the raising specific gravity

needs more power. This power requirement is linearly proportional to the specific gravity of the liquid. e.g. if 1 kw

is required for water, 1.2 kw is recommended for 1.2 specific gravity liquid.

6.

Terminal box position w.r.t outlet: The standard options are given below

6 O clock is the standard position maintained in factory. For any change,

mention while ordering the pump.

Outlet

6 O CLOCK

9 OCLOCK

Terminal Box

7.

For grinding or similar application involving abbrassive dust in the coolant:

It is recommended to use pumps without bush bearings for such applications.

In case of pumps having bush bearings or mechanical seals (see the standard

spares list in each page) they have to be ordered with carbide materials.

8.

On/off cycles: The standard pumps upto 6 stages are suitable for 40 on/off per hours. Above 6 stages pumps are

suitable for 30 on/off per hour. For higher on/off per hour applications, call factory.

9.

Pipe fittings: Use always standard G.I. fittings having good radius at bends & elbows to avoid head losses. Do not fit

an elbow or reducer nipple immediately at the pump outlet. Take the same pipe as the outlet is as far as possible, to

get the best flow/pressure at the end point of piping. Use only parallel (G) threaded fittings with butting face.

12 OCLOCK

EXISTING PUMP

3 OCLOCK

BOOSTER PUMP

10. Pressure Boosting Arrangement: The following diagram shows, how an

existing multistage pump can be connected to a Booster pump to enhance

the pressure.

11. Noise level : Maxm. 72dB for all models. For RR Series refer catalogue

page

12. Side suction pumps for outside tank mounting: These pumps are available

for series RKM0250, RKM050 ,RKM200, RKM300 & RKM060, apart from

Horizontal mounting RMH pumps. The schematic diagram is as under.

For detailed mounting ask factory. These pumps need priming. Filter

(eg. Y Filter) at suction is recommended.

13. Spares Ordering: While ordering spares or pumps, give the full model

or frame name along with the sl. No. on the nameplate. Give any

extensions given after frame / model like X,Y,XZ,etc. These indicates

the speciality of the product & helps in providing the correct spare or

product.

5

COOLANT PUMPS

CONVENTIONAL & MONOBLOCK COOLANT PUMP RV25RV250

OPTIONS

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Shaft

AL

C.I.

Velox553/AL

Velox553/CI

EN8

APPLICATION

Stem

Gunmetal/S.S

Impeller

Gunmetal/CI/S.S

Impeller Cover Gunmetal

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Shaft

Kinematical Viscocity

- 90mm2/s

Pumping Temperature - 0-600C

Teflon Coated/S.S.410

SPECIAL VERSIONS

USED ON

Avilable

* ON/OFF Rotary switch

* With flame proof motor for hazardous liquids

* For Frequent ON/OFF Cycles * For Any Immersion depth

* For high viscous liquids * To handle Hot Liquids upto 100 C

HEAD IN METRES

All lathes, Milling, CNC, retrofittings, EDM

wire and other conventional machines,

Cutting Machines, Printing machines Etc

DISCHARGE IN LPM

SIZE

RV25#

RV40

RV63

RK80^

RV100

RV160

RV250

Immersion

Depth

H

25/120

120

25/170

170

40/120

120

40/170

170

40/220

220

40/270

270

40/350

350

63/120

120

63/170

180

63/220

230

80/220

220

80/270

270

100/220

220

100/270

270

160/170

170

160/220

220

160/270

270

160/350+

350

250/170

170

250/270

270

250/350+

350

250/440+

350

440

TYPE

160 100

72

105 115

3 0 130

130

155

Flow at

2mtr hd

15%

70

25

160 100

72

105 115

3 0 130

130

155

70

40

0.1

190 100

72

105 115

3 0 130

130

155

70

63

0.18

175 140

72

110 160

G1

3 0 180

95

120

93

80

0.18

215 140

72

140 160

G1

3 2 180

150

175 100

100

0.20

235 140

72

140 160

G1

3 2 180

150

175 100

160

10

0.37

260 140

72

140 160 G11/4 3 2 180

150

175 100

250

13

0.54

H 1 H 2 A+0 B

D

d

MAX MAX -1 MAX MAX -0.2

d1

BSP

E

-0

30

80

30

80

130

180

260

30

80

130

150

200

130

180

80

130

180

260

80

130

180

260

350

L1

MAX

L2

L3

Min Hd

10%

Kw

0.08

Old

Wt

Model

in Kg

Type

5

5.5

4.5 RK1

4.5

6

6.7

7.3

12

13

14

12

13

11

RK2

13

14

RK3

15

16

20

2 1 RK200

22

23

25

28

RV Series as per IS:2161 # Equivalent to other manufacturers Type 1 ^ Not as per IS:2161, Equivalent to other manufatures Type

2 + H2 Max is 50mm Extra RV25-RV160 avalible for single phase 230V 50Hz. Tank, pipeset available in standard sizes.

6

COOLANT PUMPS

CONVENTIONAL & MONOBLOCK COOLANT PUMP RV25RV250

CONSTRUCTION

OPTIONS

Body

C.I./AL

Stem

C.I.

Impeller

C.I.

Impeller Cover C.I.

Shaft

EN8

APPLICATION

Stem

Gunmetal/S.S

Impeller

Gunmetal/S.S

Impeller Cover Gunmetal

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Shaft

Kinematical Viscocity

- 90mm2/s

Pumping Temperature - 0-800C

Teflon Coated/S.S.410

SPECIAL VERSIONS

USED ON

Avilable Extra

* Immersion depth in step of 200mm

* For high viscous liquids * To handle Hot Liquids upto 100 C

HEAD IN METRES

All lathes, Milling, CNC, retrofittings, EDM

wire. Cutting Machines, Printing machines Etc

DISCHARGE IN LPM

- Above Metalic Slinger

H1

Max

H2

Max

A+0

-1

B

Max

D

Max

d

-0.2

d1

BSP

E

-0.2

L1

Max

L3

Kw

Depth H

Wt

in Kg

RK275

300

220

310

200

82

156

225

G1

42

250

126

125

0.75

30

RK300

300

220

310

200

82

156

225

G1

42

250

126

126

1.1

30

RK400

300

220

375

200

82

175

225

G1

42

250

150

126

1.5

34

RK600

300

220

430

200

82

200

225

G2

42

250

165

126

2.25

42

RK800

300

220

465

200

82

230

225

G2

42

250

180

126

3.75

51

TYPE

Immersion

* ALL PUMPS - RV25....RV250, RK80, RK275...RK800-WITH STD. IMMERSION DEPTH ARE GLANDLESS.

THEY CAN RUN DRY & WILL NOT HAVE AIR LOCKING PROBLEM.

* STANDARD SPARES : IMPELLER FOR LONG IMMERSION PUMPS, ABOVE 300 MM, BUSH/SLEEVE.

