Beruflich Dokumente

Kultur Dokumente

Optimization of Oil Field Operations

Hochgeladen von

Daniel OlivrowCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Optimization of Oil Field Operations

Hochgeladen von

Daniel OlivrowCopyright:

Verfügbare Formate

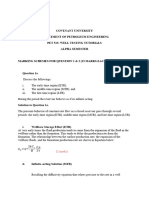

Optimization of

Oil Field Operations

Louis J. Durlofsky

Department of Energy Resources Engineering

Stanford University

Collaborators

Jerome Onwunalu

(now at BP)

Jincong He

Jon Saetrom (NTNU)

2

Smart Field Modeling

Reservoir

Data

Set Well

Controls

Update

Model

Field

Development

Optimization

Optimize

Well Settings

Optimization highly intensive computationally

3

Outline

Field development (well placement) optimization

Particle swarm optimization (PSO) algorithm

Well pattern optimization

Production optimization

Trajectory piecewise linearization (TPWL) for

surrogate modeling

Generalized pattern search method with TPWL

Conclusions

Optimization of Well Type and Placement

Solution Representation for

Field Development Optimization

Concatenation of well variables; (, ) are spatial locations:

x = {1 ,1 , 2 , 2 ,K, N , N }

well 1

well 2

well N

2N optimization variables

Representation can be generalized to handle deviated,

horizontal, or multilateral wells:

x = {( h , h , h )1 , ( t ,t , t )1 ,K}

6

Particle Swarm Optimization (PSO)

Developed originally by Kennedy & Eberhardt (1995)

Models social behavior in animals and entails a cooperative

search strategy (population-based like Genetic Algorithm)

Successfully applied for subsurface flow optimization

(groundwater remediation) by Mattot et al. (2006)

http://inlinethumb61

.webshots.com

PSO Solution Iteration

xi solution, vi particle velocity, k iteration, t = 1

Particle velocity has 3 contributions:

Particle Swarm Optimization

(2D Search Space)

PSO Neighborhood Topologies

10

Genetic Algorithm (GA) Operations

Population and selection:

}

Crossover:

Mutation:

11

PSO versus GA for Well Placement

In our tests, PSO generally outperformed GA

2 dual-lateral producers

Average PSO NPV (from 5 runs) 19% higher than GA

4 deviated producers

Average PSO NPV (from 5 runs) 7% higher than GA

12

Optimization Example: PSO versus GA

Find well location and type (20 wells) to maximize net

present value (NPV)

2D model, 100 x 100 blocks, oil-water simulation

Swarm (population): 50; iterations (generations): 100

Perform 4 runs for each algorithm

60 optimization variables

x = {1 ,1 , i1 , 2 , 2 , i2 ,K, N , N , iN }

13

Optimization Results: PSO and GA

- - PSO

GA

14

Well Locations and Types: PSO and GA

15

Solution Representation for Multiple Wells

Concatenation of well variables:

x = {1 ,1 , 2 , 2 ,K, N , N }

well 1

well 2

well N

Number of optimization variables increases with well

count high computational expense

Well count N must be specified (this should also be an

optimization variable)

May be difficult to enforce distance constraints

16

Optimization with Well Patterns

(Well Pattern Description)

17

Repeated Five-Spot Pattern

18

Optimize Parameters Associated with Pattern

a

b

(,

( )

Basic parameters: (, , a, b)

19

Allow for Rotation

20

Shearing

21

Then Replicate and Evaluate

22

Pattern Operators for WPD

Scale

Rotate

Shear

Can be expressed using transformation matrix M:

T

Wout

= MWinT

cos

M rotate =

sin

sin

cos

23

Switch Operator and Extension to

Other Patterns

Switch from

inverted to

regular pattern

Operators also defined for other pattern types:

24

Illustration of WPD with Two Operators

25

Solution Representation in

Well Pattern Description (WPD)

Fixed number of optimization parameters

Number of wells determined as part of optimization

Distance constraints easily satisfied

Can be used with a variety of optimization algorithms

Optimized solution is always a repeated pattern

26

Well-by-Well Perturbation (WWP)

