Beruflich Dokumente

Kultur Dokumente

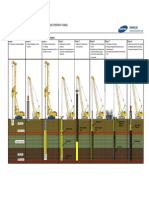

Bored Pile

Hochgeladen von

Michael RootOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bored Pile

Hochgeladen von

Michael RootCopyright:

Verfügbare Formate

METHOD

STATEMENT

for the construction

of

BORED PILES

(General Use)

Method Statement for Bored Pile

METHOD STATEMENT FOR THE

CONSTRUCTION OF BORED PILES

A.

Excavation of pile shaft

Before excavation of each bored pile, identify any possible obstruction and

confirming founding level by site inspection.

Set out the correct position of the bored pile on site. See Photo 1.

Set up the vibrator in lifted with a crane.

Install the bottom section of permanent or temporary casing into the ground by

vibrating motion exerted by the vibrator.

Excavate in soil using augering method. The auger is lowered down by a

telescopic boom to excavate soil and retrieve the auger to the top after excavation.

Move the auger with soil in it away from the excavated hole by swinging the

machine. Rotate the auger in the opposite direction to remove the soil from the

auger.

The augering process is repeated until the required depth is reached or hard layer

or rock is reached.

If necessary, use a bucket to clean the bored hole with the process similar to the

auger. However, for dumping of soil/spoils, the bucket needs to be released by

pulling a pin manually.

For hard soils and solid rock, if necessary, rock auger head can be employed to

grind into hard soils and rock and subsequent removal of fragments by bucket.

Extension of the steel casing can be done by welding on additional casing during

excavation. A sample is shown in Fig.1. However, the method may vary from

site-to-site, depending on the soil condition. If the soil is soft, simple full welding

is sufficient.

Verticality of the casing will be monitored by means of spirit level.

Continue the above procedure until the tentative completed level / sound rock

level has reached. Soil samples & rock fragments will be collected for inspection.

Method Statement for Bored Pile

Method Statement for Bored Pile

Figure 1 : Details for Connection of Casing

B.

Cleaning of Pile Shaft

The pile shaft shall be cleaned by the bucket if there are suspected loose material

at the toe. The presence of water in the shaft (if any) is OK, provided there are no

collapse of soil in the hole.

This can be checked with when the withdrawal of bucket, there shall be no debris,

soils or rock fragments in the bucket after cleaning.

The depth of the pile is checked using a weighted measuring tape.

C.

Preparation of Reinforcement Bars

The reinforcement and links cage is prepared, prefabricated prior to the

completion of the bore pile.

The links shall be prepared first and subsequently tie the required amount of

reinforcement, spaced equally onto the link.

Place circular spacers onto the spiral link at intervals required by the design.

Method Statement for Bored Pile

D.

Installation of Reinforcement Bars

When the reinforcement cages are ready, they can be installed into the pile.

The weight of the prefabricated cage can be calculated in order to select a suitable

crane for lifting. If a mechanical bored pile machine is used, the bore pile machine

engine shall be detached and the mounted crane can be used for lifting.

The prefabricated cage shall be lowered down into the hole, segment by segment

by lifting the entire cage using a suitable crane. The top of the cage will be

welded with a suitable hook for lifting of the cage.

Shall lapping of reinforcement is needed, a lap length of 40D shall be used. The

laps shall be done using welding, or tied with tie wires or U-bolts.

Repeat the step above until required depth is reached.

Photo 2: Installing the prefabricated

rebar cage into the bored hole.

Method Statement for Bored Pile

E.

Concreting (Direct Pour or Tremie Method)

Set up a working platform to the top of the temporary casing if the ground is soft

using steel plates.

If there is less than 1m of water present in the hole (can use a tape measure and a

piece of timber/wood tied at the bottom), the hole is deemed to be dry and direct

pour method can be used.

Otherwise, if the pile is flooded with water (>1m), the pile shaft shall be

concreted by Tremie Technique". The tremie pipe sections will be inserted and

be jointed until it reaches the bottom of the pile shaft.

Concrete will be poured into the tremie pipe by using a concrete skip. Concreting

will be carried out in one continuous operation to a stop-off level ( above the cutoff level ) agreed with the Client. (See Photo 3).

