Beruflich Dokumente

Kultur Dokumente

Optimized 5S Office Audit

Hochgeladen von

Waqar DarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Optimized 5S Office Audit

Hochgeladen von

Waqar DarCopyright:

Verfügbare Formate

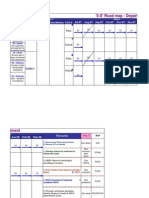

5S Production Area Audit

Location: MY office

Date:

0

Score:

Previous Score:

2

Not started; zero effort Activity started, slight

effort

Widespread activity;

however still many

opportunities for

improvement

5S No.

Description

Check Item

Detailed Audit Guide - Sort

STEP 1: Sort

1

2

3

4

5

Minimum acceptable

level sustained for at

least one (1) month

90.8

80

Best in Class results;

Manager/Superintend

ent review; Sustained

for one (1) month

Best Practice; World

Class; General

Manager review

;Sustained for at least

six (6) months

Scored by:

Me

4

3

5

3

2

STEP 1 TOTAL SCORE

Detailed Audit Guide - Straighten

7

8

9

10

11

12

13

14

17

Average 3.6

Machines, benches, etc. are arranged in a logical & neat fashion to promote a

Area layout

smooth product flow through the work area.

Lines on the floor clearly mark aisles, walkways, work areas, storage locations and

Aisles, walkways and floor markings

danger areas.

Only current labeled documents and binders necessary to do the work are stored at

Documentation and Visual signals

workstations. Documents and binders are stored in a neat and orderly manner.

Items are arranged, divided, and clearly labeled such that it is obvious where things

Visual displays and storage

are stored and if they are missing.

Tools, gages and fixtures are arranged neatly and stored, kept clean and free of any

Specific locations for fixtures & tooling

risk from damage. They are located for easy access for changeovers.

Few, if any, items are stored on the floor. Those items stored on the floor are clearly

Items on Floor

indicated with floor markings and labeling.

Liquids, solvents, flamables, and other chemicals are properly labeled and stored.

Hazmat Storage

MSDS's are available.

Safety devices are clearly marked, highly visible and unobstructed. Emergency

Emergency Access

egress routes are marked and exit signs, lights, etc. are in good condition.

Equipment is properly maintained and labeled. Critical points for daily maintenance

Equip. Maintenance

checks are clearly marked (fluid levels, etc).

3

4

5

3

2

4

4

3

4

STEP 2 TOTAL SCORE

Detailed Audit Guide - Shine

STEP 3: Shine

Average

18

All floors are clean and free of debris, oil, and dirt. Cleaning of floors is done

routinely and at appropriate predetermined intervals.

Routine cleaning of machines is apparent, there is no oil, chips, scrap laying on work

Machines/Equipment

surfaces. Glass view windows, guards, deflectors are clean & in place.

All cleaning equipment (trash cans, brooms, floor sweep, etc.) are stored in a neat

Cleaning supplies and tools manner. It is obvious where it belongs and is easily available when needed.

Hazardous materials and all storage containers are properly labeled.

All equipment, benches, fans everything in the area is cleaned on a regular basis,

Cleaning beyond machines

and ownership by operators goes beyond just the machine they run.

When unexpected delays occur, operators habitually & automatically sweep floors &

Cleaning due diligence

wipe equipment.

Where applicable, FOD prevention procedures (QPD102) are enforced. All loose

FOD Compliance

items removed before entering FOD prevention area. Shadow boxes kept clean.

15 Condition of floors

16

17

18

19

20

5

5

4

3

STEP 3 TOTAL SCORE

Detailed Audit Guide - Standardize

STEP 4: Standardize

21 Visual Control

22 Weekly/Monthly audits

23 Safety

24 Standard work

25 Methods reviewed

20

Average 3.8

Display boards are present in each production work area and accessible to all

personnel in the area.

5S audits are performed in each work area at least monthly, results are shared with

all workers and goals for new levels set with action items.

PPE notices are posted in every area and all employees are wearing the required

PPE's.

It is obvious that workers who perform similar duties, use standard methods to

achieve consistent results.

Methods are reviewed on a regular basis, and as new methods are developed, they

are quickly documented and adopted by others.

4

3

4

5

3

STEP 4 TOTAL SCORE

STEP 5: Sustain

Detailed Audit Guide - Sustain

5 Tot

Average 3.4

Only the current levels of inventory in the area is needed for the work at hand. Scrap

Components, materials & parts.

and rework items are placed in clearly marked containers.

