Beruflich Dokumente

Kultur Dokumente

EINRIP Dok Leleang Part-2

Hochgeladen von

Budi SantosoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EINRIP Dok Leleang Part-2

Hochgeladen von

Budi SantosoCopyright:

Verfügbare Formate

Republic of Indonesia

Ministry of Public Works

Directorate General of

Highway

THE EASTERN INDONESIA NATIONAL

ROAD IMPROVEMENT

PROJECT

(EINRIP)

AIP LOAN NO: AIPRD - L002

PACKAGE NO

: ESH 01

PACKAGE NAME : LAKUAN-BUOL

PROVINCE

: CENTRAL SULAWESI

PART 2

SECTION VI.1 SCOPE OF WORK

SECTION VI.2A SPECIAL SPECIFICATIONS

OCTOBER 2009

Document Code: EINRIP-ESH-01-Part 2-Sections VI.1 and VI.2A-Final

File name and location: K:\Rame-Rame\33 - Master Bidding Documents\Part 1, 3, 2VI.1 and VI.2A\ESH-01.doc

TABLE OF CONTENTS

LIST OF BIDDING DOCUMENTS -------------------------------------------------------1

SECTION VI-1 SCOPE OF WORKS -----------------------------------------------------1

SECTION VI.2A SPECIAL SPECIFICATIONS -------------------------------------3

DIVISION 7 STRUCTURES --------------------------------------------------------------3

SS 7.6 - PILING --------------------------------------------------------------------------------7

SS.7.6.1. GENERAL ---------------------------------------------------------------------7

SS.7.6.12. METHOD OF MEASUREMENT ------------------------------------------7

SS 7.10 - PVC COATED MESH GABION AND SOIL REINFORCEMENT

MESH --------------------------------------------------------------------------------------------8

SS 7.10.1 GENERAL ---------------------------------------------------------------------8

SS 7.10.2 MATERIALS ------------------------------------------------------------------9

SS 7.10.3 ASSEMBLY AND ERECTION FOR PVC COATED MESH

GABION AND SOIL REINFORCEMENT MESH UNITS-------------------------- 14

SS 7.10.4 MEASUREMENT AND PAYMENT ------------------------------------ 16

SS 7.23. OTHER INCIDENTAL BRIDGE FACILITIES -------------------------- 18

SS.7.23.1 DESCRIPTION -------------------------------------------------------------- 18

SS.7.23.2 MATERIALS ---------------------------------------------------------------- 18

SS.7.23.3 CONSTRUCTION ---------------------------------------------------------- 18

SS.7.23.4 METHOD OF MEASUREMENT ---------------------------------------- 19

SS.7.23.5 BASIS OF PAYMENT ----------------------------------------------------- 19

DIVISION 8 ROAD FURNITURE AND TRAFFIC CONTROL DEVICES-- 20

SS 8.4 MISCELLANEOUS---------------------------------------------------------------- 20

SS 8.4.1 GENERAL ---------------------------------------------------------------------- 20

SS 8.4.2 MATERIAL--------------------------------------------------------------------- 20

SS 8.4.3 EXECUTION ------------------------------------------------------------------- 21

SS 8.4.4. MEASUREMENT AND PAYMENT ---------------------------------------- 21

LIST of BIDDING DOCUMENTS

PART 1 - BIDDING PROCEDURES

Section I.

Instructions to Bidders

Section II.

Bid Data Sheet

Section III.

Evaluation and Qualification Criteria (Without Prequalification)

Section IV.

Bidding Forms

Section V.

Eligible Countries

PART 2 - WORKS REQUIREMENTS

Section VI.

Works Requirements

Section VI - 1 Scope of Work

Section VI - 2 Specifications

Section VI 2A Special Specifications

Section VI - 3 Drawings

PART 3 - CONDITIONS OF CONTRACT AND CONTRACT FORMS

Section VII. General Conditions

Section VIII. Particular Conditions

Section IX.

Annex to the Particular Conditions Contract Forms

Scope of Works and Special Specifications

SECTION VI-1 SCOPE OF WORKS

The project is located in the Indonesian province of Central Sulawesi on the island of

Sulawesi some 16 hours drive from Palu and 10 hours from Gorontalo. Details of the

location are shown on the Drawings.

The project consists of:

the replacement of 2 temporary single-lane bridges with new bridges having a

total length of 425 metres and approximately 1 km of approach road works.

the treatment of road is: 16.236 km

Scope of Bridge work

The bridge works will comprise the demolition and removal of existing bridge steel

superstructures (timber decks) and substructures and the construction of Class A

bridges using steel trusses all with 55m spans with reinforced concrete decks. The

bridges are on new alignments so the existing bridges will be used for traffic until the

new bridges are opened, after which the existing bridges can be removed.

The steel bridge materials for the project will be procured under a separate contract

and the Contractor will need to arrange for delivery of these materials to the

construction sites from the storage depot in Citeureup, West Java. The bridge

abutments and piers will be supported on 600 mm diameter driven spun piles which

will be driven mainly over water. The Class A bridge decks will have a two lane kerb

to kerb width of 7 m while the Class B ones will have a two lane width of 6 m.

The scour protection and river training works will be constructed of PVC Coated

gabions with stone mesh anchorages where needed to retain fill, with geo-textile

behind and underneath them. The abutment embankment slope protection works will

be of stone masonry construction. Pedestrian access stairs and inspection stairs are to

be provided on the high bridge abutment embankments.

