Beruflich Dokumente

Kultur Dokumente

Redman Fisher GRP Brochure 2013

Hochgeladen von

lukebrown92Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Redman Fisher GRP Brochure 2013

Hochgeladen von

lukebrown92Copyright:

Verfügbare Formate

GRP Product Guide

flowGRiP

flowtread

phenolic

flowgrate

safety

structures

Redman Fisher GRP

Redman Fisher have offered GRP flooring for 25 years and through

continued development have become the leading manufacturer

of GRP access systems and standard products from design, through to

fabrication and installation.

Redman Fisher also design, manufacturer and install mild steel,

stainless steel and aluminium grating, handrails and structures, offering

a total solutions approach.

Site installation is provided by Access Design and Engineering

a Redman Fisher division.

Quality is maintained through effective and efficient quality systems

based on BS EN ISO 9001: 2000.

REGISTRATION NUMBER: 76856

Contents

FlowGRiP flooring and covers

Page 3

flowGRiP

Page 4

Flowtread Grating

flowtread

Page 4

Phenolic Grating

phenolic

Page 5

Flowgrate Moulded Grating

flowgrate

Page 6-7

Load Tables

loads

Page 8

fixings

Page 9

Stairtreads and Fixings

Adjustable Grating Supports

Safety Access Systems

safety

Handrails, Ladders and Structures

Page 10

structures

Page 11

Redman Fisher GRP Applications

applics

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

FlowGRiP

flowGRiP

flooring and covers

GRP FlowGRiP plank flooring is a pultruded, one piece construction, interlocking tongue

and groove flooring system for large spans and specialist applications. Used where solid

flooring is required for odour control or dropped object protection. FlowGRiPs increased

strength allows clear spans up to 1400mm clear span with 5kN/m2 load.

Available with slots, for drainage, meeting 15mm dropped object specification for

offshore use. FlowGRiP provides excellent impact and loading characteristics and is

fast and easy to install with low maintenance. FlowGRiP flooring conforms to

BS4592 Part4 1992 and BS5395 Part3 1985.

Grating Depth

Standard Panel Size

Open Area %

Approx. Weight Kg/m2

40mm solid

500 x 6000

19

40mm solid

600 x 6000

16

40mm solid

600 x 6000 LD

13

40mm slotted

500 x 6000

14% (14 x 38mm)

18

LD = Light Duty

NFR and Fire Retardant options*

BS476 Part 7 Class 1, ASTM E-84, ASTM D635

Resin

Chemical Resistance**

Isophthalic Polyester

Good

Vinylester

Excellent

* NFR: Non-Fire Retardant

** Contact our technical department for Chemical Resistance Guide

Colour***

Grey BS00A05/Yellow BS08E53

***Most RAL / BS colours available

Far left:

Slotted FlowGRiP

Right:

Solid FlowGRiP

Flush-fitting Stainless

or Galvanised steel

recessed handles are

available for FlowGRiP

flooring to aid removal

of panels and reduce

the risk of trips.

Redman Fisher GRP Composites Division

Hinged Covers can

GRP edge channel

be fitted to FlowGRiP

banding is available in

to provide access or

the standard colours

inspection points.

of grey or yellow.

Tel 01952 685110

www.redmanfisher.co.uk

Flowtread Grating

flowtread

Flowtread is a Pultruded grating system manufactured using I section load bearing bars

mechanically locked and bonded to transverse bars for maximum strength.

Flowtread grating is suitable for wide spans whilst offering a large open area for drainage.

1500mm Clear span for 5kN/m2. Flowtread conforms to BS4592 Part 4 1992 and

BS5395 Part 3 1985 and withstands a 5kJ impact.

Grating Depth

Mesh Size mm

Standard Panel

Open Area %

Weight Kg/m2

25mm

38 x 150

1000 x 6000

60

15

38mm

38 x 150

1000 x 6000

60

19

Resin

Fire Retardant

BS476 Part 7 Class 1,

ASTM E-84, ASTM D635

Chemical

Resistance*

Colour

Grey RAL 7038

Yellow RAL 1021

Isophthalic Polyester

Good

Vinylester

Excellent

* Contact our technical department for Chemical Resistance Guide

Phenolic Grating

PH-S

Phenolic Flowgrate and Flowtread Type PH Gratings provide

ultimate performance where Fire Resistance, Low Smoke and

Toxicity emissions are critical. Designed to withstand prolonged

fire exposure without sustaining structural damage.

