Beruflich Dokumente

Kultur Dokumente

Nitoseal 290

Hochgeladen von

Venkata RaoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nitoseal 290

Hochgeladen von

Venkata RaoCopyright:

Verfügbare Formate

Nitoseal 290*

Flexible polyester loop and lighting sealant

Uses

For sealing horizontal cable slots in concrete and asphalt

pavements associated with :

n Road traffic signals and inductance loops

n Airport runway lighting

n Automatic barriers or gates

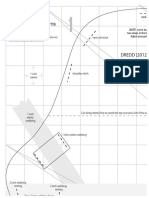

Typical examples of sealant width/depth ratios (moving

joints only)

Groove width (mm)

Sealant depth (mm)

6 - 10

10 minimum

10 - 20

As width

20 plus

20 maximum

In all cases the sealant should be finished flush with the

pavement surface.

Advantages

n Excellent adhesion to concrete, asphalt and steel

Properties

n No primer required in dry or damp conditions

The following results were obtained at a temperature of 20C

unless otherwise specified.

n Good resistance to chemicals, de-icing salts and

hydrocarbons

n Slightly flexible to accommodate limited movement

n Fast cure at 20C and above minimises traffic disruption

n Can be applied at low temperatures, cures below freezing

n Available in black for use on asphalt and grey for use on

concrete

Description

Nitoseal 290 two-component flexibilised polyester based

sealant cures to form a tough resilient seal with a limited degree

of movement. The material is self levelling and can be poured

or gunned directly into horizontal slots.

Nitoseal 290 will adhere to both concrete and asphalt surfaces

that have been well prepared whether dry or damp.

Design criteria

In the case of sawn cable grooves with no movement the

cable should be totally sealed and encapsulated within the

Nitoseal 290 to the top of the groove.

Where movement is anticipated in the sawn joint, cables

should be laid free at the base of the saw cut. An oversized

closed-cell foamed polyethylene cord should be located above

the cables acting as a bond breaker and gasket with the upper

joint then sealed using Nitoseal 290.

Nitoseal 290

The same details should apply to movement joints around

airfield lights using an oversized closed-cell foamed

polyethylene cord as a bond breaker and gasket with the upper

joint then sealed using Nitoseal 290.

Specific gravity

Pot life

:

:

Initial cure

Shore A hardness

Compressive strength

(BS 6319 Part 2)

Flexural strength

(BS 6319 Part 3)

Linear shrinkage

(ASTM C531.74)

Water absorption

(ASTM C413)

Electrical properties

DC insulation resistance

(2500 volts)

Dielectric strength

step by step (ASTM D149)

Chemical resistance

Salt water, Saturated urea

Petrol & Aviation fuel

1.8

20 mins at 35C

45 mins at 20C

30 mins at 35C

60 mins at 20C

90 @ 7 days

17 N/mm2 @ 7 days

12 N/mm2 @ 7 days

0.5%

0.15%

>2.5x109 Ohms

12.5kV/mm

Excellent

Weathering properties

QUV Weatherometer

1000 hours (ASTM G53.77):

Slight discolouration

Instructions for use

Application

Joint preparation

Groove sealing

Concrete and asphalt

Following thorough mixing, pour the Nitoseal 290 directly into

the prepared groove using a spouted container, watering can

or other suitable means. It may be practical and convenient

to fill narrow grooves using a Fosroc G gun fitted with a

plastic nozzle, which if necessary can be cut to size to suit

the joint width.

After cutting the required groove, all laitance or slurry from

the water lubricated saw blade must be completely blown

out whilst wet using oil-free compressed air. Flush grooves

with clean water prior to blowing if required. It is not necessary

to completely dry the groove.

Any slurry that has been allowed to dry, or powdered dust

from dry cutting operations should be power wire brushed or

abrasive blasted from the groove, followed by blowing with

oil-free compressed air.

