Beruflich Dokumente

Kultur Dokumente

Fuvahmullah Detld Desg Rept-23-05-10 PDF

Hochgeladen von

Tariq ShahzadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fuvahmullah Detld Desg Rept-23-05-10 PDF

Hochgeladen von

Tariq ShahzadCopyright:

Verfügbare Formate

DETAILEDDESIGNREPORT OFFUV

VHAMU

ULAH

Dev

velopm

ment of Waterr Supply &

Sew

weragee Facilities

In the Ato

oll Projeects

(Fu

uvahm

mulah a

and Utheeem

mu)

Miinistryo fHousin g,Transp

port

Environm

ment

&E

Repub

blicofM aldives

`

AL- HABSHI C

CONSULTA

ANTS OFFIICE

P .O

O. Box 27154,, Safat 131322, Kuwait.

Tel: (9655) 2430103/22433131 Fax: (965) 24311336

IN

N ASSOCIATION WIITH

P

Pte.

Ltd.

3rd floor, h. Coleezium, Ame

eenee Magu, Male 20054,, Maldives,

3 5049, - 33

31 0776, info@

@riyan.com

- 331

VOLUME 1 OF 3

23.05

5.10

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

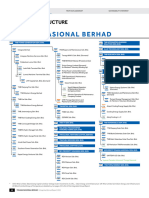

Table of Contents

1.0INTRODUCTION.............................................................................................................................4

2.0DESIGNREQUIREMENTS..............................................................................................................4

3.0OBJECTIVESOFCONSULTANCYSERVICES.................................................................................4

4.0SCOPEOFCONSULTANCYSERVICES..........................................................................................5

5.0BACKGROUNDOFENGINEERINGDESIGNREPORT.................................................................8

6.0DATACOLLECTION,SURVEYSANDINVESTIGATION...............................................................8

6.1DataCollection.............................................................................................................................8

6.2TopographySurvey......................................................................................................................9

6.3BathymetrySurvey....................................................................................................................10

6.4SocioEconomicSurvey..............................................................................................................11

6.5Soilinvestigation........................................................................................................................12

7.0PROJECTCOMPONENTS&DETAILEDDESIGNWORKS..................................................12

7.1seweragesystem.......................................................................................................................12

7.2Sewagetreatmentfacility..........................................................................................................14

7.3SewageTreatmentfacilityalternatives......................................................................................15

7.4WaterSupplySystem.................................................................................................................16

7.5ReverseOsmosisProcess...........................................................................................................17

7.5.1ProcessDescription................................................................................................................19

7.6WaterSupplyDistribution.........................................................................................................20

7.6.1.DesignConsiderations...........................................................................................................20

8.0 DESIGNSTANDARDS..........................................................................................................21

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

1 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

8.1SewerageDesignStandards......................................................................................................21

8.2WaterSupplyDesignStandards................................................................................................23

9.0 DETAILEDDESIGNOFPROJECTCOMPONENTS................................................................23

9.1SewerageNetworkVacuumsystem..........................................................................................24

9.3SewerageNetworkPumpingMains..........................................................................................29

9.4SewageTreatmentPlant...........................................................................................................29

9.5SeaOutfall.................................................................................................................................31

9.6WaterSupplynetwork...............................................................................................................33

9.7ReverseOsmosisPlant...............................................................................................................33

9.8StorageTank..............................................................................................................................34

9.9BrineWaterCollection&DisposalSystem................................................................................35

9.10FeedwaterStoragetank.........................................................................................................35

9.11TubeWell.................................................................................................................................36

9.12OceanIntakeStructure(Optional)..........................................................................................36

9.13Civil/Structural.........................................................................................................................37

9.14Electrical&Instrumentation...................................................................................................39

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

2 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

LIST OF APPENDICES -Volume 2 of 3

Bounded

Appendix -A

- Design Calculations of Vacuum Sewage Network

Appendix- B

- Design Calculations of STP

Appendix -C

- Design of Ocean Outfall

Appendix -D

- Hydraulic Calculations of Water Supply Network

Appendix -E

- Design Calculations of RO Plant, Storage Tank, Brine

Collection & Disposal

Appendix -F

- Design Calculations of Tube Well

Appendix -G - Design Calculations of Civil/Structural Works

Appendix -H

- Design Calculations of Electrical & Instrumentation

Appendix- I

- Vacuum sewer system design guideline.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

3 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

1.0

INTRODUCTION

The government of Maldives has received a loan from the Islamic Development Bank

(IDB) for the development of water supply and sewerage facilities in the islands of Gn.

Fuvahmulah and Ha. Utheeemu. Al-Habshi Consultants, Kuwait in association with

Riyan, Male was awarded the Consultancy Contract.

The consultancy service includes development of concept designs, detailed designs,

environmental impact assessments (EIAs), engineering drawings, preparation of tender

documents, assisting in tendering process and supervision of the project work in close

collaboration and under the guidance of Ministry of Housing, Transport and Environment

(MHTE) in the mentioned islands, as detailed below.

2.0

DESIGN REQUIREMENTS

The design requirement is to ensure project implementation after carrying out technical

assessments and identifying a best option for the islands considering the social norms

and community acceptance. The following principles are to be considered in designing

and constructing of the sewerage facilities.

Conventional sewerage system with minimum number of sea-outfalls.

Minimize public health and environmental impacts.

Energy efficiency.

Urban Development and Land Management Plans: and

Low-cost treatment options and technologies.

The water supply and sewerage facilities will be designed and constructed in meeting the

long-term needs and objectives of the National Development Agenda giving a design

horizon of 15-30 years.

3.0

OBJECTIVES OF CONSULTANCY SERVICES

(a) Necessary engineering services for the implementation of the project including

preparation and execution of surveys and investigation.

(b) Conceptual and Detailed Design

(c) Tender Documents

(d) Construction planning

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

4 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

(e)

(f)

(g)

(h)

(i)

(j)

(k)

(l)

4.0

Construction supervision

Environmental monitoring and management planning

Cost estimates

Tendering assistance for selection of contractors

Social considerations

Financial management

Capacity building of government agencies and island communities

Preparation of operation and maintenance manuals and

SCOPE OF CONSULTANCY SERVICES

a) Phase 1- Designing

The phase-1 of the project includes preparation of concept designs, field

investigations and survey's. Environmental Impact Assessments (EIA). Detailed

engineering designs and bidding documents.

The consultant shall execute detailed design including the following works:

Review and analyze existing data, studies, designs, reports and other available

materials pertinent to the sub projects and natural conditions around the project

area

Undertake detailed Field surveys where necessary including updated

topographic. Bathymetric current, reef and socio-economic surveys and

establish benchmarks on the islands.

Determine dry and wet weather flows for each island including water

consumption, compute flow and velocity and prepare system and drawings based

on the conditions and criteria to be approved by MWSA.

Prepare at least two appropriate sewage collection, treatment and disposal options

and develop cost estimates, economic and financial analysis for each option

proposed.

Prepare preliminary design

Design Reverse Osmosis (RO) desalinated water-supply system for the

islands including intake and reject water systems, piped network, water

storage facilities, disinfection and water treatment facilities, and plant houses.

