Beruflich Dokumente

Kultur Dokumente

A Key Performance Indicator System of Process Control As A Basis For Relocation Planning

Hochgeladen von

Abd ZouhierOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Key Performance Indicator System of Process Control As A Basis For Relocation Planning

Hochgeladen von

Abd ZouhierCopyright:

Verfügbare Formate

A Key Performance Indicator System of Process

Control as a Basis for Relocation Planning

F. Reichert, A. Kunz, R. Moryson, K. Wegener

Swiss Federal Institute of Technology Zurich, Raemistrasse 101,

8092 Zurich, Switzerland

Abstract

Many companies build up manufacturing networks to

cope with globalized competition. Among others, this

requires a decision on a technical basis, which product

should be manufactured at which location.

In this paper a key performance indicator system is

introduced to measure a locations competence on a

technical basis. This system consists of three key

performance indicators: cycle time ratio, adjusted cycle

time ratio, and stability of the cycle time.

The most important performance indicator in this key

performance indicator system is the stability of cycle time.

It indicates how experienced and stable the serial

production can be managed. This indicator is defined as

the ratio of the mean absolute deviation of the cycle time

and the achieved cycle time.

Based on this, a company can take a more objective

technical decision regarding relocation processes. The

efficiency of this key performance indicator system will

then be demonstrated in a case study.

Keywords:

Factory and Production Planning, Networking in

International Production/ Manufacturing and Logistic

Networks, Process Control

1 INTRODUCTION

Many companies build up manufacturing networks to cope with globalized

competition [1]. However, the increase of internal production networks

results in decreasing knowledge concerning production conditions in the

network. To avoid this information deficit, a complex view is necessary on

the production network and the transparency of the production structure.

In case of relocation planning respectively production planning, different

decisions depending on the time horizon must be made. Strategic

decisions deal with the question where to open new locations and have a

time horizon of at least three years [2]. The time horizon of tactical

decisions is between one and three years and defines where to place

1

Reichert, Kunz, Moryson, Wegener

production volume in existing production networks. In this paper the focus

lies on the tactical planning horizon.

In order to create transparency in the production structure within

production networks for the tactical production planning, the method MAEP (machines and equipment, processes, product, planning) was

developed [3]. This method allows comparing technical criteria of

production lines and process chains of products.

If the analysis based on the MAE-P method produces a number of

technical possibilities for the production of a production volume within a

production network, the question arises which location has the highest

technical competence within this network.

In the literature many papers deal with strategic, capacity or cost driven

approaches to answer the question where to produce production volumes

in an internal production network. Thus, the topic of this paper is where to

produce a production volume based on a technical basis and regarding

the locations competence.

2 OBJECTIVES

The goal of this analysis is to develop a key performance indicator system

to evaluate the process control of the distributed production structure in an

internal production network. Based on this knowledge, decisions of where

to place production volumes can be made more profoundly.

Firstly, the term process control in the context of production processes

and production lines in a globally allocated production network has to be

defined. Secondly, a performance indicator has to be found by which it is

possible to measure this process control. Therefore, different existing

performance indicators have to be compared. Based on this comparison, a

key performance system has to be derived.

In a practical example, the developed key performance indicator system is

used to compare where to relocate a production volume of a product of a

big producing company in the automotive electronic supplier branch.

3 THE PROCESS CONTROL PERFORMANCE INDICATOR SYSTEM

3.1 The Definition of Process Control

Within literature, the term process control is part of the term process

capability. If a process is randomly distributed between given limits and if

there are no indications of disturbance, a production process can be

named as a controlled process [4]. A capable process is a process in

which the quality attributes suffices the tolerance requirements. The

according performance indicators for process control and process

capability are called cp and cpk.

The indicators process control and capability only base on the results of

the process but not on time. The duration of the process, which was

needed to reach the cp and cpk value is not part of the indicator. In this

paper, the following approach is used to describe the process control:

rd

43 CIRP Conference on Manufacturing Systems

The process capability is the ability of a technical system not to exceed a

certain tolerance limit, while the process control represents the ability of

the user to apply the process capability of the system [5].

Consequently, the required performance indicator in this system must fulfill

the significance of the users ability to use the capability of a machine. But

additionally, the production control should also show the users ability to

use this capability within the required time. The user can be a direct

operator or an indirect employee, who repairs or plans a machine.