Only the necessary items to perform the work at hand are located in the area. There

Machines, benches, cabinets & furniture.

are no unneeded machines, tools or furniture in the area.

All tools, fixtures and jigs in the area are used on a regular basis. Any items that are

Tools, fixtures & other equipment.

used less than once a day, are stored out of the way.

No outdated, torn or soiled announcements are displayed. All bulletins are arranged

Bulletin Boards

in a straight and neat manner.

Your general impression should tell you this is the best you have seen for a

First Impression Overall

manufacturing environment.

STEP 2: Straighten

26 Maintenance

27 Area Responsibility

28 Documents: Control

29 Work Area Visits

30 5S Control & Sustaining

19

Average 3.4

Employees are adequately deployed to keep equipment operating properly. A

Preventive Maintenance program is in place and functions at a high level.

Each area of the operation, inside and out, falls under the responsibility of a manager

with 5S auditing and assignment authority.

All documents and binders are clearly labeled as to their contents. Responsibility for

control & revisions is clear. Nothing is unlabeled.

Responsible manager/staff person visits each work area on a regular basis and

provides feedback on 5S efforts and results.

Disciplined controls to assure each of above items is maintained at highest level.

There is a sense of responsibility by all employees to maintain systems.

4

3

3

3

4

STEP 5 TOTAL SCORE

Overall Average:

3.6

OVERALL SCORE

17

90.8

5S Office Area Audit

Location:

Date:

0

Score:

Previous Score:

1

Not started; zero effort Activity started, slight

effort

5S No.

Check Item

STEP 1: Sort

1

Office Supplies

Desks, chairs, cabinets &

furniture.

Documents, Files & Folders.

Bulletin Boards

First Impression Overall

2

Widespread activity;

however still many

opportunities for

improvement

3

Minimum acceptable

level sustained for at

least one (1) month

Best in Class results;

Manager/Superintend

ent review; Sustained

for one (1) month

Best Practice; World

Class; General

Manager review

;Sustained for at least

six (6) months

Description

Average:

Scored by:

Score

Work station arrangement

Aisles and hallways

Documentation and Visual

signals

Tables, shelves and cabinets

10 Closets and storage

###

Average:

###

Desks, tables and files are arranged in a logical & neat fashion to promote a smooth

flow of information through the work area.

Hallways and walk areas are free from materials, obstructions. Nothing leans

against walls, and exits are clearly marked.

Only current labeled documents and binders necessary to do the work are stored at

workstations. Documents and binders are stored in a neat and orderly manner.

Tables, shelves and cabinets are free of surface clutter. No papers or objects are

sitting on top of cabinets waiting to be filed.

Closets and storage areas are clean, well lit with clearly designated storage locations

for all items. It is easy to find what you need, and return it.

STEP 2 TOTAL SCORE

STEP 3: Shine

11

12

13

14

15

5 Tot

Only the current levels of office supplies in the area are needed for the work at hand.

There are no excess forms, paper, pens.

Only the necessary items to perform the work are located in the area. There are no

unneeded tables, chairs, cabinets... in the area.

Only the documents used on a regular basis are stored in the area. Old and dated

material is removed on a regular basis.

No outdated, torn or soiled announcements are displayed. All bulletins are arranged

in a straight and neat manner.

Your general impression should tell you this is the best you have seen for an office

area.

STEP 1 TOTAL SCORE

STEP 2: Straighten

Average:

###

All floors are clean and free of debris, oil, and dirt. Cleaning of floors is done

Condition of floors

routinely and at appropriate predetermined intervals.

Desks, computer screens, and office equipment is clean and free from dust or soil.

Equipment and furniture

All office equipment is in excellent working order.

All walls, cubical dividers, and windows are kept clean on a regular basis. Unsuitable

Walls, cubical and windows

conditions are promptly addressed.

All electrical connections are within specifications, there are no potential overloads.

Electrical Usage

Portable heaters and other appliances are used only in safe locations.

Storage of Cleaning Equipment All cleaning equipment (vacuums, trash cans) are stored in a neat manner. It is

and supplies

obvious where things belong, and available when needed.

STEP 3 TOTAL SCORE

STEP 4: Standardize

16 Standard work

17 Methods reviewed

18 Visual Display

19 Visual Control

20 Monthly audits

Average:

###

It is obvious that workers who perform similar duties, use standard methods to

achieve consistent results.