This also applies to concrete or asphalt faces around lighting

units that have been formed previously using a water

lubricated diamond coring tool.

Steel

Cleaning

Uncured Nitoseal 290 can be cleaned using Fosroc Solvent

102. Cured Nitoseal 290 can only be removed by mechanical

means.

Any spillages of Nitoseal 290 should be absorbed immediately

onto sand, sawdust or other suitable absorbent materials.

Disposal should be in accordance with local regulations.

Limitations

If bare metal, the joint faces around lighting units or posts

should be abrasive blasted to remove all traces of corrosion.

If aluminium, alloy or coated metals are to be sealed, the

surfaces should be degreased using Fosroc Solvent 102* and

allowed to dry for 5 minutes before sealing.

The correct width/depth profile may be achieved by the

installation of a foam backing cord. Alternatively, sand may

be used to encapsulate loop wire whilst acting as a bond

breaker for the joint sealant.

To obtain neat straight edged seals, masking tape should be

applied to both edges of the joint prior to sealing, the masking

tape should be removed immediately following the completion

of the works.

- Applications should not commence if the temperature of

the substrate is below 5C.

- Service temperature range of Nitoseal 290 is from - 30C

up to + 80C.

Technical support

Fosroc offers a comprehensive range of high performance,

high quality repair, maintenance and construction products.

In addition, Fosroc offers a technical support package to

specifiers, end-users and contractors, as well as on-site

technical assistance in locations all over the world.

Mixing

The two components of Nitoseal 290 are supplied in the

correct proportions for mixing. Pour the entire contents of

the liquid resin into a suitable mixing vessel and then slowly

add the powder component whilst mixing with a slow speed

drill (300 to 500 rpm) fitted with a Fosroc Sealant Mixing Paddle

(MR2). Thoroughly mix the components for not less than three

minutes ensuring a homogeneous consistent mix.

Nitoseal 290 - Page 2 of 4

Typical Joint Details

Storage

Shelf life

12 months if stored in the original unopened containers in a

cool dry place at ambient temperatures below 25C. Do not

store in direct sunlight.

Precautions

Health and safety

Some people are sensitive to resins, hardeners and solvents.

Wear suitable protective clothing, gloves and eye/face

protection. Barrier creams such as Kerodex Antisolvent or

Rozalex Antipaint provide additional skin protection.

Should accidental skin contact occur, remove immediately

with a resin removing cream such as Kerocleanse Standard

Grade Skin Cleanser or Rozaklens Industrial Skin Cleanser,

followed by washing with soap and water. Do not use solvent.

In case of contact with eyes, rinse immediately with plenty of

clean water and seek medical advice.

If swallowed, seek medical attention immediately - do not

induce vomiting.

Fire

Nitoseal 290 and Fosroc Solvent 102 are flammable. Keep

away from sources of ignition. No smoking. In the event of

fire extinguish with CO2 or foam. Do not use a water jet.

Flash points

Nitoseal 290

Solvent 102

:

:

28C

33C

For further information, refer to the Product Material Safety

Data Sheet.

Estimating

Supply

Nitoseal 290

Fosroc Solvent 102

:

:

10 litre packs

5 litre cans

Guide to sealant quantities

Number of litres required =

Joint width (mm) x groove depth (mm) x groove length (m)

1000

Adjustment should be made where necessary for the volume

of rhe cable. A further amount should be allowed for possible

wastage.