3.2 The requests to the key performance indicator of process control

A study of the Association of German Engineers (VDI) in the field of

production controlling describes six requests to evaluate performance

indicators:

Significance

Comparability

Easy acquisition of the performance indicator

Up-to-dateness and fast availability

Clear presentation

General understandability

The most important requests for the process control performance indicator

are the first three: the significance, the comparability, and the easy

acquisition. The significance of the performance indicator process control

must show the users ability to use the capability of a technical system in

terms of process quality and process time.

Beside the significance, the comparability of the performance indicator is

very important. Especially within a production network, the performance

indicator must be acquired identically at every location; otherwise the

significance of the performance indicator is restricted.

The third important request is the possibility to acquire the performance

indicator easily. If the data acquisition is easy to perform, the probability of

identically collected performance indicators is high. For this paper, an

automatic data collection for the performance indicator is assumed.

3.3 The choice of the cycle time for the performance indicator system

With these six requests for evaluating performance indicators, different key

performance indicator classes, which could have an influence on the

process capability, were evaluated. A possible influence on the process

capability is seen in the performance indicator classes of finance,

process, quality, production, costumers, and employees.

The key performance indicator classes of process and quality fulfilled the

requests from the above. In a second comparison, the key performance

indicators of these classes are compared. Mostly because of the

significance, the comparability and the easy acquisition, the performance

indicators cycle time and processing time were chosen to be the basis

for describing the process control.

Reichert, Kunz, Moryson, Wegener

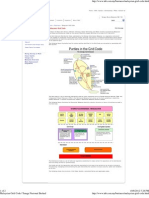

3.4 The key performance indicator system of process control

The key performance indicator system process control is measured on

two different levels, shown in Figure 1. First, the single process control is

measured, which represents a single production process in a production

line. Second, the production line control is measured, which represents the

sum of production processes in one production line.

Preassembly Line 1

eLin vel

e

L

Assembly Line 1

Pool Segment 1

Preassembly Line 2

Assembly Line 2

tPreassembly Line 1

en

gm l

e

e

s

v

e Le

Lin

Preassembly Line 2

Assembly 2

ine

ch el

Ma Lev

Measuring Point

Single Process

Control

due to

Processing Time

Line Control

due to

BottleneckCycle time

M1E

M1A

Average

& Stability

Process

Times

M2E

M2A

Average

& Stability

Process

Times

M4E

Assembly 1

Final Assem. 2

10

11

12

14

M4A

Average

& Stability

Process

Times

Final Assem. 1

Pool Segment 1

M5E

14

13

15

16

M5A

Average

& Stability

Process

Times

Bottleneck:

Average

& Stability

Cycle time

M1E Measuring Point Process 1 Entrance

M1A Measuring Point Process 1 Exit

Figure 1: Different levels of the production structure.

The process control is measured on the machine level. The time stamp of

every product at the entrance of every machine in a production line has to

be stored, as well as the time stamp when the product is leaving the

machine. With this data, the mean processing time of a product family on

every single machine in a production line can be calculated. The longest

mean processing time of a machine represents the bottleneck. Depending

on the product, the bottleneck in a production line can change.

At the bottleneck of a production line, the cycle time can be calculated by

the difference of the entrance time stamp of one product and the entrance

time stamp of the next product. The measurement of the process control at

the bottleneck of a production line represents the line control of the line

segment level shown in Figure 2.

With this data, the process control of a single process and of a production

line can be calculated. This system consists of three key performance

indicators: cycle time ratio, adjusted cycle time ratio, and stability of the

cycle time.

4

rd

43 CIRP Conference on Manufacturing Systems

The cycle time ratio

Figure 2 shows a distribution of cycle times at the bottleneck of a

production line. First, the Target Cycle Time has to be defined. The Target

Cycle Time is the average of the 10% shortest processing times. The

target time is realistic because it was measured, but it also contains

possible measurement errors.

The Process Control

Key Performance Indicator System

Cycle Times [s]

Adjustment

Cycle Time Target-Cycle Time

1.) Ratio

Actual Cycle Time

Actual-Cycle Time

Cycle Time

Target-Cycle Time

2.) Ratio

=

adjusted Actual-Cycle Time

adjusted

Actual Cycle Time

adjusted

Target Cycle Time

Observation Period [days]

Adjustment

Mean Absolute

3.)

Cycle Time

Derivation

=

Stability

Actual-Cycle Time

Actual Cycle Time

adjusted

adjusted

Target Cycle Time

Low Spreading

Stable Production

High Spreading

Instable Production

Figure 2: The Process Control Key Performance Indicator System.