Roads

The bridge approach roads will comprise a total of approximately 2km of road with a

width of 6 m with two 1.5 m shoulders built on embankment.

The total length of road treatment is: 16.236 km and drainage is being provided along

the entire of the road.

General

The project has been designed in detail. There is no allowance in the construction

contract for field design review with the exception of correcting errors in

measurements and any changes in physical characteristics or structures that may have

occurred since the design was carried out.

Scope of Works and Special Specifications

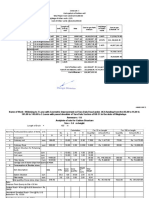

Major items of work include:

Pay Item

No.

2.3.3

Description

RCP Culvert Inside Diameter (Nominal 80 cm) 75-85 cm

Unit

Est Qty

Road

Est Qty

Bridge

Ln.M

3,079

2.3.9.2

U Ditch Type DS-2

Ln.M

11,753

SS.2.3.9.4b

U Ditch Type DS-4 + IC

Ln.M

2,675

3.1.1

Common Excavation

Cu.M

64,737

3.1.2

Rock Excavation

Cu.M

27,744

3.2.1

Common Embankment

Cu.M

17,137

14,730

4.2.1

Aggregate Base Class A

Cu.M

10,823

480

4.2.2

Aggregate Base Class B

Cu.M

18,204

448

5.1.1

Aggregate Base Class A

Cu.M

20,773

999

5.1.2

Aggregate Base Class B

Cu.M

3,135

875

6.3.5a

Asphaltic Concrete Wearing Course (AC - WC) 4 cm (fine/coarse)

Sq.M

97,375

8,265

6.3.6a

Asphaltic Concrete Binder Course (AC - BC) (fine/coarse)

Cu.M

5,979

557

7.1.3

Structural Concrete Class K350

Cu.M

1,871

1,870

7.3.4

Reinforcing Steel Deformed BJTD40

Kg

204,731

260,146

7.5.2

Transportation of Steel Bridge Structure

Cu.M

994,000

7.9

Stone Masonry

Cu.M

6,282

827

SS.7.6.10e

Precast Prestressed Concrete Pile 60 cm diameter, furnished

Ln.M

4,094

7.9

Stone Masonry

Cu.M

6,282

827

Scope of Works and Special Specifications

SECTION VI.2A SPECIAL SPECIFICATIONS

DIVISION 1 GENERAL

SECTION 1.2 PROJECT SIGN BOARD

SS 1.2.1

SS 1.2.1.1

GENERAL

Description

The work shall consist of the supply, assembly, installation,

maintaining and removing of Project Sign Board as shown in the

Standard Drawing and at both end project locations or as shown on

the Drawing or as directed by the Engineer.

The installation work for project sign board shall include all

necessary excavation, foundation, backfill, anchorages, fixtures,

fastenings and brackets.

SS 1.2.1.2

Issue of Arrangement Drawings and Construction Detail.

Arrangement drawings showing the project sign boards are

included in the Standard Drawing of Contract Documents. The

Exact location of project sign boards shall be as instructed by the

Engineer. The Contractor is required to provide two types of

project sign board as follows :

1. Project Information Sign Boards.

2. Australia Indonesia Partenrship (AIP) Sign Boards.

Each sign board shall be positioned at the beginning and at end of

project location. The Project Information Sign Board are intended

to provide brief information related to the construction

implementation. The contractor shall provide all necessary work

including painting the project information as shown in the

Drawings.

For the AIP Sign Boards, the contractor shall also provide all

necessary work except the painting of information which will be

given directly by AusAID in the form of sticker. However, the

contractor is required to provide necessary arrangement to put the

sticker on the prepared plates.

SS 1.2.1.3

(a)

Reference Standard

The configurations, dimensions, and color of project sign boards

shall confirm to Standard Drawings.

Scope of Works and Special Specifications

SS 1.2.1.4

(i)

(ii)

SS 1.2.1.5

Subminttals

Submit one galvanized steel tubular post for the road signs.

Submit one sign plate with painting already completed.

Work Scheduling

In order to provide information regarding the ongoing project

construction, the project sign boards shall be properly installed

within the first three months or as early as possible within the

Mobilization Period.

The removal of project sign boards shall be done after the Defect

Liability Period and shall be responsibility of the contractor.

SS 1.2.1.6

Maintenance of Accepted Work.

Not withstanding the Contractors obligation to carry out reflection

of unsatisfactory or failed work, in order to keep the people aware

of the ongoing project the Contractors shall also be responsible for

maintenance to prevent the project sign boards from any damages,

non-visibility and loss throughout the Confract Period, including

the Defect Liability Period.

SS 1.2.2.

MATERIALS

SS 1.2.2.1

Project Sign Board Plates

Aluminium alloy, flat sheet, hard alloy 5052-H34 complying with

ASTM B209 and having a minimum thickness of 2 mm. Such

sheets are to be degreased, etched, neutralized and processed prior

to use as project sign board plates.

SS 1.2.2.2

Project Sign Board Plate Frames and Stiffening

Aluminium alloy axtruded section of alloy 6063-T6 complying

with ASTM B221. Stiffening of traffic sign plates shall take place

when the dimensions of the sign exceed 1.0 Metre.

SS 1.2.2.3

Project Sign Board Posts

Steel H-Beam or steel pipe, hot dip galvanized, to complying with

ASTM A572 or A120 as shown in the Drawings. This includes

steel H-beam or pipe fittings and post caps. All open end shall be

capped to prevent water entry.

