Beruflich Dokumente

Kultur Dokumente

Applied Hydraulics and Pneumatics Lab Manual

Hochgeladen von

Mahendran ArumugamOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Applied Hydraulics and Pneumatics Lab Manual

Hochgeladen von

Mahendran ArumugamCopyright:

Verfügbare Formate

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

HINDUSTHAN

COLLEGE OF ENGINEERING AND

TECHNOLOGY

DEPARTMENT OF

MECHATRONICS ENGINEERING

LAB MANUAL

A.MAHENDRAN , M.E.,PGDPC., MISTE.,

Assistant Professor/Mechatronics

mahendran.hindusthan@gmail.com

hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

LIST OF EXPERIMENTS

1. Design and Testing of Pneumatic Single and Double Cylinder actuating system

2. Design and Testing of Two Hand operated Pneumatic Double Acting Cylinder

(Direct Method)

3. Design and Testing of Two Hand operated Pneumatic Double Acting Cylinder (InDirect Method)

4. Design and Testing of Pneumatic Single Acting Cylinder by two DCVs

-

Shuttle (OR) and Dual Pressure (AND) Valve

5. Design and Testing of Pneumatic Metering-In and Metering-Out circuit

6. Design and Testing of Pneumatic two Double Acting Cylinder Synchronization

circuits (Cylinders connected in Series and Parallel)

7. Design and Testing of Single Cycle operation of Pneumatic Double Acting Cylinder

8. Design and Testing of Multi-Cycle operation of Pneumatic Double Acting Cylinder

9. Design and Testing of two Pneumatic Double Acting Cylinder Sequencing circuit

(A+ B+ B- A-)

10. Design and Testing of Single acting cylinder reciprocating system using ElectroPneumatics

11. Design and Testing of Double acting cylinder reciprocating system using ElectroPneumatics

12. Design and testing of Hydraulic single and double acting cylinder reciprocating

system using fluid power simulation software

13. Design and testing of Hydraulic cylinder synchronization system using fluid

power simulation software

14. Design and testing of Hydraulic bi-directional and semi-rotary motor system

fluid power simulation software

15. Design and testing of Hydraulic cylinder sequencing system using fluid power

simulation software

16. Design and testing of Electro-Hydraulic cylinder reciprocating system

17. Design and testing of Electro-Hydraulic Bi-directional Motor system

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

01

LAB MANUAL

DESIGN AND TESTING OF

PNEUMATIC SINGLE AND DOUBLE ACTING

CYLINDER ACTUATION SYSTEM

AIM

To Design and Test Pneumatic Single and Double Cylinder actuating

system

COMPONENTS REQUIRED

Compressor

FRL unit

Single acting cylinder

Double acting cylinder

5/2 way Lever operated DCV with detent

3/2 way PB operated DCV with spring return

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus the pneumatic single and double acting cylinder systems with

appropriate control are designed and their operation is observed.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

02

LAB MANUAL

DESIGN AND TESTING OF

TWO HAND OPERATED PNEUMATIC DOUBLE

ACTING CYLINDER (DIRECT METHOD)

AIM

To Design and Test Two Hand operated Pneumatic Double Acting

Cylinder using Direct Method

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder

3/2 way PB operated DCV with spring return 2 No.

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus Two Hand operated Pneumatic Double Acting Cylinder

using Direct Method is Designed and Tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

03

LAB MANUAL

DESIGN AND TESTING OF

TWO HAND OPERATED PNEUMATIC DOUBLE

ACTING CYLINDER (IN-DIRECT METHOD)

AIM

To Design and Test Two Hand operated Pneumatic Double Acting

Cylinder using In-Direct Method

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder

Double External Air Pilot operated 5/2 way DCV

3/2 way PB operated DCV with spring return 2 No.

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus Two Hand operated Pneumatic Double Acting Cylinder

using In-Direct Method is Designed and Tested

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

04

LAB MANUAL

DESIGN AND TESTING OF PNEUMATIC

SINGLE ACTING CYLINDER USING SHUTTLE

(OR) AND DUAL PRESSURE (AND) VALVE

AIM

To Design and Test Pneumatic Single Acting Cylinder using Shuttle

(OR) and Dual Pressure (AND) Valve

COMPONENTS REQUIRED

Compressor

FRL unit

Single acting cylinder

Shuttle (OR) Valve and Dual Pressure (AND) Valve

3/2 way PB operated DCV with spring return 2 No.