The next step is to calculate the Actual Cycle Time. The Actual Cycle Time

is the average of all Cycle Times in the observation period. In our case,

the observation period is at least six month and is shown as monthly

performance indicators.

With these two figures, the first performance indicator of the key

performance indicator system can be assigned as the Cycle Time Ratio.

As shown in Figure 2, the Cycle Time Ratio is the ratio of the Target Cycle

Time and the Actual Cycle Time. This calculated value shows how long

the production line is used over a month.

The Adjusted Cycle Time Ratio

Within a production, there exist a lot of reasons for production distortions.

Distortions like no material available, no operator around, machine

breakdown, breaks, a non productive shift, or holidays can disturb the

production. In order to compare production lines at different locations, a

similar basis of a working production line is needed. Therefore, an

adjustment of the cycle times has to be done. The cycle times will be

defined to be at the tenth of the target time. Up to the tenth of the Target

Cycle Time, an operator can solve small machine problems by himself.

Above the tenth of the Target Cycle Time, there is a bigger distortion.

However, within this paper the competence has to be measured and thus

the working production line is of interest. The significance for the

calculation is that all cycle times, which last longer than the tenth of the

Target Cycle Time will be rejected from the amount of all cycle times. This

will result in a new and probably lower Actual Adjusted Cycle Time.

5

Reichert, Kunz, Moryson, Wegener

The second performance indicator of the key performance indicator

system is the Adjusted Cycle Time Ratio. This is the ratio of the Target

Cycle Time and the Actual Adjusted Cycle Time.

The Cycle Time Stability

The most important performance indicator represents the Cycle Time

Stability. The aim of measuring the process control is to show the

competence of production lines at different locations. The competence can

be explained by constant quality and reproducibility of production results.

Summarizing the production has to be stable. Expressed by a

mathematical equation, the production has to be stable.

The dispersion in this case does not show a normal distribution because

the lowest possible value is the Target Cycle Time. The result is an

asymmetric distribution. To calculate the derivation of asymmetric

distributions, the mean absolute derivation is a more robust method than

the usage of the standard derivation.

The third and most important indicator of the key performance indicator

system is the Cycle Time Stability. It is represented by the ratio of the

mean absolute derivation and the Actual Adjusted Cycle Time.

All three performance indicators are shown as percentage values and the

higher the value of a performance indicator is, the better the competence

of the production line is.

4

A CASE STUDY OF THE PROCESS CONTROL KEY

PERFORMANCE INDICATOR SYSTEM

A large automotive electronic supplier owns different plants at different

locations. In the following example, an electronic product is built at three

different plants in Eastern Europe, in South America, and in Asia. A further

product with the same production chain, the same components and the

same size should be manufactured in one of these three locations.

Therefore, the technical competence has to be compared.

Regarding to a system, which stores all production data of a product with

the time stamps of entering and leaving a machine in the production line,

the process control key performance indicator system is calculated. The

data are compared over an observation time of six month.

In the Cycle Time Ratio comparison, location 1 shows the best mean

Cycle Time Ratio, meaning that the machines are best used for

production. Figure 3 shows the Adjusted Cycle Time Ratio and the Cycle

Time Stability. If all production lines are productive, if no errors or

absences of material or workers disturb the production lines, then

production line 1 shows again the best results in the Adjusted Cycle Time

Ratio. Locations 2 and 3 both produce on a lower level.

The third performance indicator shows again the highest value of location

one. Here, the Cycle Time Stability is at a mean value of around 70% over

these six months of observation period. This value shows that the

achieved Adjusted Cycle Time was reached quite stable. The production

at this location has a higher reproducibility of the cycle time and produces

with a higher competence.

6

rd

43 CIRP Conference on Manufacturing Systems

Locations 2 and 3 show equal results in the Adjusted Cycle Time Ratio,

but very different results in the Cycle Time Stability. The explanation is that

the production in location 2 is quite unstable. The cycle time derivation of

every product at the bottleneck process is very high. So lots of small

distortions occur in the production line.