SS 1.2.2.4

Project Sign Board Posts

Steel H-Beam or steel pipe, hot dip galvanized, to complying with

ASTM A572 or A120 as shown in the Drawings. This includes

steel H-beam or pipe fittings and post caps. All open end shall be

capped to prevent water entry.

Scope of Works and Special Specifications

SS 1.2.2.5

Concrete and Cement Mortar

Concrete to be used for road sign foundation shall be Class K175

as specified in Section 7.1.

SS 1.2.2.6

Steel Plate and Trigonal Piling Post

Base plate and trigonal piling post shall be of steel to comply with

ASTM A572 as shown in the Drawings.

SS 1.2.2.7

Reflective Sheeting

Shall be Scotchlite Engineering grade or High Intensity Quality

grade or other approved colorfast reflective material. The face of

each signal shall be reflectorised in accordance with DLLAJR

requirements and the face of each guide post shall be reflectorised.

SS 1.2.3.

EXECUTION

SS 1.2.3.1

Placing Posts, Signs and Guard Rail

The number, type and location of each road sign, guide post and

kilometre post and section of guard rail shall be as instructed by the

Engineer.

All posts shall be set accurately at the required location and

elevation and in such a manner as to ensure it being held firmly in

place, especially during setting of any concrete.

SS 1.2.4.

MEASUREMENT AND PAYMENT

Payment for the project sign boards will be paid under the Lump

Sum payment for Mobilization and Demobilization in accordance

with Section 1.2 of these Specification, with payment shall be

considered full compensation for supply, assembly, installation,

maintaining, removing and incidentals necessary for the

satisfactory completion of the project cign boards in accordance

with this Section of the Specification.

Scope of Works and Special Specifications

SECTION 1.3 FIELD OFFICES AND FACILITIES

SS 1.3.1

General

This article shall be read in conjunction with Section 1.3 of the General

Specifications which is modified as follows:

SS 1.3.4

Facilities for the Employer

The facilities stated below shall be provided to the Employer by the

Contractor and shall remain the property of the Employer. These

facilities shall be provided within 30 days of the Commencement Date.

Approval letter of DGH to be issued before vehicle is mobilized

All motorized vehicles purchased by the Contractor and provided to

the Employer under this Contract shall bear the red plate numbers with

the location base of Jakarta (B).

1 (one) unit of 2 wheel Drive Vehicle with the following

requirements:

a.

New

b.

Sport Utility Vehicle (SUV)

c.

Gasoline Engine with capacity of not less than 2690 cc

d.

16 valve, DOHC Intercooler VN Turbo

f.

Manual transmission

h.

Three rows of seating capacity.

i.

Independent Seat Arrangement on Second Row with arm rest,

reclining, sliding, 100% folding and easily access to the Third

Row.

k.

Factory fitted Double Blower Air Conditioner.

1 (one) unit of 2 wheel Drive Vehicle with the following

requirements:

a.

New

b.

Multi Purpose Vehicle (MPV)

c.

Gasoline Engine with capacity of not less than 2690 cc

d.

16 valve, DOHC Turbo Direct Injection

f.

Manual transmission

SS 1.3.5

Measurement and Payment

Payment for the buildings and the facilities for the Employer described

in this section will be paid for under the Lump Sump payment for

Mobilization and Demobilization in accordance with section 1.2 of

these Specification, which payment shall be considered full

compensation for construsting, furnishing, servicing, maintaining,

cleaning, and removing upon completion of the Works all such

Scope of Works and Special Specifications

buildings, except the operation and maintenance cost of facilities

(specified above) provided to the Engineer.

DIVISION 7 STRUCTURES

SS 7.6 - PILING

SS.7.6.1. GENERAL

This article shall be read in conjunction with Section 7.6 of the General

Specifications which is modified as follows :

SS.7.6.12. METHOD OF MEASUREMENT

SS 7.6.12.2

Basis of Payment

The quantities determined as provided above, shall be paid for at the

Contract Price per unit of measurement, for the Pay Items listed below and

shown in the Bill of Quantities, which price and payment shall be full

compensation for furnishing, handling, driving, joining, extending, pile

head cutting, painting, curing, testing, reinforcing steel or prestressed steel

in concrete, explosion using, boring or other necessary equipment for

penetration, including loss of casing, all labors and any other necessary

equipment and all other costs to complete the works properly as described

in this Section.

Pay Item No.

Description

SS 7.6.10e

Precast Prestressed Concrete Pile, 60cm Linear Metre

diameter, furnished

Precast Concrete Pile, 60cmX60cm Linear Metre

square, or 60cm diameter, driven

SS 7.6.17a

Unit

Measurement

Scope of Works and Special Specifications

SS 7.10 - PVC COATED MESH GABION AND SOIL

REINFORCEMENT MESH

SS 7.10.1 GENERAL

SS 7.10.1.1 Introduction

The specification below applies to PVC Coated Mesh Gabion and/or Soil

Reinforcement Mesh to be used for retaining walls at bridge approach

embankments where specified on the Drawings.

PVC Coated Mesh Gabion shall be made from flexible woven wire

Heavily Galvanized and PVC Coated, (8 x 10) type mesh boxes with

integral panels of dimensions as specified in the Contract drawing or an

approval equivalent. Soil Reinforcement Mesh shall be the same material.

The front face box and the Soil Reinforcement Mesh if required, as shown

on the Drawings, shall be made from one continues mesh panel.