Execute detailed investigations at the sites of boreholes or intake wells for RO

water, sea- outfall; brine discharge locations for geo-physical soil, current,

reef and water quality investigations.

After approval of preliminary design prepare detailed design including site

plans, profiles long sections and drawings

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

5 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

b)

Determination of mitigation measures for negative environmental impacts

Develop separate bidding documents, working drawings, b i l l of quantities and

specifications for water supply and sewerage systems for both Utheemu and

Fuvahmulah, under the guidance of Ministry of Housing, Transport and

Environment (MHTE) and Tender Evaluation Board of Ministry of Finance and

Treasury (MoFT).

Ensure that final tender documents are technically sound and feasible and is

developed in a harmonized manner to meet the requirements of Ministry of

Housing, Transport and Environment (MHTE). Tender Evaluation Board and

Islamic Development Bank (IDB).

Phase 2- Tendering and Contract award

The Phase 2 of the project includes tendering and contract award works. The

proposed work will be carried out under the guidance of Ministry of Housing,

Transport and Environment (MHTE) and Tender Evaluation Board of Ministry of

Finance and Treasury (MoFT). This phase is expected to be completed within 3

months. The Consultants shall carry out the following works to assist the

Implementing Agencies in Tendering.

a)

b)

c)

d)

e)

Assist in the preparation of the advertisements for inviting prequalification

application and executing of prequalification evaluation (if required)

Assist in the preparation of the advertisements for inviting bids and

sending of tender documents to interested companies.

Assist in preparation of pre-bid meeting, preparation of addenda as

required and preparation of replies to questions from bidders to be carried

out in consultation with Ministry of Housing, Transport and Environment

(MHTE) and under the guidance of Tender Board of Ministry of Finance

and Treasury (MoFT).

Assist in management of any disputes, clarification and opening of relevant

tenders

Assist in evaluation of bids and preparation and presentation of evaluation

reports, recommending contract award for approval by the Government of

Maldives. During evaluation the followings points must be considered

carefully.

- Ensure that the bids are technically sound and feasible and that the

proposals are technically capable of fulfilling their responsibilities.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

6 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

f)

g)

- Ensure the tenders are financially sound and feasible including the cost

are equivalent to local market prices.

- Ensure the tender schedules are sound and feasible including the

Consideration that the contractor is capable of fulfilling the responsibilities

outlined in the contract in the allocated time.

Assist implementing agency in contract negotiations with successful

bidders.

Assist in preparation of contract documents, contract development, signing

and awarding.

c) Phase 3-Construction supervision and monitoring

The phase 3 of the project includes monitoring and supervision of construction work

to be earned out during project implementation. Expected duration of this phase is 18

months for Fuvahmulah

a)

b)

c)

d)

e)

f)

g)

Setting-out of the work

Preparation of construction drawings and documents

Review and approval of Contractor's drawings and documents

Quantity and quality control

Monitoring and control of the Work schedule

Settling of disputes or differences

Monitoring defects liability period

d) Environmental Study and Monitoring

The Consultants shall carry out environmental study and monitoring including the

following to mitigate the negative environment impacts.

a)

b)

c)

d)

e)

Preparation of environmental screening form for each sub-project to be

submitted to Environmental Protection Agency

Scoping of Environmental Impact Assessment (EIA) study if required

Execution of Environmental Impact Assessment (EIA) and preparation of the

reports according to the requirements.

Facilitation of timely response and approval from Environmental Protection

Agency

Environmental monitoring during construction works.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

7 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

5.0

BACKGROUND OF ENGINEERING DESIGN REPORT

The revised concept design after incorporation of all Comments of the Client

(MHTE) were submitted on 16/8/09 subsequent to the submission made on 16/12/08

and the various discussions and further meeting held on 8/7/09 in MHTE. MHTE

approvals to the concept design and instruction to proceed with detailed design

considering Vacuum system sewerage network (in place of conventional system)

was issued to Consultant on 15/12/09 based on which this submittal is being made

now. This Final Detailed Design Report submission is in compliance with those

MHTE comments, the Detailed Design Report is submitted in three volumes, details

as below.

1.

2.

3.

Volume 1 of 3 Detailed Design Report

Volume 2 of 3 Appendices (Detailed Design Calculations)

Volume 3 of 3 Appendices (Detailed Design Drawings)

The Detailed Design Report contains the design calculations of all project

components which are demonstrated in the following chapters of this report. The

Appendices cover the design details in depth. The Detailed Design Drawings are

prepared on the basis of detailed design and supporting calculations on standard

and international scale and in line with the MHTE design criteria document for

sewerage and water supply system.

Due to urgency and pressing demand of MHTE and the tender documents of Water

Supply and Sewerage System Fuvahmulah Island are also being prepared and shall

be submitted with the detailed design documents. The Tender Documents include for

the Bills of Quantities in Re-measured Contract format, Technical specification of all

project components, contract conditions and bidding procedures.

6.0

DATA COLLECTION, SURVEYS AND INVESTIGATION

6.1 DATA COLLECTION

The preliminary task was to complete the data collection which comprised of

identification of all pertinent informations which may be necessary for the execution

of our performance. Since we were involved in the Bankable Document Preparation

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

8 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

for the same project, Al-Habshi Consultants were in possession of the particular

datas and the various codes/standards based on which our activities were

performed, the actual reference to the particular datas collected are referred below

in the forthcoming chapters.

6.2 TOPOGRAPHY SURVEY

The Topographic Survey covered the topographical conditions of the whole land area

of the project islands above shoreline to give the basic understanding on the

topographical considerations for the preliminary design and detailed design for sewer

networks. Position, distance, dimension, ground floor level of all the existing

facilities, septic tanks and boundary walls was clearly marked in the survey drawing.

Scale of these surveys was 1:500

The objective of Topographic survey was to establish Horizontal and Vertical control

network and do a asbuilt survey of the area including existing Plot Corners and

Block Corners of land parcels, Infrastructure facility features such as electricity posts,

cable TV distribution boxes and Spot Heights of the ground specially along the

roads. Then to prepare a Topographical plan of the whole land area of the island

depicting all existing details of the area. First Horizontal and vertical control network

(3D control network) was established. The detail survey was completed using this 3D

control network and the topographical maps were prepared. The 3D control network

was established using GPS, Total Station and a digital level. The markers used for

this were made as the semipermanent markers. The markers established at

Fuvahmulah were referred as the control points. First considering the whole island,

the control points were established. For the control points, 12inch iron rods were

inserted to the ground and 4inch concrete layer was laid for the protection of the iron

rod. Two main control points (Base 1 and Base 2) were established closer to the

island office. These two main points were observed using TRIMBLE GeoXH GPS

receivers. Static observation method was used and the duration of the GPS

observation was 2hours. These observed data were processed to obtain the bearing

of the points in relation to each other. The distance between the two points was also

measured using a Total Station and while maintaining the GPS coordinates for the

main control point 1 (Base 1), the distance from main point 1 (Base 1) to main point 2

(Base 2) was plotted along the bearing of Base 2 from Base 1. The adjusted

coordinate of Main point 2 (Base 2) obtained by plotting the distance measured using

the Total Station was used as the plot coordinates of Main point 2 (Base 2). Finally

the coordinates of the Main control points were converted to UTM coordinate system.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

9 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

The vertical datum used in these surveys was the Mean Sea Level (MSL) derived

from tide readings of HDh Hanimaadhoo tide data. A digital Level was used to

carryout the level traverse along the traverse points. The level transect of the control

points were started by reading a back sight reading to the Main control point 1(Base

1) and using back sight fore sight method was used to complete the traverse back to

the first back sight point

Detail Survey was started using the established 3D Control points. Same Total

Station instrument was used for the detail surveys. First instrument was set up at a

control point (at first main control point as it is mid point of the island). Then

coordinates Main control point 1 (Base 1) were input to the instrument. Next to orient

the instrument the instruments telescope was pointed towards the Main control point

2 (Base 2) where the target was set up and the target point coordinates were

entered. Again target was established at back sight point (here at last traverse point)

and observed that for checking the orientation. Here vertical height difference

method was used to check the vertical accuracy of the observation.

