Beruflich Dokumente

Kultur Dokumente

04 Two Three Way Ball Valves For CNG Applications

Hochgeladen von

Nilesh MistryOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

04 Two Three Way Ball Valves For CNG Applications

Hochgeladen von

Nilesh MistryCopyright:

Verfügbare Formate

Two/Three Way Ball Valves

For CNG Applications

www.sealexcel.com

TWO/THREE WAY BALL VALVES

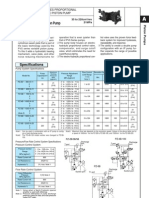

SEEALEXCEL Series BV107 mul series Ball Valves perform ono services where quick and posi ve shut o required.

The compact and rugged design having spring loaded seat for high cycle life and ensure low opera ng torque.

Features :

Applica ons :

Two/Three way Compact Design.

CNG Applica on

Trunnion Ball Design having bearing support to minimize

opera ng torque and seat wear

Instrument Air lines.

Blowout Proof Stem.

High pressure Instrument lines

General Plant Service.

Panel Moun ng.

Low Opera ng Torque.

Handle Indicates Direc on of Flow.

Opera ng Parameters :

Posi ve Handle Stops.

Pressure Ra ng

: Upto 6000 psig (408 bar) at cwp.

Spring Loaded Peek Seat ensure perfect sealing.

Temperature Ra ng

: 50 C to 160 C

Variety of End congura on includes SEALEXCEL WellLok

Tube Fi ngs, NPT/BSPT pipe connec ons.

100% Factory tested.

Sr. No.

Part Descrip on

Material

Material of Construc on :

1.

Handle / Insert

Nylon / Brass

2.

Handle Screw

Stainless Steel

3.

Panel Nut

SS316

4.

Stem ORing

Viton

5.

Stem

SS316

2

3

11

6.

Connector End Seal

PTFE

4

5

6

12

13

14

7.

Port End Connector

SS316

8.

Seat Retainer

SS316

9.

Seat Spring

SS301

15

10.

Seat

PEEK

11.

Stem Backup

PTFE

12.

Stem Oring Backup

PTFE

13.

Stem Washer

PEEK

14.

Stem Bearing

PEEK

15.

Seat Retainer Oring

Viton

16.

Seat Retainer Oring Backup

PTFE

17.

Seat Retainer Guide

SS316

18.

Ball

SS316

19.

Valve Body

SS316

16

17

18

19

10

Flow Data

Orice 0.187 (4.8 mm)

Valve

Pressure Drop

to Atmosphere

( p) PSI

Air SCFM Water GPM

at 70O F (20O C) at 70O F(20O C)

2Way

1500

840

46

Cv = 1.2

6000

3300

93

3Way

1500

530

29

Cv = 0.75

6000

2100

58

Tes ng

Standard Test : Each valve is factory tested with nitrogen

at 1000 psig (69 bar) for leakage at the seat and packing,

the maximum allowable leak rate of 0.1 sccm

Optional Hydrostatic test : This test is performed with

deionised water at 1.5 time the working pressure.

1.06

0.55

0.38 max. panel thickness

29/32 panel hole

drill

TWO WAY 2BV107

End Connec on

Valve Type

Inlet

3Way

B

A

2Way

0.55

0.38 max. panel thickness

29/32 panel hole

drill

2.125

1.50

1.06

2.125

1.50

THREE WAY 3BV107

Orice

Outlet

inch (mm)

1/8 Female NPT

1/8 Female NPT

0.187 (4.8)

1/4 Female NPT

1/4 Female NPT

1/4 WellLok

Cv

Dimensions (inches)

Ordering Number

1.2

2.94

1.47

2BV107FF2NEK

0.187 (4.8)

1.0

3.94

1.97

2BV107FF4NEK

1/4 WellLok

0.187 (4.8)

1.6

4.14

2.07

2BV107TT250EK

3/8 WellLok

3/8 WellLok

0.187 (4.8)

1.4

4.38

2.19

2BV107TT375EK

1/2 WellLok

1/2 WellLok

0.187 (4.8)

1.0

4.60

2.30

2BV107TT500EK

6mm WellLok

6mm WellLok

0.187 (4.8)