US Coastguard Level 2 is available for Offshore applications.

phenolic

With the added advantages of:

High strength

Lightweight

Corrosion Resistance

Anti-Slip

PH-SQ

Grating

Thickness

Panel Size mm

Weight/m2

Mesh

Open %

USCG

Flowgrate PH-S

41mm

3660 x 1220

22 Kg

Solid

Flowgrate PH-SQ

38mm

3660 x 1220

18 kg

38x38

68%

Flowgrate PH-R

38mm

3660 x 1220

20 Kg

150x38

55%

Flowtread PH

38mm

6000 x 1000

20 Kg

150x38

60%

Colour: Orange/Brown

PH-R

Please contact our sales office for our product data sheet.

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

Flowgrate Moulded Grating

flowgrate

Flowgrate open mesh and solid top grating is a cost effective, lightweight solution for Walkways,

Platforms, Gullies, Trenches and Mezzanines, offering good chemical resistance together

with excellent anti-slip properties. Flowgrate is easy to install and available in a variety of

thickness and mesh sizes.

Thickness (mm)

Panel Size (mm)

Mesh (mm)

Open Area %

Appx Weight Kg/m2

13

3660 x 1220

50 x 50

72

25

3660 x 1220

25 x 100

65

13

25

3660 x 1220

38 x 38

70

12

40

3660 x 1220

38 x 38

70

18

40

3660 x 1220

19 x 19

34

24*

50

3660 x 1220

50 x 50

72

20*

* Also available with 3mm gritted solid top

Resin

Colour*

Features

Isophthalic Polyester

Dark Grey RAL 7043

Chemical Resistant, Fire Retardant to BS476 Part 7 Class 1, ASTM - E84 and ASTM - D635

Isophthalic Vinylester

Light Grey RAL 7040

Enhanced Chemical Resistance, Fire Retardant to ASTM - E84 and ASTM - D635

Phenolic**

Brown

Excellent Fire Retardant Properties, Meets BS476 Part 7 Class 0 and US Coastguard Approval

* Other colours Green RAL 6017, Yellow RAL 1003

** See Phenolic Data sheet

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

FlowGRiP

FlowGRiP

Uniform Distributed Loads (UDL) kN/m2

Concentrated Loads (C/L) kN/m width

flowGRiP

FlowGRiP solid

(500mm wide)

Span (mm)

FlowGRiP slotted

(500mm wide)

FlowGRiP solid

(600mm LD)

FlowGRiP solid

(500mm wide)

FlowGRiP slotted

(500mm wide)

FlowGRiP solid

(600mm LD)

UDL

(kN/m2)

Deflection

(mm)

UDL

(kN/m2)

Deflection

(mm)

UDL

(kN/m2)

Deflection

(mm)

Deflection

UDL

(kN/m width) (mm)

UDL

Deflection

(kN/m width) (mm)

UDL

Deflection

(kN/m width) (mm)