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus the Pneumatic Single Acting Cylinder using Shuttle (OR)

and Dual Pressure (AND) Valve is Designed and Tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

05

LAB MANUAL

DESIGN AND TESTING OF

PNEUMATIC METERING-IN AND

METERING-OUT CIRCUIT

AIM

To Design and Testing of Pneumatic Metering-In and Metering-Out

circuit

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder

5/2 way Lever operated DCV with detent

Flow control valve

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus Pneumatic Metering-In and Metering-Out circuit is

Designed and Tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

06

LAB MANUAL

DESIGN AND TESTING OF

TWO PNEUMATIC DOUBLE ACTING CYLINDER

SYNCHRONIZATION CIRCUITS

AIM

To Design and Testing of two Pneumatic Double Acting Cylinder

Synchronization circuits (Cylinders connected in Series and Parallel)

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder 2 No.

5/2 way Lever operated DCV with detent

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus two Pneumatic Double Acting Cylinder Synchronization

circuits (Cylinders connected in Series and Parallel) are Designed and

Tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

07

LAB MANUAL

DESIGN AND TESTING OF

SINGLE CYCLE OPERATION OF PNEUMATIC

DOUBLE ACTING CYLINDER

AIM

To Design and Testing of Single Cycle operation of Pneumatic Double

Acting Cylinder

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder

5/2 way Lever operated DCV

Double External Air Pilot operated 5/2 way DCV

Roller operated 3/2 way DCV with spring return

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus Single Cycle operation of Pneumatic Double Acting Cylinder is

Designed and Tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

08

LAB MANUAL

DESIGN AND TESTING OF

MULTI CYCLE OPERATION OF PNEUMATIC

DOUBLE ACTING CYLINDER

AIM

To Design and Testing of Multi-Cycle operation of Pneumatic Double

Acting Cylinder

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder

5/2 way Lever operated DCV

Double External Air Pilot operated 5/2 way DCV

Roller operated 3/2 way DCV with spring return

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus Multi Cycle operation of Pneumatic Double Acting Cylinder is

Designed and Tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

09

LAB MANUAL

DESIGN AND TESTING OF

PNEUMATIC SEQUENCING CIRCUIT

AIM

To Design and Testing of Pneumatic Sequencing circuit (A+ B+ B- A-)

COMPONENTS REQUIRED

Compressor

FRL unit

Double acting cylinder

5/2 way Lever operated DCV

Double External Air Pilot operated 5/2 way DCV

Roller operated 3/2 way DCV with spring return

Junction box with slider valve

Tubes and connectors

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection as per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to the

system

5. Regulate and set the required pressure (3 - 5 bar) using FRL units

regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Observe the operation of the system by actuating appropriate valves

and controls

RESULT

Thus Pneumatic Sequencing circuit is designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

10

LAB MANUAL

DESIGN AND TESTING OF

SINGLE ACTING CYLINDER USING

ELECTRO PNEUMATICS

AIM

To Design and Test Single acting cylinder reciprocating system

using Electro-Pneumatics

APPARATUS

Compressor

Single acting cylinder

FRL unit

Single solenoid operated 5/2 way DCV

PB and selector switch controls

Relay box and SMPS

Junction box with slider valve

Tubes, connectors and cables

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection (both pneumatic and electrical) as

per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to

the system

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

5. Regulate and set the required pressure (3 - 5 bar) using FRL

units regulator

6. Operate the slide valve of the junction and allow the air into the

system

7. Turn ON the SMPS and allow the 24V dc to pass through the

system

8. Observe the operation of the system by actuating appropriate

solenoids.

RESULT

Thus the single acting cylinder reciprocating system using

Electro-Pneumatics is designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex.No.:

11

LAB MANUAL

DESIGN AND TESTING OF

DOUBLE ACTING CYLINDER USING

ELECTRO PNEUMATICS

AIM

To Design and Test Double acting cylinder reciprocating system

using Electro-Pneumatics

APPARATUS

Compressor

Double acting cylinder

FRL unit

Double solenoid operated 5/2 way DCV

PB and selector switch controls

Relay box and SMPS

Junction box with slider valve

Tubes, connectors and cables

PROCEDURE

1. RUN the compressor and store the pressurized air in the receiver

tank

2. Connect the FRL unit inlet to the tank outlet

3. Make the circuit connection (both pneumatic and electrical) as

per the diagram

4. Turn ON the tank outlet valve and receive the pressurized air to

the system

5. Regulate and set the required pressure (3 - 5 bar) using FRL

units regulator

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

6. Operate the slide valve of the junction and allow the air into the

system

7. Turn ON the SMPS and allow the 24V dc to pass through the

system

8. Observe the operation of the system by actuating appropriate

solenoids.