1.6

4.14

2.07

2BV107TT6MEK

8mm WellLok

8mm WellLok

0.187 (4.8)

1.5

4.14

2.07

2BV107TT8MEK

10mm WellLok

10mm WellLok

0.187 (4.8)

1.3

4.40

2.20

2BV107TT10MEK

12mm WellLok

12mm WellLok

0.187 (4.8)

1.0

4.60

2.30

2BV107TT12MEK

1/8 Female NPT

1/8 Female NPT

0.187 (4.8)

0.75

2.94

1.47

3BV107FF2NEK

1/4 Female NPT

1/4 Female NPT

0.187 (4.8)

0.75

3.94

1.97

3BV107FF4NEK

1/4 WellLok

1/4 WellLok

0.187 (4.8)

0.75

4.14

2.07

3BV107TT250EK

3/8 WellLok

3/8 WellLok

0.187 (4.8)

0.75

4.38

2.19

3BV107TT375EK

1/2 WellLok

1/2 WellLok

0.187 (4.8)

0.75

4.60

2.30

3BV107TT500EK

6mm WellLok

6mm WellLok

0.187 (4.8)

0.75

4.14

2.07

3BV107TT6MEK

8mm WellLok

8mm WellLok

0.187 (4.8)

0.75

4.14

2.07

3BV107TT8MEK

10mm WellLok

10mm WellLok

0.187 (4.8)

0.75

4.40

2.20

3BV107TT10MEK

12mm WellLok

12mm WellLok

0.187 (4.8)

0.75

4.60

2.30

3BV107TT12MEK

Dimensions are for reference only and subject to change without no ce

Viton is the registered trademark of Dupont

Catalog No. BV107814

Das könnte Ihnen auch gefallen

- Autoclave Subsea Ball ValvesDokument20 SeitenAutoclave Subsea Ball Valvesvp989Noch keine Bewertungen

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDokument6 SeitenAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNoch keine Bewertungen

- Three Way ValvesDokument8 SeitenThree Way ValvesWalter JosephNoch keine Bewertungen

- H 07121 Choke ManifoldDokument2 SeitenH 07121 Choke ManifoldmonokoeNoch keine Bewertungen

- 'C' Series Control ValvesDokument12 Seiten'C' Series Control Valvesابزار دقیق100% (1)

- Valvulas Diafragma InformacionDokument4 SeitenValvulas Diafragma InformacionCHRISTIANCHIROQUENoch keine Bewertungen

- Air Vacuum ValvesDokument4 SeitenAir Vacuum ValvesmariuspiNoch keine Bewertungen

- PressureDokument84 SeitenPressureHangloque GabanoNoch keine Bewertungen

- FlowMon Catalogue 2Dokument12 SeitenFlowMon Catalogue 2dhanu_aquaNoch keine Bewertungen

- Equilibar Hygienic FD Series Back Pressure RegulatorDokument4 SeitenEquilibar Hygienic FD Series Back Pressure RegulatorEquilibarNoch keine Bewertungen

- Pressure Releif ValveDokument24 SeitenPressure Releif Valvemtalha_loveNoch keine Bewertungen

- Series 826YD Specification SheetDokument2 SeitenSeries 826YD Specification SheetFEBCONoch keine Bewertungen

- Apco Airvacuum Valves Avv Sales 601Dokument8 SeitenApco Airvacuum Valves Avv Sales 601Jhony MedranoNoch keine Bewertungen

- Fisher SUB 250Dokument6 SeitenFisher SUB 250shuyuanz6595Noch keine Bewertungen

- Needle ValvesDokument38 SeitenNeedle ValvesRavichandran MohanNoch keine Bewertungen

- Hoke Needle ValvesDokument38 SeitenHoke Needle ValvesmartinvandoornNoch keine Bewertungen

- 67 FRDokument8 Seiten67 FRFabian De Jesus Aragon GomezNoch keine Bewertungen

- CP 220 PDFDokument10 SeitenCP 220 PDFLITONNoch keine Bewertungen

- PRH09 PDFDokument4 SeitenPRH09 PDFengp3077Noch keine Bewertungen

- Check-Mate: Ram and Uni-Drum Package Selection GuideDokument11 SeitenCheck-Mate: Ram and Uni-Drum Package Selection Guidevasuraj002Noch keine Bewertungen