All the observations were stored in the internal memory of the Total Station as well

as they were entered in the field book manually. All the stored data were downloaded

using the Tcom software. First using the row data file a Microsoft Excel file was

created. After creating the corrected coordinate file of detail survey, through the

Tcom software . Dxf" files were developed to use to plot the digital CAD plan.

Four permanent benchmarks were established on the islands. Bench mark at

Fuvahmulah is located near harbor and near either side of Rasgfannu and Maaneru

road (main road across the island). The Northing and Easting for these benchmarks

were given in UTM and their vertical heights are referred to MSL. The horizontal

coordinate system used for the topographic surveys was UTM for the horizontal

coordinates. The spheroid for this projection is WGS 84. The vertical datum used for

these surveys was Mean Sea Level (MSL). The mapping scale for these surveys

was 1:500. The heights of the features measured in these surveys were plotted as

spot heights on the map

6.3 BATHYMETRY SURVEY

A large part of the bathymetric survey was carried out as acoustic depth (z)

measurements together with GPS position (x, y) fixings. Acoustic depth

measurement systems measure the elapsed time that an acoustic pulse takes to

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

10 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

travel from a generating transducer to the waterway bottom and back. In areas

where the water depths were too shallow (over the reef flat) for the survey boat to

safe navigation, the Total Station together with a fixed height prism pole was used to

measure the sea bottom levels. At Fuvahmulah due to the swell condition lagoon

depth and near reef crust depths were not taken. The lagoon depths at the proposed

STP outfall area is shallow, just below MSL, while the reef crust area is almost at

MSL. The reef area is observed to be of spur and groove formation with sharp drop

off from the crust area to depths of 3m, and from this point onwards a shallow flat is

observed to depths up to -10m, from this point onwards the reef slope is observed to

have a gradual slope down to depths exceeding -100m. Due to the high energy

nature of the area it may be required to have armored sheathing for the out fall pipe

at reef crust and the flat area, since rocks may move at the spur and groove area

and cause damage. It has to be noted that moving north of the proposed location,

reef slope is gradual, possibly making it slightly easy for laying the pipe.

6.4 SOCIO-ECONOMIC SURVEY

A detailed Socio-economic Survey was conducted with an aim to (a) develop a

socio-economic profile of the island based on survey data, census data, and existing

information, (b) undertake community consultations with different community groups

including youth, women, fishermen, traders, NGO's development committees ,

Island Council and others and gather their views and incorporate them in project

development, (c) ensure community involvement and community participation in the

project design, construction and operation and maintenance, (d) provide necessary

information that will help to formulate a proper operation and maintenance

mechanism and finance the overall project O & M in the long run, (e) identify the

willingness to pay and other economic concerns and help to address them in the

design and implementation of the project, (f) assist in the evaluation of the costs and

benefits of the different options feasible to the project site conditions.

It was observed that the issue of the household connections for both the water and

sewerage raised by the people of Fuvahmulah needs to be addressed through

community dialogue before implementation of the project. Community sensitization

activities are to be undertaken prior to the commencement of work, if the

Government sticks on to community taps. The water and sewerage projects

proposed to be implemented will strengthen the overall socio- economic status of the

islanders. Universally, appropriate and standardized systems of water and sewerage

will enhance the social status of the people, particularly that of women. Tourism

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

11 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

prospects will be an added economic component for the future development in the

island. Socio-politically, the implementation of the water and sewerage projects will

diffuse the pent up emotions of the community.

6.5 SOIL INVESTIGATION

We analyzed a formally drilled borehole data carried out by Geo Engineering Pvt Ltd,

Maldives for MWSC in 2006. According to the data given for well BH-7, the

transmisivity co-efficient by using software developed by Prof. Gerrit Van Tonder of

the Institute for Groundwater Studies, University of the Free State is shown in given

format and the data extracted from DEVELOPMENT BY PUMP RECORD SHEET 12 conducted for BH 07 on 03.08.2006 has taken for analyzed. In the Gerrit Van

Tonder format software average Q sustain (sustainable yield) is shown as 1.39 l/S

with standard deviation 1.22. Transmissivity estimates from derivatives 99.33 m3

/day. This Transmissivity value is rather high value but can accept due to high

porous calcareous sand. According to the Gerrit Van Tonder format software there

is no value given in the format. The reason to be the data entered it from the informal

pumping test. Simple laboratory test done for deeply excavated samples gives the

storativity as 0.410 m3.

7.0

PROJECT COMPONENTS & DETAILED DESIGN WORKS

7.1 SEWERAGE SYSTEM

Various different sewerage system were analyzed during the concept stage of the

project and a techno-financial analysis was carried out to actually establish the

technically most feasible and financially viable sewerage system i.e. Vacuum

Sewerage System for Fuvahmullah Island considering long term efficiency of this

system which comprises of sewers network, Two Vacuum Station and a sewage

treatment plant.

The Vacuum sewer system design is mainly based on (1) EPA Alternative

Wastewater Collection Systems Chapter 3 and (2) Guideline of Developer volume ii

(from Malaysia Water Association) design criteria. A copy of both guidelines is

attached in this report Appendix- I

The sewage is collected from each household by means of an inspection chamber

and Vacuum chamber at suitable intervals, and allowed to flow to vacuum stations for

onward pumping to the treatment plant. The sewage from 6 to 10 houses is

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

12 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

connected to a vacuum chamber by a gravity network. The Vacuum chambers are

connected to main Sewer lines with vacuum pressure. These main sewer lines are

further connected to two zonal Vacuum stations, which should be capable to create

sufficient vacuum pressure in all main sewers laid all over the Island. The vacuum

station is designed for each Island sewer zone to receive the flow of the sewage from

each House connections, for further pumping to the sewage treatment plant, which

will reduce the BOD and SS levels substantially in line with the EPA regulations and

standards for domestic wastewater disposal. The resultant effluent will be pumped

back to deep sea through sea outfall. The sludge which is resulted from the sewage

treatment also will be pumped back to sea on a monthly basis which is no more

septic.

