Beruflich Dokumente

Kultur Dokumente

002 Working at Height Risk Assessment

Hochgeladen von

gangadharan000Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

002 Working at Height Risk Assessment

Hochgeladen von

gangadharan000Copyright:

Verfügbare Formate

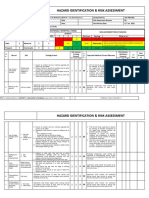

HAZARD IDENTIFICATION & RISK ASSESSMENT

Location

(Department/Project):

CONSTRUCTION OF 3 SCHOOLS GROUP 7A (PACKAGE 3)

Conducted by:

Muhammad Ibrahim

Date:

Checked by:

Bernardo Mercado

Date:

MAIN

ACTIVITY

10 Jun

2013

11th Jun

2013

Assessment No.

TAK-RISK-002

Risk Assessment Revision

00

Next Review Date

12th Jun. 2013

Working at Heights (Applicable to R.A # 5, 6, 9 & 26)

RISK ANALYSIS

LIKELIHO

OD

th

VALU

E

SEVERITY

VALU

E

LIKELIHOOD(L) X SEVERITY(S) =

RISK(R)

SEVERITY

LIKELIHO

3

2

1

OD

RISK ASSESSMENT RESULT RANKING

Risk

Score

Ranking

Unlikely

Minor

69

High(H)

Likely

Moderate

34

Medium(

M)

Frequent

Catastroph

ic

12

Low(L)

No.

Hazard

Risk

Existing Control

NOTE: For detailed definition of SEVERITY, LIKELIHOOD & RANKING, please refer to TAK-014 REV. 0

Risk

Analysis

(Existing

Control)

L

S

R

1st

Eva

l.

What to do?

Immediate attention and action required. Shall consider

whether to eliminate or modify the activitiy. (Stop the

work.)

Specific monitoring procedures required, management

responsibility must be specified. Shall consider what

can be done to eliminate the risk to prevent any

negative outcomes.

Manage through routine procedures.

Can proceed with the activity as planned

Required Additional

Control Measures

Risk

Analysis

(Additional

Controls)

L

S

R

2nd

Eval

.

FORM NO. TAK-014-002 REV. 0

Final

Evaluation

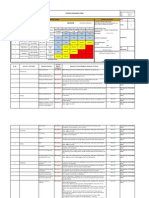

HAZARD IDENTIFICATION & RISK ASSESSMENT

1.

Operatives must ensure to wear full

body harness while working @ height

of 2 m and the lanyard hook properly

secured to rigid post strong enough

to support weight of persons working

2.

1.

Use of fixed and mobile

scaffold

Multiple body injury due to

collapse of scaffold

3.

4.

2.

Moving on the platform

Fall from height

1.

Ensure to conduct tool box

meeting regarding the proper use

of scaffold.

Ensure erection of aluminium

scaffold must be done according

to manufacturer guidelines.

Ensure the erection/dismantling of

scaffold must be done by certified

scaffolder.

Only attached green tag scaffold

will be used and refrain from using

red tag scaffold.

Use of ladder (straight

and A-Type)

1.

2.

Fall from heights

Ladder fall or tip-over

NOTE: For detailed definition of SEVERITY, LIKELIHOOD & RANKING, please refer to TAK-014 REV. 0

Worksites

Supervisors

shall

monitor the operatives and

ensure to wear safety harness

1.

3.

3.

Ensure to conduct tool box

meeting regarding the correct use

of ladder

4. Operatives must ensure to check

the ladder prior to use.

Oil or slippery on rungs

Rungs and rails are not split or

broken

Feet, slips locks and spreader

are working.

5. Operatives must ensure to wear

full body harness while working @

height of 2 m and the lanyard

hook properly secured to rigid

post strong enough to support

weight of persons working

6. Ensure to assigned people

holding the ladder below while

people working on top.

2.

2.

M

3.

Prior to start of job,

supervisor to assess the

working

at

elevation

irrespective of the height and

consider

primary

fall

protection

devices

for

heights.

Supervisor to assess the

physical

condition

and

competence

of

persons

assigned for the job, duration

of the job and weather

conditions.

Prior to start of job,

supervisor to assess the

working

at

elevation

irrespective of the height and

consider

primary

fall

protection

devices

for

heights.

Supervisor to assess the

physical

condition

and

competence

of

persons

assigned for the job, duration

of the job and weather

conditions.