Methods are reviewed on a regular basis, and as new methods are developed, they

are quickly documented and adopted by others.

Display boards are present in each designated work area and accessible to all

personnel in the area.

Standard methods sheets and visual aids are present in the area, they are stored in

neat and logical locations, with fast and easy access to workers.

5S audits are performed in each work area at least monthly, results are shared with

all workers and goals for new levels set with action items.

STEP 4 TOTAL SCORE

STEP 5: Sustain

21 Maintenance

22 Document Control

23 Area Responsibility

24 Supervisor Area Visits

25 5S Control & Sustaining

Average:

###

Employees are adequately deployed to keep office equipment and computers

operating properly.

All documents are labeled clearly as to contents. Responsibility for control &

revisions is clear. Nothing is unlabeled or unclear as to its origin/source.

Each area of the operation, inside and out, falls under the responsibility of a manager

with 5S auditing and assignment authority.

Responsible manager/staff person visits each work area on a regular basis and

provides feedback on 5S efforts and results.

Disciplined controls to assure each of above items is maintained at highest level.

There is a sense of responsibility by all employees to maintain systems.

STEP 5 TOTAL SCORE

Overall Average:

###

OVERALL SCORE

Das könnte Ihnen auch gefallen

- 5 S Presentation Basic TrainingDokument82 Seiten5 S Presentation Basic TrainingEmman Bosito100% (1)

- Office 5S ChecklistDokument15 SeitenOffice 5S ChecklisttahirNoch keine Bewertungen

- 5S/TPM Meeting Summary and Audit ToolsDokument5 Seiten5S/TPM Meeting Summary and Audit ToolsChatnoir NoirNoch keine Bewertungen

- 5S Audit Check Sheet: Department: - Completed By: - Supervisor: - DateDokument1 Seite5S Audit Check Sheet: Department: - Completed By: - Supervisor: - DateP K Senthil Kumar33% (3)

- 5S Audit ChecklistDokument5 Seiten5S Audit ChecklistZahid Hussain100% (3)

- 5S Audit FormDokument2 Seiten5S Audit Formmounirs719883Noch keine Bewertungen

- 5S ManualDokument23 Seiten5S ManualBittuNoch keine Bewertungen

- 5S Office Area Audit ScorecardDokument2 Seiten5S Office Area Audit ScorecardNavnath Tamhane100% (2)

- 5S Audit ChecklistDokument5 Seiten5S Audit ChecklistDaniel2116Noch keine Bewertungen

- The Secret To Japanese SuccessDokument51 SeitenThe Secret To Japanese Successshahzaiblatafat12Noch keine Bewertungen

- 6S Levels of Achievement Matrix Self AssessmentDokument3 Seiten6S Levels of Achievement Matrix Self AssessmentAnbalagan Ravichandran100% (1)

- 5S Diagnostic ChecklistDokument6 Seiten5S Diagnostic Checklistvikkasverma.in50% (2)

- Presentation 6 S STARTER TrainingDokument96 SeitenPresentation 6 S STARTER Trainingm_ramas2001Noch keine Bewertungen

- 5S Audit Checklist Documents Standardization and Continuous ImprovementDokument10 Seiten5S Audit Checklist Documents Standardization and Continuous ImprovementJamal AbdullahNoch keine Bewertungen

- 5S Implementation Plan at Work PlaceDokument18 Seiten5S Implementation Plan at Work PlacemanishlmehtaNoch keine Bewertungen

- 5S Audit FormDokument1 Seite5S Audit FormViorel IosubNoch keine Bewertungen

- 5S Routine Audit FormDokument8 Seiten5S Routine Audit Formblackbarby100% (3)

- 5S Audit Checklist - ShopfloorDokument6 Seiten5S Audit Checklist - Shopfloortony s0% (1)

- 5S Audit SheetDokument3 Seiten5S Audit Sheetleansensei67% (3)

- QE (5S) Responsibilities and RolesDokument3 SeitenQE (5S) Responsibilities and RolesAdie Caberte0% (1)

- 5S Monthly Audit ChecklistDokument6 Seiten5S Monthly Audit ChecklistZahid Hussain50% (2)

- 5S Levels of ExcellenceDokument2 Seiten5S Levels of ExcellenceAshokNoch keine Bewertungen

- 5S ImplementationDokument35 Seiten5S ImplementationPrateek Gupta100% (1)