For Soil Reinforcement Mesh, the mesh twists shall be oriented vertically

on the gabion face and perpendicular to the front face in the reinforcement

panel.

SS 7.10.1.2 Reference Standards

Standar Nasional Indonesia (SNI) :

SNI 03-3046-1992

Kawat Bronjong Dan Bronjong Berlapis PVC (Polivinil

Chlorida)

ASTM / BBA / BS :

BBA 93/075-1998

BBA 00/R119-2000

BS 1052/1980

BS 443/1982

Standard/Certificate Agreement for Gabion in Roads and

Bridges Construction.

Standard/Certificate Agreement for Soil Reinforcement

Mesh in Roads and Bridges Construction.

Kawat baja lunak dengan kuat tarik 41-51 kg/mm2 untuk

keperluan umum

Kawat baja berlapis galvanis

Scope of Works and Special Specifications

ASTM A-975-1997

ASTM D792

ASTM D2240

ASTM D412/92

ASTM D1242/92

ASTM D1499/92a

ASTM D746

Standard Specification for Double-Twisted Hexagonal Mesh

Gabions and Revet Mattresses (Metallic-Coated Steel Wire

or Metallic-Coated Steel Wire with PVC Coating)

Specific Gravity dari selimut PVC

Hardness dari selimut PVC

Tensile Strength & Modulus Elasticity dari selimut PVC

Abrasion Resistance & Creeping Corrosion

UV Resistance

Brittleness Temperature

SS 7.10.1.3 Submittals

Sample of Wire with Manufacturers certificate that satisfy Reference

Standards in Section SS 7.10.1.3

SS 7.10.2 MATERIALS

SS 7.10.2.1 Steel Wire

All steel wire used in the fabrication of the PVC Coated Mesh Gabion and

Soil Reinforcement Mesh also in the wiring operations during

construction shall exceed BS 1052/80, having a tensile strength of not less

than 41 kg/mm2 and not exceeding 51 kg/mm2.

Wire diameters and relevant tolerances shall be in accordance with the

following table:

Wire Diameter

Mm

2.20

2.70

3.00

3.40

Tolerance

mm

0.06

0.08

0.08

0.10

All wire used in the fabrication of the gabions and in the wiring operations

during construction shall be Heavily Galvanized and PVC Coated in

accordance with BS 443/82. The minimum mass of the zinc coating shall

be as shown in the table below:

Diameter of Wire

Mm

2.20

2.70

3.00

3.40

Weight of Coating

g/sq.m

240

260

275

275

Scope of Works and Special Specifications

The adhesion of the zinc coating to the wire shall be such that when the

wire is wrapped six times around a four wire diameter size mandrel it shall

not flake or crack to such an extent that any zinc can be removed by

rubbing with bare fingers.

All wire used in the fabrication of Soil Reinforcement Mesh and also in

the wiring operations during construction shall have extruded onto it, after

coating it with zinc in accordance with the foregoing specification, a

coating of Poly Vinyl Chloride, otherwise referred to as PVC or other

plastic material having superior characteristics than PVC as otherwise

approved.

The PVC coating shall be 0.50mm average thickness with a tolerance of

0.05mm, and nowhere shall be less than 0.40mm thickness. The PVC shall

be grey in color.

The PVC shall be capable of resisting deleterious effects of natural

weather exposure, immersion in salt water and not show any material

difference in its initial characteristics which are:

a. Specific Gravity of PVC

Shall be 1.30 to 1.35 in accordance with ASTM D 792-91

b. Durometre Hardness of PVC

Shall be 50 to 60 shore D, in accordance with ASTM D 2240-91 (ISO

868-1985)

c. Volatile Loss of PVC

At 105C for 24 hours - Shall not be greater than 5%

In accordance with ASTM D 2287-92 E2.

Residual Ashes shall be less than 2% according to ASTM D2124-62T.

d. Tensile Strength of PVC

Shall not be less than 210 kg/sq.cm in accordance with ASTM D 41292.

e. Elongation of PVC

Shall not be less than 200% and not greater than 280% in accordance

with ASTM D 412-92.

f. Modulus of Elastiity at 100% of Elongation of PVC

Shall not be less than 190 kg/sq.cm in accordance with ASTM D 41287.

g. Resistance to Abrasion of PVC

The loss in volume shall be less than 0.30cm3 in accordance with

ASTM D 1242-56.

10

Part 2 Scope of Works and Special Specifications

h. Creeping Corrosion

Maximum penetration of corrosion of the wire core from a square cut end shall

not be greater than 25mm when the specimen has been immersed for 2000

hours in a 50% solution of HCL (Hydrochloric Acid 12 BE).

SS 7.10.2.2 Wire Mesh

Wire mesh shall be mechanically pre-PVC Coated Mesh to become a uniform

hexagonal woven mesh wherein the joints are formed by twisting each pair of

wires through three half-turns (commonly known as double twist), in such a

manner that unraveling is prevented. Double-twist mesh is demonstrated in the

sketch below :

The standard core wire diameters shall be as follows:

Mesh Type

Zinc Body Wire

diameters

PVC Wire

Diameter

8 x 10

2.7

3.7

8 x 10

3.0

4.0

Remarks

PVC Coated Mesh

Gabion and Soil

Reinforcement Mesh

PVC Coated Mesh

Gabion Only

11

Part 2 Scope of Works and Special Specifications

Certain other wire diameters may be utilized if the contract drawings and/or Engineer allow

alternative sizes. The wire mesh dimensional layout is as per the diagram below for the

various mesh sizes:

Mesh Type

8 x 10

X ( mm )

80

Y ( mm )

110

Tolerance %

+ 10 %

The Mesh tensile strength should exceed 42 50 kN/m or above. The wire mesh dimensions

above are subject to minor differentiation within the tolerance depending on the diameter of

the wire, and if the wire is Zinc+PVC coated.