Same number of variables as concatenation approach

but much smaller search space, and N is specified

27

Example 1: Problem Set Up

2D model, 100 x 100 grid blocks

Oil-water system, 10 years of production

Injector BHP: 6000 psi, Producer BHP: 1000 psi

Maximize NPV; run optimization multiple times

permeability

field

28

Algorithm Performance Pattern Optimization

(one pattern operator)

Best NPV using standard well patterns: $2151 MM

29

Example 1: Optimization Results

injector

30

Comparison of Concatenation and WPD+WWP

(5 runs, 4 operators, 8000 total simulations)

WWP (average)

WPD (best)

Concatenation (average,

# of wells specified)

Number of simulations

WPD+WWP outperformed concatenation for all 5 runs

31

Optimized Well Locations

injector

Concatenation

WPD+WWP

32

Example 2: Problem Set Up

2D model, 80 x 132 grid blocks

Oil-water-gas system, 5 years of production

Injector BHP: 2900 psi, Producer BHP: 1200 psi

Use 40 PSO particles, perform 5 runs using 3DSL

log permeability

field

33

Example 2: Optimization Results

34

Example 2: Optimization Results

WPD (pattern)

WPD+WWP performance

WWP after WPD

35

Example 2: Well Locations

injector

36

37

Production Optimization Problem

Seek to minimize:

J (u) = NPV(u) = roQo (u) + cwpQwp (u) + cwiQwi (u)

u controls, Qj cumulative production/injection

ro , cw oil revenue, water costs

subject to bound & linear/nonlinear constraints

Penalty function method:

min J (u) + h(u)

h constraint violation,

penalty parameter

38

Oil-Water Flow Equations

Mass balance equations for j = oil, water

S j

t

( j kp ) + q j = 0

Sj - phase saturation (volume fraction), p - pressure

j (Sj ) - phase mobility, k - permeability tensor, qj - source

Discretize: x - states (p, Sw), u - controls (pwell),

O(105-106) grid blocks

) ( ) (

g x n+1 , x n , u n+1 = A x n+1 , x n + F x n+1 + Q x n+1 , u n+1 = 0

Newtons method:

J = g , J = g x

39

Trajectory Piecewise Linearization (TPWL)

Basic idea

Use states and Jacobians generated and saved during

training run(s) to represent new solutions

Approach

Run training simulations (g(x,u) = 0)

Record states and Jacobian matrices (xi, gi/xi)

Represent new solutions (xn+1) as expansions around

saved states (xi+1)

Map into l-dim reduced space z using POD (xz)

References: Rewienski & White (2003), Vasilyev et al. (2003),

Qu & Chapman (2006), Cardoso & Durlofsky (2010), He et al. (2010)

40

Linearization around Saved States

x2

i=3

i=1

2D state space

i=4

i=2

i=5

i=6

u0

i =7

i=8

u1

x1

Save xi and gi/xi (u0)

Represent solutions for u1 using xi and gi/xi

41

TPWL for Reservoir Flow Equations

Discretized flow equations:

g n+1 = A n+1 + F n+1 + Q n+1 = 0

Linearized representation for new state xn+1:

g i +1

g i +1 n

g i +1 n +1

i

i +1 u u i +1

g n +1 g i +1 + i +1 x n+1 x i +1 +

x

x

+

i

x

x

u

x: states (p, Sw)

u: controls (BHPs)

42

Expansion around Saved States

Linearized representation:

J

i +1

(x

n +1

i +1

A i +1 n

Q i +1 n +1

i

=

x x + i +1 u u i +1

i

u

x

POD (SVD) applied to snapshot matrix: x z

TPWL representation (reduced space, multiply by T ):

( )

z n +1 = z i +1 J ir+1

A i +1 n i Q i +1 n +1

z z + i +1 u u i +1

i

x r

u r

J ir+1 = T J i +1

(ll l)

l ~ O(102 103)

43

Test Case Portion of SPE 10 Model

60

60

30 = 108,000 cells (216,000 unknowns)

w = 60 lb/ft3, o = 45 lb/ft3

High resolution for all 72 well blocks

l = 304 (basis optimization applied); 448 unknowns

44

Training and Test Runs

=0

=1

Training

input

Target

input

Test runs:

u = (1 )uTraining + uTarget

45

Production Rates for = 0.3

P1

P2

P3

P4

46

Production Rates for = 0.5

P1

P2

Run Time

P3

GPRS/CPR

~1 hr

TPWL

~2 sec

P4

47

TPWL as a Proxy for Optimization

Apply TPWL for direct search methods

Perform an initial training simulation

Retrain TPWL after specified number of iterations,

distance from last training, etc.