- SRC Alpha Version1 PDFDokument26 SeitenSRC Alpha Version1 PDFRajat JainNoch keine Bewertungen

- Enerpac High Pressure Hand PumpsDokument2 SeitenEnerpac High Pressure Hand PumpsMachineryengNoch keine Bewertungen

- 63 Injection Sampling AssembliesDokument4 Seiten63 Injection Sampling AssembliesAbdul Hannan NazeerNoch keine Bewertungen

- Paxtonengineeringbulletin PipingDokument4 SeitenPaxtonengineeringbulletin PipingMuhammadObaidullahNoch keine Bewertungen

- Pipe RoutingDokument4 SeitenPipe RoutingJaykumarNoch keine Bewertungen

- Delta Et Vacuum SystemDokument16 SeitenDelta Et Vacuum SystemsanjeevnnNoch keine Bewertungen

- Unique Single Seat Valve-Simply UniqueDokument8 SeitenUnique Single Seat Valve-Simply UniquelggomezupbNoch keine Bewertungen

- Oxygen Lance SystemDokument31 SeitenOxygen Lance SystemsirishaNoch keine Bewertungen

- Automatski Odzracni Ventil - CaleffiDokument4 SeitenAutomatski Odzracni Ventil - CaleffiNovica BanicevicNoch keine Bewertungen

- Lift Check ValvesDokument4 SeitenLift Check Valveslejyoner62Noch keine Bewertungen

- 3" Iron Model T-20: Smith Meter® PD Rotary Vane MeterDokument4 Seiten3" Iron Model T-20: Smith Meter® PD Rotary Vane MeterSeka Vilar SorucoNoch keine Bewertungen

- Catalogo de Shut Off (PF)Dokument8 SeitenCatalogo de Shut Off (PF)luis_d_mNoch keine Bewertungen

- SAE J189-1998 Power Steering Return Hose - Low PressureDokument5 SeitenSAE J189-1998 Power Steering Return Hose - Low Pressurekhhose100% (1)

- C72H NorgrenDokument4 SeitenC72H NorgrenHernando HerreraNoch keine Bewertungen

- KV20Dokument59 SeitenKV20Junior Francisco QuijanoNoch keine Bewertungen

- Catálogo Válvula DirecionalDokument20 SeitenCatálogo Válvula DirecionalcristianoclemNoch keine Bewertungen

- Parker - FiltrosDokument16 SeitenParker - FiltrosLaerteBessaMatias1Noch keine Bewertungen

- E-Self Priming PumpsDokument27 SeitenE-Self Priming PumpsTeguh SetionoNoch keine Bewertungen

- CKEI enDokument2 SeitenCKEI enSergio MasinNoch keine Bewertungen

- Reservoir Accessories: Filler Breathers, Strainers, Diffusers, Fluid Level/Temperature GaugesDokument15 SeitenReservoir Accessories: Filler Breathers, Strainers, Diffusers, Fluid Level/Temperature GaugesPartsGopher.comNoch keine Bewertungen

- Dynex PF 1300 SpecsDokument7 SeitenDynex PF 1300 SpecsAdeel HassanNoch keine Bewertungen

- Unique SSV - Tank OutletDokument6 SeitenUnique SSV - Tank OutletlggomezupbNoch keine Bewertungen

- SideWinder 40 60 80 CHMCL PMP BrchreDokument4 SeitenSideWinder 40 60 80 CHMCL PMP BrchreSH McNoch keine Bewertungen

- Api 598Dokument13 SeitenApi 598SurachaiAumongkolNoch keine Bewertungen

- Control Choke Valve 9000Dokument8 SeitenControl Choke Valve 9000sabi_shi100% (2)

- Pedrollo CP 25-200ADokument4 SeitenPedrollo CP 25-200AChristian Ve GaNoch keine Bewertungen

- CP 25 PedrolloDokument4 SeitenCP 25 PedrolloDeivid Hernandez100% (1)