268.8

1.30

268.86

1.40

125.13

1.10

54.12

1.5

50.66

1.5

22.52

1.5

300

161.5

2.00

148.08

2.00

89.66

2.00

37.85

2.0

34.88

2.0

17.05

400

91.48

2.50

83.14

2.50

51.85

2.50

27.30

2.5

24.91

2.5

12.99

2.5

500

56.19

3.00

50.78

3.00

32.28

3.00

20.30

3.0

18.46

3.0

10.06

3.00

600

36.74

3.50

33.08

3.50

21.30

3.50

15.66

3.5

14.14

3.5

7.95

3.50

700

25.24

4.00

22.67

4.00

14.72

4.00

12.36

4.0

11.13

4.0

6.39

4.00

800

18.04

4.50

16.18

4.50

10.57

4.50

9.98

4.5

8.97

4.5

5.24

4.50

900

13.32

5.00

11.93

5.00

7.83

5.00

8.21

5.0

7.37

5.0

4.35

5.00

1000

10.11

5.50

9.04

5.50

5.96

5.50

6.87

5.5

6.15

5.5

3.67

5.50

1100

7.84

6.00

7.01

6.00

4.63

6.00

5.83

6.0

5.21

6.0

3.13

6.00

1200

6.2

6.50

5.54

6.50

3.67

6.50

5.00

6.5

4.47

6.5

2.7

6.50

1300

4.99

7.00

4.46

7.00

2.96

7.00

4.34

7.0

3.87

7.0

2.35

7.00

1400

4.07

7.50

3.63

7.50

2.41

7.50

3.79

7.5

3.39

7.5

2.07

7.50

1500

3.37

8.00

3.00

8.00

2.00

8.00

3.35

8.0

2.99

8.0

1.83

8.00

1600

2.81

8.50

2.51

8.50

1.67

8.50

2.97

8.5

2.65

8.5

1.63

8.50

1700

2.38

9.00

2.12

9.00

2.66

9.0

2.37

9.0

1.46

9.00

1800

2.02

9.50

1.80

9.50

2.39

9.5

2.13

9.5

1.31

9.50

1900

1.74

10.00

1.55

10.00

2.16

10.0

1.93

10.0

1.19

10.00

2000

Clear span Deflection limited to L/200

1.50 kN/m2

2075mm

2016mm

1763mm

3.00 kN/m2

1664mm

1601mm

1393mm

5.00 kN/m2

1401mm

1346mm

1169mm

7.50 kN/m2

1218mm

1173mm

1015mm

Flowtread Gratings

flowtread

Flowtread Gratings

Uniform Distributed Loads (UDL) kN/m

Concentrated Load (kN/300mm width at mid span)

25mm (38x38)

38mm (38x38)

Span (mm)

UDL

(kN/m2)

25mm

Deflection

(mm)

UDL

(kN/m2)

40mm

Deflection

(mm)

Span (mm)

C/L

(kN)

Deflection

(mm)

C/L

(kN)

Deflection

(mm)

300

177.28

1.5

449.51

1.5

300

33.24

1.5

84.28

1.5

400

74.79

2.0

189.64

2.0

400

18.70

2.0

47.41

2.0

500

42.18

2.5

111.89

2.5

500

13.18

2.5

34.97

2.5

600

24.41

3.0

64.75

3.0

600

9.15

3.0

24.28

3.0

700

16.09

3.5

44.11

3.5

700

7.04

3.5

19.30

3.5

800

10.78

4.0

29.55

4.0

800

5.39

4.0

14.78

4.0

900

7.78

4.5

22.05

4.5

900

4.38

4.5

12.40

4.5

1000

5.67

5.0

16.07

5.0

1000

3.55

5.0

10.05

5.0

1100

4.35

5.5

12.08

5.5

1100

2.99

5.5

8.30

5.5

1200

3.35

6.0

9.76

6.0

1200

2.51

6.0

7.32

6.0

1300

2.64

6.5

7.68

6.5

1300

2.14

6.5

6.24

6.5

1400

2.11

7.0

6.15

7.0

1400

1.85

7.0

5.38

7.0

1500

1.72

7.5

5.0

7.5

1500

1.61

7.5

4.68

7.5

1600

1.41

8.0

4.12

8.0

1600

1.41

8.0

4.12

8.0

1700

3.43

8.5

1700

3.65

8.5

1800

2.89

9.0

1800

3.25

9.0

1900

2.46

9.5

1900

2.92

9.5

2000

2.11

10.0

2000

2.63

10.0

2100

1.73

10.0

2100

2.28

10.0

2200

1.44

10.0

2200

1.98

10.0

UDL

Clear span Deflection limited to L/200

1.50 kN/m2

1569mm

2177mm

3.00 kN/m2

1245mm

1778mm

5.00 kN/m2

1043mm

1500mm

7.50 kN/m2

911mm

1310mm

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

C/L

Phenolic Gratings

Phenolic Gratings

phenolic

Concentrated Load (kN/300mm width at mid span)

Uniform Distributed Loads (UDL) kN/m

38mm Square

Moulded

38mm Rectangular 40mm Rectangular

Moulded Superspan Pultruded

38mm Square

Moulded

38mm Rectangular 40mm Rectangular

Moulded Superspan Pultruded

Mesh

38x38mm

38x152mm

38x152mm

Mesh

38x38mm

38x152mm

38x152mm

Span (mm)