Generalized Pattern Search

(GPS)

Retrain

Training

(Kolda et al., 2003)

48

Production Optimization: Case 1

Optimization set up

Optimize NPV using generalized pattern search (GPS)

Oil: $80/bbl, prod. water: $-36/bbl, inj. water: $-18/bbl

Geological model: portion of Stanford VI model

30x40x4 = 4800 grid blocks

4 producers and 2 injectors

Simulation time: 1800 days (200 day intervals)

9 control variables for each producer (36 in total)

(BHP)min = 1,000 psia; (BHP)max = 3,000 psia

49

Optimization Result: NPV Evolution

50

Optimization Result: NPV Summary

Method

NPV (initial)

$106

NPV (final)

$106

# of full

simulations

Full-order GPS

49.9

170.1

2500

TPWL-guided

GPS

49.9

169.0

15

TPWL model construction ~ 2time for training run

51

Optimization Results: Final BHP Schedules

52

Production Optimization: Case 2

Optimization set up

Oil: $80/bbl, prod. water: $-10/bbl, inj. water: $-5/bbl

GPS with incremental penalty

Geological model: larger portion of Stanford VI

20,400 grid blocks, 4 producers and 2 injectors

Simulation time: 1800 days (200 day intervals)

Prod: (BHP)min = 1,000 psia; (BHP)max = 3,000 psia

Inj: (BHP)min = 5,500 psia; (BHP)max = 7,500 psia

Nonlinear constraints: water fractions < 50%

53

34%

Water Cut Violation

Optimization Results

54

Optimization Results: Injector BHP Schedules

Method

TPWL-guided

GPS

# of full

NPV (initial) NPV (final)

$106

simulations

$106

729

975

~12

55

Summary and Future Work

Applied particle swarm optimization (PSO) for determining

placement of new wells

Devised new treatments for optimizing multiwell (field)

development problems

Demonstrated use of TPWL (trajectory piecewise

linearization) procedure for fast reservoir simulation

Incorporated TPWL into generalized pattern search

optimization of oil production

Future work: meta-optimization techniques for use with

PSO; enhance TPWL and clarify criteria for retraining;

combine field development & production optimization

56

Das könnte Ihnen auch gefallen

- Upscaling of Geocellular Models For Flow Simulation: Louis J. DurlofskyDokument46 SeitenUpscaling of Geocellular Models For Flow Simulation: Louis J. Durlofskychem352Noch keine Bewertungen

- Upscaling of Geocellular Models For Flow Simulation: Louis J. DurlofskyDokument46 SeitenUpscaling of Geocellular Models For Flow Simulation: Louis J. DurlofskyLukito Ardhi NugrohoNoch keine Bewertungen

- Part 12 Superposition Single and Multi WellDokument22 SeitenPart 12 Superposition Single and Multi WellChai Cws0% (1)

- Reduced Order Model Applied To Water Flooding OptimizationDokument18 SeitenReduced Order Model Applied To Water Flooding OptimizationFoundation CMGNoch keine Bewertungen

- Halliburton - Real Time Production Optimization & Reservoir Management PDFDokument21 SeitenHalliburton - Real Time Production Optimization & Reservoir Management PDFFernandoEnriqueCalveteGonzálezNoch keine Bewertungen

- Lecture1-PO SS2011 01 Introduction p26Dokument26 SeitenLecture1-PO SS2011 01 Introduction p26Everton CollingNoch keine Bewertungen