Zykluszeitvergleich bereinigt und Stabilitt der Zykluszeit

100

Location 1

Location 2

Location 3

90

Soll [%] [%]

Target Ist/

/ Actual

80

70

60

50

40

30

20

Apr

Mai

Jun

Jul

Aug

Sep

Apr

Mai

Jun

Jul

Aug

Sep

Apr

Mai

Jun

Jul

Aug

Sep

Apr

Mai

Jun

Jul

Aug

Sep

Apr

Mai

Jun

Jul

Aug

Sep

Apr

Mai

Jun

Jul

Aug

Sep

10

Adjusted

Cycle

Time Ratio

Cycle

Time

Stability

Adjusted

Cycle

Time Ratio

Cycle

Time

Stability

Adjusted

Cycle

Time Ratio

Cycle

Time

Stability

Figure 3: The Adjusted Cycle Time Ratio and the Cycle Time Stability of

the three compared locations.

The recommendation for the requested question where to produce a next

product volume can be derived out of a technical perspective. In this case,

location 1 will be recommended because of the better usage of their

existing production lines seen in the Cycle Time Ratio and in the Adjusted

Cycle Time Ratio, but especially because of the highest Cycle Time

Stability. This value is between 30% and 50% higher than at the other

locations and shows that the mean Adjusted Cycle Time is much more

often reached than at the other locations. A higher stability and

reproducibility can be found at this location.

5 CONCLUSION

The three performance indicators of the process control key performance

indicator system are able to compare the performance of production lines

at different locations.

Many different parameters influence the process control of a production

line, see Figure 4. The influence factors are manpower, machine, method,

material and environment. The three indicators describe the sum of all

influences on the process control of a production line. In the above

described example, a lot of the compared parameters had an equal

influence on all three locations. Since the production lines in all three

examined locations are identical, the influence of the machine can be

7

Reichert, Kunz, Moryson, Wegener

taken out of the comparison. The used materials for the product, like the

components, as well as the deployed method to run the line like the

maintenance intervals are also identical. The only factor, which differs

between the three production facilities, is the parameter manpower. As a

part of the parameter manpower the factors degree of education or

especially the factor fluctuation have a big influence.

Method

Environment

Temperature

Standardization

Automation

Humidity

Relocation

Production Line

Quality

Machine Type

Quantity

Manufacturer

Purchasing

Material

Cause

Software

Machine

Degree of

Education

Cultural

Specifics

Fluctuation

Differences in the

Process Control

Availability of

direct Employee

Availability of

indirect Employee

Language

Manpower

Effect

Figure 4: Parameters influencing the Process Control.

In the future, big companies with internal production networks can use this

system to clarify, where to produce a production volume on a technical

basis. With the key performance indicators explained in this article, the

sum of all influences in the process control is described. A future work

could be to analyze, how the influences are weighted to each other.

In addition, we will use this key performance indicator system not only to

clarify, where to produce certain production volume in a tactical horizon. In

short observation times, the process control indicator system can help. In

daily observations, the stability of the cycle time can be measured and it

can be analyzed why the stability may vary over a 24 hour base.

6 REFERENCES

[1] Kinkel, S., Zanker, C.,2007, Globale Produktionsstrategien in der

Automobilzulieferindustrie, Springer, Berlin, Heidelberg, New York.

[2] Abele, E, Kluge, J., Nher, U, 2006, Handbuch globale Produktion,

Carl Hanser Verlag, Mnchen, Wien.

[3] Reichert, F., Kunz, A., Moryson, R, 2008, MAE-P3 - A System to

Gain Transparency of Production Structure as a Basis for Production

Relocation Planning, icseng 19th International Conference on

Systems Engineering, Proceedings: 458-463.

[4] Hering, E., Triemel, J., Blank, H.-P, 1993, Qualittssicherung fr

Ingenieure, VDI, Verlag Dsseldorf.

[5] Wildemann, H., 1996, Controlling im TQM, Springer-Verlag, Berlin,

Heidelberg.

8

Das könnte Ihnen auch gefallen

- Obesity and Risk FactorDokument61 SeitenObesity and Risk FactorSaad MotawéaNoch keine Bewertungen

- Process Control ProcedureDokument12 SeitenProcess Control ProcedureGrazel MDNoch keine Bewertungen

- Behavior Based SafetyDokument51 SeitenBehavior Based SafetysixejoNoch keine Bewertungen

- Iso9001 2015 Risk Management LinkedinDokument14 SeitenIso9001 2015 Risk Management LinkedinAbd ZouhierNoch keine Bewertungen

- Loop Checking A Technicians GuideDokument24 SeitenLoop Checking A Technicians GuideJ Mohamed UvaisNoch keine Bewertungen