- WI QMS 01 5S ImplementationDokument19 SeitenWI QMS 01 5S ImplementationDisha Shah100% (3)

- Strategy for Performance ExcellenceDokument31 SeitenStrategy for Performance ExcellenceMahesh KumarNoch keine Bewertungen

- 5S Audit SheetDokument3 Seiten5S Audit SheetMohamed SalaheldinNoch keine Bewertungen

- 5S Check SheetDokument8 Seiten5S Check SheetDONNoch keine Bewertungen

- 5S Training and ImplementationDokument66 Seiten5S Training and ImplementationLlehk FranciscoNoch keine Bewertungen

- 5S Implementation Plan at Work PlaceDokument18 Seiten5S Implementation Plan at Work Placebrock100% (24)

- 6s AuditchecklistDokument14 Seiten6s Auditchecklisthasan_waqar20040% (1)

- 5S Training OfficeDokument21 Seiten5S Training OfficeDhiraj Pradhan100% (1)

- 6S Audit Draft)Dokument3 Seiten6S Audit Draft)pikeman666100% (3)

- 5s Training Slides 432Dokument60 Seiten5s Training Slides 432vg_raj100% (3)

- 5S Audit ChecklistDokument12 Seiten5S Audit Checklistmogul_hunkNoch keine Bewertungen

- 5 S Information and Training OutlineDokument5 Seiten5 S Information and Training Outlinekprasad_mlNoch keine Bewertungen

- 5S Roles and ResponsibilitiesDokument5 Seiten5S Roles and Responsibilitiessenk197100% (1)

- 5S Pocket GuideDokument28 Seiten5S Pocket Guidesathyabalaraman100% (3)

- 5S Evaluation SheetDokument8 Seiten5S Evaluation SheetNashwa SaadNoch keine Bewertungen

- 5S Implementation GuideDokument24 Seiten5S Implementation GuideRajesh Sahasrabuddhe100% (1)

- Advance 5S AuditsDokument21 SeitenAdvance 5S AuditsPhạm Thanh VấnNoch keine Bewertungen

- 5S Principles and ApplicationDokument168 Seiten5S Principles and ApplicationLuzviminda Rustia Capili MoralesNoch keine Bewertungen

- 5S - Levels of ExcellenceDokument2 Seiten5S - Levels of ExcellenceHartoyo SwiNoch keine Bewertungen

- 5S VariousFormsDokument14 Seiten5S VariousFormssragen_cuk96% (23)

- Seiri Audit ChecklistDokument4 SeitenSeiri Audit Checklistthephaiduong100% (1)

- MMI Industries 6S Audit ChecklistDokument2 SeitenMMI Industries 6S Audit ChecklistAisyah Nabilah Johary100% (7)

- 5S Checklist OkDokument2 Seiten5S Checklist Okmichelle ann100% (1)

- Implement 5S ManagementDokument3 SeitenImplement 5S ManagementSivakumaar Nagarajan100% (2)

- 5S For OfficesDokument3 Seiten5S For OfficesckopoletoNoch keine Bewertungen

- 06 5s Implementation Plan and Training Guide v20130618Dokument13 Seiten06 5s Implementation Plan and Training Guide v20130618thouraya hsan100% (1)

- UNI-DIL 5S REVAMP MASTER PLANDokument1 SeiteUNI-DIL 5S REVAMP MASTER PLANDayal Weerasooriya100% (4)

- 5S Implementation Plan UploadDokument21 Seiten5S Implementation Plan UploadRahul KumarNoch keine Bewertungen

- 5SDokument67 Seiten5SAnonymous Ln4luWFd100% (3)

- Design for Six SIGMA Complete Self-Assessment GuideVon EverandDesign for Six SIGMA Complete Self-Assessment GuideBewertung: 1 von 5 Sternen1/5 (1)

- Manufacturing Facilities A Complete Guide - 2019 EditionVon EverandManufacturing Facilities A Complete Guide - 2019 EditionNoch keine Bewertungen

- 5S Audit FormDokument2 Seiten5S Audit Formsigmasundar100% (1)

- 5 S ChecklistsDokument11 Seiten5 S Checklistsjahazi2Noch keine Bewertungen

- 5S ChecklistsDokument5 Seiten5S ChecklistsRheneir MoraNoch keine Bewertungen

- Category Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftDokument109 SeitenCategory Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftblitzkrigNoch keine Bewertungen