RESULT

Thus the double acting cylinder reciprocating system using

Electro-Pneumatics is designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

DESIGN AND TESTING OF

Ex. No.:

HYDRAULIC SINGLE AND DOUBLE CYLINDERS

12

USING SIMULATION SOFTWARE

AIM

To design and test the Hydraulic single and double acting

cylinder reciprocating system using fluid power simulation software

COMPONENTS REQUIRED

Simulation Software (Automation Studio / AUTOMSIM)

PC with power supply

PROCEDURE

1. Turn on the system and enter into software.

2. Open New file and save the same in appropriate location

3. Start designing the circuit using Hydraulic section

4. Use respective valves, actuators, fluid conditioners, power

circuits etc., while designing

5. Save the file again after completion of circuit design

6. Go to online simulation mode and test the circuit for its

operation

7. Quit simulation mode and close the file

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

RESULT

Thus by using Fluid Power simulation software Hydraulic single

and double acting cylinder reciprocating system designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex. No.:

LAB MANUAL

DESIGN AND TESTING OF

HYDRAULIC CYLINDER SYNCHRONIZATION

13

CIRCUIT USING SIMULATION SOFTWARE

AIM

To design and test the Hydraulic cylinder synchronization

system using fluid power simulation software

COMPONENTS REQUIRED

Simulation Software (Automation Studio / AUTOMSIM)

PC with power supply

PROCEDURE

1. Turn on the system and enter into software.

2. Open New file and save the same in appropriate location

3. Start designing the circuit using Hydraulic section

4. Use respective valves, actuators, fluid conditioners, power

circuits etc., while designing

5. Save the file again after completion of circuit design

6. Go to online simulation mode and test the circuit for its

operation

7. Quit simulation mode and close the file

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

RESULT

Thus by using Fluid Power simulation software Hydraulic

cylinder sequencing system designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

Ex. No.:

LAB MANUAL

DESIGN AND TESTING OF HYDRAULIC

BI-DIRECTIONAL AND SEMI ROTARY MOTOR

14

SYSTEM USING SIMULATION SOFTWARE

AIM

To design and test the Hydraulic bi-directional and semi-rotary

motor system fluid power simulation software

COMPONENTS REQUIRED

Simulation Software (Automation Studio / AUTOMSIM)

PC with power supply

PROCEDURE

1. Turn on the system and enter into software.

2. Open New file and save the same in appropriate location

3. Start designing the circuit using Hydraulic section

4. Use respective valves, actuators, fluid conditioners, power

circuits etc., while designing

5. Save the file again after completion of circuit design

6. Go to online simulation mode and test the circuit for its

operation

7. Quit simulation mode and close the file

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

RESULT

Thus by using Fluid Power simulation software Hydraulic bidirectional and semi-rotary motor system designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

DESIGN AND TESTING OF

Ex. No.:

HYDRAULIC CYLINDER SEQUENCING CIRCUIT

15

USING SIMULATION SOFTWARE

AIM

To design and test the Hydraulic cylinder sequencing system

using fluid power simulation software

COMPONENTS REQUIRED

Simulation Software (Automation Studio / AUTOMSIM)

PC with power supply

PROCEDURE

1. Turn on the system and enter into software.

2. Open New file and save the same in appropriate location

3. Start designing the circuit using Hydraulic section

4. Use respective valves, actuators, fluid conditioners, power

circuits etc., while designing

5. Save the file again after completion of circuit design

6. Go to online simulation mode and test the circuit for its

operation

7. Quit simulation mode and close the file

RESULT

Thus by using Fluid Power simulation software Hydraulic

cylinder sequencing system designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

DESIGN AND TESTING OF

Ex. No.:

ELECTRO-HYDRAULIC DOUBLE ACTING

16

CYLINDER RECIPROCATING SYSTEM

AIM

To design and test the Electro-Hydraulic cylinder reciprocating

system

COMPONENTS REQUIRED

Hydraulic double acting cylinder

Solenoid operation 4/3 way DCV

Electrical driver unit

Power Pack ( Reservoir, Filter, Pump, Pressure regulator

etc.,)

PROCEDURE

1. Make the connections both hydraulic and electrical as per the

circuit design

2. Turn ON the controls to pump the oil from reservoir to flow

across the circuit.