7

COOLANT PUMPS

HIGH DISCHARGE PUMP (FLOODING TYPE) RK3.5 TO RK7 & COUPLED RKC SERIES

OPTIONS

CONSTRUCTION

Body

Stem

Pump Housing

Impeller

Shaft

Flange

Bush/sleeve

C.I.

C.I.

C.I.

C.I.

EN8

C.I.

GM/EN9

APPLICATION

Stem

Pump Housing

Impeller

Shaft

Bush/sleeve

Gunmetal

Gunmetal

Gunmetal

Stainless Steel

Carbide/Carbide

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity

- 90mm2/s

Pumping Temperature - 0-800C

SPECIAL VERSIONS

USED ON

Avilable

With Flame Proof Motors to pump hazardous liquids

For frequent on/off cycles For any immersion depths

For high viscous liquids To handle hot liquids up 1000C

With below shown mounting (give A&B dimensions)

All CNC machines to flush chips, to transfer

fluid for Filteration, Cyclone Filter, Chip

Conveyors, EDM Wire cut machines, Heat

treatment plants, Grinding machnes, Granite

and Indoor Fountains.

RK3.5 TO

RK7

RKC100 TO 500

Coupled Version

A (Optional

Mounting)

A (Optional

Mounting)

B

TYPE

COUPLED

NON

RSM

SIDE

IMMERSION

H1

SUCTION

DEPTH

MAX

H2 MAX

COUPLED

NON

A+0

d1

-1

MAX

MAX

-0.2

BSP

L1

INLET

MAX

BSP

L3

POWER IN

Wt

KW / HP

in Kg

Inch

COUPLED

COUPLED

RKC-100 RK 3.5/311 RSM 3.5

311

200

420

236

141

82

156 165

G1" 1 2

200 126 G1 " 120 0.75/1.0

28

RKC-150

RK 4/311

RSM 4

311

200

420

236

141

82

156 165

G1" 1 2

200 126 G1 " 120

1.1/1.5

30

RKC-200

RK 5/311

RSM 5

311

200

454

280

141

82

170 165

G1" 1 2

200 135 G1 " 120

1.5/2.0

39

RKC-300

RK 6/311

311

200

500

310

181

82

208 215

G1" 1 5

250 155 G1 " 125 2.25/3.0

50

RKC-400

RK 7/311

311

200

590

430

181

82

225 215

G2" 1 5

250 165 G2 " 125 3.75/5.0

60

* STANDARD SPARES : IMPELLER, BUSH & SLEEVE.

SERVICE AND SPARES AVAILABLE THROUGH OUR COUNTRY WIDE DEALERS NETWORK

ASK US FOR MORE DETAILS

8

COOLANT PUMPS

DISCHARGE IN LPM

RAJAMANE RPP - ALL POLYPROPELENE PUMPS

More

r

o

f

ASK

ls

detai

RPP160 IN VERTICLE IMMERSSION TYPE.

ALL WET ENDS IN POLY-PROPELENE

RPP5-IN HORIZONTAL MOUNTING.

ALL WET PARTS IN POLY-PROPELENE.

Flow : 400 LPM Max Head : 30 MTR. Max in both version

9

COOLANT PUMPS

VERTICAL FOOT MOUNTED RMB-V SERIES

OPTIONS

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Shaft

Mechanical seal

C.I./AL.

C.I.

AL.

C.I.

EN8

Carbon/Ceramic

APPLICATION

Stem

Impeller

Impeller Cover

Shaft

Mechanical seal

Gunmetal

C.I./Gunmetal

Gunmetal

S.S.

Carbide/Carbide

SPECIAL VERSIONS

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity

- 90mm2/s

Pumping Temperature - 0-500C

The liquid media should be prefiltered for

moderete contamination. (0.5-1 mm, 20%).

USED ON

Avilable

With flame proof motor for hazardous liquids.

HEAD IN METRES

All CNC machines, lathes, and machining centres.

DISCHARGE IN LPM

TYPE

d1

d2

DISCHARGE

(LPM)

HEAD

(M)

Kw

Wt.

Kg.

RMB-V-50

300

145

160

80

160

50

0.25

14

RMB-V-100

330

145

G1"

G1

160

110

180

100

0.37

16

NOTE :

1. THE ABOVE SHOWN PERFORMANCE CURVE IS FOR WATER , WITHOUT NON-RETURN VALVE & WATER LEVEL

300 MM BELOW THE PUMP SUCTION. PUMP DELIVERS HIGHER DISCHARGE WHEN CONNECTED AT TANK

LEVEL (20-30% MORE), AND REDUCES AS THE WATER LEVEL DROPS.

2. THE PUMP CAN PRIME, FOLLOWING INITIAL PRIMING, UPTO 400 MM. FOR HIGHER DEPTHS UPTO 600 MM

A NON-RETURN VALVE IS TO BE USED AT THE DELIVERY SIDE. USE OF NON RETURN VALVE CAUSES A DROP

OF 10% IN THE PERFORMANCE.

3. THE SUCTION LINE MUST BE AIR TIGHT, AND AVOID THE USE OF FOOT VALVE.

STANDARD SPARES : IMPELLER, MECHANICAL SEAL AND GASKET (SEALING) SET.

10

COOLANT PUMPS

HIGH PRESSURE - LOW IMMERSION RR50 SERIES

Body

Stem

Impeller

Impeller Cover

Shaft

Bush Bearing

APPLICATION

OPTIONS

CONSTRUCTION

C.I./A.L.

C.I.

Bronze

C.I.

EN8

GM

Stem

Impeller Cover

Shaft

Bush Bearing

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity

- 90mm2/s

Pumping Temperature - 0-800C

Clear Media

- Prefiltered

(50 microns)

USED ON

Gunmetal

Gunmetal

S.S.410

Carbon

SPECIAL VERSIONS

Avilable

With flame proof motor for hazardous liquids

With dual speed motor

Special versions to handle hot liquids upto 2000C

HEAD IN METRES

All CNC machines, lathes, and machining

centres. Most suited for through tool cooling,

deep hole drilling, chilling units and industrial

washing machine.

RR25

DISCHARGE IN LPM

TYPE

No. of

Stgs

RR50 LP

RR50 HP

RR50-2

RR25

IMMERSION

DEPTH (H)

140

190

240

290

370

140

190

240

290

370

160

210

260

310

390

H1

MAX

100

150

200

280

330

100

150

200

280

330

130

180

230

300

360

H2

MAX

A+0

-1

B

D

MAX MAX

d

-0.2

d1

BSP

E

-0.2

L1

MAX

L3

Kw

Wt

in Kg

275

100

82

156

115

G3/4"

30

130

115

120

0.54

18

300

100

82

156

115

G3/4"

30

130

126

120

0.75

20

350

100

82

170

115

G3/4"

30

130

135

120

1.5

24

150

110

225

100

82

140

115

G3/4"

32

130

115

70

0.54

12

STANDARD SPARES : IMPELLER, BUSH & SLEEVE AND SPACERS

11

COOLANT PUMPS

MULTISTAGE COOLANT PUMPS RKM025 & RKM050

OPTIONS

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Shaft

Mechanical Seal

C.I./AL.