UPVC PN-06 pipes of minimum 110, and 160 mm outer diameter are used for the

household connection to vacuum chambers with a slope of 1:100, whereas the main

sewer which is interconnecting vacuum valve chambers and vacuum stations, is 110,

125, 160, 200, and 250 mm diameter PVC Schedule 40, SDR 21 solvent welded pipe,

to meet the future population and laid in a saw tooth profile with a slope ranges from

0.2 % to 2%. (1) For 100-125 mm diameter pipe: 80 % pipe diameter or 0.2 %

gradient. (2) For 150-250 mm diameter pipe: 40 % pipe diameter or 0.2 % gradient.

The design of vacuum sewage profile is based on attached EPA alternative sewage

design criteria (Appendix-I) table 3-2, 3-3, 3-4, and lift height is based on table 3.1.

The minimum suction pressure at each vacuum interface unit will be 5 ft and the

frictional losses in the vacuum pipe will not go beyond 2 feet. The losses on account

of static lift will not go beyond 11 feet. The upper velocity limits are even more in the

vacuum sewers which exclusively depend upon the value of vacuum in the vacuum

sewage network. The velocity may up to range 4.6 5.5 m/sec depends on value of

volume in line and vacuum pipe diameter, thereby providing a non-clogging and

trouble free drainage system. The piping is properly sized to handle the

recommended maximum permissible flow from all house drains and vacuum

chambers connections. Minimum cover over sewer are regulated to 900mm as

instructed by MHTE through their comments on Concept Design and all gravity and

vacuum sewer pipes are bedded with sand. Each household is provided with an

Inspection Chambers, 600mm diameter HDPE chambers installed in individual

households for the tenant to carry out house connections. For every 6 to 10 number

of houses one vacuum valve pit is provided.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

13 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Two Vacuum Stations are provided in Fuvahmullah at convenient and suitable

locations to develop sufficient vacuum pressure in each sewer zone. The total

available head loss for vacuum station should be between 18 to 23 feet.

The Outfall discharge pipe should be made of 250 mm HDPE pipe, which is laid on a

trench over the reef and ocean by using concrete ballast blocks located at an

appropriate distance. The Ocean Outfall effluent mixing Design Criteria is taken as a

minimum port exit velocity of 4m/sec, initial dilution as 1:100 and Bacterial reduction

to be 1000 MPN/100 ml.

7.2 SEWAGE TREATMENT FACILITY

Considering the low ground water table profiles of the Maldivian islands and other

environment constraints, we considered the following 4 type of sewage treatment

technologies.

A.

B.

C.

D.

Oxidation Process based on Activated Sludge with Extended Aeration

Rotating Biological Reactor (RBC):

Submerged Aerobic Filter (SAF)

Sequencing Batch Reactor (SBR)

Technical comparison, advantages and disadvantages of sewage treatment process

were detailed out in the conceptual design, resulting in finally recommending the

Oxidation Ditch Process based on Activated Sludge with Extended Aeration System

for Fuvahmulah Island. The selection of a particular process for sewage treatment is

affected by diurnal and seasonal flow variations, sewerage strength (variability of

wastewater constituents) infiltration / inflow, ambient temperature and its induced

septicity, degree of treatment required, magnitude and direction of wind etc.

The extended aeration process holds wastewater in closed endless loop channel to

aerate for 18 hours or more and the organic wastes are removed under aerobic

conditions. Air is supplied by mechanical rotor through rotating action. The

wastewater is screened to remove large suspended or floating solids before entering

the aeration chamber, where it is mixed, and oxygen is added. The solids settle out

and are returned to the aeration channel to mix with incoming wastewater. The

clarified wastewater flows to a collection channel before being diverted to the

disinfection system. The sludge is periodically removed from the units. In Aeration

tank (extended aeration), suspended microbial growth is maintained for the biological

oxidation of organics. Surface or Diffused aeration system is provided to meet the

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

14 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

oxygen requirement of micro organisms and to keep the liquor in completely mixed

regime.

7.3

SEWAGE TREATMENT FACILITY ALTERNATIVES

The following types of sewage treatment facilities were analyzed and studied.

A. Sewage treatment facility with secondary treatment and effluent disposed to sea.

Customarily, the sewage of household used to be disposed direct to the sea

which has made alarm on the environmental conditions around the shore. The

authorities have prohibited such disposal and the consultant proposes to have

secondary treatment before disposing the effluent to deep sea, the process steps

are tabulated below.

Process stage

Purpose

Preliminary Treatment

Screening and grit removal flow measurement

Secondary Treatment by

Oxygenations by means of Aerations followed by

Bio-Remediation

clarification-separations of effluent and sludge.

Sludge Treatment/Removal

Sludge dewatering /digestions/ disposal

Standards for effluent are as shown below.

EFFLUENT STANDARD

Parameter

Value

Total Suspended Solids (TSS)

150 mg/l

Bio-chemical oxygen demand (BOD)

40 mg/l

Fecal Chloroforms

100 org/ 100 ml

Oil & Grease

5 mg/l

Residual chlorine

0.1 mg/l

Nitrates as N

15 mg/l

Free and saline Ammonia as N

10 mg/l

Phosphate as P

10 mg/l

Chemical Oxygen Demand

40 mg/l

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

15 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

B. Sewage treatment facility with tertiary treatment and effluent used for irrigation

purpose. Level of Treatment: Tertiary treatment is provided to secondary treated

sewage for re-use applications. Dualmedia granular filtration and subsequent

disinfection is used as the tertiary level of treatment when TSE is intended to be

used for irrigation of landscaping/agriculture where vegetables/crops not eaten

raw are cultivated. Highly Advanced level of Treatment using Reverse Osmosis

(R.O) is considered when TSE can be used for agriculture of vegetables/fruits

eaten raw. The required Effluent standards would be as follows.

Sl No.

Parameter

Symbol

Standard

Biochemical Oxygen Demand

BOD5

10mg/l

Total Suspended Solids

TSS

10mg/l

Ammonia cal Nitrogen

NH3

1mg/l

C. Sewage treatment facility with tertiary treatment and effluent used for fresh

groundwater lens recharge. Long-term, large-scale pumping without subsequent

replacement of groundwater can result in fissures and land subsidence. The

most serious problem is the permanent loss of an aquifers storage capacity.

When considering Fuvahmulah Island in the drought especially in the month of

March extraction of water from pure water lens is serially damage to the pure

water lens. Artificial recharging can be applied in rainy season as well a in the

drought. In rainy season rain water can be injected to the ground by construction

of injection well at nearby areas of Sault water extraction wells. In the drought

treated waste water can inject to the ground through injecting wells. Tertiary

treated waste water can be recharged to the ground subject to strict quality

control of the same, should there be any compromise on the quality, and the

recharged water may result in adverse effect on the overall ground water. A

provision of the tertiary treatment and necessary ground water recharge will be

allocated in the Bills of Quantities as provisional items.

7.4 WATER SUPPLY SYSTEM

Various water supply alternatives were studied thoroughly during the concept design

stage which included the surface source, Exploring ground water potentials, Rain

Water Harvesting and Desalination. The process of RO system has many merits like

less energy dependence, less maintenance, easy operation, few personnel, lower

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

16 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

thermal brine impact, advanced membrane technology, etc. Moreover, RO plants

are widely and effectively used in many countries in such situations. Besides, RO

plant is available locally in different capacities. And hence, could be adopted

conveniently for the present and further expansion as per the growing requirements.