- PAKISTAN HOSIERY MANUFACTURERS & EXPORTERS ASSOCIATION PROVISIONAL LIST OF VOTERSDokument74 SeitenPAKISTAN HOSIERY MANUFACTURERS & EXPORTERS ASSOCIATION PROVISIONAL LIST OF VOTERSWaqar DarNoch keine Bewertungen

- Be Your Best Executive Summary PDFDokument2 SeitenBe Your Best Executive Summary PDFsridharchebroluNoch keine Bewertungen

- Trace - 2020-07-28 09 - 59 - 45 300Dokument7 SeitenTrace - 2020-07-28 09 - 59 - 45 300Waqar DarNoch keine Bewertungen

- Great Meetings Executive Summary PDFDokument2 SeitenGreat Meetings Executive Summary PDFKalyan Kumar100% (1)

- Oee Pocket GuideDokument2 SeitenOee Pocket GuideBaroszNoch keine Bewertungen

- Ifa Audit Oee Action PDFDokument1 SeiteIfa Audit Oee Action PDFAngelikaNoch keine Bewertungen

- OEE Manual Top Loss ReportDokument2 SeitenOEE Manual Top Loss ReportAnzarNawazNoch keine Bewertungen

- FBA Quick Start en-US PDFDokument26 SeitenFBA Quick Start en-US PDFАнна ОрлеоглоNoch keine Bewertungen

- 100 Question - FPM - Summer19 - KEYDokument14 Seiten100 Question - FPM - Summer19 - KEYWaqar DarNoch keine Bewertungen

- File 02 PDFDokument107 SeitenFile 02 PDFWaqar DarNoch keine Bewertungen

- Be Your Best Executive Summary PDFDokument2 SeitenBe Your Best Executive Summary PDFsridharchebroluNoch keine Bewertungen

- Domestic Gas Connection Process Flow ChartDokument1 SeiteDomestic Gas Connection Process Flow ChartWaqar DarNoch keine Bewertungen

- File 02 PDFDokument107 SeitenFile 02 PDFWaqar DarNoch keine Bewertungen

- Realme Service Center Locations and Contact Details in Major Pakistani CitiesDokument1 SeiteRealme Service Center Locations and Contact Details in Major Pakistani CitiesusamaNoch keine Bewertungen

- FBA Quick Start en-US PDFDokument26 SeitenFBA Quick Start en-US PDFАнна ОрлеоглоNoch keine Bewertungen

- Cresent BahumanDokument7 SeitenCresent BahumanWaqar DarNoch keine Bewertungen

- File 02 PDFDokument107 SeitenFile 02 PDFWaqar DarNoch keine Bewertungen

- Epaper - EPaperDokument1 SeiteEpaper - EPaperWaqar DarNoch keine Bewertungen

- Primavera Project Planner P6 Homework No. 1:: Submitted ToDokument5 SeitenPrimavera Project Planner P6 Homework No. 1:: Submitted ToWaqar DarNoch keine Bewertungen

- Quality Audit Plan - SNGPL: Purpose: Audit Scope: Audit TeamDokument2 SeitenQuality Audit Plan - SNGPL: Purpose: Audit Scope: Audit TeamWaqar DarNoch keine Bewertungen

- Resource ID Resource Description Unit of Measure Resource TypeDokument4 SeitenResource ID Resource Description Unit of Measure Resource TypeWaqar DarNoch keine Bewertungen

- Wa0004Dokument1 SeiteWa0004Waqar DarNoch keine Bewertungen

- MBTI TestsDokument31 SeitenMBTI TestsWaqar DarNoch keine Bewertungen

- BU Const ActivitiesDokument7 SeitenBU Const ActivitiesWaqar DarNoch keine Bewertungen

- Time and Motion StudyDokument25 SeitenTime and Motion StudyWaqar DarNoch keine Bewertungen

- Key matching questions and analogiesDokument40 SeitenKey matching questions and analogiesWaqar DarNoch keine Bewertungen

- Primavera Project Planner P6 Assignment No. 1:: Bahria University, Lahore Campus (BULC)Dokument4 SeitenPrimavera Project Planner P6 Assignment No. 1:: Bahria University, Lahore Campus (BULC)Waqar DarNoch keine Bewertungen

- Wa0018Dokument4 SeitenWa0018Waqar DarNoch keine Bewertungen

- Brief (Ali Ahmed) - CHAIN COSTDokument11 SeitenBrief (Ali Ahmed) - CHAIN COSTWaqar DarNoch keine Bewertungen