C.I.

Noryl/P.P.

Noryl/P.P.

SS410

Carbon/Ceramic

Stem

Shaft

Mechanical Seal

Impeller

Impeller Cover

APPLICATION

Gunmetal / SS

S.S.

SiC/SiC

SS316

SS316

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity - 5 CST max

Pumping Temperature - 0-500C

SPECIAL VERSIONS

Avilable

With Flame Proof Motors to pump hazardous liquids

With dual speed motor

With full water proof construction to pump demineralised /

deionised water

Horizontal & Vertical foot moonted

USED ON

Most suited for chilling units, EDM wire cut,

spark erosion machines, small CNC lathes and

machining centres etc.

HEAD IN METRES

D6a

DISCHARGE IN LPM

TYPE

NO OF

STAGES

IMMERSION

DEPTH (H)

H1

MAX

H2

MAX

A+0

B

-1 MAX

D

d

MAX -0.2

d1

BSP

L1

MAX

L2

Kw

Wt

in Kg

RKM02505

195

140

215

100

72

140

115

130

105

70

0.37

15

RKM02510

10

315

260

320

100

82

156

115

130

126

70

0.75

22

RKM02515

15

435

380

360

100

82

170

RKM054

220

170

300

100

72

140

115

130

135

70

1.5

30

115

130

105

70

0.54

16

RKM058

360

290

320

100

82

156

115

130

126

70

0.75

22

RKM0512

12

495

415

360

100

82

170

115

130

135

70

1.5

30

STANDARD SPARES : IMPELLER COVER, IMPELLER, MECHANICAL SEAL

12

COOLANT PUMPS

MULTISTAGE HORIZONTAL COOLANT PUMP RMH 0250 SERIES

OPTIONS

CONSTRUCTION

Motor body

Suction cover

Impeller

Delivery cover

Impeller Cover

Shaft

AL

C.I.

Noryl

C.I.

Noryl

SS410

APPLICATION

Suction cover

Delivery cover

S.S/Brass/Gunmetal

S.S/Brass/Gunmetal

Types of Fluids

With spl. Constn.

Kinematical Viscocity Pumping Temperature -

SPECIAL VERSIONS

Water

Cooling Emulsion

Cooling/Cutting Oils

Light Chemicals

Washing solutions

1 CST (Max.10CST)

0 500C

USED ON

Avilable

With flame proof motor for hazardous liquids

All CNC machines, lathes, and machining centres.

Most suited for washing machines, Electrochemical

deburring machine, drilling, chilling units,

Descaling, etc.

HEAD IN MTRS

3/4 BSP

3/4 BSP

DISCHARGE IN LPM

DIMENSIONAL DET

AILS

DETAILS

No. of

Stags

RMH 02503

80

100

RMH 02504

90

RMH 02505

90

H1

L1

MOUNTING

HOLE DIA

POWER

(KW/HP)

63

140

114

146

355

0.18/0.25 #

112

71

170

144

169

380

0.25/0.33 #

112

71

195

144

192

405

0.37/0.5 #

discharge

REFER

GRAPH

TYPE

(Dimension A & B are mounting holes for the pump/ SUCTION & DELIVERY is G 3/4BSP, female threading)

# - also available with 1 PHASE 230V, 50HZ., CAPACITOR START/RUN MOTOR.

STANDARD SPARES : IMPELLER, BUSH & SLEEVE, MECHANICAL SEAL, O-RINGS AND SPACERS

13

COOLANT PUMPS

MULTISTAGE COOLANT PUMP RKM 060 SERIES

CONSTRUCTION

Body

C.I.

Stem

C.I.

Impeller

SS316

Impeller Cover

SS316

Shaft

SS410

Mechanical Seal Carbon/Ceramic

SPECIAL VERSIONS

OPTIONS

APPLICATION

Stem

Gunmetal/AL./SS

Mechanical Seal SiC/SiC

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity - 45CST

Pumping Temperature - 0-800C

SPECIAL FEATURES

All SS pump construction with sheet

metal technology, light weight, wide

application, efficient, elegant in

appearance, long trouble free seals &

bushes, double sealing stem.

All CNC machines, lathes, and machining centres.

Most suited for through tool cooling, deep hole

drilling, chilling units, EDM wire cut machines

and industrial washing machine.

HEAD IN METRES

Avilable

With flame proof motor for hazardous liquids

With dual speed motor / frequency drive.

Pressure booster pumps, to increase the pressure. (See page 10)

Side suction arrangement see technical information sheet 4 & 5

USED ON

DISCHARGE IN LPM

TYPE

RKM0604

RKM0606

RKM0608

RKM0612

RKM0616

RKM0620

No. of IMMERSION

DEPTH (H)

4

190

6

240

8

290

12

390

16

490

20

590

H1

MAX

110

150

200

300

400

500

H2

MAX

320

370

370

410

410

455

A+0

-1

140

140

140

140

140

140

B

MAX

82

82

82

82

82

82

D

MAX

140

156

156

170

170

206

d

-0.2

160

160

160

160

160

160

d1

E

BSP -0.2

G1" 48

G1" 48

G1" 48

G1" 48

G1" 48

G1" 48

F

180

180

180

180

180

180

L1

MAX

105

126

126

135

135

155

L3

Kw

96

96

96

96

96

96

0.54

0.75

1.10

1.50

2.25

3.00

Wt

in Kg

16.0

19.0

20.0

23.0

25.0

32.0

STANDARD SPARES : IMPELLER, SLEEVE, IMPELLER COVER WITH BUSH, MECHANICAL SEAL AND SPACERS

14

COOLANT PUMPS

RAJAMANE-BRINKMANN RTH 45 SERIES HIGH PRESSURE PUMPS

OPTIONS

CONSTRUCTION

Motor body

Stem

Impeller

Impeller cover

Mechanical Seal

Shaft

C.I.

C.I.

S.S. 316

S.S. 316

SiC/SiC

S.S. 316

APPLICATION

Stem

Bronze

Types of Fluids

With spl. Constn.

Kinematical Viscocity Pumping Temperature -

Water

Cooling Emulsion

Cooling/Cutting Oils

Light Chemicals

Washing solutions

45mm2/s

0 800C

SPECIAL VERSIONS

With frequency drive

USED ON

With Dual speed Motor

HEAD IN METRES (10 mtr.=1 bsr or 1 kg/sq.cm)

All CNC machines, lathes, and machining centres.

Most suited for through tool cooling, deep hole

drilling, chilling units and industrial washing

machine Temperature controlling units, etc.