SS 7.10.2.3 Selvedges

The cut edges of all mesh used in the construction of PVC Coated Mesh Gabion,

also the bottom edges of diaphragms and the end of the soil reinforcing tail in Soil

Reinforcement Mesh shall have a tight selvedge with a wire having a diameter of

at least 3.4mm.

The side selvedge of all and any mesh panels shall be woven integrally with the

main mesh as described in the above section 2.2 with a selvedge wire of at least

3.40 mm in diameter.

SS 7.10.2.4 Diaphragms and End Panels

The rear/side panels shall have a selvedge on the top, bottom and vertical sides as

described in section SS 7.10.2.3 The diaphragms shall be selvedge and on the top

and vertical sides.

The rear and side panels of the box gabion shall be formed by a continuous panel

connected to the main panel, along the bottom of the rear panel, either by a spiral

wire through the mesh openings or mechanically placed by four connecting rings.

12

Part 2 Scope of Works and Special Specifications

SS 7.10.2.5 Lacing and Bracing Wire

Sufficient lacing and bracing wire must be supplied with the gabion cages to

perform all the wiring operations to be carried out in the construction of the PVC

Coated Mesh Gabion and Soil Reinforcement Mesh work.

The lacing and bracing wire shall be made from Heavily Galvanized Wire with

PVC Coating and have a core diameter of 2.20 mm.

SS 7.10.2.6 Box Sizes

PVC Coated Mesh Gabion and Soil Reinforcement Mesh shall be mechanically

pre-PVC Coated Mesh in such a manner that the sides, ends and diaphragms can

be assembled at the construction site into rectangular baskets of the standard sizes

indicated below or as specified and shown in the Drawings.

Mesh type

Width (W)

Length (L1)

Length (LS)

80 x 100 mm

1m or 2m

1m

3m, 4m, 5m and 6m, or as

shown on the Drawings

0.5m or 1m

every 1m

Depth (H)

Diaphragm

Picture of the PVC Coated Mesh Gabion and Soil Reinforcement Mesh below :

W

L1

PVC Coated Mesh Gabion

L1

Soil Reinforcement Mesh

All PVC Coated Mesh Gabion and Soil Reinforcement Mesh dimensions shall be within a

tolerance limit of 5% of the required size.

13

Part 2 Scope of Works and Special Specifications

SS 7.10.2.7 Stone Fill For Facing Box

The material used for PVC Coated Mesh Gabion and Soil Reinforcement Mesh

facing box fill shall be clean, dense hard and durable stone, rounded and angular

shape.

The size of the rock that satisfies the construction of PVC Coated Mesh Gabion

and Soil Reinforcement Mesh is between 15 cm 25 cm (tolerance 5%) and at

least 85% by weight of the stone shall have a size equal to or larger than the size

above. No rock shall pass through the mesh.

SS 7.10.3 ASSEMBLY AND ERECTION FOR PVC COATED MESH GABION AND

SOIL REINFORCEMENT MESH UNITS

SS 7.10.3.1 Scope

This specification details the requirements from the assembly stage through to the

final wiring of the completed PVC Coated Mesh Gabion and Soil Reinforcement

Mesh units.

The contractor shall provide to the Engineer, for his approval, full details and

specifications of the PVC Coated Mesh Gabion and Soil Reinforcement Mesh he

proposes to use in this contract. Only those products so approved by the Engineer

shall be allowed to be incorporated in the works.

SS 7.10.3.2 Preparation

The site shall be surveyed, cleared, trimmed level and the ground compacted

accordingly.

Prior to assembly, the PVC Coated Mesh Gabion and Soil Reinforcement Mesh

units shall be opened out flat on the ground and stretched to remove all kinks and

bends.

The PVC Coated Mesh Gabion and Soil Reinforcement Mesh unit shall be

assembled individually by raising the front panel (with lid), the hinged rear panel,

and the two ends vertical ensuring that all creases are in the correct position and

that tops of all four sides are even. The diaphragm panel should be located in a

vertical plane centrally within the facing box.

The four corner edges of the facing box shall be laced first followed by the edges

of the internal diaphragm to the sides.

In all cases, lacing shall commence by twisting the end of the lacing wire tightly

around the selvedges. It shall then pass round the two edges being joined using

alternate single and double loops at 100mm intervals and be securely tied off at

the bottom. The ends of all lacing wires shall be turned to the inside of the box on

14

Part 2 Scope of Works and Special Specifications

completion of each lacing operation. Each loop shall be pulled tight to prevent the

joint opening during filling.

SS 7.10.3.3 Erection

Only assembled boxes, or groups of boxes, shall be positioned in the structure.

The side, or end, from which work is to proceed, shall be secured either to the

completed work, or by rods or stakes driven into the ground at the corner. These

stakes must be secure and reach at least to the top of the gabion box.

Further gabion boxes shall be positioned in the structure as required, each being

securely laced to the preceding one along all common corners and diaphragms.

Using the lacing technique described above.