Nitoseal 290 - Page 3 of 4

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

n waterproofing membranes & waterstops

n joint sealants & filler boards

n cementitious & epoxy grouts

n specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and refurbishment

of damaged concrete. Fosrocs Systematic Approach to

concrete repair features the following :

n hand-placed repair mortars

n spray grade repair mortars

n fluid micro-concretes

n chemically resistant epoxy mortars

n anti-carbonation/anti-chloride protective coatings

n chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

REGIONAL SALES OFFICES IN :

Al Gurg Fosroc LLC

P. O. Box 657

Dubai

United Arab Emirates

TEL : (04) 285 8606

FAX : (04) 285 9649

DUBAI

ABU DHABI

BAHRAIN

KUWAIT

OMAN

QATAR

Al Gurg Fosroc

Al Gurg Fosroc

YBA Kanoo

Boodai

GETCO

Tadmur

TEL : 285 8787

TEL : 673 1779

TEL : 738200

TEL : 481 7618

TEL : 771 5080

TEL : 441 3628

FAX : 285 2023

FAX : 673 1449

FAX : 732828

FAX : 483 2124

FAX : 771 7554

FAX : 444 0812

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of

which may be obtained on request. Whilst Fosroc endeavours to ensure that the technical information on this data sheet is correct at the time of printing,

it is the customers responsibility to satisfy himself, by checking with the company that this information is still current at the time of use, that the product is

suitable for the intended application, and that the actual conditions of use are in accordance with those recommended. Because Fosroc has no control over

the conditions of use of its products, all recommendations or suggestions regarding the use of these products are made without guarantee.

www.fosrocgulf.com

UAE/0326/

Das könnte Ihnen auch gefallen

- Nitoseal 290Dokument4 SeitenNitoseal 290shanon33Noch keine Bewertungen

- Nitoseal 220Dokument4 SeitenNitoseal 220Venkata RaoNoch keine Bewertungen

- PlastisealDokument4 SeitenPlastisealVenkata RaoNoch keine Bewertungen

- Nitoseal 130Dokument2 SeitenNitoseal 130Venkata RaoNoch keine Bewertungen

- Nitocote EN901Dokument4 SeitenNitocote EN901kalidindivenkatarajuNoch keine Bewertungen

- Epoxy tile adhesive and grout guideDokument2 SeitenEpoxy tile adhesive and grout guideVenkata RaoNoch keine Bewertungen

- Nitomortar TC2000Dokument3 SeitenNitomortar TC2000MuhammedHafis100% (1)

- Nitobond Ep..Dokument4 SeitenNitobond Ep..budhikurniawanNoch keine Bewertungen

- Nitocote cm210Dokument4 SeitenNitocote cm210Venkata RaoNoch keine Bewertungen

- Epoxy Tile Adhesive & Grout GuideDokument2 SeitenEpoxy Tile Adhesive & Grout GuideBalasubramanian AnanthNoch keine Bewertungen

- Cicol EtslurryDokument4 SeitenCicol EtslurryVenkata RaoNoch keine Bewertungen

- Nitoprime ZincrichDokument4 SeitenNitoprime ZincrichVenkata RaoNoch keine Bewertungen

- Conbextra Ep300Dokument4 SeitenConbextra Ep300Venkata RaoNoch keine Bewertungen

- (PDS) Conbextra EP300Dokument4 Seiten(PDS) Conbextra EP300Faizal HaziziNoch keine Bewertungen

- Nitoseal 105: Uses PropertiesDokument2 SeitenNitoseal 105: Uses PropertiesVenkata RaoNoch keine Bewertungen

- Conbextra EP10Dokument2 SeitenConbextra EP10MuhammedHafis100% (1)

- Tds - Emaco s88c TDokument2 SeitenTds - Emaco s88c TVenkata RaoNoch keine Bewertungen

- Nitomortar ELDokument4 SeitenNitomortar ELmilanbrasinaNoch keine Bewertungen

- Nitoseal 130 : Constructive SolutionsDokument2 SeitenNitoseal 130 : Constructive SolutionsmilanbrasinaNoch keine Bewertungen

- Nitomortar TC2000 Epoxy ResinDokument3 SeitenNitomortar TC2000 Epoxy ResingrtunaNoch keine Bewertungen

- Nitoseal 125Dokument2 SeitenNitoseal 125Hantu TuahNoch keine Bewertungen

- Fosroc Nukote ST: Constructive SolutionsDokument4 SeitenFosroc Nukote ST: Constructive SolutionsRaj PatelNoch keine Bewertungen