Considering all these factors, especially on the social acceptability, RO plants for the

design capacities are recommended for the islands of Fuvahmulah. As a standby it is

suggested to maintain the RSW and wells catering for the washing and other

purposes.

Extraction of Sea water could be either by drilling a bore hole of 40-50m in the

ground or direct extraction from the ocean. Groundwater extraction is through drilling

a tubewell into the rock strata. The temperature of water extracted by this method is

lower than that of water extracted from sea; this will affect the quality of treatment.

Because of this low temperature a better quality drinking water could be produced

compared to direct extraction from ocean. Other advantages include free from fecal

contamination, better maintainability of the water extraction system and less likely to

be damaged due to storms.

In the direct extraction system, a 200 mm pipe is laid though reef up to Deep Ocean

and sea water is sucked by a pump through a strainer attached at the end of the pipe

line, and pumped towards the RO plant. Further to a detailed techno - economic

analysis, the bore hole sea water extraction is preferred in Fuvahmulah Island. Four

number test bore wells are to be drilled and converted to two tube wells are

proposed to extract deep groundwater which will feed water to 2 Nos R.O. Plants. If

this option is not workable, the sea water pumping option is designed as optional

item.

The water supply pipeline network is designed to cover the whole of the islands

including houses and institutional building according to land use plan. However, the

current execution works will be limited to community taps without household

connections. At present, adequate provision is made to install stand posts fitted with

taps depending on the number of houses within each block to facilitate convenient

collection of safe drinking water.

7.5 REVERSE OSMOSIS PROCESS

The feed water for the operation of RO is from the tube well. After the primary

treatment, water is subjected to RO treatment. Once, fresh water is separated, the

water left behind called Brine needs to be disposed. Brine is highly dense and also

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

17 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

polluted. In RO, feed water is pumped at high pressure through permeable

membranes, separating salts from the water. The feed water is pretreated to remove

particles that would clog the membranes. The quality of the water produced depends

on the pressure, the concentration of salts in the feed water, and the salt permeation

constant of the membranes. Product water quality can be improved by adding a

second pass of membranes, whereby product water from the first pass is fed to the

second pass.

Quality of desalinated water from RO will be as follows.

Feed Water to RO Plant

Product from RO Plant

Ca

448.00

0.60

Mg

1330.00

1.78

Na

11400.00

89.15

383.00

3.88

NH4

0.00

0.00

Sr

0.10

0.00

Ba

5.80

0.01

Fe

0.00

0.00

Mn

0.00

0.00

CO3

0.50

0.00

HCO3

132.00

1.88

SO4

2940.00

3.50

CI

20600.00

143.60

NO3

0.00

0.00

Fe

0.00

0.00

SiO2

1.00

1.01

CO2

2.66

2.63

Sum of lons

37240.40

244.41

TDS

37173.23

243.45

Ph

7.50

6.50

(asCaCO3)

6595.82

8.83

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

18 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Feed Water to RO Plant

Product from RO Plant

Hardness

7.5.1

PROCESS DESCRIPTION

1.

Ultra-Filtration as Reverse Osmosis Pre-filter System.

The UF Feed Pump will draw the sea water from a Sea water Storage Tank

which sea water of Total Dissolve Solid < 38,000ppm is passed through the bag

filter (100 micron) as the first line of protection to remove all large and abrasive

debris prior to channeled to the UF system.

The UF system with the filtration pore size of 0.1 micron, which is very effectively

removing the microorganisms and suspended from the sea water.

The permeate is then passed through the Ultra-Filtration (UF) unit operating in a

dead-end mode and stored in the UF Back Flush Tank and UF Permeate Tank

(supply by others). The unit comprises of a number of UF S860 Ultra-Filtration

membrane with preset timer for automatic back flushing. The water for the back

flushing is drawn from the UF Back Flush Tank. The UF S860 membrane has

pore size of less then 0.1 micron and is capable of producing permeate with

high degree of cleanliness suitable as Reverse Osmosis (RO) feed water.

Thus, the RO unit will be able to maintain high flux and quality of permeate

water with minimum maintenance and worries on the clogging or fouling.

The UF Back Flushing water is discharge back to the sea.

2.

Reverse Osmosis (RO) System for Sea Water Desalination Process.

The RO process operates in a cross flow mode with 40% recovery where high

pressure pump drawn the water from UF Permeate Tank and feeding toward

RO unit. The UF permeate is first passed through a guard filter follow by treating

with anti-scalant and neutralization with Sodium Meta-Bisulphate. The guard

filter is just another precaution to protect the RO unit in the event of any

contamination from the UF Permeate Tank.The dosing of sodium Meta

bisulphate is also able to serve as disinfection.

The RO Permeate with Total Dissolve Solid < 500ppm is then channeled to the

RO Permeate Tank. The Reject water with Total Dissolve Solid > 60,000ppm is

diverted to the Energy Recovery / Pressure Exchange Unit to recover most of

the waste energy prior to discharge back to sea.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

19 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Chlorine could be added at the RO Permeate for further disinfection prior to

supply to the consumer.

Cleaning-in-place (CIP) for RO is used to provide chemical cleaning periodically

to eliminate the clogging issue.

Detailed RO process flow diagram is attached in Appendix- E

7.6 WATER SUPPLY DISTRIBUTION

The two options considered were Water supply network with above ground storage

tank with a 15 -20 m height water tower and Water supply system with pressurized

pumped loop system. On the storage tank option, treated water from RO plant will be

stored in an above ground tank designed for 6 hours of average day demand and

further it is pumped to a 10-15 m height water tank tower which is designed for 4

hours storage of average day demand. The ground tank will be GRP and the tower

tank shall be constructed by Reinforced Concrete. On the pumped loop system,

Triplex or Duplex pumps with pressure regulator are used to maintain the head

throughout the piping network. The pump will start and stop according to the pressure

reduction in the water supply piping network caused by water usage. The storage

tank option was selected for further detailed design works.

7.6.1. DESIGN CONSIDERATIONS

Water demand estimates

Per capita water consumption for drinking and culinary application has been

estimated at 30 litres/ person/ day, considering a population of 16206 people. Peak

daily demand is taken as 2.5 times of average daily water demand.

Network sizing

The pipe sizing is done considering the peak flow rate expected in the network. It has

also considered the future requirement to provide house connection to the residents.

The maximum velocity in the pipe network is set to below 1.5 meters/ second. The

maximum flow is expected only on the feeding line from the elevated tank to the pipe

network. The network analysis is done with EPANET software is attached in

Appendix- D Water supply hydraulic calculation. For the purpose of the calculation,

the total flow of 29.3 L/s is assumed to deliver through 30 outlets, each with a

discharge flow of 0.975 L/s. The outlets are strategically located considering the

density of population. The density of outlets in the water network will be high where

the population density is high and vice versa. The distribution of the valve outlet and

the flow parameters derived from the calculation thus provides a realistic water flow

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

20 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

distribution through the network. The maximum velocity on the feeding line is 1.66

meters/ second.