"

100

160

DISCHARGE IN LPM

MODEL

D1

POWER(kW)

2800 RPM

1440 RPM

FLOW

IN LPM

HEAD IN MTRS

2800 RPM 1440 RPM

RTH45/470

860

475

385

170

2.0

0.6

30

132

20

RTH45/540

940

540

400

190

2.25

0.75

30

168

25

RTH45/690

1090

690

400

190

3.3

1.0

30

222

40

Note: 1.Conduit size will be given as per customers requirement. Please specify the same while ordering.

2.Std. motor will be single speed 2800 RPM. Dual speed motor is on request.

STANDARD SPARES : IMPELLER, SLEEVE, IMPELLER COVER WITH BUSH, MECHANICAL SEAL AND SPACERS

15

COOLANT PUMPS

MULTISTAGE HORIZONTAL COOLANT PUMP RMH 060 SERIES

OPTIONS

CONSTRUCTION

Motor body

Suction cover

Impeller

Delivery cover

Impeller Cover

Shaft

Mechanical seal

APPLICATION

C.I/AL

Suction cover

S.S/Brass/Gunmetal

C.I.

Delivery cover S.S/Brass/Gunmetal

SS316

Mechanical seal SiC/SiC

C.I.

SS316

SS410

Carbon/Ceramic

Types of Fluids

With spl. Constn.

Kinematical Viscocity Pumping Temperature -

Water

Cooling Emulsion

Cooling/Cutting Oils

Light Chemicals

Washing solutions

1 CST (Max.10CST)

0 800C

SPECIAL VERSIONS

USED ON

Avilable

With flame proof motor for hazardous liquids

All CNC machines, lathes, and machining centres.

Most suited for washing machines, Electrochemical

deburring machine, drilling, chilling units,

Descaling, etc.

1 BSP

6

HEAD IN M.TR.S

1 BSP

DISCHARGE IN LPM

DIMENSIONAL DET

AILS

DETAILS

No. of

Stgs

H1

H2

L1

MOUNTING

HOLE DIA

POWER

(KW/HP)

RMH-0602

80

100

63

162

114

155

380

0.25/0.33 #

RMH-0603

90

112

71

170

144

180

465

0.37/0.5 #

RMH-0604

90

112

71

170

144

205

465

0.54/0.75

RMH-0606

100

125

80

179

165

255

560

10

0.75/1.0

RMH-0608

100

125

80

179

165

305

610

10

1.1/1.5

discharge

REFER

GRAPH

TYPE

(Dimension A & B are mounting holes for the pump/ SUCTION & DELIVERY of G1BSP, female threading)

# - also available with 1 PHASE 230V, 50HZ., CAPACITOR START/RUN MOTOR.

STANDARD SPARES : IMPELLER, BUSH & SLEEVE, MECHANICAL SEAL, O-RINGS AND SPACERS

16

COOLANT PUMPS

MULTISTAGE COOLANT PUMP RKM - 100 SERIES

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Shaft

Bush Bearing

C.I./A.L.

C.I.

A.L.

C.I.

EN8

GM

OPTIONS

Stem

Impeller

Impeller Cover

Shaft

Bush Bearing

APPLICATION

Gunmetal

C.I./Gunmetal/Brass

Gunmetal/S.S.

S.S. 410

SiC/SiC

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity - 40 CST max

Pumping Temperature - 0-800C

SPECIAL VERSIONS

USED ON

Avilable

With Flame Proof Motors to pump hazardous liquids

With dual speed motor

For chiller units

HEAD IN METRES

All CNC machines lathes and machining centres.

Most suited for through tool cooling, deep hole

drilling etc. Also suitable for Industrial washing.

Type

No. of Immersion H1 H2

Stgs

Depth

Max Max

RKM-120

2

215

160 320

265

225 360

315

275 360

RKM-130

3

230

130

300

160 340

350

210

RKM-140

4

265

150

335

225 355

385

275

RKM-150

5

320

150

390

220 355

440

270

RKM-160

6

360

150

430

330 355

480

380

A+0

B

D

d

-1 Max Max -0.2

d1

BSP

L1

Max

L3

Power in WT

KW

in KG

17

0.54

18

19

140

82

140 160

G1

30 180

105 110

140

82

157 160

G1

30 180

125 110

1.1

31

140

82

170 160

G1

30 180

135 110

1.5

40

140

82

170 160

G1

30 180

135 110

1.7

42

140

82

170 160

G1

30 180

135 110

2.0

46

STANDARD SPARES : IMPELLER, BUSH AND SPACERS.

17

COOLANT PUMPS

MULTISTAGE COOLANT PUMPS RKM200 & RKM300

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Guide vane

Shaft

Mechanical Seal

Bush/Sleeve

C.I.

C.I.

Brass

C.I.

Noryl-30% GF

EN8

Carbon/Ceramic

Carbon/Carbon

OPTIONS

APPLICATION

Stem

Impeller

Impeller Cover

Shaft

Mechanical Seal

Bush/Sleeve

Gunmetal

C.I.

Gunmetal/S.S.

S.S.

SiC/SiC

(for Grinding)

SiC/SiC

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity

- 90mm2/s

Pumping Temperature - 0-500C

USED ON

SPECIAL VERSIONS

All CNC machines lathes and machining centres.

Most suited for through tool cooling, deep hole

drilling etc. Also suitable for Industrial washing,

grinding Machine.

HEAD IN METRES

Avilable

With Flame Proof Motors to pump hazardous liquids

With dual speed motor

Booster arrangment (see page 5)

Side suction arrangement (see page 5)

Upto 6 Stages available in Horizontal Construction.

DISCHARGE IN LPM

TYPE

RKM-206

RKM-210

RKM-214

RKM-218

RKM-222

RKM-226

RKM-304

RKM-306

RKM-308

RKM-310

NO OF IMMERSION

STAGES DEPTH H

6

270

10

430

14

580

18

710

22

830

26

970

4

250

6

340

8

420

10

500

H1

H2

MAX MAX

180 410

320 410

480 410

580 410

720 480

840 480

120 370

190 410

280 480

350 480

A+0

-1

140

140

140

140

140

140

140

140

140

140

B

MAX

82

100

100

100

110

110

82

100

110

110

D

MAX

208

225

225

225

280

280

208

225

280

280

d

0.2

160

180

180

180

180

180

180

180

180

180

d1

BSP

G1"

G1"

G1"

G1"

G1"

G1"

G1"

G1"

G1"

G1"

STANDARD SPARES : IMPELLER, BUSH & SLEEVE, MECHANICAL SEAL AND SPACERS

18

9

9

9

9

9

9

9

9

9

9

180

220

220

220

220

220

220

220

220

220

L1

MAX

160

215

215

215

220

220

165

215

220

220

L2

Kw

110

110

110

110

110

110

110

110

110

110

1.5

3.0

4.0

5.5

7.5

7.5

2.25

3.0

3.7

5.5

COOLANT PUMPS

MULTISTAGE COOLANT PUMP RKM 250 SERIES

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Shaft

Bush Bearing

C.I./AL.