- Air Valves-Complete (Dragged)Dokument2 SeitenAir Valves-Complete (Dragged)ArmandoNoch keine Bewertungen

- Rig DesginDokument25 SeitenRig DesginImam PranadipaNoch keine Bewertungen

- Rig DesginDokument25 SeitenRig Desginriobm100% (1)

- Accessories: Value Series GaugesDokument8 SeitenAccessories: Value Series GaugesarmandotrifulcaNoch keine Bewertungen

- Air Release 2014Dokument4 SeitenAir Release 2014Aly AnisNoch keine Bewertungen

- Cokebuster: A Proven SolutionDokument11 SeitenCokebuster: A Proven Solutionengg_mech77Noch keine Bewertungen

- Fisher 67cfrDokument8 SeitenFisher 67cfrTuấn Anh NguyễnNoch keine Bewertungen

- All About HidrolicDokument7 SeitenAll About Hidrolicpiteng1945100% (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationVon EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationBewertung: 4.5 von 5 Sternen4.5/5 (21)

- 2015 Q1 - Intertek - MalaysiaDokument1 Seite2015 Q1 - Intertek - MalaysiaNilesh MistryNoch keine Bewertungen

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesDokument10 SeitenWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryNoch keine Bewertungen

- Supplier Quality Assurance ManualDokument29 SeitenSupplier Quality Assurance ManualNilesh Mistry0% (1)

- Resources Industrial Thomson ValveLineCard OnlineversionDokument4 SeitenResources Industrial Thomson ValveLineCard OnlineversionNilesh MistryNoch keine Bewertungen

- Valve Con STR FeaturesDokument1 SeiteValve Con STR FeaturesNilesh MistryNoch keine Bewertungen

- VS3 VS6 Instrumentation ValvesDokument2 SeitenVS3 VS6 Instrumentation ValvesNilesh MistryNoch keine Bewertungen

- Cat Acvbr9000Dokument16 SeitenCat Acvbr9000Nilesh MistryNoch keine Bewertungen

- Instrumentation Tube: Tube and Tube AccessoriesDokument4 SeitenInstrumentation Tube: Tube and Tube AccessoriesNilesh MistryNoch keine Bewertungen

- Tech Ascend CNC Student ManualDokument42 SeitenTech Ascend CNC Student ManualabyzenNoch keine Bewertungen

- 02 Precision Pipe FittingsDokument28 Seiten02 Precision Pipe FittingsNilesh MistryNoch keine Bewertungen

- 11 Why Sealexcel Tube FittingsDokument20 Seiten11 Why Sealexcel Tube FittingsNilesh MistryNoch keine Bewertungen

- Quick Release Coupling: CouplingsDokument3 SeitenQuick Release Coupling: CouplingsNilesh MistryNoch keine Bewertungen

- L&T Globe Control ValvesDokument4 SeitenL&T Globe Control ValvesNilesh MistryNoch keine Bewertungen

- 08 Push in Fittings For PneumaticDokument20 Seiten08 Push in Fittings For PneumaticNilesh MistryNoch keine Bewertungen

- L&T Gate Globe Check Valves API 602Dokument12 SeitenL&T Gate Globe Check Valves API 602Nilesh MistryNoch keine Bewertungen

- ValvesDokument13 SeitenValvesNilesh MistryNoch keine Bewertungen

- Unlock-B31.3 Process Piping Course - 01 IntroductionDokument19 SeitenUnlock-B31.3 Process Piping Course - 01 IntroductionProkopNoch keine Bewertungen

- Marley ValveDokument4 SeitenMarley ValveM Fadli AzhariNoch keine Bewertungen

- Dimensi Pompa DESMIDokument8 SeitenDimensi Pompa DESMIDeddyNoch keine Bewertungen

- PDFDokument100 SeitenPDFharshkumar patelNoch keine Bewertungen

- Fluid Flow CalculationsDokument11 SeitenFluid Flow CalculationsmbaliNoch keine Bewertungen

- 3600 Marine Engine Application and Installation Guide: PipingDokument10 Seiten3600 Marine Engine Application and Installation Guide: PipingmikelinchpNoch keine Bewertungen