Inference

A minimum pressure of 9.69 meter pressure is available at the hydraulically most

remote flowing node (node 92). Maximum flow velocity of 1.66 meters/ second is

developed on LINK 1, which is the main supply header from the overhead tank at the

calculated peak flow of 29.25 L/s.

8.0

DESIGN STANDARDS

8.1 SEWERAGE DESIGN STANDARDS

The plots within the Fuvahmulah Island shall be provided with a comprehensive

Vacuum based system for sanitary pipe work. All plots have individual inspection

chamber and is connected to the foul water system network. The whole island is

divided as 2 zones; each zone has its own vacuum station. Pressure lines from each

vacuum zone are connected to the sewage treatment plant.

Sanitary Water Drainage Design Data.

GEOGRAPHICAL INFORMATION

Area

420.00 Hec

MOAD

Length

4500m

MOAD

Width

1200m

MOAD

Distance from Male

493.67 km

MOAD

Longitude

73o 25' 40' E

MOAD

Latitude

00o 17'53" N

MOAD

PROJECTED POPULATION

POPULATION CURRENT

10506

MOAD

GROWTH RATIO

1.3%

MOAD

PROJECTED POPULATION IN 30 YEARS

14604

MOAD

ADD FOR MIGRATION (15%)

2191

MOAD

TOTAL PROJECTED POPULATION IN

30

16206

YEARS

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

21 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

TOTAL NO. OF HOUSEHOLDS/ BUILDING

2639

MOAD

AVERAGE NO OF PERSON/ HOUSEHOLD

MOAD

Flow calculation is based on MWSA design criteria for sewage network 2007.

EPA Alternative Wastewater collection system, Chapter-3 (Attached as Appendix-I)

Guideline of developer volume II (From Malaysia water association) (Attached as

Appendix-I)

Min Pipe Cover

900 mm as per MHTE Sewerage

design criteria

Discharge load and hydraulic calculations

- BS EN 12056

Amount of sewage is calculated based on the total population.

From the above design data projected population for 30 years

= 16206

According latest received land use plan from MOH total number

Of plots including existing, under construction and future plots,

= 2639

Therefore average no of person per house =

16206/2639

= 6.1 6

According to MWSA design criteria 2007

Average daily water usage/ Person

= 180 lpd.

For design of sewage system consider 70 - 80 % of water usage / person/day.

Total waste water generated / person/ day is 180* 0.80

= 144

Other Standards used for the design works are as listed below

Sanitation Guidelines from MWSA 2003

General guidelines for domestic waste water disposal from MWSA 2006

EPA Alternative Wastewater collection system, Chapter-3 (Attached as Appendix-I)

Guideline of developer volume II (From Malaysia water association) (Attached as

Appendix-I)

General EIA Guidelines from MWSA 2004

Five years Activity Plan of MWSA (2006-2010) May 2006

Water & Sanitation policy statement from MEEW July 2005

Design Criteria for sewerage system from MEEW Jan 2007

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

22 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

International Water Supply & Sewerage Design Criteria

Wastewater disposal guidelines, MWSA

8.2 WATER SUPPLY DESIGN STANDARDS

Water supply pipe line network is divided in 02 zones. The piping network consists of

100mm, and 80 mm size HDPE pipes according to ASTM standard. The main water

supply network loop would be of 100mm and sub lines are of 80 mm diameter pipes.

The total network is designed such as it should be able to deliver constant flow, with

minimum head of 5m at the farthest point at all times. Valve chambers are provided at

each junction of main line and sub lines, for providing servicing and maintenance

easiness. The network is designed such as it should be easily accessible from each

individual housing and institutional plots, so that, future authority can make the individual

connection comfortably, according to future water demand.

The system is developed for Fuvahmulah Island is designed in accordance with

international standards and the following regulations.

Sanitation Guidelines from MWSA - 2003

General guidelines for domestic waste water disposal from MWSA 2006

General EIA Guidelines from MWSA -2004

Five years Activity Plan of MWSA (2006-2010) May 2006

Water & Sanitation policy statement from MEEW July 2005

Design Criteria for sewerage system from MEEW Jan 2007

International Water Supply & Sewerage Design Criteria

The current British Standard Specifications and Codes of Practice apply to all

construction works and materials. For design calculations 30 Liter per day per person is

considered which is for the drinking and cooking purposes.

9.0

DETAILED DESIGN OF PROJECT COMPONENTS

The detailed design calculations are attached to the following Appendices A, an abstract

of the calculations with the methodology is narrated below.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

23 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

9.1 SEWERAGE NETWORK-VACUUM SYSTEM

UPVC pipes of minimum 110 and 160 mm size are used for the household 600mm

HDPE inspection chamber and further connection to Vacuum collection chambers (VC),

whereas the main Vacuum sewer is made of 110, 125, 160, 200, and 250 mm PVC

Schedule 40, SDR 21 solvent welded pipe, to meet the future population and laid in a

saw tooth profile with a slope ranges from 0.2 % to 2%. (1) For 100-125 mm diameter

pipe: 80 % pipe diameter or 0.2 % gradient. (2) For 150-250 mm diameter pipe: 40 %

pipe diameter or 0.2 % gradient. The design of vacuum sewage profile is based on

attached EPA alternative sewage design criteria (Appendix-I) table 3-2, 3-3, 3-4, and lift

height is based on table 3.1. The minimum suction pressure at each vacuum interface

unit will be 5 ft and the frictional losses in the vacuum pipe will not go beyond 2 feet. The

losses on account of static lift will not go beyond 11 feet. The upper velocity limits are

even more in the vacuum sewers which exclusively depend upon the value of vacuum in

the vacuum sewage network. The velocity may up to range 4.6 5.5 m/sec depends on

value of volume in line and vacuum pipe diameter, thereby providing a non-clogging and

trouble free drainage system.

Two Vacuum Stations are provided in Fuvahmullah at convenient and suitable locations

to develop sufficient vacuum pressure in each sewer zone. The total available head loss

for vacuum station should be between 18 to 23 feet.

All Sewage Vacuum network is designed for a projected population of 30 years. Design

flow is calculated based on the following methodology.

a) Considered daily waste water generated should be equal to 144 Lit/Day/Person

which is 80% of total water consumption/person/day i.e. 180 Lit/day/person (MWSA

Design Criteria). Remaining 20% is considered as losses by evaporation and

transportation.

b) All gray water and black water from each house, Institutions and Industries are

connected to the sewage network.

c) Design flow is obtained by adding Peak Dry Whether flow, and Institutional flow.

d) Peak Dry weather flow is obtained by multiplying peak factor to average dry weather

flow.

e) Average Dry whether flow is obtained by multiplying 30 years projected population to

waste water generated per person per day (144 LPD).

f) Design Flow Calculation

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

24 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Wastewater flow rate per day (average flow) = 2,700.00 m/day = 112.50 m/hr

Peak flow factor is vary from place to place depending on variables design consideration

such as premises type, water consumption per person per day, daily peak hour,

seasonal activity and population size. The most important criteria to be incorporated in

this design are knowledge relating to local conditions which may affect directly to the

sewerage system daily operation. Therefore, the flows estimation used for the vacuum

sewerage system in this project based on the Code of Practice for the Design and

Installation of Sewerage Systems.