- SPE 119156 Automatic Well Placement Optimization in A Channelized Turbidite Reservoir Using Adjoint Based SensitivitiesDokument9 SeitenSPE 119156 Automatic Well Placement Optimization in A Channelized Turbidite Reservoir Using Adjoint Based Sensitivitiessajjad moradiNoch keine Bewertungen

- Pet 531 ADokument12 SeitenPet 531 AIgbereyivwe TejiriNoch keine Bewertungen

- 6 OneD Unconstrained OptDokument29 Seiten6 OneD Unconstrained OptLolie SaidNoch keine Bewertungen

- Dynamic Programing and Optimal ControlDokument276 SeitenDynamic Programing and Optimal ControlalexandraanastasiaNoch keine Bewertungen

- Control Systems Lab - SC4070: DR - Ir. Alessandro AbateDokument35 SeitenControl Systems Lab - SC4070: DR - Ir. Alessandro AbatemakroumNoch keine Bewertungen

- Chap 8Dokument50 SeitenChap 8Karthick ManojNoch keine Bewertungen

- MIT2 29F11 Lect 11Dokument20 SeitenMIT2 29F11 Lect 11costpopNoch keine Bewertungen

- Constraint Satisfaction ProblemsDokument49 SeitenConstraint Satisfaction ProblemsPoonam KumariNoch keine Bewertungen

- Exercise - Numerical Methods For Process Simulation: Algebraic Solvers Problem 1: CSTRDokument6 SeitenExercise - Numerical Methods For Process Simulation: Algebraic Solvers Problem 1: CSTRMcChima LeonardNoch keine Bewertungen

- Well Testing Res Des ConceptsDokument59 SeitenWell Testing Res Des ConceptsAvinash_Negi_7301100% (1)

- Numerical Solution of Single Odes: Euler Methods Runge-Kutta Methods Multistep Methods Matlab ExampleDokument16 SeitenNumerical Solution of Single Odes: Euler Methods Runge-Kutta Methods Multistep Methods Matlab ExampleZlatko AlomerovicNoch keine Bewertungen

- CN2116-Unit 12-2013Dokument25 SeitenCN2116-Unit 12-2013Jiaqi ChuaNoch keine Bewertungen

- Simulation Paper Nit RourkelaDokument2 SeitenSimulation Paper Nit RourkelaYASHNoch keine Bewertungen

- MCMC BriefDokument69 SeitenMCMC Briefjakub_gramolNoch keine Bewertungen

- WT&D (Optimization of WDS) PDFDokument89 SeitenWT&D (Optimization of WDS) PDFAbirham TilahunNoch keine Bewertungen

- Partial Least Squares A TutorialDokument12 SeitenPartial Least Squares A TutorialGutama Indra GandhaNoch keine Bewertungen

- Desopt 2016 02 PDFDokument36 SeitenDesopt 2016 02 PDFAndrea ChaseNoch keine Bewertungen

- DC AnalysisDokument27 SeitenDC AnalysisJr CallangaNoch keine Bewertungen

- DSE 3151 25 Sep 2023Dokument9 SeitenDSE 3151 25 Sep 2023KaiNoch keine Bewertungen

- Liu2017 Article AFastAndStableAlgorithmForLineDokument31 SeitenLiu2017 Article AFastAndStableAlgorithmForLineAman JalanNoch keine Bewertungen

- Slide Jaya Alg Vs Cuckoo Search AlgDokument14 SeitenSlide Jaya Alg Vs Cuckoo Search AlgMashuk AhmedNoch keine Bewertungen

- Z TestDokument39 SeitenZ Testanmolgarg12950% (2)

- 04-Build-Up TestDokument53 Seiten04-Build-Up Testwisam alkhooryNoch keine Bewertungen

- Well Test Interpretation ENSPM 5aDokument51 SeitenWell Test Interpretation ENSPM 5aMygroup 5544100% (2)

- Biogeography-Based Optimization: Dan Simon Cleveland State University Fall 2008Dokument39 SeitenBiogeography-Based Optimization: Dan Simon Cleveland State University Fall 2008Srini VasNoch keine Bewertungen