C.I.

AL.

C.I.

EN8

Carbon/GM

OPTIONS

APPLICATION

Stem

Impeller

Impeller Cover

Shaft

Bush Bearing

Gunmetal

C.I./Gunmetal

Gunmetal

S.S.410

Carbide

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity

- 90 mm2/s

Pumping Temperature - 0-800C

USED ON

SPECIAL VERSIONS

All CNC machines, lathes, and machining

centres. Most suited for through tool cooling,

deep hole drilling, chilling units and industrial

washing machine, grinding machine.

HEAD IN METRES

Avilable

With flame proof motor for hazardous liquids

With dual speed motor

DISCHARGE IN LPM

TYPE

RKM-252

RKM-253

RKM-254

RKM-255

No. of IMMERSION H1

Stgs DEPTH H MAX

2

150

95

205

135

280

205

330

255

3

265

190

335

260

385

310

4

320

240

390

310

440

380

5

375

295

445

365

495

435

H2

MAX

260

340

A+0

-1

140

140

B

MAX

75

79

D

MAX

157

157

d

-0.2

160

160

d1 E+0

BSP -1

G1" 20

G1" 30

L1

L3

MAX

180 126 110

180 126 110

Kw

Wt

in Kg

1.1 26

1.1 30

340

140

79

157

160

G1"

30

180 126 110

1.5

34

355

140

79

178

160

G1"

30

180 126 110

1.7

46

375

140

82

208

160

G1"

30

180 165 110 2.25

54

STANDARD SPARES : IMPELLER, BUSH & SLEEVE, MECHANICAL SEAL AND SPACERS

19

COOLANT PUMPS

HIGH PRESSURE HIGH DISCHARGE COOLANT PUMPS RMS 400, 600 & 800

OPTIONS

CONSTRUCTION

Body

Stem

Impeller

Impeller Cover

Shaft

Bush/Sleeve

C.I.

C.I.

C.I.

C.I.

SS410

EN31/EN24

APPLICATION

Stem

Impeller

Impeller Cover

Shaft

Bush/Sleeve

Gunmetal

C.I./Gunmetal

Gunmetal

S.S.

Carbide

Types of Fluids - Water

- Cooling Emulsion

- Cooling/Cutting Oils

Kinematical Viscocity

- 90 mm2/s

Pumping Temperature - 0-800C

USED ON

SPECIAL VERSIONS

Avilable

Imm. depths in step of 200 mm.

With flame proof motor for hazardous liquids.

to handle larger chips for transfer to filteration unit.

HEAD IN METRES

All CNC machines, lathes, machining centres,

Most suited for grinding m/c.s, filteration units

chip conveyors, washing machines, etc.

DISCHARGE IN LPM

TYPE

RMS-402

RMS-403

RMS-404

RMS-406

RMS-602

RMS-604

RMS-802

RMS-803

So. of IMMERSION H1

Stages DEPTH H MAX

2

3

4

6

2

4

2

3

375

450

525

675

375

525

375

450

295

370

445

595

295

445

295

370

H2 A+0

B

D

MAX -1 MAX MAX

d

-0.2

d1

BSP

E+0

-1

L1

MAX

L3

Kw

Wt

in Kg

310

360

375

430

465

465

465

465

225

225

225

225

225

225

225

225

G1"

G1

G1"

G1"

G2"

G2"

G2"

G2

42

42

42

42

42

42

42

42

250

250

250

250

250

250

250

250

126

165

180

180

165

180

180

180

126

126

126

126

126

126

126

126

3.0

4.0

5.5

7.5

4.0

7.5

7.5

9.0

30

45

50

65

53

62

56

70

200

200

200

200

200

200

200

200

82

82

82

82

82

82

82

82

STANDARD SPARES: IMPELLER, BUSH & SLEEVE (IF USED)

20

156

225

230

200

230

230

230

230

COOLANT PUMPS

OIL SKIMMERS - ROS SERIES

OPTIONS

CONSTRUCTION

Motor Body

Support Assembly

Belt

Wiper

Drive Pulley

Driven Pulley

Powder coated

Powder coated

PU

Teflon

SS410

Nylon

APPLICATION

Motor Body

SS316/304

Support Assembly SS316/304

Belt

PVC/SS316

Driven Pulley

SS316/304

Oil collection/seperation

tray with mounting railings

Types of Fluids

Liquid Temperature -

Oils

Coolant Emulsion

Mild Chemicals

0-500C

USED ON

STANDARD ACCESSORIES

All CNC machines, conventional machines,

washing machine, electro plating grinding

machines, etc. where floating oil is to be

extracted for better life of coolant and finish of

components.

TIMER - FOR ROS1 & ROS2

ROS1 - BELT TYPE

230V1, 1 PHASE.

0.04 KW

Dimensions of ROS1 models:

Model

ROS1-40-225

ROS1-40-300

ROS1-40-500

Belt

width

Immersion

Depth

40

40

40

225

300

500

75

ROS2 - DISC TYPE 230V, 1 PHASE, 0.04KW

MODEL : ROS2 - 5 - 215

STANDARD SPARES: BELT, DRIVEN PULLEY, WIPER, DISC

21

COOLANT PUMPS

OIL SKIMMERS - ROS SERIES

Dimensions of ROS3

415V, 3PH, 0.04KW models:

Model

Belt Immersion

width

Depth

ROS3-40-225

ROS3-40-300

ROS3-40-500

ROS3-80-500

40

40

40

80

225

300

500

500

STIRRERS - RSB SERIES

CONSTRUCTION

Motor Body

Impeller

Shaft

AL

Al./Bronze

SS410

USED ON

APPLICATION

Types of Fluids

- Water

- Coolant Emulsion

Liquid Temperature - 0-800C

Chilling units, Mixing barrels,

coolant tanks, etc.

SPECIAL VERSIONS

Available with Flame Proof Motors.

Any immersion depth Upto 600 mm

DIMENSIONAL DET

AILS

DETAILS

TYPE

H1

H2

MAX

A+0

-1

d

PCD

D

MAX

L1

MAX

POWER

(KW/HP)

Weight

in Kg.App.

RSB63L 225

275

210

95

115

140

10

120

115

0.18/0.25

10

RSB71L 225

275

250

110

130

160

10

140

125

0.37/0.50

15

Supply Voltage 415V, 50HZ, 3PH and RPM 1440. Optional RPM 960

available for longer immersion stirrers.

STANDARD SPARES : IMPELLER

22

C M Y K

COOLANT PUMPS

OTHER SPECIALITY PRODUCTS

Small Induction motors:

For various application in

centralized lubrication,

hydraulic power pack,

units, gear boxes,

advertisements, etc.

Special purpose Induction Motors: for

1.