Work that involves restricted

vision or hot work such as

welding or oxy cutting should

preferably not be performed

from a ladder. Preference

should be given to the use of

temporary work platforms

FORM NO. TAK-014-002 REV. 0

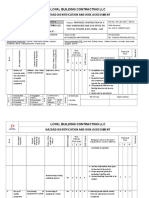

HAZARD IDENTIFICATION & RISK ASSESSMENT

1.

4.

Spillage and loose

materials/tools

1.

2.

Slip

Trips

2.

1.

5.

Tools, equipment and

materials from height.

Body injury of person

working down under due to

accidental fall.

2.

3.

6.

Flying/airborne particles

7.

Striking objects hit with

installed protruding

utilities

Eye injury

1.

2.

Eye injury

Head injury.

Platform is kept neat, tidy and free

of loose materials/tools. Spillage

shall be cleaned up immediately

using absorbent materials and

any slippery surfaces cleaned and

degreased.

Maintain

good

housekeeping

around the work area.

Operatives shall ensure that all

items of equipment and tools are

positioned in a safe and secured

manner.

Never place any tool near the

edge of working platform if not

secured.

Operatives shall ensure to use

rope or basket for lifting of

materials

Operatives shall ensure to wear the

correct eye protection for the task at

hand ie goggles when grinding,

handling chemicals etc.

Operatives shall remain vigilant when

moving around the platform and

ensure to wear hard hat and eye

protection always to avoid head

injury.

NOTE: For detailed definition of SEVERITY, LIKELIHOOD & RANKING, please refer to TAK-014 REV. 0

Worksites

Supervisors

shall

monitor

the

standards

of

housekeeping during routine

walk around and implement

clean ups when necessary

Supervisors shall monitor the

position of all plant, tools and

equipment to ensure that it is

safe and secure.

Supervisor shall monitor the

workforce during routine walk

around to ensure that they are

wearing the correct type of PPE.

Supervisor shall monitor the

workforce during routine walk

around to ensure that they are

wearing the correct type of PPE.

FORM NO. TAK-014-002 REV. 0

HAZARD IDENTIFICATION & RISK ASSESSMENT

NOTE: For detailed definition of SEVERITY, LIKELIHOOD & RANKING, please refer to TAK-014 REV. 0

FORM NO. TAK-014-002 REV. 0

Das könnte Ihnen auch gefallen

- Risk Assessment - Lifting OperationsDokument6 SeitenRisk Assessment - Lifting OperationsJishad Nalakath83% (87)

- Risk Assesment 16 - Pre - Assembly and Erection ofDokument7 SeitenRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNoch keine Bewertungen

- Aboveground Piping Installation Works 2016Dokument7 SeitenAboveground Piping Installation Works 2016Aldrin75% (4)

- Risk assessment for excavation worksDokument3 SeitenRisk assessment for excavation worksYaser A. Al-Bustanji72% (18)

- Working at Height Risk AssessmentDokument7 SeitenWorking at Height Risk AssessmentAshish100% (3)

- Forklift Risk AssessmentDokument6 SeitenForklift Risk AssessmentMoayed Altaweel76% (29)

- HEALTH & SAFETY RISK ASSESSMENTDokument52 SeitenHEALTH & SAFETY RISK ASSESSMENTmujahid113794% (36)

- Generic Risk AssessmentDokument8 SeitenGeneric Risk Assessmentmorgojoyo100% (3)

- Risk AssessmentDokument10 SeitenRisk AssessmentKyaw Kyaw Aung89% (9)

- Site Activities Risk AssessmentDokument50 SeitenSite Activities Risk Assessmentjamie542393% (41)

- Working at Height Risk AssessmentDokument2 SeitenWorking at Height Risk Assessmentvismay83% (6)

- Grinding Equipment Risk AssessmentDokument3 SeitenGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Electric Hand Drill Risk AssessmentDokument4 SeitenElectric Hand Drill Risk AssessmentTariq AkhtarNoch keine Bewertungen

- Hyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectDokument4 SeitenHyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectYounis Khan100% (1)

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONDokument6 SeitenRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanNoch keine Bewertungen

- Welding and Radiography Risk AssessmentDokument11 SeitenWelding and Radiography Risk AssessmentAldrin75% (8)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDokument12 SeitenRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Risk Assessment - Confined Space Entry - Labours Work Inside The Pipe08122011-1Dokument4 SeitenRisk Assessment - Confined Space Entry - Labours Work Inside The Pipe08122011-1nayakya40% (5)

- Risk AssessmentDokument4 SeitenRisk AssessmentSyedQamarIqbal50% (2)

- Hot Work Risk Assessment and PermitDokument3 SeitenHot Work Risk Assessment and Permitstitchvn75% (12)