3. The double solenoid operated spring centered 4/3 way DCV is

operated which allows the oil to flow across the circuit in one

direction.

4. Then the respective push button is operated to actuate the

solenoid operated DCV

5. Observe the direction of cylinder, changes with respect to the

change in solenoid actuation

RESULT

Thus the Electro-Hydraulic cylinder reciprocating system is

designed and tested.

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

mahendran.hindusthan@gmail.com

APPLIED HYDRAULICS AND PNEUMATICS LAB

LAB MANUAL

DESIGN AND TESTING OF

Ex. No.:

ELECTRO - HYDRAULIC BIDIRECTIONAL

17

MOTOR SYSTEM

AIM

To design and test the Electro-Hydraulic bidirectional motor

system

COMPONENTS REQUIRED

Hydraulic Bidirectional Motor

Solenoid operation 4/3 way DCV

Electrical driver unit

Power Pack ( Reservoir, Filter, Pump, Pressure regulator

etc.,)

PROCEDURE

1. Make the connections both hydraulic and electrical as per the

circuit design

2. Turn ON the controls to pump the oil from reservoir to flow

across the circuit.

3. The double solenoid operated spring centered 4/3 way DCV is

operated which allows the oil to flow across the circuit in one

direction.

4. Then the respective push button is operated to actuate the

solenoid operated DCV

5. Observe the direction of cylinder, changes with respect to the

change in solenoid actuation

RESULT

Thus the

Electro-Hydraulic bidirectional motor system is

designed and tested.

mahendran.hindusthan@gmail.com

Das könnte Ihnen auch gefallen

- VOLVO 240 SECT. 2 - ENGINE d20 d24 - Repairs Part 2Dokument96 SeitenVOLVO 240 SECT. 2 - ENGINE d20 d24 - Repairs Part 2Myselvf100% (1)

- LEBH4623-00 (C7-C32 ACERT - Manuale Di Installazione Elettronica)Dokument135 SeitenLEBH4623-00 (C7-C32 ACERT - Manuale Di Installazione Elettronica)jorgedavidgonzalez100% (1)

- ME 1305 - Applied Hydraulics and PneumaticsDokument7 SeitenME 1305 - Applied Hydraulics and PneumaticsUva ShruthikaNoch keine Bewertungen

- 8127280a002 GBDokument129 Seiten8127280a002 GBLuci Lucian100% (3)

- ME8694 - Hydraulics and Pneumatics Question BankDokument14 SeitenME8694 - Hydraulics and Pneumatics Question BankelabalajiNoch keine Bewertungen

- SKF Locknut Shaft Details InchDokument6 SeitenSKF Locknut Shaft Details InchKOMATSU SHOVELNoch keine Bewertungen

- Components for Pneumatic Control Instruments: The Static and Dynamic Characteristics of Pneumatic Resistances, Capacitances and Transmission LinesVon EverandComponents for Pneumatic Control Instruments: The Static and Dynamic Characteristics of Pneumatic Resistances, Capacitances and Transmission LinesNoch keine Bewertungen

- Position Control of DC Motor Using Genetic Algorithm Based PID ControllerDokument35 SeitenPosition Control of DC Motor Using Genetic Algorithm Based PID ControllerSarat Chandra100% (1)

- Pc130-7 Spare Parts CatalogueDokument285 SeitenPc130-7 Spare Parts CatalogueNishant Sinha100% (19)

- D3E8034DF5E Gearbox 09GDokument216 SeitenD3E8034DF5E Gearbox 09GVasile-Cristian Rusu50% (2)

- AL4 DPO Transmission Rebuild ManualDokument72 SeitenAL4 DPO Transmission Rebuild ManualAhmed Fotoh100% (1)