- Sparse Optimization Lecture: Basic Sparse Optimization ModelsDokument33 SeitenSparse Optimization Lecture: Basic Sparse Optimization ModelsCatalin TomaNoch keine Bewertungen

- Introduction To Quantum Computing: Miklos SanthaDokument31 SeitenIntroduction To Quantum Computing: Miklos SanthaJinto JohnsonNoch keine Bewertungen

- Overton TalkDokument41 SeitenOverton Talkluka alexNoch keine Bewertungen

- Chapter 5 - Managing Class A ItemsDokument17 SeitenChapter 5 - Managing Class A ItemsKhánh Đoan Lê ĐìnhNoch keine Bewertungen

- Tfaws2011 Ae 001Dokument28 SeitenTfaws2011 Ae 001Ameenuddin MohammedNoch keine Bewertungen

- Veldhoven Aug 2005 JansenDokument84 SeitenVeldhoven Aug 2005 JansenkurtpeekNoch keine Bewertungen

- Dynamic Programming: Department of CSE JNTUA College of Engg., KalikiriDokument66 SeitenDynamic Programming: Department of CSE JNTUA College of Engg., KalikiriMaaz ChauhannNoch keine Bewertungen

- SAHADEB - Logistic Reg - Sessions 8-10Dokument145 SeitenSAHADEB - Logistic Reg - Sessions 8-10Writabrata BhattacharyaNoch keine Bewertungen

- 1 Transformation Into CNFDokument4 Seiten1 Transformation Into CNFMade Alam KamajanaNoch keine Bewertungen

- 01 Revision1 ResDokument4 Seiten01 Revision1 ResNicholas LeocholasNoch keine Bewertungen

- Control Systems Lab - SC4070: DR - Ir. Alessandro AbateDokument39 SeitenControl Systems Lab - SC4070: DR - Ir. Alessandro AbatemakroumNoch keine Bewertungen

- Control Systems Lab (SC4070) : Georg SchitterDokument28 SeitenControl Systems Lab (SC4070) : Georg SchittermakroumNoch keine Bewertungen

- Numerical Modelling in Fortran: Day 6: Paul Tackley, 2017Dokument53 SeitenNumerical Modelling in Fortran: Day 6: Paul Tackley, 2017Roberto CoelhoNoch keine Bewertungen

- Exam in Automatic Control II Reglerteknik II 5hp: Good Luck!Dokument10 SeitenExam in Automatic Control II Reglerteknik II 5hp: Good Luck!Armando MaloneNoch keine Bewertungen

- Non-Linear Least Squares: in General We Are Not Lucky Enough To Have A Linear Problem. in This CaseDokument49 SeitenNon-Linear Least Squares: in General We Are Not Lucky Enough To Have A Linear Problem. in This CaseSyarif HidayatNoch keine Bewertungen

- International Journal of C Numerical Analysis and Modeling Computing and InformationDokument7 SeitenInternational Journal of C Numerical Analysis and Modeling Computing and Informationtomk2220Noch keine Bewertungen

- Outline: SamplingDokument43 SeitenOutline: Samplingdjoseph_1Noch keine Bewertungen

- Sec6 Steepest AscentDokument13 SeitenSec6 Steepest AscentSaheed A BusuraNoch keine Bewertungen

- B KLDokument4 SeitenB KL53melmelNoch keine Bewertungen

- Farz6 PosterDokument1 SeiteFarz6 PosterFarzaneh SedighiNoch keine Bewertungen

- Fast Signal Processing Algorithms Week 3Dokument58 SeitenFast Signal Processing Algorithms Week 3M Ali NaeemNoch keine Bewertungen

- Assignment 1Dokument1 SeiteAssignment 1Hafizuddin AdzharNoch keine Bewertungen

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)Von EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)Noch keine Bewertungen

- Calculus on Heisenberg Manifolds. (AM-119), Volume 119Von EverandCalculus on Heisenberg Manifolds. (AM-119), Volume 119Noch keine Bewertungen

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportVon EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNoch keine Bewertungen

- Difference Equations in Normed Spaces: Stability and OscillationsVon EverandDifference Equations in Normed Spaces: Stability and OscillationsNoch keine Bewertungen