- RISK ASSES-105-Erection of Steel Structure BuildinDokument4 SeitenRISK ASSES-105-Erection of Steel Structure BuildinRochdi Bahiri75% (8)

- Risk Assessment For Cable InstallationDokument15 SeitenRisk Assessment For Cable InstallationKaruppu Samy86% (7)

- JSA for Night Work at Laydown AreaDokument2 SeitenJSA for Night Work at Laydown Areagulryz84100% (9)

- 13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLDokument13 Seiten13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLMARIAN100% (1)

- Hazard Identification Risk Assessment and Risk ControlDokument7 SeitenHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Risk Assessment in A Welding and Construction SiteDokument3 SeitenRisk Assessment in A Welding and Construction SiteFad Tobi75% (8)

- Risk Assessment for 10 Villa Construction ProjectDokument5 SeitenRisk Assessment for 10 Villa Construction ProjectFrancis Enriquez Tan100% (3)

- ConfinedSpace RiskAssessmentDokument9 SeitenConfinedSpace RiskAssessmentrashid zaman100% (4)

- Risk Assessment Procedures ManualDokument12 SeitenRisk Assessment Procedures ManualTony Gallacher60% (5)

- Excavation Risk Assessment SheetDokument3 SeitenExcavation Risk Assessment SheetMuhammad Ibrahim93% (45)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDokument9 SeitenHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDokument7 SeitenHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- 2.risk Assessment of Working at HeightDokument7 Seiten2.risk Assessment of Working at HeightRisal Sinu50% (2)

- LKC - Lifting Risk AssessmentDokument4 SeitenLKC - Lifting Risk AssessmentAdam EatonNoch keine Bewertungen

- Demolition Risk AssessmentDokument41 SeitenDemolition Risk AssessmentVenkadesh Periathambi100% (3)

- Working at Height Risk AssessmentDokument9 SeitenWorking at Height Risk AssessmentNebosh Diploma Assignment83% (6)

- RA-LBC-007 Risk Assessment Concrete WorksDokument8 SeitenRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- Risk Asses 65-Piping Fabricated and Assembly - H03Dokument11 SeitenRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNoch keine Bewertungen

- RA - 018 01 Scaffolding Erection and DismantlingDokument14 SeitenRA - 018 01 Scaffolding Erection and DismantlingVuong Bui95% (63)

- Incident Report: Proj. N. Unit Document Code Serial NDokument1 SeiteIncident Report: Proj. N. Unit Document Code Serial NSyed Ali HassanNoch keine Bewertungen

- RISK ASSES-106-Erection of Steel Structure BuildinDokument4 SeitenRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDokument11 SeitenRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Risk Assessment of Scaffolding Works - Rev. 1Dokument20 SeitenRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Working at Height: Activity-Based Risk Assessment FormDokument7 SeitenWorking at Height: Activity-Based Risk Assessment Formfredo100% (3)

- Jsa For Lifting (Crane) 016Dokument6 SeitenJsa For Lifting (Crane) 016aliraza572270% (27)

- Consolidated International Contractor Risk AssessmentDokument45 SeitenConsolidated International Contractor Risk Assessmentkumar100% (1)

- 1326370398-HS6-54 Use of MEWP Risk AssessmentDokument2 Seiten1326370398-HS6-54 Use of MEWP Risk AssessmentJohn David Hoyos Marmolejo83% (6)

- Project:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONDokument20 SeitenProject:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONghaleb alhourani100% (1)

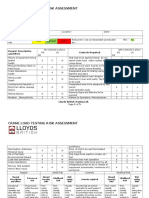

- Crane Load Testing Risk AssessmentDokument5 SeitenCrane Load Testing Risk Assessmentdel3333100% (4)

- Construction Risk Assessments IndexDokument41 SeitenConstruction Risk Assessments Indexmasoodae100% (4)

- Jsa For Civil Confined Space EntryDokument11 SeitenJsa For Civil Confined Space EntryKhuda BukshNoch keine Bewertungen

- Column Lifting & Erection JSADokument7 SeitenColumn Lifting & Erection JSAAli Mohsin100% (3)

- Concrete Formwork Suspended SlabDokument5 SeitenConcrete Formwork Suspended SlabKate HopleyNoch keine Bewertungen

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralDokument2 SeitenJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- SAFE PROCEDURES FACADE INSTALLATIONDokument12 SeitenSAFE PROCEDURES FACADE INSTALLATIONZaw Ko Ko OoNoch keine Bewertungen

