Beruflich Dokumente

Kultur Dokumente

15 Acoustic Detailing Apr 07

Hochgeladen von

Igor Veloso AviOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

15 Acoustic Detailing Apr 07

Hochgeladen von

Igor Veloso AviCopyright:

Verfügbare Formate

April 2007

Data Sheet 15

Uniclass

CI/SfB

Aggregate Concrete Blocks

EPIC

L3221:A4

F611:X221

Ff2

Acoustic detailing for framed buildings

Introduction

This data sheet covers the basic principles required to provide satisfactory acoustic junctions

and basic acoustic design to realise the full potential of the construction.

Manufacturers provide acoustic data on their blocks primarily based upon laboratory test

values (Rw - A single-number value which characterizes the airborne sound insulation

measured in a laboratory).

Most specifications require a DnT,w value to be met (a single-number which characterizes

the actual airborne sound insulation between rooms).

As a general rule of thumb, a DnT,w value would be expected to be 5 to 8dB lower than

the equivalent Rw value, due to adverse flanking conditions and workmanship on site.

Ctr is a correction value added to the DnT,w value for dwellings and some other applications

to place greater importance on the lower frequency values.

Good Design

In general the aim is to provide an airtight structure with either adequate mass to prevent

the passage of sound or isolation of the structure, to prevent the passage of vibration / noise.

Where ever possibe a direct sound path should be avoided.

Stagger the doors of apartments opening on to the same hall so they are not opposite one

another. Sound travels best in straight lines. Everytime it changes direction, some of it is

absorbed and some diffused.

Use halls to isolate apartments. Two walls with an air space between them cut sound

transmission about 50% more than a single wall twice as heavy as either of the two walls.

Place windows as far away from separating walls as is possible. The closer windows are

to each other on either side of a separating wall, the more sound will pass from one

apartment to the other. Simply separating windows will stop much of this sound.

This guidance applies equally to the spacing of doors in corridors.

Concrete Block Association

60 Charles Street, Leicester LE1 1FB

Tel: 0116 253 6161 Fax: 0116 251 4568

Email: enquiries@cba-blocks.org.uk

Website: www.cba-blocks.org.uk

(Ajv)

Junction Details - Movement Control

Movement joint to internal wall

Sealant where required

Movement joint at an intersecting wall

25 x 3mm flat section

metal tie with one end

de-bonded at 450mm

vertical centres

Sealant where required

Joint filler

Joint filler

25 x 3mm flat section metal

tie with one end de-bonded

at 450mm vertical centres

Proprietary profile for forming joint

through wet finish

Movement joint at external wall junction

to separating wall

25 x 3mm flat section metal

tie with one end de-bonded

at 450mm vertical centres

Joint filler

25mm x 3mm flat section

metal tie with one end

de-bonded at 450mm

vertical centres

Joint Filler

Plaster finish

Sealant where required

Proprietary type

movement bead

Wall ties at maximum

300mm vertical centres

Outer leaf

Junction Details - Junctions at Columns

Movement joint at concrete column

Movement joint to blockwork at internal steel column

Sealant

Sealant where

required

Concrete

column

25 x 3mm flat

section metal ties

with de-bonding

sleeves at 450mm

vertical centres

Joint

filler

Concrete

column

75mm min.

Joint filler

Dovetail

channel

cast into

column

Flexible ties at max.

300mm vertical

centres

Fire and acoustic

protection to

column

2 layers of 12.5mm

plasterboard with

staggered joints

Column

Mineral wool

10kg/m

Movement joint to blockwork at steel column in cavity wall

Column

2 layers of 12.5mm

plasterboard with

staggered joints

Mineral wool

10kg/m

Fire and acoustic

protection to

column

225mm max.

40mm min.

Movement joint to blockwork at steel

frame blockwork encasing column

Flat section metal ties

de-bonding sleeves at

vertical centres. Allow

100mm embedment.

Ties fixed to column

(eg. shot fired).

Wall ties at maximum

300mm vertical centres

Outer leaf

De-bonded tie every second course.

Note that clearance must be given

to allow for steelwork movement

Internal blockwork butting steel frame

Flexible ties with

suitable drip

De-bonded tie fixed to

steelwork. Note that

clearance must

be given to allow for

steelwork movement

Joint filled with polyethylene foam or

similar sealant used where required

Head Restraint

Metal angle

Straps in perpend joints

Compressible filler

(Polyethylene foam

or similar)

Compressible filler

between wall and

soffit to allow for

deflection of floor

Metal angles provide

restraint to top of wall

- fixed to soffit only

Head restraint

bolted to concrete,

restraining top

of block wall

Indicative Values (Rw)

215mm Dense block wall plastered both sides.

No Joint in wall

58dB

Unfilled movement joints

16dB

Mineral wool filler to movement joint

34dB

15 x 15mm polyethylene foam and sealant one side

52dB

15 x 15mm polyethylene foam and sealant both sides

57dB

As can be seen, provided the joint is fully filled with a compressible filler and sealed on

both sides, a movement joint need not have a detrimental effect upon the acoustic quality

of a masonry wall.

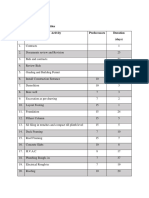

Dwelling houses and flats - performance standards for separating walls, floors and stairs

that have a separating function

Airborne sound

insulation min. values

DnT,w + Ctr dB

Impact sound insulation

max.values LnT,w dB

Purpose built dwelling houses and flats

Walls

45

Floors and stairs

45

62

Dwelling houses and flats formed by a material change of use

Walls

43

Stairs

43

64

Rooms for residential purposes - performance standards for separating walls, floors and

stairs that have a separating function

Airborne sound

insulation min. values

DnT,w + Ctr dB

Impact sound insulation

max.values LnT,w dB

Purpose built rooms for residential purposes

Walls

43

Floors and stairs

45

62

Rooms for residential purposes formed by a material change of use

Walls

43

Stairs

43

64

It is important to note that the evaluation of airborne sound now includes the Ctr value

to take an account of low frequency sound that gives rise to a significant number

of complaints.