- TD Quintolubric 888 68Dokument2 SeitenTD Quintolubric 888 68Haitham YoussefNoch keine Bewertungen

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Dokument51 SeitenThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloNoch keine Bewertungen

- Online Examination System For AndroidDokument7 SeitenOnline Examination System For AndroidSri Sai UniversityNoch keine Bewertungen

- Piping Handbook - Hydrocarbon Processing - 1968Dokument140 SeitenPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- Simatic EKB Install 2012-03-08Dokument2 SeitenSimatic EKB Install 2012-03-08Oton SilvaNoch keine Bewertungen

- Optimizing Technique-Grenade Explosion MethodDokument18 SeitenOptimizing Technique-Grenade Explosion MethodUday Wankar100% (1)

- Comparative Tracking Index of Electrical Insulating MaterialsDokument6 SeitenComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNoch keine Bewertungen

- Compact 40/25Dokument58 SeitenCompact 40/25znim04Noch keine Bewertungen

- Biodegradability of SurfactantsDokument1 SeiteBiodegradability of SurfactantsTinnysumardiNoch keine Bewertungen

- Fluid Mechanics Seventh Edition by Frank M. WhiteDokument1 SeiteFluid Mechanics Seventh Edition by Frank M. WhiteDarKaiserNoch keine Bewertungen

- Teaching Finite Element Analysis For Design Engineers: August 2011Dokument7 SeitenTeaching Finite Element Analysis For Design Engineers: August 2011Nelu CheluNoch keine Bewertungen

- Genius Publication CatalogueDokument16 SeitenGenius Publication CatalogueRaheel KhanNoch keine Bewertungen

- Antikythera MechanismDokument25 SeitenAntikythera MechanismchetansergiurazvanNoch keine Bewertungen

- A9K CatalogueDokument152 SeitenA9K CatalogueMohamed SaffiqNoch keine Bewertungen

- Stock # Carbon Weight Burn Temp Puncture StrengthDokument8 SeitenStock # Carbon Weight Burn Temp Puncture StrengthMintNoch keine Bewertungen

- Ammonia Production From Natural Gas-Haldor Topsoe ProcessDokument22 SeitenAmmonia Production From Natural Gas-Haldor Topsoe ProcessYash BhimaniNoch keine Bewertungen

- Oracle Jrockit Mission Control Lab GuideDokument17 SeitenOracle Jrockit Mission Control Lab GuideashuhegdeNoch keine Bewertungen

- Internship Report May 2016Dokument11 SeitenInternship Report May 2016Rupini RagaviahNoch keine Bewertungen

- EM230 BR BM3 Fitting InstructionsDokument2 SeitenEM230 BR BM3 Fitting InstructionsRoman BabaevNoch keine Bewertungen

- Supplier GPO Q TM 0001 02 SPDCR TemplateDokument6 SeitenSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoNoch keine Bewertungen

- Turbin 1Dokument27 SeitenTurbin 1Durjoy Chakraborty100% (1)

- Cbse PMT 2012Dokument33 SeitenCbse PMT 2012Vishal RamakrishnanNoch keine Bewertungen

- Estimate SR 14-15 02 KHANDEKARDokument5 SeitenEstimate SR 14-15 02 KHANDEKARAkshay SavvasheriNoch keine Bewertungen

- Component Modeling - HDokument5 SeitenComponent Modeling - HVasu IyerNoch keine Bewertungen

- Riscv SpecDokument32 SeitenRiscv SpeckartimidNoch keine Bewertungen

- HiraDokument30 SeitenHiravijay kumar singhNoch keine Bewertungen

- Experiment 5 DACDokument3 SeitenExperiment 5 DACABHISHEK SHARMANoch keine Bewertungen

- WEISER Locks and HardwareDokument24 SeitenWEISER Locks and HardwareMaritime Door & WindowNoch keine Bewertungen

- Advance Logic Activity On CountersDokument31 SeitenAdvance Logic Activity On CountersKrinx BuliganNoch keine Bewertungen

- JDE ApplicationDokument642 SeitenJDE ApplicationAnonymous cputyzNoch keine Bewertungen