Adjacent panels in Soil Reinforcement Mesh shall be laced longitudinally to

provide a homogeneous reinforcement layer.

All lacing wire in Soil Reinforcement Mesh shall be PVC coated.

SS 7.10.3.4 Geotextile

Non-woven geotextile as specified in S.S. 3.5 shall be placed at the back of each

gabion layer in PVC Coated Mesh Gabion, not in Soil Reinforcement Mesh work.

The non-woven geotextile shall be placed at the back of each gabion layer and

extend 0.5m above the lower panel and 0.5m below the higher panel to prevent

migration of fines.

SS 7.10.3.5 Stretching

Final stretching of the gabion boxes shall be carried out using a pull-lift of at least

one tonne capacity, firmly secured to the free end of the assembled gabion boxes.

Whilst under tension, the gabion boxes shall be securely laced along all edges

(top, bottom and sides) and at diaphragm points, to all adjacent boxes.

SS 7.10.3.6 Filling

Filling shall be carried out whilst gabion boxes are under tension.

The front face and all other faces which will be exposed in the completed

structure shall be hand packed with the stones placed so as to produce a neat

face free from excessive bulges, depressions and voids.

Internal bracing wires shall be provided on the exposed faces at the rate of 4/cu.m

at 330mm centres to prevent distortion of the gabion units during filling and in the

completed structure. These bracing wires shall be wrapped around two of the

mesh wires and extend from front to back. Additional bracing wires shall be

provided on exposed ends at a rate of 4/sq.m of face.

15

Part 2 Scope of Works and Special Specifications

Mechanical filling equipment may be used with the approval of the Engineer and

providing adequate precautions are taken to protect the PVC coating from

abrasion during filling operations.

Tension on the gabion boxes shall be released only when fully laced and

sufficiently full to prevent the mesh from slackening.

All gabions shall be overfilled by 25mm using flat stone to allow for minor

settlement and to provide a level surface for subsequent layers.

SS 7.10.3.7 Structural Embankment Material

Backfill as specified elsewhere shall be placed between each subsequent mesh

panel layer to the full extent of the mesh reinforcement at each level.

SS 7.10.3.8 Compaction

The backfill shall be compacted as specified elsewhere in these specifications for

embankment construction unless otherwise specified on the drawings.

Care shall be taken to ensure heavy compaction equipment does not come into

contact with the mesh panels or within 1.0m of the gabions.

Compaction adjacent to the gabions should be done using hand operated rollers or

plate compactors.

SS 7.10.4 MEASUREMENT AND PAYMENT

SS 7.10.4.1 Method of Measurement

The quantity to be measured for payment of PVC coated mesh gabion shall be the

number of cubic metres of the PVC Coated Mesh Gabions complete in place and

accepted. The dimensions to be used in calculating this quantity shall be the

nominal dimensions of each gabion basket as prescribed in the Drawing or as

directed by the Engineer.

The quantity to be measured for payment of Soil Reiforcement Mesh shall be the

number of square metres of the Soil Reinforcement Mesh measured outside the

perimeter of the attached PVC coated mesh gabion complete in place and

accepted. The dimensions to be used in calculating this quantity shall be the

nominal dimensions as prescribed on the Drawings or as directed by the Engineer.

Geotextile shall be measured and paid separately in accordance with Section SS

3.5.2 of these Specifications.

16

Part 2 Scope of Works and Special Specifications

SS 7.10.4.2 Basis of Payment

The quantity, determined as provided above, shall be paid for at the contract price

per unit of measurement, for the Pay Items listed below and shown in the Bill of

Quantities, which price and payment shall be full compensation for all necessary

excavation and backfill, for supplying, fabricating and placing all materials, wire,

basket, including all labor, equipment, tools, testing and other work necessary for

the satisfactory completion of the work as prescribed in the Drawing and this

Specification.

Pay Items

Description

Unit Measurement

SS 7.10.3a

PVC Coated Mesh Gabions

Cubic Metres

SS 7.10.4

Additional Price for Soil Reinforcement

Mesh to PVC Coated Mesh Gabions

Square Metres

17

Part 2 Scope of Works and Special Specifications

SS 7.23.

OTHER INCIDENTAL BRIDGE FACILITIES

SS.7.23.1 DESCRIPTION

This works shall consist of furnishing and installation of drainage and pull boxes

of electricity facilities for bridges, Reinforces Concrete frames and other incidental

bridges facilities. All works shall be performed in strict accordance with the

Drawings and these Specifications and as directed by the Engineer.

SS.7.23.2 MATERIALS

(a)

Drain pipe material shall conform to the requirements of JIS K 6741 (un

plasticized Poly Vinyl Chloride pipes). Deck drain material shall conform to

the requirements of JIS G 5101 (Carbon Steel Castings), JIS G 5501 (Grey

Iron Casting), and JIS G 3101 (Rolled Steel for General Structures: SS 400).

All metal deck drain material including support brackets shall be galvanized.

(b)

Pull box material shall conform to the requirements of JIS G 3101 (Rolled

Steel for General Structures: SS 400) and shall be galvanized.

SS.7.23.3 CONSTRUCTION

(a)

Drainage Facilities:

(i)

(ii)

(a)

Drain pipe, catch basin and deck drains those are to encased in concrete

shall be installed by the Contractor as indicated on the Drawing.

Drain pipe shall be fixed as indicated on the Drawing or as directed by

the Engineer.