UDL

(kN/m2)

UDL

(kN/m2)

UDL

(kN/m2)

Span (mm)

C/L

(kN)

Deflection

(mm)

C/L

(kN)

Deflection

(mm)

C/L

(kN)

Deflection

(mm)

300

214.23 1.5

131.83 1.5

400

90.38

2.0

55.62

2.0

479.87 1.5

300

40.17

1.5

24.72

1.5

98.18

1.5

202.44 2.0

400

22.60

2.0

13.90

2.0

55.20

500

46.27

2.5

58.84

2.0

2.5

103.65 2.5

500

14.46

2.5

18.39

2.5

35.33

600

21.05

3.0

2.5

46.82

3.0

67.03

3.0

600

7.89

3.0

17.56

3.0

24.53

700

13.26

3.0

3.5

29.49

3.5

42.21

3.5

700

5.80

3.5

12.90

3.5

20.51

800

3.5

8.88

4.0

22.92

4.0

28.28

4.0

800

4.44

4.0

11.46

4.0

15.70

4.0

900

6.24

4.5

16.10

4.5

19.86

4.5

900

3.07

4.5

9.06

4.5

13.70

4.5

1000

4.55

5.0

11.74

5.0

14.48

5.0

1000

2.48

5.0

7.34

5.0

11.09

5.0

1100

3.42

5.5

8.82

5.5

10.88

5.5

1100

2.05

5.5

6.06

5.5

9.46

5.5

1200

2.63

6.0

6.79

6.0

8.38

6.0

1200

1.72

6.0

5.09

6.0

7.94

6.0

1300

2.07

6.5

5.34

6.5

6.59

6.5

1300

1.47

6.5

4.34

6.5

6.77

6.5

1400

1.66

7.0

4.28

7.0

5.28

7.0

1400

1.27

7.0

3.74

7.0

5.84

7.0

1500

1.35

7.5

3.48

7.5

4.29

7.5

1500

1.10

7.5

3.26

7.5

5.08

7.5

1600

2.87

8.0

3.53

8.0

1600

2.87

8.0

4.47

8.0

1700

2.39

8.5

2.95

8.5

1700

2.54

8.5

3.96

8.5

1800

2.01

9.0

2.48

9.0

1800

2.26

9.0

3.53

9.0

1900

1.71

9.5

2.11

9.5

1900

2.03

9.5

3.17

9.5

2000

1.47

10.0

1.81

10.0

2000

1.83

10.0

2.86

10.0

2100

1.49

10.0

2100

2.47

10.0

2200

2.15

10.0

2300

1.88

10.0

Deflection

(mm)

Deflection

(mm)

Deflection

(mm)

Clear span Deflection limited to L/200

flowgrate

1.50 kN/m2 1447mm

1985mm

2096mm

3.00 kN/m2 1149mm

1576mm

1690mm

5.00 kN/m2 969mm

1329mm

1425mm

7.50 kN/m2 846mm

1161mm

1245mm

Flowgrate Gratings

Flowgrate Gratings

Uniform Distributed Loads (UDL) kN/m2

Concentrated Load (kN/300mm width at mid span)

25mm

38mm

50mm

25mm

38mm

Mesh

38x38mm

38x38mm

50x50mm

Mesh

38x38mm

38x38mm

50x50mm

Span (mm)

UDL

(kN/m2)

Deflection

(mm)

UDL

(kN/m2)

Deflection

(mm)

UDL

(kN/m2)

Span (mm)

C/L

(kN)

Deflection

(mm)

C/L

(kN)

Deflection

(mm)

C/L

(kN)

Deflection

(mm)