To receive other data sheets in this series, a list of CBA members or

for further information please visit our website at www.cba-blocks.org.uk

CBA Technical Helpline 0116 222 1507

The Concrete Block Association 2007

Although The Concrete Block Association does its best to ensure that any advice,

recommendation or information it may give is accurate, no liability or responsibility of any

kind (including liability for negligence) is accepted in this respect by the Association, its

servants or agents.

This datasheet is manufactured from ECF (Elemental Chlorine Free) pulp sourced from

certified or well managed forests and plantations. It is totally recyclable, biodegradable

and acid-free.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Minoan and Ethruscan ArchitectureDokument15 SeitenMinoan and Ethruscan ArchitectureMSTEM-H Rafael, MarkNoch keine Bewertungen

- Bosch GST 75 E ProfessionalDokument167 SeitenBosch GST 75 E ProfessionalAdriana AlvesNoch keine Bewertungen

- Cast in Place Concrete PilesDokument3 SeitenCast in Place Concrete PilesHasnain BukhariNoch keine Bewertungen

- List of Construction Activities PCM 2Dokument2 SeitenList of Construction Activities PCM 2Chelsea BalanagNoch keine Bewertungen

- Types of WindowDokument30 SeitenTypes of WindowRod AquinoNoch keine Bewertungen

- Transformer Vault PlacementDokument7 SeitenTransformer Vault PlacementMuhammad RafsanzaniNoch keine Bewertungen

- BSD - Plate 13-Reflected Ceiling Plan - BSCE 2B - (Silvestre, Michael A.)Dokument1 SeiteBSD - Plate 13-Reflected Ceiling Plan - BSCE 2B - (Silvestre, Michael A.)Michael SilvestreNoch keine Bewertungen

- Assignment 1a - MasonryDokument4 SeitenAssignment 1a - MasonryAnnisa WisdayatiNoch keine Bewertungen

- White Coast Complex Balchik Resort Varna BulgariaDokument32 SeitenWhite Coast Complex Balchik Resort Varna BulgariadavisNoch keine Bewertungen

- SP30Dokument287 SeitenSP30Ajoy Mc100% (1)

- A Hancock Shaker Clock: Project Reference GuideDokument9 SeitenA Hancock Shaker Clock: Project Reference GuidePakito XtradaNoch keine Bewertungen

- Portable Office CabinDokument5 SeitenPortable Office Cabinmaliqueredzuan100% (1)

- Le Corbusier and The Architectural-Promenade, Flora SamuelDokument48 SeitenLe Corbusier and The Architectural-Promenade, Flora SamuelJC Tsui100% (2)

- Principles of Foundation Engineering Si Edition 8th Edition Das Solutions ManualDokument25 SeitenPrinciples of Foundation Engineering Si Edition 8th Edition Das Solutions ManualJeremySmithwrok100% (45)

- Hitachi Circuit Breakers and Miniature Circuit BreakersDokument146 SeitenHitachi Circuit Breakers and Miniature Circuit BreakersWilliamBradley PittNoch keine Bewertungen

- PDF PLC Roofing GuideDokument27 SeitenPDF PLC Roofing GuideBushral YusobNoch keine Bewertungen

- Renaissance Revival Interiors: Renaissance Villa Farnese BalustradingDokument2 SeitenRenaissance Revival Interiors: Renaissance Villa Farnese Balustradingpujari sai kumar babuNoch keine Bewertungen

- Serviceability AISC ASCEDokument3 SeitenServiceability AISC ASCErpb10100% (1)

- Danny Bridson - Courtyard Housing StudyDokument14 SeitenDanny Bridson - Courtyard Housing StudyKhiem NguyenNoch keine Bewertungen

- Garbag Linen ChutesDokument24 SeitenGarbag Linen Chutessultanprince100% (1)

- Bus Coupler Specs PDFDokument11 SeitenBus Coupler Specs PDFRaj ChavanNoch keine Bewertungen

- Above Ceiling Closure Check ListDokument13 SeitenAbove Ceiling Closure Check ListNabeel RumaniNoch keine Bewertungen

- AA 2013 BrochureDokument24 SeitenAA 2013 BrochureChaw Su LwelNoch keine Bewertungen

- Agenda Item 3.1.1 - Attachment 2Dokument504 SeitenAgenda Item 3.1.1 - Attachment 2Pranav HarmilapiNoch keine Bewertungen

- Building in A BagDokument4 SeitenBuilding in A BagNguyen Do Hung33% (3)

- Acoustic MaterialsDokument6 SeitenAcoustic MaterialsLeanne Mae Patuga0% (1)

- Inventory HSN Code RequiredDokument21 SeitenInventory HSN Code RequiredPralhad PadwalNoch keine Bewertungen

- Bonbas Goulds Pumps 36-3756M PDFDokument44 SeitenBonbas Goulds Pumps 36-3756M PDFAntonio ArteroNoch keine Bewertungen

- Mini House Concept by JWDADokument3 SeitenMini House Concept by JWDAcnathapolNoch keine Bewertungen

- Boq 01Dokument7 SeitenBoq 01abobeedoNoch keine Bewertungen