Peak flow factor (assumption)

= 3.8

Design wastewater flow rate (peak flow)

= 427.50 m/hr

Number of vacuum station

= 2nos

Design wastewater flow rate (peak flow) per vacuum station

= 7.13 m/min

= 213.75 m/hr

= 3.56 m/min

g) Vacuum Sewage system Design.

Vacuum Sewer Reticulation

The vacuum sewer network is designed based on the peak flows of the propose

development and the individual pipe size selection which depends on:( a ) The capacity of wastewater to be collected and conveyed by the sewer reticulation.

( b ) The distance of the vacuum sewer pipeline.

The selection of the vacuum sewer pipe sizes shall be based on the table below (From

Guideline of developer vol.2 (Malaysia water association attached in Appendix-I) :

Vacuum Sewer

Nominal

Diameter

Maximum Flow

Maximum

Transported

Pipe Length

(mm)

(Liters/Sec)

(m)

110

2.0

600

125

5.0

1000

160

10.0

1500

200

16.0

No limit

250

30.0

No limit

If the lengths recommended for the pipe size are exceeded prior to flow limit being

reached, then the next size of sewer is chosen irrespective of the flow being transported.

The minimum and maximum pipe sizes recommended for the Network System's

collecting and conveyance mains shall be 100mm and 250mm respectively. However,

the "crossover" pipe work connecting a collection chamber to the vacuum network mains

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

25 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

shall be typically 90mm nominal diameter. A saw-tooth profile enables sewers to be

placed at shallow depths along its length, and can be designed to ensure that sewage

seals the pipe at low points within the network. A lift within a saw-tooth profile shall

consist of two 45 degree elbows and a straight piece of pipe. Ideally the minimum

distance between two adjacent lifts should not be less than 3 meters so as to avoid

possible sewage backflows within the sewer system. Generally the vertical drop between

lifts shall be the larger of:

- For 100-125mm diameter: 80% pipe diameter or 0.2% gradient

- For 150-250mm diameter: 40% pipe diameter or 0.2% gradient

In general vacuum sewers are sloped at minimum gradient of 0.2 percent towards the

Vacuum station.

h) Typical Vacuum Valve chamber design.

The vacuum valves we propose to the Fuvahmulah project are single valve collection

chamber. The valve can be serving up to 40 liters per cycles.

Base on the Fuvahmulah design, 90 % of valve chambers are connected by a group of

10 houses then

Total flow towards each pit

= 10x6x144 liter/day

= 8,640liter/day or 6 liter/min.

Total peak flow per minute

= 6 liter/min x 5 (peak flow factor)

= 30 liter/min.

Therefore,

Maximum interface valve operate per minute

= 30 liter/min

Divide38 liter/cycle

=0.75 time/min.

The sump heights of 76 cm and 135 cm both 45 cm in diameter at the bottom and 90 cm

in diameter at the top will be used depending upon the above flow requirement. For any

increased flow based on future site condition same sump pit size with depth up to 1

meter is recommended. One 7.5 cm (3 inch) diameter opening, with an elastomeric

seal, is pre-cut should be installed to accept the vacuum sewer line.

The pit bottom should be 6 mm thick at the edges and 8 mm thick in the center. Valve

bottom should be provided with holes pre- cut for 7.5 cm suction line, 10 cm

cleanout/sensor line and the sump securing bolts.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

26 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Cast Iron covers and frames generally 45 kg and 40 kg weight should be used for

covering the valve chamber.

The deepest section for fiberglass material valve pit shall be 2.4 meter, therefore any for

any section of valve pit deeper than 2.4 meter should be of Reinforced cement concrete

and the maximum depth of reinforced cement concrete section should be 3 meter,

however, the special care is required to select the depth of Valve Pit depth, since the

amount of lift available is going to be 1.5 meter (5 feet).

A typical Buffers Tank is designed and attached in the design drawing to take care of

larger flows for attenuation coming from institutions like schools, hospitals and offices.

(Refer to Fig. 3-14. EPA Alternative Wastewater Design criteria Chapter 3) for flow

capacity more than 2 L/s.

i)

Vacuum Station Equipment Design.

a. Vacuum Pump Design.

The vacuum pumps are operate on a duty and standby/assist mode. The vacuum

pumps will operate through electrical control panel which base on signal from pressure

switches fixed on the collection tank.

The vacuum pumps and collection tanks are sized to evacuate the collection piping to

its operating level is not greater than 3 minutes, nor less than 1 minute.

The vacuum pump capacity required (m3/min), Qvp = A x Qmax

where,

Qvp = The vacuum pump capacity required (m3/min)

Qmax = Design flow rate (peak flow)

A

= Factor in vacuum pump sizing

Factor in vacuum pump sizing,

A = (Air liquid ratio x Atmosphere pressure) / Absolute pressure

b. Discharges pump Design.

The discharge pump capacity required (m3/min),

where,

Qdp

= 1.1 x Qmax

Qvp = The vacuum pump capacity required (m3/min)

Qmax = Design flow rate (Peak flow)

A

= Factor in discharge pump sizing

c. Pump discharge head calculation.

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

27 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Total head of the discharge pump, HT = Ha - Pc/9.8 + hs + hd

Where,

HT

Ha

Pc

hs

hd

= Total heads (m)

= Actual static heads (m)

= Max degree of vacuum collection tank (kPa)

= Head loss of suction pipe (m)

= Head loss of delivery pipe (m)

d. Vacuum collection tank design.

Design Criteria

The vacuum collection tank size is selected base on four important factors as follow:(a) The volume allowed for wastewater collected and vacuum pressure storage is

enough.

(b) The tank structure is a safe to sustain a negative pressure of -80kPa.

(c) The tank is made by an anti-corrosion material, or have a corroded spare thickness

and anti-corroded coating.

(d) The consideration of sludge or rubbish removal without affected to the vacuum sewer

operation.

At the project, the storage volume of the tank is calculated based on the volume of

sewage collected as the dry weather flow (average flow) enters the collection tank over a

period of 10 minutes (also to comply MS1228:1991 minimum 6 cycles/hour for pump

operation)

Design Capacity

The operational capacity (VO) for wastewater vacuum collection tank is calculated using

the formula below.

Vacuum collection tank design capacity, Vct = 3 x Vo

At design waste water flow, Qin(max) > or = 1/2 Qout

Vo = T x Qout / 4

where,

Vct

Vo

T

e. Bio filter Design

= Collection tank design capacity (m3)

= Operational capacity (m3)

= Discharge pump operate interval (minute) = 10.00 min

Bio Filter is sized by using the following formula

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

28 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Vm

where,

= Q x EBCT 60 s/min

Vm

Q

EBCT

= Media volume (ft3)

= Airflow rate (ft3/min)

= Empty Bed Contact Time (s), 15 seconds

Detailed design Calculation of Vacuum Sewage system is attached in Appendix A

9.3 SEWERAGE NETWORK-PUMPING MAINS

a) Design of pumping main from each vacuum station is designed based on 30 years

projected population design flow.

b) Flow velocity should be between 0.6 to 3.5 m/sec

c) Diameters of pumping main HDPE pipe shall be of 300 mm and 250mm dia, to

reduce the frictional loss and increase the pump stability.

d) All pipe bends and supports shall be supported with thrust blocks.

e) Pipe junctions will be provided with valve chambers.