- Process Groups PMBOKDokument1 SeiteProcess Groups PMBOKWaqar DarNoch keine Bewertungen

- EC 351 AC Analog Communication Lab ManualDokument117 SeitenEC 351 AC Analog Communication Lab Manualhodibaaba1Noch keine Bewertungen

- Radiography 2 ProcedureDokument9 SeitenRadiography 2 ProceduresheikmoinNoch keine Bewertungen

- Ulei Honda Jazz 1.4i CVTDokument1 SeiteUlei Honda Jazz 1.4i CVTcmlad1Noch keine Bewertungen

- Description Wincc Project Scanner enDokument9 SeitenDescription Wincc Project Scanner enDugPigeonNoch keine Bewertungen

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDokument8 SeitenC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNoch keine Bewertungen

- SemaphoreDokument29 SeitenSemaphoreSaranya ThangarajNoch keine Bewertungen

- 11 Iso 10110Dokument28 Seiten11 Iso 10110fmeylanNoch keine Bewertungen

- DISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFDokument16 SeitenDISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFedmarrobNoch keine Bewertungen

- High-Efficiency Controllers for Notebook ComputersDokument28 SeitenHigh-Efficiency Controllers for Notebook ComputerscNoch keine Bewertungen

- Lars Part Ix - Safety Managment System Requirements-SmsDokument24 SeitenLars Part Ix - Safety Managment System Requirements-SmssebastienNoch keine Bewertungen

- Diamond Pin Locator and V Blocks 1Dokument8 SeitenDiamond Pin Locator and V Blocks 1pratik thakareNoch keine Bewertungen

- Banyule Standard DrawingsDokument103 SeitenBanyule Standard DrawingsTarek AbulailNoch keine Bewertungen

- P28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayDokument8 SeitenP28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayFreddy de los SantosNoch keine Bewertungen

- Physical and Chemical Changes Lab ReportDokument5 SeitenPhysical and Chemical Changes Lab ReportWilliam CarriereNoch keine Bewertungen

- Panasonic Model TG6511FXDokument82 SeitenPanasonic Model TG6511FXLakiLakicNoch keine Bewertungen

- PW DebugDokument2 SeitenPW DebugAimeeFieldsNoch keine Bewertungen

- Alcatel Support Document For Cable System in CubaDokument11 SeitenAlcatel Support Document For Cable System in CubaDEGNISSODENoch keine Bewertungen

- Chapter 5-The Memory SystemDokument80 SeitenChapter 5-The Memory Systemjsanandkumar22Noch keine Bewertungen

- 72.core Cut Reference SP-24Dokument1 Seite72.core Cut Reference SP-24DMJ NagpurNoch keine Bewertungen

- Sae j419 1983 Methods of Measuring Decarburization PDFDokument8 SeitenSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiNoch keine Bewertungen

- Drum Unloading SystemDokument2 SeitenDrum Unloading SystemJas SumNoch keine Bewertungen

- GaAs solar cell modeling improves efficiencyDokument4 SeitenGaAs solar cell modeling improves efficiencyTarak BenslimaneNoch keine Bewertungen

- Database Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyDokument2 SeitenDatabase Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyStan DitonaNoch keine Bewertungen

- SPECIFICATION WRITING MODULEDokument3 SeitenSPECIFICATION WRITING MODULEHana YeppeodaNoch keine Bewertungen

- Building A Big Data Platform For Smart Cities: Experience and Lessons From SantanderDokument8 SeitenBuilding A Big Data Platform For Smart Cities: Experience and Lessons From SantanderDylan GuedesNoch keine Bewertungen

- The Golden Rules For PilotsDokument4 SeitenThe Golden Rules For PilotsSE KotariNoch keine Bewertungen

- Supports For Pipelines 1758uk 7-03-15 PDFDokument46 SeitenSupports For Pipelines 1758uk 7-03-15 PDFAndor MolitoriszNoch keine Bewertungen

- LHR IndstryDokument84 SeitenLHR Indstryabubakar09ect50% (2)

- 1.2 Beams With Uniform Load and End Moments: CHAPTER 1: Analysis of BeamsDokument8 Seiten1.2 Beams With Uniform Load and End Moments: CHAPTER 1: Analysis of Beamsabir ratulNoch keine Bewertungen

- Aqap2120 Ed 1 PDFDokument18 SeitenAqap2120 Ed 1 PDFmaccione4311Noch keine Bewertungen