- Model equipment availability and reduce costsDokument10 SeitenModel equipment availability and reduce costsrlopezlealNoch keine Bewertungen

- Carl Zeiss GDxPRODokument254 SeitenCarl Zeiss GDxPROPandula MaddumageNoch keine Bewertungen

- RCM ProcedureDokument11 SeitenRCM ProcedureMuneéb IrfanNoch keine Bewertungen

- Marketing PlanDokument11 SeitenMarketing PlanMritunjay KumarNoch keine Bewertungen

- ANA Cordon and Search TTP DeliverableDokument33 SeitenANA Cordon and Search TTP DeliverablejpgvenancioNoch keine Bewertungen

- A Introduction To Advanced Process ControlDokument5 SeitenA Introduction To Advanced Process Controlsandeep lal100% (1)

- Production Planning & ControlDokument46 SeitenProduction Planning & ControlAbdullah Sabry Azzam100% (3)

- Control Loop Performance Monitoring - ABB's Experience Over Two DecadesDokument7 SeitenControl Loop Performance Monitoring - ABB's Experience Over Two DecadesAzamat TastemirovNoch keine Bewertungen

- Online Shopping RequirementsDokument19 SeitenOnline Shopping Requirementsbruh tesheme100% (1)

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingVon EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNoch keine Bewertungen

- Risk Management Basic ISO 31000Dokument17 SeitenRisk Management Basic ISO 31000Carlos Escobar100% (5)

- Developing Meaningful Key Performance Indicators V5Dokument39 SeitenDeveloping Meaningful Key Performance Indicators V5Abd ZouhierNoch keine Bewertungen

- Bip 0072-2014 PDFDokument94 SeitenBip 0072-2014 PDFgrNoch keine Bewertungen

- Aksa Lte NW AssessmentDokument43 SeitenAksa Lte NW AssessmentSenthilkumar Purushothaman100% (2)

- Quality Assurance Matrix in Automotive Industry: ArticleDokument6 SeitenQuality Assurance Matrix in Automotive Industry: Articlepavan kalyanNoch keine Bewertungen

- Android Application For Analysis of Productivity of Precision Machine ShopDokument7 SeitenAndroid Application For Analysis of Productivity of Precision Machine ShopIJRASETPublicationsNoch keine Bewertungen

- Chapter 6 ControlDokument148 SeitenChapter 6 Control.ılı.Govíиð ЯäJ.ılı.Noch keine Bewertungen

- Reliability-Centered Maintenance Planning Based On Computer-Aided FMEADokument7 SeitenReliability-Centered Maintenance Planning Based On Computer-Aided FMEAAhmed El-FayoomiNoch keine Bewertungen

- Value stream design for lean factory optimizationDokument39 SeitenValue stream design for lean factory optimizationjosephsedNoch keine Bewertungen

- NCP 27Dokument26 SeitenNCP 27Atish kumar100% (1)

- Smude Mba Sem2 All AssignmentsDokument168 SeitenSmude Mba Sem2 All AssignmentsAshok BabuNoch keine Bewertungen

- 5 LeanFinalDokument8 Seiten5 LeanFinalMd. Shad AnwarNoch keine Bewertungen

- Quality Assurance Matrix in Automotive Industry: ArticleDokument6 SeitenQuality Assurance Matrix in Automotive Industry: ArticleAbdullah BalouchNoch keine Bewertungen

- Quality Assurance Matrix in Automotive Industry: January 2012Dokument6 SeitenQuality Assurance Matrix in Automotive Industry: January 2012gcldesignNoch keine Bewertungen

- Cirp Annals - Manufacturing TechnologyDokument24 SeitenCirp Annals - Manufacturing TechnologyBosco BeloNoch keine Bewertungen

- Benefits Parallel ProcessingDokument4 SeitenBenefits Parallel ProcessingAnnaKarenina56Noch keine Bewertungen

- Performance Excellence in The Upstream IndustryDokument11 SeitenPerformance Excellence in The Upstream IndustryRachid Hassi RmelNoch keine Bewertungen

- Cópia de Monitoring and Control For Thermoplastics Injection MoldingDokument6 SeitenCópia de Monitoring and Control For Thermoplastics Injection MoldingRHOKKHANNoch keine Bewertungen

- Proceedings of Symposium in Production and Quality Engineering Kasetsart University, 4-5 June 2002, pp.104-111Dokument8 SeitenProceedings of Symposium in Production and Quality Engineering Kasetsart University, 4-5 June 2002, pp.104-111csrajmohan2924Noch keine Bewertungen