- Behaviour Based Observation ChecklistDokument3 SeitenBehaviour Based Observation ChecklistVaradaraju ThirunavukkarasanNoch keine Bewertungen

- SAFE LIFTING WITH SCISSOR LIFTDokument6 SeitenSAFE LIFTING WITH SCISSOR LIFTjokerseri100% (3)

- Risk RegisterDokument37 SeitenRisk RegisterSufiyan Farooq100% (1)

- Tullow Safety Rule 3 Working at Height ChecklistDokument2 SeitenTullow Safety Rule 3 Working at Height ChecklistWanwaniouan Pomme100% (1)

- SWMS Scaffold FixedDokument11 SeitenSWMS Scaffold FixedEdha AliNoch keine Bewertungen

- AL UDEID AIR BASE RACEWAY MODIFICATION PROJECTDokument12 SeitenAL UDEID AIR BASE RACEWAY MODIFICATION PROJECTgangadharan000Noch keine Bewertungen

- Learn Hindi Through English Medium by Ratnakar NaraleDokument21 SeitenLearn Hindi Through English Medium by Ratnakar NaraleVijaya Manjoola50% (2)

- Pyrotenax IM CDE0923 PyroMiFireSurvivalCable en Tcm445 38627Dokument12 SeitenPyrotenax IM CDE0923 PyroMiFireSurvivalCable en Tcm445 38627gangadharan000Noch keine Bewertungen

- Electric Panel Feed Water TankDokument1 SeiteElectric Panel Feed Water Tankgangadharan000Noch keine Bewertungen

- Learn Hindi Through TamilDokument24 SeitenLearn Hindi Through Tamilkesavansr80% (10)

- 6 AM-IsP-I16021-MS-DR-001 Installation of Above Ground Drainage Pipes and FittingsDokument10 Seiten6 AM-IsP-I16021-MS-DR-001 Installation of Above Ground Drainage Pipes and Fittingsgangadharan000Noch keine Bewertungen

- Method of Duct Installation, Insulation, Leak TestingDokument4 SeitenMethod of Duct Installation, Insulation, Leak Testinggangadharan00067% (6)

- 23 - 26 TemperatureDokument4 Seiten23 - 26 Temperaturegangadharan000Noch keine Bewertungen

- Motor Current RM TechnicalDokument1 SeiteMotor Current RM TechnicalPhani VarmaNoch keine Bewertungen

- 2016 NETA Exam Candidate HandbookDokument48 Seiten2016 NETA Exam Candidate Handbookgangadharan0000% (1)

- 4 AM-IsP-I16021-MS-PL-001 Installation of Waterline Pipes and FittingsDokument11 Seiten4 AM-IsP-I16021-MS-PL-001 Installation of Waterline Pipes and Fittingsgangadharan000Noch keine Bewertungen

- Method Statement For Conduit Installation Including Accessories PVC & GIDokument17 SeitenMethod Statement For Conduit Installation Including Accessories PVC & GIgangadharan000100% (1)

- 3209 Bluu MS El 001Dokument7 Seiten3209 Bluu MS El 001gangadharan000Noch keine Bewertungen

- HSSE & SP Audit ProcedureDokument41 SeitenHSSE & SP Audit Proceduregangadharan000100% (3)

- UPDA QATAR - Electrical Drives (Cranes)Dokument3 SeitenUPDA QATAR - Electrical Drives (Cranes)gangadharan0000% (1)

- A1110 113 3GS A 0002Dokument69 SeitenA1110 113 3GS A 0002gangadharan000Noch keine Bewertungen

- Special Tool Risk AssessmentDokument1 SeiteSpecial Tool Risk Assessmentgangadharan000Noch keine Bewertungen

- ADDC Electricity Wiring Regulations - Mar.2014Dokument276 SeitenADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- 009 Installation of Pumps Risk AssessmentDokument2 Seiten009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Manpower HistogramDokument5 SeitenManpower Histogramgangadharan000100% (2)

- Daniel G. Oro JR.: Work ExperienceDokument6 SeitenDaniel G. Oro JR.: Work Experiencegangadharan000Noch keine Bewertungen

- Method of Statement For Installation of Wires and CablesDokument6 SeitenMethod of Statement For Installation of Wires and Cablesgangadharan000100% (3)

- Eee Interview Questions and Answers PDF - Indianitjobs4uDokument10 SeitenEee Interview Questions and Answers PDF - Indianitjobs4ugangadharan000Noch keine Bewertungen

- Fall Protection and Roof Safety Systems 2013 14Dokument24 SeitenFall Protection and Roof Safety Systems 2013 14Widiyanto WidiyantiNoch keine Bewertungen