Pull Box

Pull box and conduit for lighting in bridge parapets shall be installed as

indicated on the drawings, or directed by the Engineer, before the concrete is

placed. After concrete hardens it shall be checked that pull box can open

freely.

18

Part 2 Scope of Works and Special Specifications

SS.7.23.4 METHOD OF MEASUREMENT

The quantities of drain pipe to be paid for will be the number linear metres

measured along the central lines of pipe runs and no extra measurement will be

made for bends or junction pieces.

The quantities of deck drain to be paid for shall be measured by the number of

each type, completed in place and accepted.

Pull boxes and conduits for electrical work will be the number of unit as indicated

on the drawings, completed in place and accepted by the Engineer.

SS.7.23.5 BASIS OF PAYMENT

The quantities measured as specified above, will be paid for at the Contract unit

price per linear metre of drain pipe and number of unit of deck drain and pull box

facilities. Drain pipe shall be 10 cm, 15 cm and 20 cm diameter. Payments for

drain pipe, deck drain and pull box will be deemed to include for all fitting and

support necessary to install the drains in accordance with the details shown on the

Drawings.

The price and payment for the items shall be considered full compensation for

labor, tools and equipment, furnishing of materials, fabricating, transporting, and

setting of each item and all other incidental works connected therewith.

Pay Item No. Description

Unit

Measurement

SS.7.23.1

Linear metre

SS.7.23.2

SS.7.23.3

SS.7.23.4

SS.7.23.5

Drain PVC pipe, 10 cm dia. With fittings and

supports

Drain PVC pipe, 15 cm dia. With fittings and

supports

Drain PVC pipe, 20 cm dia. With fittings and

supports

Deck Drain

Pull box for electrical work

Linear metre

Linear metre

Unit

Unit

19

Part 2 Scope of Works and Special Specifications

DIVISION 8 ROAD FURNITURE AND TRAFFIC CONTROL

DEVICES

SS 8.4 MISCELLANEOUS

SS 8.4.1

GENERAL

This article shall be read in conjunction with Section 8.4 of the General

Specifications which is modified as follows :

SS 8.4.1.1

Description

The work shall consist of the supply, assembly and installation of replacement or

additional road furniture such as road signs, guide posts, kilometre posts, guard

rails, road studs, cat eyes, curbs, sidewalk, traffic light and road illumination,

coloured surfacing for road on the school safety zone (ZoSS, Zona Selamat

Sekolah) and the application of pavement markings to either new or newly overlaid

pavement surfaces, at locations shown on the Drawings or as directed by the

Engineer.

The installation work for road furniture shall include all necessary excavation,

foundation, backfill, anchorages, fixtures, fastenings and brackets.

SS 8.4.2

MATERIAL

SS 8.4.2.11. Road Paint

Material for colour surfacing marking on the safety school zone (ZoSS, Zona

Selamat Sekolah) shall consists of :

- white Portland cement,

- methyl methacrylate resin or acrylic base material or anionic elastomeric

polymer.

- pigment material

- water

The cement used shall be Portland cement conforming to SII-13-1977

(AASHTO M85).

Water used in mixing, curing, or other designated applications shall be clean and

free from harmful matter such as oil, salt, acid, alkali, sugar, or organic

materials. Water shall be tested in accordance with, and shall meet the

requirements of SNI 03-6817-2002 (AASHTO T26). Water known to be of

potable quality may be used without being tested.

Proportion and mixing instruction shall be as the manufacturers guideline. The

mixture shall provide a medium texture, non-skid surface that is well suited for

medium to high traffic areas. The diluted material shall be homogeneous.

Segregation before or during application will not be permitted. A mechanical

20

Part 2 Scope of Works and Special Specifications

drill mixer is recommended and mixture should be stirred until homogeneous.

Periodic mixing should take place as job progresses to ensure consistent

application. Over dilution will cause streaking, foaming, adhesion failure, sand

fall-out and poor overall durability of the coating.

SS 8.4.3

EXECUTION

SS 8.4.3.4.

Painting of Pavement Markings

(a)

Preparation of Road Surface

New hot-mix asphalt surfaces must be allowed 14 days minimum cure

time prior to application. For new Portland cement concrete surfaces, a

minimum of 28 days cure time is required

No part of the application of colour surfacing marking on the safety school

zone should be conducted during rainfall, or when rain is imminent.

(b)

Application of Pavement Marking Paint

(xi) Mixture for colour surfacing marking on the safety school zone shall

be applied by rubber bladed squeegee on the clean, dry surface. The

finish surface shall have a uniform appearance and be free from

ridges and tool marks

SS 8.4.4.

MEASUREMENT AND PAYMENT

SS 8.4.4.1. Method of Measurement

(d)

The quantity of paint pavement marking or thermoplastic pavement marking

or colour surfacing marking on the safety school zone to be paid for shall

be the number of square metres of road or thermoplastic or colour surfacing

marking applied to the surface in accordance with the Drawings and

accepted by the Engineer.

SS 8.4.4.2. Basis of Payment

The quantities measured as provided above shall be paid at the Contract unit

price per unit measurement for the Pay Items listed below and given in the Bill

of Quantities, which price and payment shall constitute full compensation for all

materials, labour, equipment, tools and incidentals necessary for the satisfactory

completion of the work in accordance with this Section of the Specifications.

Pay Item No.