As concreting proceeds, the level of the concrete relative to the ground level can

be monitored by measuring with weighted tape after each skip of concrete is

placed.

The tremie pipe can then be extracted piece by piece as the concreting goes on.

The temporary casing can either be extracted simultaneously by the vibrator in

course of concreting, or after completion of concreting. A head of about 2 m

(minimum) is always maintained between the top of concrete and the bottom of

steel casing.

If a length of permanent casing is required, the extraction of casing shall be

stopped after the bottom of casing reaches the required level.

If the length of the permanent casing is already installed to depth, leave the casing

intact after concreting.

Method Statement for Bored Pile

Photo 3 : Concreting using a tremie pipe.

Method Statement for Bored Pile

Das könnte Ihnen auch gefallen

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideVon EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNoch keine Bewertungen

- Method Statement For Driven Precast Concrete PilesDokument27 SeitenMethod Statement For Driven Precast Concrete PilesMohammed Wahhab67% (6)

- Sheet Piles Method StatementDokument3 SeitenSheet Piles Method StatementLandon Mitchell100% (5)

- DAO 2000-98 Safety RulesDokument118 SeitenDAO 2000-98 Safety RulesKaring Paalan Paredes50% (2)

- MS 01 - Bored PilesDokument31 SeitenMS 01 - Bored PilesDinesh PriyankaraNoch keine Bewertungen

- Method Statement of Bridge#13Dokument1 SeiteMethod Statement of Bridge#13Dhoni Ertanto80% (10)

- Bored Piling Method StatementDokument8 SeitenBored Piling Method StatementTAHER AMMAR100% (1)

- 采矿专业英语大全Dokument50 Seiten采矿专业英语大全Dino ChengNoch keine Bewertungen

- Method Statement For Piling Work (Edited)Dokument18 SeitenMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- 04.method Statement For Shoring & DewateringDokument5 Seiten04.method Statement For Shoring & DewateringPja Shantha100% (2)

- Method StatementDokument15 SeitenMethod StatementKrushna RamaNoch keine Bewertungen

- As 3785.3-2005 Underground Mining - Shaft Equipment Drum Winding Gripper SystemsDokument8 SeitenAs 3785.3-2005 Underground Mining - Shaft Equipment Drum Winding Gripper SystemsSAI Global - APACNoch keine Bewertungen

- ROB Construction Method StatementDokument9 SeitenROB Construction Method StatementRamesh Joshi100% (2)

- (O) - 1 Bored PileDokument16 Seiten(O) - 1 Bored Pileautienhai100% (4)

- Bored Piling Works - 8 Stages from Pre-boring to BackfillingDokument1 SeiteBored Piling Works - 8 Stages from Pre-boring to BackfillingAnonymous S7Cq7ZDgP100% (1)

- Piling RequirementsDokument80 SeitenPiling Requirementsthusi67% (3)

- Kiswire Steel Wire RopeDokument28 SeitenKiswire Steel Wire RopeMulatua Sirait100% (3)

- Method Statement For Columns2Dokument5 SeitenMethod Statement For Columns2Jasmine TsoNoch keine Bewertungen

- Gabion Construction Method StatementDokument3 SeitenGabion Construction Method StatementIsaiah DongoNoch keine Bewertungen

- Method Statement For Bored PilesDokument18 SeitenMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- Bored Pile Construction - ChrisDokument38 SeitenBored Pile Construction - ChrisTerry Choi100% (2)

- Work Method Statement of RCP Works Pipe LayingDokument6 SeitenWork Method Statement of RCP Works Pipe LayingLod.N.S100% (3)

- Complete Mine PlanDokument30 SeitenComplete Mine PlanJasmeet Singh SalujaNoch keine Bewertungen

- Method Statement For Bored PilingDokument5 SeitenMethod Statement For Bored Pilingjhc112386% (7)

- GTS, PTS & Technical Data Sheet of Pakaldul H.E.projectDokument121 SeitenGTS, PTS & Technical Data Sheet of Pakaldul H.E.projectSujeet Kumar50% (2)