- Applied Hydraulics and Pneumatics ME1305Dokument8 SeitenApplied Hydraulics and Pneumatics ME1305kv19852009Noch keine Bewertungen

- PLC Lab ManualDokument64 SeitenPLC Lab ManualNaveen Kumar100% (4)

- Hydraulic and pneumatic systems examDokument2 SeitenHydraulic and pneumatic systems examAravinthNoch keine Bewertungen

- Chapter 2 - Discrete-State Control Part IDokument41 SeitenChapter 2 - Discrete-State Control Part IYu Gen Xin100% (1)

- Massey Ferguson 6711 TRACTOR (ECO4 TIER 2 TIER 3) (F5239005 - 99999999) Service Parts Catalogue Manual (Part Number 6246214)Dokument16 SeitenMassey Ferguson 6711 TRACTOR (ECO4 TIER 2 TIER 3) (F5239005 - 99999999) Service Parts Catalogue Manual (Part Number 6246214)bvk2980022Noch keine Bewertungen

- Automation and CNC (Computer Numeric Control) MachinesDokument2 SeitenAutomation and CNC (Computer Numeric Control) MachinesAbhigya BhatnagarNoch keine Bewertungen

- Digital Controlled System Lab Manual PDFDokument43 SeitenDigital Controlled System Lab Manual PDFsoumencha100% (3)

- NC, CNC & Robotics: An IntroductionDokument143 SeitenNC, CNC & Robotics: An IntroductionshafiqNoch keine Bewertungen

- Offer For Maxturn+ & Maxmill+Dokument8 SeitenOffer For Maxturn+ & Maxmill+Reddi PrasadNoch keine Bewertungen

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionVon EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNoch keine Bewertungen

- Thomas Flexible Disc CouplingDokument52 SeitenThomas Flexible Disc Couplingkwakwa4100% (1)

- RX50Dokument519 SeitenRX50Vinícius FerrazNoch keine Bewertungen

- 十字路口交通灯PLC控制程序的研究与设计Dokument35 Seiten十字路口交通灯PLC控制程序的研究与设计Zeng LinNoch keine Bewertungen

- Mechatronics Lab ManualDokument44 SeitenMechatronics Lab Manualarun2386Noch keine Bewertungen

- MT6603 DMS Unt 3 PDFDokument39 SeitenMT6603 DMS Unt 3 PDFKarthi KeyanNoch keine Bewertungen

- Computer Aided Metrology PrinciplesDokument3 SeitenComputer Aided Metrology PrinciplesramptechNoch keine Bewertungen

- PLC Question BankDokument3 SeitenPLC Question BankAjay kumarNoch keine Bewertungen

- Question Bank SensorsDokument2 SeitenQuestion Bank SensorsJasmine Kaur ButtarNoch keine Bewertungen

- Ihp Unit 6: Pneumatic CircuitsDokument35 SeitenIhp Unit 6: Pneumatic CircuitsAkash MarkhaleNoch keine Bewertungen

- Me6712 Mechatronics Lab Manual PDFDokument46 SeitenMe6712 Mechatronics Lab Manual PDFAhmed M H Al-Yousif50% (2)

- Unit 2Dokument6 SeitenUnit 2hariharanbookNoch keine Bewertungen

- Introduction To Control SystemsDokument28 SeitenIntroduction To Control SystemsAK MizanNoch keine Bewertungen

- CIM-2 MarksDokument18 SeitenCIM-2 MarksHod MechNoch keine Bewertungen

- Me2401 Mechatronics - 2 Marks With Answer PDFDokument15 SeitenMe2401 Mechatronics - 2 Marks With Answer PDFSiva RamanNoch keine Bewertungen

- ME 2305 Applied Hydraulics and Pneumatics: Dhanalakshmi Srinivasan Instuitute of Research and TechnologyDokument10 SeitenME 2305 Applied Hydraulics and Pneumatics: Dhanalakshmi Srinivasan Instuitute of Research and TechnologyAnonymous p8bHAAxNoch keine Bewertungen

- Extra Exercise Pneumatics Sequence CircuitDokument1 SeiteExtra Exercise Pneumatics Sequence CircuitJ.m.MoraNoch keine Bewertungen

- Unit Ii Automated Flow LinesDokument94 SeitenUnit Ii Automated Flow LinesRajesh Shah100% (1)