- Renderoc LaxtraDokument2 SeitenRenderoc LaxtraAlexi ALfred H. TagoNoch keine Bewertungen

- Nitoproof 600Dokument4 SeitenNitoproof 600sandeepuaeNoch keine Bewertungen

- Fosroc Nukote JF80Dokument3 SeitenFosroc Nukote JF80Balasubramanian AnanthNoch keine Bewertungen

- 21-5 PDS AiDokument3 Seiten21-5 PDS Aiuocmogiandi_aNoch keine Bewertungen

- Nitoseal® 200Dokument4 SeitenNitoseal® 200Venkata Raju KalidindiNoch keine Bewertungen

- TDS - Mastertop 300Dokument3 SeitenTDS - Mastertop 300Venkata RaoNoch keine Bewertungen

- Nitoproof 100 PDFDokument2 SeitenNitoproof 100 PDFmilanbrasinaNoch keine Bewertungen

- Lock Cover Sealing Method Statement Rev 1Dokument7 SeitenLock Cover Sealing Method Statement Rev 1agusfitriyadiNoch keine Bewertungen

- NitofixDokument2 SeitenNitofixpravi3434Noch keine Bewertungen

- Cold Applied Waterproofing MembraneDokument2 SeitenCold Applied Waterproofing MembraneSyed ShahbazNoch keine Bewertungen

- Nitoseal 220 PDFDokument4 SeitenNitoseal 220 PDFmilanbrasinaNoch keine Bewertungen

- Nitocote HT120Dokument4 SeitenNitocote HT120Venkata Raju KalidindiNoch keine Bewertungen

- Nitoseal 777 PDFDokument4 SeitenNitoseal 777 PDFmilanbrasinaNoch keine Bewertungen

- Polycoat RbeDokument2 SeitenPolycoat RbejovindhaNoch keine Bewertungen

- Basf Masterflow 9200 DB EngDokument4 SeitenBasf Masterflow 9200 DB Engapi-283891975Noch keine Bewertungen

- TDs - Emaco R101Dokument3 SeitenTDs - Emaco R101Venkata RaoNoch keine Bewertungen

- TDS - Emaco S88 PlusDokument2 SeitenTDS - Emaco S88 PlusVenkata RaoNoch keine Bewertungen

- Nitotile 489 : Constructive SolutionsDokument2 SeitenNitotile 489 : Constructive SolutionsmilanbrasinaNoch keine Bewertungen

- Ferreko No 3 pc560Dokument2 SeitenFerreko No 3 pc560vijayarangam1984Noch keine Bewertungen

- Conbextra EP300Dokument4 SeitenConbextra EP300Venkata Raju KalidindiNoch keine Bewertungen

- Nitocote EN901Dokument4 SeitenNitocote EN901ArieIndrawanNoch keine Bewertungen

- Single component adhesive for Idrostop waterproof jointsDokument2 SeitenSingle component adhesive for Idrostop waterproof jointsPrateek JainNoch keine Bewertungen

- BITUSTICK - XL-Tecnical Data SheetDokument2 SeitenBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- TDS Nitomortar TC2000 Saudi ArabiaDokument3 SeitenTDS Nitomortar TC2000 Saudi ArabiaHarry BawingNoch keine Bewertungen

- Ambigard - 2K Waterproof Coating For ConcreteDokument4 SeitenAmbigard - 2K Waterproof Coating For ConcreterudrabirNoch keine Bewertungen

- Abrasion-Resistant Epoxy Lining MortarDokument4 SeitenAbrasion-Resistant Epoxy Lining MortarBalasubramanian AnanthNoch keine Bewertungen

- Nitocote Et550Dokument4 SeitenNitocote Et550Venkata RaoNoch keine Bewertungen

- Methodology For TERRACE Waterproofing NITOPROOF 600 PDFDokument7 SeitenMethodology For TERRACE Waterproofing NITOPROOF 600 PDF폴로 쥰 차100% (1)