- Graficos de ControlDokument7 SeitenGraficos de ControlAli BadfaceNoch keine Bewertungen

- Design and Management of Manufacturing Systems for Production QualityDokument24 SeitenDesign and Management of Manufacturing Systems for Production Qualitymobassher01866044145Noch keine Bewertungen

- Optimum Control Limits for Software Quality ProcessesDokument9 SeitenOptimum Control Limits for Software Quality Processesharshi91Noch keine Bewertungen

- Lead Time Reduction Through Lean Technique in An Engine Assembly LineDokument7 SeitenLead Time Reduction Through Lean Technique in An Engine Assembly LineVarun KumarNoch keine Bewertungen

- METAS College PPC OverviewDokument52 SeitenMETAS College PPC OverviewColonel AlbalNoch keine Bewertungen

- Examen SEPTIEMBRE 2022Dokument2 SeitenExamen SEPTIEMBRE 2022ROMINANoch keine Bewertungen

- AI For Improving The Overall Equipment Efficiency in Manufacturing IndustryDokument22 SeitenAI For Improving The Overall Equipment Efficiency in Manufacturing IndustryBushra AzharNoch keine Bewertungen

- Design For Supply ChainDokument15 SeitenDesign For Supply ChainSuryakant GideNoch keine Bewertungen

- Puter - Integrated Production Planning and Control The Opt ApproachDokument6 SeitenPuter - Integrated Production Planning and Control The Opt ApproachDĕĕpáķ ŚĥáŕmáNoch keine Bewertungen

- Material Flow Control in Remanufacturing Systems WDokument26 SeitenMaterial Flow Control in Remanufacturing Systems Whajahora3Noch keine Bewertungen

- SPC YW 8 Aug 2019 V0.4Dokument4 SeitenSPC YW 8 Aug 2019 V0.4Sana ImranNoch keine Bewertungen

- Operations Status and Bottleneck Analysis and Improvement of A Batch Process Manufacturing Line Using Discrete Event SimulationDokument12 SeitenOperations Status and Bottleneck Analysis and Improvement of A Batch Process Manufacturing Line Using Discrete Event SimulationkinfegetaNoch keine Bewertungen

- Production System IsDokument6 SeitenProduction System IsAnjali AgrawalNoch keine Bewertungen

- Ijmet: International Journal of Mechanical Engineering and Technology (Ijmet)Dokument13 SeitenIjmet: International Journal of Mechanical Engineering and Technology (Ijmet)IAEME PublicationNoch keine Bewertungen

- All About Performance TestingDokument7 SeitenAll About Performance TestingraviskskskNoch keine Bewertungen

- WP 1080 0604 Loadrunner Best Prac Guide.Dokument19 SeitenWP 1080 0604 Loadrunner Best Prac Guide.yeossefNoch keine Bewertungen

- Maintenance Management AssignmentDokument9 SeitenMaintenance Management AssignmentRajni KumariNoch keine Bewertungen

- Article MechanismMachineTheory Budinger PDFDokument17 SeitenArticle MechanismMachineTheory Budinger PDFfei312chenNoch keine Bewertungen

- Welding SPCDokument3 SeitenWelding SPCnineapril82Noch keine Bewertungen

- An Approach For Factory-Wide Control Utilizing Virtual MetrologyDokument12 SeitenAn Approach For Factory-Wide Control Utilizing Virtual MetrologyDennis AtyugrasiwiNoch keine Bewertungen

- Assignment-6Dokument24 SeitenAssignment-6jayesh tahasildarNoch keine Bewertungen

- Report ChaptersDokument48 SeitenReport ChaptersRaghul ArulNoch keine Bewertungen

- Assignment: Name: P. VaishnaviDokument16 SeitenAssignment: Name: P. Vaishnavivaishnavi_mscmbaNoch keine Bewertungen

- Selection and Evaluation of Commercial Scada Systems For The Controls of The Cern LHC ExperimentsDokument3 SeitenSelection and Evaluation of Commercial Scada Systems For The Controls of The Cern LHC Experimentssina20795Noch keine Bewertungen

- SMU MBA Project Synopsis Discusses Manufacturing Optimization StrategyDokument6 SeitenSMU MBA Project Synopsis Discusses Manufacturing Optimization Strategyhirak_buronNoch keine Bewertungen