- 309 Mechatronics MCQDokument27 Seiten309 Mechatronics MCQMr.G.Chandrasekar mechanicalstaffNoch keine Bewertungen

- Lecture Notes On Fluid Power Systems: Unit IDokument10 SeitenLecture Notes On Fluid Power Systems: Unit ItadiwosNoch keine Bewertungen

- Robot Actuators & Feed Back ComponentsDokument25 SeitenRobot Actuators & Feed Back ComponentsANONYMOUS PDFSNoch keine Bewertungen

- Fluid Power with ApplicationsDokument9 SeitenFluid Power with ApplicationstadiwosNoch keine Bewertungen

- Mechatronics Lab ManualDokument55 SeitenMechatronics Lab ManualSoumi Bandyopadhyay SB100% (1)

- Mechatronics and Industrial Automation Question PaperDokument1 SeiteMechatronics and Industrial Automation Question PaperSrinivas KronosNoch keine Bewertungen

- Measurements and Instrumentation Question BankDokument4 SeitenMeasurements and Instrumentation Question BankSurya SekaranNoch keine Bewertungen

- Components of NC Systems Classification of NC Machines Consructional DetailsDokument32 SeitenComponents of NC Systems Classification of NC Machines Consructional DetailsVaibhav Vithoba NaikNoch keine Bewertungen

- PID Control of Water Level in A Coupled Tank SystemDokument9 SeitenPID Control of Water Level in A Coupled Tank SystemEioAsan100% (1)

- Unit-7-Wireless-Modulation-Techniques-And-Hardware Malini MamDokument40 SeitenUnit-7-Wireless-Modulation-Techniques-And-Hardware Malini MamRoopa NayakNoch keine Bewertungen

- Control Systems and Instrumentation Lab GuideDokument3 SeitenControl Systems and Instrumentation Lab GuideskrtamilNoch keine Bewertungen

- SRM Valliammai Engineering College Question Bank on Sensors and TransducersDokument12 SeitenSRM Valliammai Engineering College Question Bank on Sensors and TransducersRevathy G100% (1)

- Automatic Bottle Filling System Using PLC Based Controller: Md. Liton Ahmed, Shantonu Kundu, Md. RafiquzzamanDokument8 SeitenAutomatic Bottle Filling System Using PLC Based Controller: Md. Liton Ahmed, Shantonu Kundu, Md. Rafiquzzamanbishal shahNoch keine Bewertungen

- SEC Mechatronics Lab Manual R2013 Shan PDFDokument93 SeitenSEC Mechatronics Lab Manual R2013 Shan PDFMonish KumarNoch keine Bewertungen

- Mechatronics - UNIT1-FHDokument23 SeitenMechatronics - UNIT1-FHsaba100% (3)

- Sensors & ActuatorsDokument67 SeitenSensors & Actuatorsmahendra naik100% (1)

- Pneumatic System - 1Dokument12 SeitenPneumatic System - 1Ikram NajihuddinNoch keine Bewertungen

- 22534-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Dokument32 Seiten22534-2019-Winter-Model-Answer-Paper (Msbte Study Resources)rashmi patil100% (1)

- Syringe Actuated Mechanical ArmDokument17 SeitenSyringe Actuated Mechanical ArmMohd Subhan0% (1)

- Applied Hydralics and Pneumatics 2 MarksDokument10 SeitenApplied Hydralics and Pneumatics 2 MarksVignesh VickyNoch keine Bewertungen

- PLC QuestionDokument14 SeitenPLC QuestionWaseem AhmadNoch keine Bewertungen

- ECE485/585: Programmable Logic Controllers Exam #1 (Sample Style Questions) Instructor: Dr. D. J. JacksonDokument4 SeitenECE485/585: Programmable Logic Controllers Exam #1 (Sample Style Questions) Instructor: Dr. D. J. Jacksonnida haqNoch keine Bewertungen

- Chapter3-Industrial Automation SynthesisDokument36 SeitenChapter3-Industrial Automation SynthesisThuan HuynhNoch keine Bewertungen

- Module - Time Delay ValveDokument9 SeitenModule - Time Delay ValvescribdNoch keine Bewertungen

- ME 1305 Applied Hydraulics and PneumaticsDokument6 SeitenME 1305 Applied Hydraulics and PneumaticsSuresh VeluNoch keine Bewertungen