2.

3.

4.

5.

6.

Special voltages-110V, 220V, 560V, etc.

Speeds - single or dual speeds

High frequencies - 400Hz, 50/60Hz

Mountings

Extended shaft motors

Special class of insulation & for humid

conditions - like class H.

7. Hollow shaft motors

8. Torque motors

For use in automats, defence equipments, cooling units & many more.

Standard motors are also manufactured. Ask for detailed catalog of the same.

Auto-Electric parts : Parts manufactured for automobile industry.

SPECIFICATIONS / DIMENSIONS ARE SUBJECT TO CHANGE DUE TO

CONTINUOUS IMPROVEMENT IN THE PRODUCTS.

23

CMYK

HIGH PRESSURE SCREW PUMPS - TFS, FFS

Range: For Coolant emulsion: 10-300 LPM @ 10-100 bar

For Oils: 10-330 LPM @ 10-120 bar.

Motor power: 0.5-90.00 kW.

Application: Machining, Grinding, Through tool machining, etc.

Mounting: Horizontal & Immersion type.

Features: Compact mounting, quieter operation due to ground &

hardened screws, long life due to specially treated screw spindles & use

of silicon carbide bushings, easy mounting, variable pressure operating either manually or electronically, variable flow control by dual speed motor

or frequency drive

HIGH FLOW PUMPS-STA,SFL,TAL

Range: For Coolant emulsion: 1000-2600 LPM Pressure: 4 bar

Motor power: 2.6-21.5 kW.

Application: Machining, Grinding, Filtration, Chip conveying, Flooding.

Special Versions: For foamed coolants, dirty liquids upto 20 mm chip

sizes, quick suctioning.

Features: Very rugged construction, very low maintenance, can handle

almost all sorts of contamination/ chip types found in machine tool industry,

non-clogging type impellers, no mechanical seal-ensure longer life span,

space saving immersion type design, available with frequency drive or pole

changing motor to save power.

RIPL/P24/07

DS-R-MRK-001 R3

CHIP CUTTER PUMPS-SFC

Range: For Coolant emulsion 1000-2600 LPM

Pressure: 4 bar Motor power: 2.6-21.5 kW.

Chip handling: Aluminium chips of any size.

Application: Filtration, Chip conveying.

Special Versions: Any range & type of pump can be given with this

attachment.

Features: Very specially designed cutters for long life, stirrer to cut the

bundled chips, requires no extra effort to take out chips from the tank or

machining area, filtration can be simplified.

Ask for detailed catalogue

Manufacturer:

Rajamane Industries Pvt. Ltd.,

Whitefield Road, Mahadevapura Post, Bangalore - 560 048.

Ph: 080 - 2852 4410 / 2852 4262 Fax: 080 - 2852 4320

E-mail: coolantpump@rajamane.com

Web: www.rajamane.com

Dealer:

Das könnte Ihnen auch gefallen

- Amada Operators ManualDokument110 SeitenAmada Operators ManualJeff Dunn86% (7)

- Kirloskar KG645 - User Manual For Genset Controller PDFDokument123 SeitenKirloskar KG645 - User Manual For Genset Controller PDFsandsrd Rd87% (62)

- Bearing Size ChartDokument17 SeitenBearing Size Chartocchitya100% (16)

- LG Split Type Air Conditioner Complete Service ManualDokument74 SeitenLG Split Type Air Conditioner Complete Service ManualArt Del R Salonga85% (75)

- Koel Engine, Ha Operation and Maintenance Manual (Ha - SR)Dokument89 SeitenKoel Engine, Ha Operation and Maintenance Manual (Ha - SR)Karthik K Raja75% (12)

- Kirloskar HA294 Parts ListDokument92 SeitenKirloskar HA294 Parts ListSyed Wajid85% (13)

- 4g11 Tg2 Engine Parts BookDokument64 Seiten4g11 Tg2 Engine Parts Bookrahmeds123100% (2)

- Stanvac National Price List DT 01-01-2018Dokument22 SeitenStanvac National Price List DT 01-01-2018Pankaj Mittal67% (6)

- Equivalent ChartDokument36 SeitenEquivalent ChartJashim Uddin100% (1)

- 15 To 62.5 kVA Air Cooled PDFDokument200 Seiten15 To 62.5 kVA Air Cooled PDFJaisonNoch keine Bewertungen

- Kirloskar MRP Price ListDokument144 SeitenKirloskar MRP Price Listengg2012elect85% (26)

- DGD-161 4spcr Bs Engine Tata 407Dokument522 SeitenDGD-161 4spcr Bs Engine Tata 407Best Auto Tech100% (2)

- CG AlternatorsDokument23 SeitenCG AlternatorsHitesh Shinde100% (2)

- RPM 8 ManualDokument37 SeitenRPM 8 Manualshaik kaleesha vali73% (56)

- Pre-Installation For HAAS MillsDokument8 SeitenPre-Installation For HAAS MillsManish DandekarNoch keine Bewertungen

- Owner's Manual - MahindraDokument47 SeitenOwner's Manual - MahindrakapsethdceNoch keine Bewertungen

- Operation Manual Elc 100lp PLC With Ms6 DhuDokument27 SeitenOperation Manual Elc 100lp PLC With Ms6 DhuGurunathan Ammasai85% (13)

- Parts Catalogue - MDIDokument47 SeitenParts Catalogue - MDIsengottaiyan83% (6)

- Cp30 Mci300 Manual (New)Dokument213 SeitenCp30 Mci300 Manual (New)Er Rakesh Choudhary100% (2)

- CP30 Electric V2Dokument44 SeitenCP30 Electric V2SAYAN CHATTERJEE100% (2)

- LVDH 600 Cu ElDokument26 SeitenLVDH 600 Cu Elrahul_choubey_980% (5)

- Kirloskar 4R1040 Engine PDFDokument94 SeitenKirloskar 4R1040 Engine PDFSakthi Aravind91% (11)

- BP - Spare Parts Catalogue PDFDokument66 SeitenBP - Spare Parts Catalogue PDFSubhash RaybageNoch keine Bewertungen

- Spare Part Catalog - cv01 6sl 9088tDokument85 SeitenSpare Part Catalog - cv01 6sl 9088tbabaisandip100% (5)

- Directional Control Valves Ng6 Ng32 Do3 d10 PDFDokument92 SeitenDirectional Control Valves Ng6 Ng32 Do3 d10 PDFchidambaram kasiNoch keine Bewertungen

- Fanuc Beta Servo MotorDokument124 SeitenFanuc Beta Servo MotorengineermarkNoch keine Bewertungen

- Supply Chain Management of Zara: End Term ProjectDokument32 SeitenSupply Chain Management of Zara: End Term ProjectMukund Verma100% (1)