- Coiled Tubing BHA ManualDokument12 SeitenCoiled Tubing BHA ManualSamuel OnyewuenyiNoch keine Bewertungen

- Saes J 001Dokument11 SeitenSaes J 001Ramy KamalNoch keine Bewertungen

- AE307 Final SolutionDokument12 SeitenAE307 Final SolutionHüseyin Anıl ÖztürkNoch keine Bewertungen

- CCI Скороc Кинетич Энерг Рабоч Сред Регулир Трим Control Valve Trim Fluid Kinetic Energy Velocity 2007Dokument9 SeitenCCI Скороc Кинетич Энерг Рабоч Сред Регулир Трим Control Valve Trim Fluid Kinetic Energy Velocity 2007derbyolaNoch keine Bewertungen

- Cim & SKS Price List DT 10-Nov-2021Dokument6 SeitenCim & SKS Price List DT 10-Nov-2021ISRAR SHAHNoch keine Bewertungen

- Experiment No: 5: Measurement of Co-Efficient of Discharge For An Orifice MeterDokument7 SeitenExperiment No: 5: Measurement of Co-Efficient of Discharge For An Orifice MeterManoj guptaNoch keine Bewertungen

- Tip Loss Corrections For Wind Turbine Computations - Shen PDFDokument19 SeitenTip Loss Corrections For Wind Turbine Computations - Shen PDFJose Da SilvaNoch keine Bewertungen

- Gas LiftDokument35 SeitenGas LiftHìnhxămNơigóckhuấtTimAnh100% (1)

- Glass Lined PipingDokument6 SeitenGlass Lined PipingPawel MielnikNoch keine Bewertungen

- Edward Forged Steel Catalog PDFDokument132 SeitenEdward Forged Steel Catalog PDFThái Mai ĐìnhNoch keine Bewertungen

- R2B P3 206 02 P HD 00211 - Datasheet For OnOff - Ball Valves, U 21000 - Rev.1Dokument49 SeitenR2B P3 206 02 P HD 00211 - Datasheet For OnOff - Ball Valves, U 21000 - Rev.1Diana Paula Echartea MolinaNoch keine Bewertungen

- Introduction To Fluids in MotionDokument3 SeitenIntroduction To Fluids in MotionEditor IJRITCCNoch keine Bewertungen

- VONBERG Check - Valve - Poppet INLINE 10301 500 - Series PDFDokument1 SeiteVONBERG Check - Valve - Poppet INLINE 10301 500 - Series PDFFahrul Nur ArifinNoch keine Bewertungen

- 5 Pressure Relief ValvesDokument11 Seiten5 Pressure Relief ValvesNyoman RakaNoch keine Bewertungen

- Pipeline Calculation PDFDokument7 SeitenPipeline Calculation PDFZulfitrizulkarnain ZulkarnainNoch keine Bewertungen

- Type Ahw2Dokument8 SeitenType Ahw2Mamiherintsoa Issaia RanaivoarimananaNoch keine Bewertungen

- Katalog Fitting KomanDokument18 SeitenKatalog Fitting KomanDavidNoch keine Bewertungen

- 3 PumpDokument19 Seiten3 PumpAzhar SabriNoch keine Bewertungen

- Pressure Shut-Off Valve, Pilot Operated Types DA and DAWDokument12 SeitenPressure Shut-Off Valve, Pilot Operated Types DA and DAWÂnderson Silva BrasilNoch keine Bewertungen

- Assignment 4Dokument10 SeitenAssignment 4mahmoud EissaNoch keine Bewertungen

- Design and Selection Criteria For Check ValvesDokument26 SeitenDesign and Selection Criteria For Check Valvesmhopgood100% (3)

- Basic Flow MeasurementDokument50 SeitenBasic Flow MeasurementjashkishoreNoch keine Bewertungen

- MSS SP 61-Pressure Testing of ValvesDokument10 SeitenMSS SP 61-Pressure Testing of ValvesharishcsharmaNoch keine Bewertungen

- 2.25 Advanced Fluid Mechanics: MIT Department of Mechanical EngineeringDokument6 Seiten2.25 Advanced Fluid Mechanics: MIT Department of Mechanical EngineeringLorenzo YapNoch keine Bewertungen