300

34.53

1.5

80.67

1.5

153.73 1.5

300

6.47

1.5

15.13

1.5

28.82

1.5

400

14.57

2.0

34.03

2.0

64.85

2.0

400

3.64

2.0

8.51

2.0

16.21

2.0

500

7.96

2.5

22.74

2.5

39.89

2.5

500

2.49

2.5

7.11

2.5

12.47

2.5

600

4.61

3.0

13.16

3.0

28.37

3.0

600

1.73

3.0

4.94

3.0

10.64

3.0

700

3.01

3.5

9.04

3.5

17.87

3.5

700

1.32

3.5

3.95

3.5

7.82

3.5

800

2.02

4.0

6.77

4.0

14.09

4.0

800

1.01

4.0

3.39

4.0

7.05

4.0

900

1.42

4.5

4.76

4.5

10.28

4.5

900

0.80

4.5

2.68

4.5

5.78

4.5

1000

3.47

5.0

7.49

5.0

1000

0.65

5.0

2.17

5.0

4.68

5.0

1100

2.61

5.5

5.98

5.5

1100

0.53

5.5

1.79

5.5

4.11

5.5

1200

2.14

6.0

4.60

6.0

1200

1.61

6.0

3.45

6.0

1300

1.69

6.5

3.62

6.5

1300

1.37

6.5

2.94

6.5

1400

1.35

7.0

2.90

7.0

1400

1.18

7.0

2.54

7.0

1500

2.36

7.5

1500

1.03

7.5

2.21

7.5

1600

1.94

8.0

1600

1.94

8.0

1700

1.62

8.5

1700

1.72

8.5

1800

1.36

9.0

1800

1.53

9.0

1.50 kN/m2

883mm

1352mm

1744mm

3.00 kN/m2

701mm

1049mm

1384mm

5.00 kN/m2

591mm

902mm

1167mm

7.50 kN/m2

517mm

773mm

1020mm

Deflection

(mm)

50mm

Clear span Deflection limited to L/200

Redman Fisher GRP Composites Division

UDL

Tel 01952 685110

www.redmanfisher.co.uk

C/L

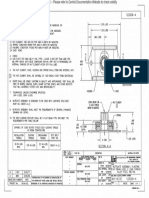

Stairtreads and Fixings

GRP stairtreads are supplied with a high visibility anti-slip nosing, available with fixings and optional GRP support angles.

Maximum recommended tread width 1000mm Complies with load requirements of BS4592 Pt 4.

FlowGRiP

Flowtread

150mm

WIDTH

LENGTH

Flowgrate

WIDTH

LENGTH

40mm

15mm

50X50mm GRP

ANGLE

125mm

40mm

15mm

15mm

50X50mm GRP

ANGLE

125mm

30mm

30mm

50X50mm GRP

ANGLE

125mm

30mm

CD-02-1

CD-12-1

CD-13-1

CD-02-2

CD-02-2

CD-13-2

CD-68-1

CD-13-1

CD-71

CD-11-2

CD-13-2

Fixings available in 316 Stainless and Galvanised mild steel also suitable for use with Phenolic gratings.

Adjustable Grating Supports

Work Stations and Raised Flooring 50mm to 600mm.

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

Safety Access Systems

35% of major work injuries are caused by slips and trips. Our systems are

designed to help reduce this hazard, relieving the expensive of down-time

and insurance claims.

safety

Safety Access Systems offers a complete range of products to help

improve safety in dry, wet or oily conditions.

Safety Flat Sheet

Advantages

Minimal preparation

Ready for immediate use

Suitable for use over Chequer Plate, Concrete, Open Grating and Timber

Corrosion resistant

High visibility

Range of anti-slip grades

Fixings can be supplied

Retrofit or new build

Made to measure

Landings

Slip Resistance

DIN 51 130 Ramp Test: (Maximum Value: R13)

Grade

Value

Fine

R12

Medium

R13

Coarse

R12

TRRL Pendulum Test: Coefficient of Friction

Grade

Wet

Dry

Fine

Satisfactory

Excellent

Medium

Excellent

Excellent

Coarse

Excellent

Excellent

Safety Tread Covers

Availability

Product

Size

Safety Flat Sheet

3 x 1.25m

Landings

2.5 x 1m

Safety Tread Covers

Going: 100 to 350mm

Width: up to 3m

Ladder Rung Covers

Rung: 100 to 350mm

Sizes: 19, 25 and 30mm

Safety Timber Sheet

Thickness: 13, 18, 24 and 30mm

Panels: up to 1.5m x 3m

Safety Adhesive Tapes

Width: 20mm to 1m

Length: 18m

Ladder Rung Covers

Self-Adhesive Tapes

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

10

Handrails, Ladders and Structures

structures

Handrails and Screens

Redman Fisher GRP handrails offer a lightweight corrosion

resistant system, manufactured to suit the loading requirements of:

BS6180 and BS EN ISO 14122. Side or base mounted systems can be

supplied pieced small or in pre-fabricated frames for site installation

Ladders

Redman Fisher GRP Ladders are manufactured in accordance

with the dimensional requirements of:

BS4211 1994, Specification for ladders for permanent access

to chimneys, other high structures, silos and bins

BS5395 Part3 1985, Code of Practice for the design of industrial

type stairs, permanent ladders and walkways

Structures

Redman Fisher GRP structures are fabricated with profiles

manufactured using the latest pultrusion process, offering lightweight

and high strength GRP sections, providing a cost effective alternative

to steel. (Up to 50% weight of equivalent steel structure.)

Drawings and structural calculations can be provided where required.

Comparative costs

Maintenance

Installation

Surface Treatment

Cutting and

fabrication

Fabrication/Machining

Our extensive facilities

ensure grating and

structures can be cut

and fabricated ready

to install.

Design

GRP

STEEL

ST/STEEL

Material

Site Installation

Redman Fisher operates an ISO 9001-2000 quality system, for the design, manufacture and site

installation of GRP, Steel and Aluminium Flooring and structures.

Our installation teams have full accreditation in CITB (Construction Industry Training Board),

CSCS (Construction Skills Certificate Scheme) and IPAF (International Power Access Federation).

Redman Fisher GRP Composites Division

Tel 01952 685110

www.redmanfisher.co.uk

11

Redman Fisher GRP Applications

Product type

Application

Examples

Chemical and process

Chemical Resistant

Corrosion Resistant

Low Maintenance

Non-Sparking

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Water and waste treatment

Odour Control

Lightweight

High Strength

Corrosion Resistant

Anti-slip

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Rail and transport

Lightweight

Anti-Slip

Fire Retardant

Non-Conductive

Low Smoke and Toxicity

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Offshore and marine

Lightweight

Impact Resistant

Fire Retardant

Corrosion Resistant

Low Maintenance

Ease of Fabrication

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Power generation

Non-Conductive

Lightweight

Chemical Resistant

Anti-Slip

Long Life

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Architectural

Versatile

Anti-Slip

Colour Options (FlowGRiP)

Comfort of use

Aesthetically Pleasing

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Roof access

Lightweight

Corrosion Resistant

Low Maintenance

Easy To Install

Redman Fisher GRP Composites Division

flowGRiP

flowgrate

flowtread

safety

phenolic

structures

Tel 01952 685110

www.redmanfisher.co.uk

GRP Product Guide

Redman Fisher Engineering Limited

Halesfield 18

Telford

Shropshire

TF7 4JS

Tel: 01952 685110

Fax: 01952 685117

www.redmanfisher.co.uk

Information, recommendations etc. given in our literature, by our employees, representatives, agents and

distributors, with regard to our products and their uses, are based upon extensive experience and given in good

faith and without guarantee, since conditions of use are beyond our control. The customer must be satisfied that

the product is suitable for the purpose for which it is intended to be used and the conditions under which it is to

be used are suitable. Under no circumstances will Redman Fisher be liable for incidental or consequential damage

arising from any alleged negligence. All orders are accepted subject to our Conditions of Sale, which will be

supplied on request, which prevail over any terms or conditions in or referred to in the order or correspondence.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Attribute Achievement FormDokument14 SeitenAttribute Achievement Formlukebrown920% (5)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Beam Design Formulas With Shear and MomentDokument20 SeitenBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Risk Assessment HazardsDokument3 SeitenRisk Assessment Hazardslukebrown92Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Microsoft Project - HotelDokument4 SeitenMicrosoft Project - Hotellukebrown92Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- HotelDokument1 SeiteHotellukebrown92Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Combiflex SG BrochureDokument8 SeitenCombiflex SG BrochureJOHNNY CASTILLO LAGOSNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- JM Piezoproducts 105eng Multilayer Piezo BendersDokument1 SeiteJM Piezoproducts 105eng Multilayer Piezo BendersLuan Engenharia BackupNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- ASTM D709 Standard Specification For Laminated Thermosetting Materials PDFDokument34 SeitenASTM D709 Standard Specification For Laminated Thermosetting Materials PDFgalvaosilvaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Science-G6q1w3l4-Classification of ColloidsDokument11 SeitenScience-G6q1w3l4-Classification of ColloidsJeson Palomares100% (1)