- Concure 90 PDFDokument4 SeitenConcure 90 PDFmilanbrasinaNoch keine Bewertungen

- Brush BondDokument4 SeitenBrush BondVenkata RaoNoch keine Bewertungen

- LokfixDokument4 SeitenLokfixstructdesignNoch keine Bewertungen

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsVon EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- TDS - Mastertile 30 - WPMDokument2 SeitenTDS - Mastertile 30 - WPMVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 40Dokument2 SeitenTDS - Mastertile 40Venkata RaoNoch keine Bewertungen

- TDS - Mastertile 200 - LatexDokument2 SeitenTDS - Mastertile 200 - LatexVenkata RaoNoch keine Bewertungen

- Tds - WaboflexrejDokument4 SeitenTds - WaboflexrejVenkata RaoNoch keine Bewertungen

- Nitocote SN CremeDokument2 SeitenNitocote SN CremeVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 530 - RbgroutDokument1 SeiteTDS - Mastertile 530 - RbgroutVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 540 - WjgroutDokument2 SeitenTDS - Mastertile 540 - WjgroutVenkata RaoNoch keine Bewertungen

- Tds - Waboflex SRDokument3 SeitenTds - Waboflex SRVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 550 - DgroutDokument3 SeitenTDS - Mastertile 550 - DgroutVenkata RaoNoch keine Bewertungen

- TDS - Wabocrete IIDokument2 SeitenTDS - Wabocrete IIKingshuk SarkarNoch keine Bewertungen

- Tds - Wabodec PDokument3 SeitenTds - Wabodec PVenkata RaoNoch keine Bewertungen

- BFG InternationalDokument2 SeitenBFG InternationalVenkata RaoNoch keine Bewertungen

- TDS - Rheomix 141Dokument4 SeitenTDS - Rheomix 141Venkata RaoNoch keine Bewertungen

- Rheofinish 202: Solvent Based Chemical Release AgentDokument2 SeitenRheofinish 202: Solvent Based Chemical Release AgentVenkata RaoNoch keine Bewertungen

- Nitocote RiDokument2 SeitenNitocote RiVenkata Rao0% (1)

- Epoxy tile adhesive and grout guideDokument2 SeitenEpoxy tile adhesive and grout guideVenkata RaoNoch keine Bewertungen

- Brush BondDokument4 SeitenBrush BondVenkata RaoNoch keine Bewertungen

- TDS - Masterkure 161Dokument2 SeitenTDS - Masterkure 161Venkata Rao0% (1)

- 3696 2Dokument7 Seiten3696 2Venkata RaoNoch keine Bewertungen

- TDS - Masterkure 106Dokument2 SeitenTDS - Masterkure 106Venkata RaoNoch keine Bewertungen

- TDS Rheomix 121Dokument3 SeitenTDS Rheomix 121Tanzeel Liaqat100% (1)

- TDS - Masterkure 107Dokument2 SeitenTDS - Masterkure 107Venkata Rao100% (1)

- 875 5Dokument20 Seiten875 5Venkata RaoNoch keine Bewertungen

- Fosroc Acid Etch Concrete CleanerDokument2 SeitenFosroc Acid Etch Concrete CleanerVenkata RaoNoch keine Bewertungen

- 1200 5Dokument11 Seiten1200 5Venkata RaoNoch keine Bewertungen

- Proofex GPXDokument2 SeitenProofex GPXVenkata RaoNoch keine Bewertungen

- 5640Dokument9 Seiten5640Venkata RaoNoch keine Bewertungen

- Supercast PVCDokument8 SeitenSupercast PVCVenkata RaoNoch keine Bewertungen

- Nitotile LM GroutDokument2 SeitenNitotile LM GroutVenkata RaoNoch keine Bewertungen