- Control Perspective of Manufacturing SystemsDokument13 SeitenControl Perspective of Manufacturing SystemsSandeep TamrakarNoch keine Bewertungen

- PRIMETAL - 8A-4 Through-Process Optimization (TPO) PDFDokument12 SeitenPRIMETAL - 8A-4 Through-Process Optimization (TPO) PDFKetnipha SukwannawitNoch keine Bewertungen

- How Can We Improve The Trust in Process Analzers?Dokument19 SeitenHow Can We Improve The Trust in Process Analzers?Andres FlorezNoch keine Bewertungen

- A Data Analytics Model For Improving Process Control I 2022 Decision AnalytiDokument12 SeitenA Data Analytics Model For Improving Process Control I 2022 Decision AnalytiVikash KumarNoch keine Bewertungen

- Successfully Designing Integrated Substations: NtroductionDokument12 SeitenSuccessfully Designing Integrated Substations: NtroductionHassanNoch keine Bewertungen

- Chapter Overview: 2: Modeling BasicsDokument84 SeitenChapter Overview: 2: Modeling BasicsGigiNoch keine Bewertungen

- All About Performance TestingDokument4 SeitenAll About Performance TestingraviskskskNoch keine Bewertungen

- Bioler House OptimizationDokument6 SeitenBioler House OptimizationChetan JhaNoch keine Bewertungen

- New Testing Paradigm for Product DevelopmentDokument5 SeitenNew Testing Paradigm for Product Developmentuamiranda3518Noch keine Bewertungen

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationVon EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNoch keine Bewertungen

- Ann Carruthers Event Presentation Notes RemovedDokument13 SeitenAnn Carruthers Event Presentation Notes RemovedAbd ZouhierNoch keine Bewertungen

- Ann Carruthers Event Presentation Notes RemovedDokument13 SeitenAnn Carruthers Event Presentation Notes RemovedAbd ZouhierNoch keine Bewertungen

- Role of ISO 37500 With OPBOK PDFDokument4 SeitenRole of ISO 37500 With OPBOK PDFAbd ZouhierNoch keine Bewertungen

- Ann Carruthers Event Presentation Notes RemovedDokument65 SeitenAnn Carruthers Event Presentation Notes RemovedAbd ZouhierNoch keine Bewertungen

- Get Your ISO 45001 2018 Training Materials NowDokument3 SeitenGet Your ISO 45001 2018 Training Materials NowAbd Zouhier0% (1)

- Obstructive Sleep Apnea and Analgesia - SJH PowerpointDokument29 SeitenObstructive Sleep Apnea and Analgesia - SJH PowerpointAbd ZouhierNoch keine Bewertungen

- AITC 1411 Obstructive Sleep ApneaDokument31 SeitenAITC 1411 Obstructive Sleep ApneaAbd ZouhierNoch keine Bewertungen

- Obstructive Sleep Apnea and Analgesia - SJH PowerpointDokument29 SeitenObstructive Sleep Apnea and Analgesia - SJH PowerpointAbd ZouhierNoch keine Bewertungen

- The Need For Perioperative Screening in Sleep Apnea PatientsDokument62 SeitenThe Need For Perioperative Screening in Sleep Apnea PatientsAbd ZouhierNoch keine Bewertungen

- Project Timeline Milestones VisualDokument1 SeiteProject Timeline Milestones VisualAbd ZouhierNoch keine Bewertungen

- 2193 1801 3 28Dokument13 Seiten2193 1801 3 28Abd ZouhierNoch keine Bewertungen

- Monthly Business Budget1Dokument1 SeiteMonthly Business Budget1Mohamad RofiqNoch keine Bewertungen

- Lecture Plan 05 FullDokument9 SeitenLecture Plan 05 FullAbd ZouhierNoch keine Bewertungen

- Benchmarking Manual Part 2Dokument14 SeitenBenchmarking Manual Part 2Abd ZouhierNoch keine Bewertungen

- Ratf FinalDokument194 SeitenRatf FinalAbd ZouhierNoch keine Bewertungen

- ISO 16192:2010-06 (E) : Space Systems - Experience Gained in Space Projects (Lessons Learned) - Principles and GuidelinesDokument1 SeiteISO 16192:2010-06 (E) : Space Systems - Experience Gained in Space Projects (Lessons Learned) - Principles and GuidelinesAbd ZouhierNoch keine Bewertungen