- MS 122009 4Dokument1 SeiteMS 122009 4staedtlerpNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Soil TypesDokument3 SeitenSoil TypesAnonymous jdC36sKP57Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Si̇lan KBM 403 (Eng)Dokument7 SeitenSi̇lan KBM 403 (Eng)GİZEM D.Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Vaccum Test MethodDokument4 SeitenVaccum Test MethodMahmud AlamNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- An Overview of Silicone SoftenerDokument3 SeitenAn Overview of Silicone SoftenersiliconemanNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Activity No. 9 - PHAN111 Assay of NaCl Injection Post-LabDokument15 SeitenActivity No. 9 - PHAN111 Assay of NaCl Injection Post-LabAyille Dorado ArcigalNoch keine Bewertungen

- CO2 Injection in CBMDokument14 SeitenCO2 Injection in CBMmhuf89Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Selecting Amines For Sweetening Units PDFDokument9 SeitenSelecting Amines For Sweetening Units PDFGui Do EspNoch keine Bewertungen

- PHC Calculation ASSHTO-LRDF 2007Dokument3 SeitenPHC Calculation ASSHTO-LRDF 2007Nguyen D CongNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Dod HDBK 263Dokument76 SeitenDod HDBK 263Asif HamidNoch keine Bewertungen

- P6 Magnet ElectricityDokument9 SeitenP6 Magnet ElectricityHarshaWakodkarNoch keine Bewertungen

- ACT Crack Chemistry AnswersDokument76 SeitenACT Crack Chemistry AnswersMahmoud EbaidNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 6 Bodies Mortuary FreezerDokument10 Seiten6 Bodies Mortuary FreezerRaul CostiniucNoch keine Bewertungen

- Example of BBSDokument42 SeitenExample of BBSkevinNoch keine Bewertungen

- Grit Comparison 07-23-09Dokument3 SeitenGrit Comparison 07-23-09lamebmxNoch keine Bewertungen

- Flow Process Papan Gipsum Aplus NewDokument2 SeitenFlow Process Papan Gipsum Aplus NewBambang Waluyo Hadi SNoch keine Bewertungen

- ELECTROPHORESIS - Lecture Notes - Complete PDFDokument19 SeitenELECTROPHORESIS - Lecture Notes - Complete PDFRaviIdhayachanderNoch keine Bewertungen

- Is 1570Dokument164 SeitenIs 1570Sumit Shyamal63% (8)

- 1-s2.0-S0301479717307521-Main - PDF Eliminacin de Metales Por NanofiltracionDokument6 Seiten1-s2.0-S0301479717307521-Main - PDF Eliminacin de Metales Por NanofiltracionJaime CazaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- ANSYSd BListDokument114 SeitenANSYSd BListAnonymous nfHBPXz178Noch keine Bewertungen

- Dynamic Recrystalization and Grain Growth Behavior of 20SiMn Low Carbon Alloy SteelDokument5 SeitenDynamic Recrystalization and Grain Growth Behavior of 20SiMn Low Carbon Alloy Steelpratik charkhawalaNoch keine Bewertungen

- QUIZ 2 Landfill AnswersDokument4 SeitenQUIZ 2 Landfill AnswersSigmund SiyNoch keine Bewertungen

- Chemistry in The LaundryDokument38 SeitenChemistry in The LaundryAldayantiNoch keine Bewertungen

- Shear Dowel: Shear Force Transmission in Expansion JointsDokument7 SeitenShear Dowel: Shear Force Transmission in Expansion Jointsmoug_thNoch keine Bewertungen

- Article WJPR 1405426296Dokument25 SeitenArticle WJPR 1405426296Joel Morales PerezNoch keine Bewertungen

- Tegopren 5840 1020 en Oi AsDokument2 SeitenTegopren 5840 1020 en Oi AsmajidNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)