- 1 Unit MCQ LDCSDokument3 Seiten1 Unit MCQ LDCSGopalakrishnan.G MEC-AP/ECENoch keine Bewertungen

- Industrial Automation 1Dokument41 SeitenIndustrial Automation 1Chandan Chandan100% (2)

- Iii B.Tech Ii Sem Eie (R18) : PLC Intermediate and Advanced FunctionsDokument83 SeitenIii B.Tech Ii Sem Eie (R18) : PLC Intermediate and Advanced FunctionsSrinivas PapaniNoch keine Bewertungen

- Chapter 7 Numerical Control and Industrial RoboticsDokument53 SeitenChapter 7 Numerical Control and Industrial RoboticsYousab CreatorNoch keine Bewertungen

- Record MechatronicsDokument46 SeitenRecord MechatronicsSandeepakNoch keine Bewertungen

- Circuit Diagram: Single Acting Cylinder With One Way Pressure ValveDokument16 SeitenCircuit Diagram: Single Acting Cylinder With One Way Pressure ValveKARTHINoch keine Bewertungen

- Jastram Model H Helm Pumps: Engineered For Life at SeaDokument2 SeitenJastram Model H Helm Pumps: Engineered For Life at SeaingdanilocfNoch keine Bewertungen

- Ribblex Price ListDokument22 SeitenRibblex Price ListDipen patraNoch keine Bewertungen

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix PWK) Service Repair Manual (PWK00001 and Up)Dokument28 SeitenCaterpillar Cat 216B3 Skid Steer Loader (Prefix PWK) Service Repair Manual (PWK00001 and Up)rpoy9396615Noch keine Bewertungen

- Air Dryer - Maint - Manual - Rev - 1 PDFDokument34 SeitenAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuNoch keine Bewertungen

- AMSOIL Diesel Injector Clean (ADF) PDFDokument2 SeitenAMSOIL Diesel Injector Clean (ADF) PDFamsoildealerNoch keine Bewertungen

- Price List 2020-21Dokument3 SeitenPrice List 2020-21Nikhil SalujaNoch keine Bewertungen

- 37 Series & 57 Series: Repair ManualDokument12 Seiten37 Series & 57 Series: Repair ManualSACHINNoch keine Bewertungen

- 7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitDokument52 Seiten7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitFernando ChavesNoch keine Bewertungen

- Recommended Stock of Spare Parts For BC-3200Dokument1 SeiteRecommended Stock of Spare Parts For BC-3200Mosab Babikir100% (1)

- Johnson Demountable Bearing BrochureDokument20 SeitenJohnson Demountable Bearing BrochureJulio FerrerNoch keine Bewertungen

- Air Conditioning TechnicianDokument3 SeitenAir Conditioning Technicianaungmyothant7792Noch keine Bewertungen

- FIFE Symat 70G PDFDokument25 SeitenFIFE Symat 70G PDFmartian18298706100% (1)

- Seal Gas SystemsDokument2 SeitenSeal Gas Systemsdonald sinananNoch keine Bewertungen

- Track Chain Idler, Brackets and Cover - ST10415: Parts ListDokument6 SeitenTrack Chain Idler, Brackets and Cover - ST10415: Parts ListCesar CauperNoch keine Bewertungen

- Clutch Cable PDFDokument4 SeitenClutch Cable PDFVEERAMANINoch keine Bewertungen

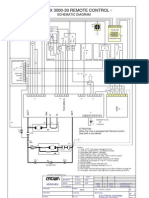

- SX 3000-30 REMOTE CONTROL SCHEMATIC DIAGRAMDokument8 SeitenSX 3000-30 REMOTE CONTROL SCHEMATIC DIAGRAMAngela ZMNoch keine Bewertungen

- VG824 Cut-Grooving ToolDokument4 SeitenVG824 Cut-Grooving ToolMarcos FuentesNoch keine Bewertungen

- Engine Power G.V.W. Payload Body Heaped (SAE 2:1) : English 09-2014Dokument6 SeitenEngine Power G.V.W. Payload Body Heaped (SAE 2:1) : English 09-2014César PérezNoch keine Bewertungen

- Valve Guide - Inspect: Testing and AdjustingDokument2 SeitenValve Guide - Inspect: Testing and AdjustingSuharto ZuhriNoch keine Bewertungen