Detailed Calculations are attached in Appendix A

9.4 SEWAGE TREATMENT PLANT

Oxidation Ditch Process based on Activated Sludge with Extended Aeration System is

selected as sewage treatment process for Fuvahmulah Island. The selection of a

particular process for sewage treatment is affected by diurnal and seasonal flow

variations, sewerage strength (variability of wastewater constituents) infiltration / inflow,

ambient temperature and its induced septicity, degree of treatment required, magnitude

and direction of wind etc.

The extended aeration process holds wastewater in closed endless loop channel to

aerate for 18 hours or more and the organic wastes are removed under aerobic

conditions. Air is supplied by mechanical rotor through rotating action. The wastewater is

screened to remove large suspended or floating solids before entering the aeration

chamber, where it is mixed, and oxygen is added. The solids settle out and are returned

to the aeration channel to mix with incoming wastewater. The clarified wastewater flows

to a collection channel before being diverted to the disinfection system. The sludge is

periodically removed from the units. In Aeration tank (extended aeration), suspended

microbial growth is maintained for the biological oxidation of organics. Surface or

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

29 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Diffused aeration system is provided to meet the oxygen requirement of micro organisms

and to keep the liquor in completely mixed regime.

The site selection for the outfall location was based on the locations identified for the

sewage treatment plant (STP). The location for STP was initially identified in consultation

with island community especially with that of the officials in the Island office. The island

office been the responsible agency indicated the potential areas for the STP based on

the housing plots, the need for future housing plots and other essential infrastructure.

The final approval for the STP site was based on the consultation with Ministry of

Housing and Urban Development (currently under Ministry of Housing, Transport and

Environment) to ensure that the sewerage network and related infrastructure is

appropriately included in the future development plan for the island.

Amount of sewage going to sewage treatment plant is calculated based on the total

population.

From the above design data projected population for 30 years

According latest received land use plan from MOH total number

of plots including existing, under construction and future plots,

Therefore average no of person per house =

16206/2639

According to MWSA design criteria 2007

Average daily water usage/ Person

For design of sewage system the international practice is taking 70 usage / person/day.

Then total waste water generated / person/ day is 180* 0.80

= 16206

= 2639

= 6.1

= 180 lpd.

80 % of water

= 144

STPFLOWCALCULATIONFuvahmulah

Description

Population

Present

After15years

After30years

11000

13352

16206

Average

flow/Person/

DayinLitter

Averageflow Assumed10%of

towardsSTPin averageflowas

Institutionalflow

Littre/day

144

144

144

1,584,000

1,922,635

2,333,665

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

158,400

192,264

233,367

Assumed5%of

averagedailyflow

asotherflows

79,200

96,132

116,683

TotalFlow

towardsSTPin

M3/Day

30 / 39

1,822

2,211

2,684

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Based on above calculation a treatment plant facility should be provided for a capacity of

30 years, (ie 2700 m3 Average daily flow) design period and equipments are designed

for 15 years projected population.

Detailed Calculations are attached in Appendix B

9.5 SEA OUTFALL

The Outfall discharge pipe should be made of 250 mm HDPE pipe, which is laid on a

trench over the reef and ocean by using concrete ballast blocks located at an

appropriate distance. The Ocean Outfall effluent mixing Design Criteria is taken as a

minimum port exit velocity of 4m/sec, initial dilution as 1:100 and Bacterial reduction to

be 1000 MPN/100 ml.

The shoreline consists of a narrow (5 to 15m) berm of coral sand mixed with rubble and then

a wide, partially sub-tidal shelf of coral rock, with sandy lagoon inter mixed, with relatively

suitable surface (superficial) that appear suitable for direct laying of a pipeline. Current

speeds on the shelf at the time, as observed at the shoreline only, were very low and would

not affect the construction method

The island of Fuvahmullah with several openings, therefore oceanic currents influence and

tidal fluctuations and its influence to the atoll basin is relatively good with high mixing

potential and short residential time of atoll lagoonal waters.

Proposed site for STP was inspected in October 2008 and March 2009 and a site at the

south-eastern end of the island has been selected from the two sites short listed It is likely

that the outfall alignment would take it SE beneath the land and foreshore to a -15 m MSL,

following a depth contour over a length of about 240m.

Current measurements were undertaken using a drogue system and a GPS, leading to

currents in the order of 0.5to 0.7m/s in a coast parallel direction (southeast to northwest

along the reef margin). This current speed enhances initial dilution and keeps the plume

away from the coast (follow the reef margin). Tide range on that day (also annual) was

relatively small (approximately 1 m) and this current was most likely caused by the tidal

currents and wind speed at the time of the recording winds (up to 10 knots estimated, as

measured by hand-held anemometer). Ocean currents are variable in the Maldives

influenced by tidal (whole water body) and wind (surface) driven movement of water body.

Due to the small amplitude of tide currently speeds within the atoll are relatively small.

However, currently of 0.7 m/s or above has been recorded, which are considered strong, in

the narrow passes in the atoll rims of Maldives. It is estimated that currents of 0.2m/s will

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

31 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

facilitate adequate mixing of the effluents. Although the island is within the atoll basin,

relatively wide channels on all sides of atoll peripheral reefs provide a setting for appropriate

mixing of the effluents especially with that of secondary level treatment as proposed.

Seabed inspection showed that the bed is essentially coral rock with well consolidated coral

formations including encrusting and massive coral formations, more true beyond the surf

zone. Near-shore seabed substrate is dominated by sand intermitted with coral and rocky

out crops. Some seabed preparation will be required to ensure that the pipeline and

installation collar weights are laid on the seabed without being twisted so that the collar

weights are in even contact with the seabed.

Initial Dilution

The Initial Dilution can be calculated by using the following equation: S = ubz/Q

Where

S

u

b

z

Q

Initial Dilution

Ocean Current Speed

Effective Diffuser Length

Effective Mixing Depth

Wastewater Discharge Rate

m/s

m

m

0.05

0.7

0.4

15

m3/s

m/sec

m

m

Diffuser Port Dimensions

Discharge Pipe Diameter

200

mm

Pumping velocity

1.6

m/s

Discharge

0.05 m3/s

Assume that opening in discharge pipe is 40% of the pipe area

Effective area of discharge port

(3.14*0.25*0.20*0.20*0.4)

Hence Diffuser Exit Velocity

(0.0316/0.007065)

Initial Dilution

For Sea Outfall Sea Current Velocity

Therefore Initial Dilution (S)= ubz/Q

0.01256

4

m2

m/s

0.7

m/s

(0.7*0.40*15/0.05)

84

Say

84

Since the Initial Dilution is less than 100, so increase the depth of Diffuser and then

calculate until it become more than 100

Al-Habshi Consultants, Kuwait In association with Riyan.Pte Ltd

32 / 39

DEVELOPMENT OF WATER SUPPLY & SEWERAGE FACILITY IN ATOLLS PROJECT

FUVAHMULAH, MALDIVES

Detailed Design Report - Volume 1 of 3

Detailed Calculations and Plume modeling software outputs are attached in Ocean