Description

Unit Measurement

SS 8.4.3h

Additional sign with reflector of Each

engineering grade, without post

SS 8.4.13

Coloured Surfacing for Road

Square Metre

21

Part 2 Scope of Works and Special Specifications

22

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Retaining WallDokument16 SeitenRetaining WallAana SamsNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Coastal Protection StructuresDokument107 SeitenCoastal Protection StructuresKhrl K Khrl88% (8)

- Bill of Quantities Sample 01Dokument13 SeitenBill of Quantities Sample 01Javan Omiti0% (2)

- Brochure ZA ProductGuideDokument16 SeitenBrochure ZA ProductGuideAli MasyhurNoch keine Bewertungen

- Gabion Structures PresentationDokument24 SeitenGabion Structures PresentationRahul50% (4)

- Management Systems For Gabion Construction and InstallationsDokument4 SeitenManagement Systems For Gabion Construction and InstallationsSebastián LagosNoch keine Bewertungen

- Design Principle of Gabion Retaining WallDokument11 SeitenDesign Principle of Gabion Retaining WallAbhilash AbhiNoch keine Bewertungen

- Gabions & Reno Mattresses: C ASTM A975!Dokument2 SeitenGabions & Reno Mattresses: C ASTM A975!nathychidazNoch keine Bewertungen

- Can Bamboo Be A Suitable Replacement For Steel in The Use of Gabions?Dokument3 SeitenCan Bamboo Be A Suitable Replacement For Steel in The Use of Gabions?Engineers Without Borders UKNoch keine Bewertungen

- Marine Port Structure GuidanceDokument12 SeitenMarine Port Structure Guidancemulyadi100% (1)

- Standard Small Span Concrete Bridges ManualDokument59 SeitenStandard Small Span Concrete Bridges ManualJared MakoriNoch keine Bewertungen

- Peta Lokasi DISIMP2 EnglishDokument1 SeitePeta Lokasi DISIMP2 EnglishBudi SantosoNoch keine Bewertungen

- Einrip SBD Ess 02 Part 2 Div10 Eng FinalDokument14 SeitenEinrip SBD Ess 02 Part 2 Div10 Eng FinalBudi SantosoNoch keine Bewertungen

- Jbic Chapter1 enDokument53 SeitenJbic Chapter1 enBudi SantosoNoch keine Bewertungen

- User's Guide BIDDokument115 SeitenUser's Guide BIDBudi SantosoNoch keine Bewertungen

- Innovative Reinforced Soil Structures For High Walls and Slopes Combining Polymeric and Metallic ReinforcementsDokument8 SeitenInnovative Reinforced Soil Structures For High Walls and Slopes Combining Polymeric and Metallic ReinforcementsmatteoNoch keine Bewertungen

- Design of Revetment at Pathein RiverDokument23 SeitenDesign of Revetment at Pathein Riverthiri sandarNoch keine Bewertungen

- Jinbiao Full Brochure PDFDokument24 SeitenJinbiao Full Brochure PDFDarren ChungNoch keine Bewertungen

- Change of Scope For Gabion of Tura Dalu RoadDokument33 SeitenChange of Scope For Gabion of Tura Dalu RoadChandan Kumar DasNoch keine Bewertungen

- Sample Gabion Bandhara Estimate Rock Toe PDFDokument18 SeitenSample Gabion Bandhara Estimate Rock Toe PDFrushikesh rautNoch keine Bewertungen

- Gabion CageDokument2 SeitenGabion CageNusaibah YusofNoch keine Bewertungen

- ComplianceDokument3 SeitenCompliancerichrd villanuevaNoch keine Bewertungen

- Companies For Slope Protection and Ground ImprovementDokument74 SeitenCompanies For Slope Protection and Ground ImprovementNikko San QuimioNoch keine Bewertungen

- Lecture 34 PDFDokument49 SeitenLecture 34 PDFalfredomotaNoch keine Bewertungen

- Introduction to Gabion StructuresDokument81 SeitenIntroduction to Gabion StructuresPranav Mahajan50% (2)

- TOS 6 Unit 1 Retaining Walls ContinuedDokument11 SeitenTOS 6 Unit 1 Retaining Walls ContinuedDaniSh PathAnNoch keine Bewertungen

- Traning Manual NREGA June 2009Dokument230 SeitenTraning Manual NREGA June 2009Rama KrishnaNoch keine Bewertungen

- Gabion: Jump To Navigationjump To SearchDokument3 SeitenGabion: Jump To Navigationjump To Searchshafareena91Noch keine Bewertungen

- CH HW in GabionEmbankment MaharashtraDokument5 SeitenCH HW in GabionEmbankment MaharashtraIshwarya ThiagarajanNoch keine Bewertungen

- Catálogo de Gaviones Tejidos PRODAC (Inglés) PDFDokument9 SeitenCatálogo de Gaviones Tejidos PRODAC (Inglés) PDFpapolamNoch keine Bewertungen

- Retaining Wall Design and Construction ManualDokument120 SeitenRetaining Wall Design and Construction ManualShirley MunozNoch keine Bewertungen

- Product: Designated by Government To Issue European Technical ApprovalsDokument6 SeitenProduct: Designated by Government To Issue European Technical ApprovalschanakawidNoch keine Bewertungen

- Gabion Baskets For Retaining WallDokument2 SeitenGabion Baskets For Retaining WallChin Thau WuiNoch keine Bewertungen

- Gabion Walls and Their Use: January 2016Dokument4 SeitenGabion Walls and Their Use: January 2016besartNoch keine Bewertungen