- Event Schedule Planner 2015Dokument3 SeitenEvent Schedule Planner 2015viller_lpNoch keine Bewertungen

- PE806 Hazop JUN KULDokument8 SeitenPE806 Hazop JUN KULAbd ZouhierNoch keine Bewertungen

- Daf Ipres PaperDokument7 SeitenDaf Ipres PaperAbd ZouhierNoch keine Bewertungen

- New Project Plan DefinitionDokument30 SeitenNew Project Plan DefinitionVictor AndresNoch keine Bewertungen

- Lead MeetDokument4 SeitenLead MeetilkerkozturkNoch keine Bewertungen

- Toolkit11 Data To Improve CareDokument6 SeitenToolkit11 Data To Improve CareAbd ZouhierNoch keine Bewertungen

- Hazmat EvaluationDokument28 SeitenHazmat EvaluationAbd ZouhierNoch keine Bewertungen

- One Piece Film Z 1080p Torrent PDFDokument3 SeitenOne Piece Film Z 1080p Torrent PDFLauraNoch keine Bewertungen

- Indian Institute of Management Calcutta: Master of Business Administration For ExecutivesDokument9 SeitenIndian Institute of Management Calcutta: Master of Business Administration For ExecutivesBapun Mishra100% (1)

- Conscious Competence Learning ModelDokument2 SeitenConscious Competence Learning ModelMaanveer SinghNoch keine Bewertungen

- Lesson Plan Template: The Pearl AcademiesDokument3 SeitenLesson Plan Template: The Pearl Academiesapi-300023217Noch keine Bewertungen

- Malaysia Grid CodeDokument2 SeitenMalaysia Grid Codebee398Noch keine Bewertungen

- Adjustable Accurate Reference SourceDokument2 SeitenAdjustable Accurate Reference SourceJoey TorresNoch keine Bewertungen

- HP Warranty Order Format (WOF) repair parts documentDokument1 SeiteHP Warranty Order Format (WOF) repair parts documentAnonymous BH8FLrUebNoch keine Bewertungen

- Gpover Ip FormatDokument61 SeitenGpover Ip FormatGaurav SethiNoch keine Bewertungen

- Blaze Magazine VOL 04 ISSUE 09Dokument28 SeitenBlaze Magazine VOL 04 ISSUE 09Sunway UniversityNoch keine Bewertungen

- MMP - Intro To ElectronicDokument12 SeitenMMP - Intro To ElectronicAye Chan OoNoch keine Bewertungen

- Vxlan White Paper c11 729383Dokument10 SeitenVxlan White Paper c11 729383steve stevensonNoch keine Bewertungen

- Pitch Error BacklachDokument12 SeitenPitch Error BacklachmcspvNoch keine Bewertungen

- Noise Barriers Standards FrameworkDokument50 SeitenNoise Barriers Standards FrameworkanandalaharNoch keine Bewertungen

- 1 Guntha Horizontal Green Poly House ProjectDokument1 Seite1 Guntha Horizontal Green Poly House ProjectRajneeshNoch keine Bewertungen

- Cameron LNG - 53 - CL PDFDokument8 SeitenCameron LNG - 53 - CL PDFvburrhodesNoch keine Bewertungen

- Websphere Application Server Runtime Architecture: Welcome ToDokument24 SeitenWebsphere Application Server Runtime Architecture: Welcome ToluweinetNoch keine Bewertungen

- UDI Productcatalogue 2015Dokument4 SeitenUDI Productcatalogue 2015Ryan TayNoch keine Bewertungen

- Chinese Material To AstmDokument4 SeitenChinese Material To Astmvalli rajuNoch keine Bewertungen

- MBA Final ProjectDokument108 SeitenMBA Final ProjectMindy Thomas67% (3)

- Commercial Grade Dedication GuidanceDokument64 SeitenCommercial Grade Dedication Guidancealien686Noch keine Bewertungen

- How to Write Effective Business and Technical ReportsDokument10 SeitenHow to Write Effective Business and Technical ReportsDemverNoch keine Bewertungen

- PSR 640Dokument188 SeitenPSR 640fer_12_328307Noch keine Bewertungen

- 3GenData Intellinasv9000Dokument2 Seiten3GenData Intellinasv9000FH ChowNoch keine Bewertungen

- Understanding Future Tenses with "Be Going To" and "WillDokument11 SeitenUnderstanding Future Tenses with "Be Going To" and "WillYasmín CastilloNoch keine Bewertungen