- AAU5243 DescriptionDokument30 SeitenAAU5243 DescriptionWisut MorthaiNoch keine Bewertungen

- AVANTIZ 2021 LNR125 (B927) EngineDokument16 SeitenAVANTIZ 2021 LNR125 (B927) EngineNg Chor TeckNoch keine Bewertungen

- Installation Instruction XALM IndoorDokument37 SeitenInstallation Instruction XALM IndoorVanek505Noch keine Bewertungen

- Desert Power India 2050Dokument231 SeitenDesert Power India 2050suraj jhaNoch keine Bewertungen

- PharmacologyAnesthesiology RevalidaDokument166 SeitenPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Corn MillingDokument4 SeitenCorn Millingonetwoone s50% (1)

- Your Inquiry EPALISPM Euro PalletsDokument3 SeitenYour Inquiry EPALISPM Euro PalletsChristopher EvansNoch keine Bewertungen

- Postnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoDokument11 SeitenPostnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoRadha SriNoch keine Bewertungen

- Identifying The TopicDokument2 SeitenIdentifying The TopicrioNoch keine Bewertungen

- Roadmap For Digitalization in The MMO Industry - For SHARINGDokument77 SeitenRoadmap For Digitalization in The MMO Industry - For SHARINGBjarte Haugland100% (1)

- Calibration Motion Control System-Part2 PDFDokument6 SeitenCalibration Motion Control System-Part2 PDFnurhazwaniNoch keine Bewertungen

- Key formulas for introductory statisticsDokument8 SeitenKey formulas for introductory statisticsimam awaluddinNoch keine Bewertungen

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDokument7 SeitenOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalNoch keine Bewertungen

- Easa Ad Us-2017-09-04 1Dokument7 SeitenEasa Ad Us-2017-09-04 1Jose Miguel Atehortua ArenasNoch keine Bewertungen

- Obligations and Contracts Bar Questions and Answers PhilippinesDokument3 SeitenObligations and Contracts Bar Questions and Answers PhilippinesPearl Aude33% (3)

- WassiDokument12 SeitenWassiwaseem0808Noch keine Bewertungen

- Timely characters and creatorsDokument4 SeitenTimely characters and creatorsnschober3Noch keine Bewertungen

- Failure Analysis Case Study PDFDokument2 SeitenFailure Analysis Case Study PDFScott50% (2)

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Dokument14 SeitenDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiNoch keine Bewertungen

- Ali ExpressDokument3 SeitenAli ExpressAnsa AhmedNoch keine Bewertungen

- Second Law of EntrophyDokument22 SeitenSecond Law of EntrophyMia Betia BalmacedaNoch keine Bewertungen

- Bandung Colonial City Revisited Diversity in Housing NeighborhoodDokument6 SeitenBandung Colonial City Revisited Diversity in Housing NeighborhoodJimmy IllustratorNoch keine Bewertungen

- Singer NM37 57manualDokument266 SeitenSinger NM37 57manualpaulkoby100% (2)

- Cells in The Urine SedimentDokument3 SeitenCells in The Urine SedimentTaufan LutfiNoch keine Bewertungen

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Dokument228 SeitenHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- Huawei WCDMA Primary Scrambling Code PlanningDokument22 SeitenHuawei WCDMA Primary Scrambling Code PlanningZeljko Vrankovic90% (31)

- Cianura Pentru Un Suras de Rodica OjogDokument1 SeiteCianura Pentru Un Suras de Rodica OjogMaier MariaNoch keine Bewertungen

- Vehicle Registration Renewal Form DetailsDokument1 SeiteVehicle Registration Renewal Form Detailsabe lincolnNoch keine Bewertungen

- Covey - Moral CompassingDokument5 SeitenCovey - Moral CompassingAsimNoch keine Bewertungen

- Judge Vest Printable PatternDokument24 SeitenJudge Vest Printable PatternMomNoch keine Bewertungen