- OSHA Ladder Safety Brochure - FinalDokument6 SeitenOSHA Ladder Safety Brochure - FinalNaveed RabbaniNoch keine Bewertungen

- Ansi A14 2 1990 PDFDokument83 SeitenAnsi A14 2 1990 PDFAndres Antonio Moreno Castro100% (1)

- Abtech Safety 2010 EmailDokument32 SeitenAbtech Safety 2010 EmailpnsanatNoch keine Bewertungen

- Hse Training Basic ScaffoldingDokument49 SeitenHse Training Basic ScaffoldingRosli Bin Abdul Shukor100% (1)

- Role of Housekeeping in Hospitality IndustryDokument63 SeitenRole of Housekeeping in Hospitality Industryshailenss67% (6)

- M119-1207 (Fallguard)Dokument38 SeitenM119-1207 (Fallguard)lidiaNoch keine Bewertungen

- Working at Height SafetyDokument71 SeitenWorking at Height SafetyAtma Prakash SinhaNoch keine Bewertungen

- CSCS Sample ExamDokument13 SeitenCSCS Sample ExamKrish DoodnauthNoch keine Bewertungen

- LadderDokument3 SeitenLadderayyapparajNoch keine Bewertungen

- Questions Bank For HSE PersonnelaDokument39 SeitenQuestions Bank For HSE PersonnelaJithu Thampi100% (3)

- Water Tower BQDokument1 SeiteWater Tower BQIsaac Mureithi MainaNoch keine Bewertungen

- AHA WorksheetDokument6 SeitenAHA WorksheetRev DezviNoch keine Bewertungen

- Topic For TBMDokument19 SeitenTopic For TBMdauxomNoch keine Bewertungen

- Ladder SafetyDokument6 SeitenLadder SafetyNaMeiNaNoch keine Bewertungen

- House Keeping Check List: Sl. No. DescriptionDokument24 SeitenHouse Keeping Check List: Sl. No. Descriptionsanjeev kumarNoch keine Bewertungen

- Design Project - Final Report (Modified)Dokument17 SeitenDesign Project - Final Report (Modified)maria_santhosh_inigoNoch keine Bewertungen

- Fire Fighting Equipment and Ladders ExplainedDokument143 SeitenFire Fighting Equipment and Ladders ExplainedMELCHOR RUFONNoch keine Bewertungen

- BoostLi Energy Storage Module Reconstruction Guide Netherlands TMNLDokument132 SeitenBoostLi Energy Storage Module Reconstruction Guide Netherlands TMNLMichael TeljeurNoch keine Bewertungen

- Orangery Construction Risk AssessmentDokument11 SeitenOrangery Construction Risk AssessmentAngela DaveyNoch keine Bewertungen

- Employee Safety HandbookDokument40 SeitenEmployee Safety HandbookcharibackupNoch keine Bewertungen

- HAGS UniPlay 205 PDFDokument116 SeitenHAGS UniPlay 205 PDFKostas PapadopoulosNoch keine Bewertungen

- Italscale - Alu MerdevineDokument46 SeitenItalscale - Alu MerdevineDajan KuzmicNoch keine Bewertungen

- Risk Assessment - FUJAIRAH LABOUR CAMPDokument4 SeitenRisk Assessment - FUJAIRAH LABOUR CAMPamenmohamm3dNoch keine Bewertungen

- Elevated Work Safety PolicyDokument33 SeitenElevated Work Safety PolicyVasant Kumar VarmaNoch keine Bewertungen

- Ladders Engineering Data Sheet Ontario - 2014Dokument5 SeitenLadders Engineering Data Sheet Ontario - 2014Eric0% (1)

- Atk - 001844-Mos-Acm-0002 - 00 - Method Statement For Formworks Cooling Tower FoundationDokument15 SeitenAtk - 001844-Mos-Acm-0002 - 00 - Method Statement For Formworks Cooling Tower Foundationtiote moussaNoch keine Bewertungen

- Portable Ladder Safety: Presented By: Steve Caldwell WHS Advisor (NTA)Dokument21 SeitenPortable Ladder Safety: Presented By: Steve Caldwell WHS Advisor (NTA)RadhaKrishnan RNoch keine Bewertungen

- TLEDokument4 SeitenTLEEspano FaithNoch keine Bewertungen

- Sheet: Reducing Falls in Construction: Safe Use of Extension LaddersDokument3 SeitenSheet: Reducing Falls in Construction: Safe Use of Extension LaddersjefhdezNoch keine Bewertungen