- KG934V1 7-14Dokument8 SeitenKG934V1 7-14Niten GuptaNoch keine Bewertungen

- Kirloskar ContactorsDokument6 SeitenKirloskar ContactorsMAYUR GENSET100% (1)

- Generating Set User Manual - KG320WS To KG625WSDokument152 SeitenGenerating Set User Manual - KG320WS To KG625WSGiangDoNoch keine Bewertungen

- KG934V1 1-6 KirloskarDokument6 SeitenKG934V1 1-6 KirloskarNiten Gupta100% (2)

- User Manual For KGPI Genset DV0.083.02.0.PRDokument234 SeitenUser Manual For KGPI Genset DV0.083.02.0.PRGiangDoNoch keine Bewertungen

- Product Data Sheet: Type: 6M14 12V Starter MotorDokument2 SeitenProduct Data Sheet: Type: 6M14 12V Starter Motorvishal.nitham50% (2)

- ELC With Processor - Manual PDFDokument14 SeitenELC With Processor - Manual PDFrahul_choubey_9100% (1)

- 1AL 485 - G1 TG2 TAG3 EngineDokument30 Seiten1AL 485 - G1 TG2 TAG3 Engineajay67% (3)

- CP 18 Control Panel Component IdentificationDokument26 SeitenCP 18 Control Panel Component IdentificationDEBABRATA SASMALNoch keine Bewertungen

- Conmat CRP 300Dokument22 SeitenConmat CRP 300nirmal82% (11)

- Kirloskar 6R1080TA PAGE 1-10Dokument10 SeitenKirloskar 6R1080TA PAGE 1-10Niten Gupta0% (1)

- Installation Manual - Coil CoolerDokument16 SeitenInstallation Manual - Coil CoolerRS100% (2)

- 2H.831.01.0.00 - KG 934 Version 2 ManualDokument47 Seiten2H.831.01.0.00 - KG 934 Version 2 ManualAlfiya Anam100% (1)

- PBL Series M Catalouge PDFDokument121 SeitenPBL Series M Catalouge PDFshivanandr2481100% (6)

- Heinzmann Training PDFDokument10 SeitenHeinzmann Training PDFRath Asypaden100% (1)

- 4 X3.6TAA G1 (35 40kVA) PDFDokument4 Seiten4 X3.6TAA G1 (35 40kVA) PDFCHETAN PRAJAPATI RDONoch keine Bewertungen

- Et PN Iso Pump Instruction Manual-OrgDokument60 SeitenEt PN Iso Pump Instruction Manual-OrgSd Ver69% (13)

- Al 485 - g1 Tg2 Tag3 Tag4 EngineDokument32 SeitenAl 485 - g1 Tg2 Tag3 Tag4 Enginerahul mehta100% (1)

- 367589988-822559671518-MCI-70-Bro2014-pdf - 2020-12-04T152139.294 PDFDokument4 Seiten367589988-822559671518-MCI-70-Bro2014-pdf - 2020-12-04T152139.294 PDFManjit SinghNoch keine Bewertungen

- 6R1080TA Spare PartsDokument87 Seiten6R1080TA Spare PartsHarneak Singh Gujral60% (5)

- Oil Equivalant Lube ChartDokument2 SeitenOil Equivalant Lube ChartSanjay Abhyankar77% (13)

- E30-E45 60 HZ Omm ManualDokument90 SeitenE30-E45 60 HZ Omm Manualdonono0% (1)

- KG 545 EmsDokument32 SeitenKG 545 EmsRoyston fernandes0% (2)

- Kirloskar DG Set ManualDokument168 SeitenKirloskar DG Set ManualAnonymous JrbKz8N90% (10)

- E-Governor IntroductionDokument13 SeitenE-Governor Introductionbalu9999Noch keine Bewertungen

- KG Controllers KG541-KG934 - KG640-KG645-KG745 Feature Comparison-R07 - 1st September 2019Dokument13 SeitenKG Controllers KG541-KG934 - KG640-KG645-KG745 Feature Comparison-R07 - 1st September 2019Sanjeev KumarNoch keine Bewertungen

- Kirloskar Pump 4R1040 Maintenance SheetDokument95 SeitenKirloskar Pump 4R1040 Maintenance SheetArun ShyamrajNoch keine Bewertungen

- Owner Manual - C2 - MDI-NEFDokument49 SeitenOwner Manual - C2 - MDI-NEFMAYUR GENSET100% (4)

- Owners Manual 5 kVA MahindraDokument34 SeitenOwners Manual 5 kVA MahindraMAYUR GENSET100% (3)

- PFC8 PFC14Dokument3 SeitenPFC8 PFC14pinku_thakkar73% (11)

- KG934V1 13-18Dokument6 SeitenKG934V1 13-18Niten GuptaNoch keine Bewertungen

- EmsDokument46 SeitenEmsravi kumarNoch keine Bewertungen

- Kg-545 Automatic Mains Failure UnitDokument35 SeitenKg-545 Automatic Mains Failure UnitJack GehlotNoch keine Bewertungen

- A2FM MotorDokument21 SeitenA2FM Motortestas cia100% (1)

- Salami Catalog Group2Dokument35 SeitenSalami Catalog Group2ado_22Noch keine Bewertungen

- CepDokument7 SeitenCeppramod_tryNoch keine Bewertungen

- Catalogo Bombas NachiDokument57 SeitenCatalogo Bombas NachiCesar Muñoz OssesNoch keine Bewertungen

- 608 750GDokument2 Seiten608 750GbioarquitecturaNoch keine Bewertungen

- Industrial Fluid Power PDFDokument141 SeitenIndustrial Fluid Power PDFchidambaram kasi33% (3)

- Databook COOLSIDE-CW PDFDokument48 SeitenDatabook COOLSIDE-CW PDFchidambaram kasiNoch keine Bewertungen

- Technical Information: Features of PhotomicrosensorsDokument13 SeitenTechnical Information: Features of Photomicrosensorschidambaram kasiNoch keine Bewertungen

- RXYQ-T9 EEDEN15-200 1A Data-Books English PDFDokument57 SeitenRXYQ-T9 EEDEN15-200 1A Data-Books English PDFchidambaram kasiNoch keine Bewertungen

- (Diy) Design and Fabricate Your Own Satellite Dish of - All Sizes - , Ask How PDFDokument6 Seiten(Diy) Design and Fabricate Your Own Satellite Dish of - All Sizes - , Ask How PDFchidambaram kasiNoch keine Bewertungen

- Yasnac Motoman Robot Manual PDFDokument375 SeitenYasnac Motoman Robot Manual PDFchidambaram kasi100% (5)

- KirloskerDokument36 SeitenKirloskerArup NathNoch keine Bewertungen

- PT-MT Kurs NotuDokument300 SeitenPT-MT Kurs NotuBahadir TekinNoch keine Bewertungen

- Ffilsan Cross Ref. 2013Dokument78 SeitenFfilsan Cross Ref. 2013Daniel ArbeláezNoch keine Bewertungen

- Furnaces and RefractoriesDokument36 SeitenFurnaces and Refractoriesengkassem100% (5)

- Elevate Training Eng PDFDokument36 SeitenElevate Training Eng PDFpanduNoch keine Bewertungen

- Schneider Altivar ATV12 ManualDokument133 SeitenSchneider Altivar ATV12 ManualAne RodriguesNoch keine Bewertungen

- C BAND Satellites Recivable in A INDIA PDFDokument3 SeitenC BAND Satellites Recivable in A INDIA PDFchidambaram kasiNoch keine Bewertungen

- C Power Acb Catalogue PDFDokument35 SeitenC Power Acb Catalogue PDFsabeer100% (1)

- Free To Air, Indian TV, Free TV, Satellite TV, FTA Channels PDFDokument18 SeitenFree To Air, Indian TV, Free TV, Satellite TV, FTA Channels PDFchidambaram kasi100% (1)

- Ku Band Coverage Details PDFDokument4 SeitenKu Band Coverage Details PDFchidambaram kasiNoch keine Bewertungen

- Satellite TV Channels List - Raveen SiteDokument3 SeitenSatellite TV Channels List - Raveen Sitechidambaram kasiNoch keine Bewertungen

- Siemens Motor StarterDokument72 SeitenSiemens Motor StarterRitesh ChaudharyNoch keine Bewertungen

- Fuji Igbt-Ipm Application Manual: Quality Is Our MessageDokument77 SeitenFuji Igbt-Ipm Application Manual: Quality Is Our MessageAri Ercilio Farias FereirraNoch keine Bewertungen

- Belt ManualDokument111 SeitenBelt ManualscribddaduNoch keine Bewertungen

- DD Direct Plus 140 Channel List Frequency Wise Updated - NagarUntari PDFDokument14 SeitenDD Direct Plus 140 Channel List Frequency Wise Updated - NagarUntari PDFchidambaram kasi100% (1)

- Lesson A9025 - Intro To V Belts PDFDokument5 SeitenLesson A9025 - Intro To V Belts PDFchidambaram kasiNoch keine Bewertungen

- Yajur Veda Ammavasai Tharpanam - Opt PDFDokument32 SeitenYajur Veda Ammavasai Tharpanam - Opt PDFchidambaram kasi100% (2)

- Solid State Tesla CoilDokument7 SeitenSolid State Tesla CoilJboscoNoch keine Bewertungen

- Siemens Motor StarterDokument72 SeitenSiemens Motor StarterRitesh ChaudharyNoch keine Bewertungen

- API Standards For Safe Offshore Operations BrochureDokument1 SeiteAPI Standards For Safe Offshore Operations BrochureAnonymous 70lCzDJvNoch keine Bewertungen

- TEM List 2Dokument42 SeitenTEM List 2aminNoch keine Bewertungen

- ENGEL Press Release Inject2blowDokument4 SeitenENGEL Press Release Inject2blowTirthankar ChandraNoch keine Bewertungen

- NDT Report TestDokument10 SeitenNDT Report TestAnjas FarizqiNoch keine Bewertungen

- BPVC Code Cases 5 PDFDokument54 SeitenBPVC Code Cases 5 PDFEymenNoch keine Bewertungen

- Problem Set I For International Trade # Partial Solutions ... - CER-ETH PDFDokument14 SeitenProblem Set I For International Trade # Partial Solutions ... - CER-ETH PDFJGNoch keine Bewertungen

- Operations Management CaseDokument10 SeitenOperations Management Casebeyiii100% (1)

- Catalogue For AutoDokument20 SeitenCatalogue For Autoali4299Noch keine Bewertungen

- TMP 23909-Spiral Separator-228133665Dokument3 SeitenTMP 23909-Spiral Separator-228133665froufouNoch keine Bewertungen

- Top 25 Lean ToolsDokument2 SeitenTop 25 Lean ToolsAnonymous dv2IR074100% (1)

- Production Operations Management - MGT613 2010 Final Term Solved Papers All in One FileDokument62 SeitenProduction Operations Management - MGT613 2010 Final Term Solved Papers All in One FileMuzammil QamarNoch keine Bewertungen

- Machine Design14Dokument101 SeitenMachine Design14Jm Beja100% (1)

- Etrma Imds Vulcanised Rubber Pseudo Susbtances Tyres Guidance 2Dokument9 SeitenEtrma Imds Vulcanised Rubber Pseudo Susbtances Tyres Guidance 2rockraghav100% (1)

- Accepted Engineering Practice StandardsDokument5 SeitenAccepted Engineering Practice StandardsMuhammad Shakil JanNoch keine Bewertungen

- Lean Certification White PaperDokument16 SeitenLean Certification White PaperrajakoppulaNoch keine Bewertungen

- Mossa ResumeDokument4 SeitenMossa ResumeNikhatRizaviNoch keine Bewertungen

- Byk-330 TDS (En)Dokument2 SeitenByk-330 TDS (En)Onesany TecnologiasNoch keine Bewertungen

- KAMCODokument16 SeitenKAMCOArun Krishnan100% (1)

- Fish ProcessingDokument9 SeitenFish ProcessingKenkoi Sanchez100% (1)

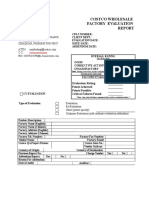

- Costco Factory Evaluation Report 22FEB05Dokument17 SeitenCostco Factory Evaluation Report 22FEB05Shaaban Noaman100% (1)

- Scope of Technical TextilesDokument2 SeitenScope of Technical Textiles09m008_159913639Noch keine Bewertungen

- (BS en 124) - Gully Tops and Manhole Tops For Vehicular and Pedestrian AreasDokument78 Seiten(BS en 124) - Gully Tops and Manhole Tops For Vehicular and Pedestrian Areasion ingenieria ion ingenieria100% (2)

- Swep Report 1Dokument7 SeitenSwep Report 1Rizzle25% (4)

- Accident Due To Rope HaulagesDokument2 SeitenAccident Due To Rope HaulagesadityatheaaaNoch keine Bewertungen

- Form Ability Od A8011 Aluminium Alloy SheetDokument6 SeitenForm Ability Od A8011 Aluminium Alloy SheetwojciechsciezorNoch keine Bewertungen

- Report About Casting DefectsDokument6 SeitenReport About Casting DefectsAbdul Rehman FaisalNoch keine Bewertungen

- Is 2062 (2011) - Hot Rolled Medium and High Tensile Structural SteelDokument14 SeitenIs 2062 (2011) - Hot Rolled Medium and High Tensile Structural Steelsridar_2004Noch keine Bewertungen

- c006b QDokument54 Seitenc006b QpchakkrapaniNoch keine Bewertungen

- Proceedings English Complete - RevBDokument217 SeitenProceedings English Complete - RevBFran Jimenez100% (1)