- Method Statement For Jet GroutingDokument2 SeitenMethod Statement For Jet GroutingAlsonChin0% (1)

- Herrenknecht Mining Mechanised Shaft-Raise Excavation Webinar 22jan2020 PDFDokument81 SeitenHerrenknecht Mining Mechanised Shaft-Raise Excavation Webinar 22jan2020 PDFSeasonNoch keine Bewertungen

- Pasay City CDP 2014-2019Dokument220 SeitenPasay City CDP 2014-2019Michael Root71% (7)

- UAP Docs 200-208Dokument85 SeitenUAP Docs 200-208Julia Esquivias-Virtucio60% (5)

- UAP Docs 200-208Dokument85 SeitenUAP Docs 200-208Julia Esquivias-Virtucio60% (5)

- PDA Testing Method for Bored Piles & Micro PilesDokument12 SeitenPDA Testing Method for Bored Piles & Micro PilesWee Chek83% (6)

- Mining Subsidence Engineering - Helmut KratzschDokument551 SeitenMining Subsidence Engineering - Helmut Kratzschferry verali100% (2)

- Method Statement BorepileDokument47 SeitenMethod Statement BorepileIera Jamil100% (1)

- Method Statement For Bored Piles (Badulla) AmendedDokument17 SeitenMethod Statement For Bored Piles (Badulla) AmendedSri Maha Bodiya - Project [GDP Engineering]100% (1)

- Ocrfhwa If-99-025 Gec 10 Drilled Shafts (1999) - Ocr - Part1Dokument25 SeitenOcrfhwa If-99-025 Gec 10 Drilled Shafts (1999) - Ocr - Part1Alan Valdez MontoyaNoch keine Bewertungen

- Underground Coal MineDokument17 SeitenUnderground Coal MineFavorSea Industrial Channel Limited100% (1)

- Method Statement For Installation of Soil Nails With For Slope StabilizationDokument11 SeitenMethod Statement For Installation of Soil Nails With For Slope StabilizationDelon Yau100% (2)

- Bored Cast In-Situ Pile Method StatementDokument10 SeitenBored Cast In-Situ Pile Method StatementVijay JamadarNoch keine Bewertungen

- Approved CLUP 2014-2022Dokument106 SeitenApproved CLUP 2014-2022Michael Root67% (3)

- Vertical Shaft Boring MachinesDokument2 SeitenVertical Shaft Boring MachinesTony ChanNoch keine Bewertungen

- MFL For Wire RopesDokument19 SeitenMFL For Wire RopesMathavaraj Dharmaraj100% (2)

- Embankment Construction MethodologyDokument16 SeitenEmbankment Construction MethodologyTinwin HtutNoch keine Bewertungen

- Method Statement of Concreting Pile Cap Rev02Dokument3 SeitenMethod Statement of Concreting Pile Cap Rev02Mohd Hafizul Hj Tanalol75% (4)

- Mos Survey WorkDokument4 SeitenMos Survey Workaniesbaek100% (1)

- Tunnel Blasting TechniquesDokument25 SeitenTunnel Blasting TechniquesBaga Yoice100% (1)

- Method Statement Precast PilesDokument5 SeitenMethod Statement Precast PilesBenni AmirNoch keine Bewertungen

- Method Statement For Piling WorksDokument2 SeitenMethod Statement For Piling Worksshahul_hamid_277% (22)

- Bored PileDokument9 SeitenBored PileMichael RootNoch keine Bewertungen

- Bored PileDokument9 SeitenBored PileMichael RootNoch keine Bewertungen

- Architects Code of EthicsDokument9 SeitenArchitects Code of EthicsMark Gella Delfin100% (1)

- Major Components of FlyoverDokument3 SeitenMajor Components of FlyoverSaran KumarNoch keine Bewertungen

- Raiseboring RSADokument26 SeitenRaiseboring RSAsijuaNoch keine Bewertungen

- Install Micropile Method StatementDokument9 SeitenInstall Micropile Method Statementkazauser67% (3)

- Install Horizontal Drainage DrainsDokument3 SeitenInstall Horizontal Drainage DrainsTaqiuddin MJNoch keine Bewertungen

- Method Statements For Earth Work ExcavationDokument5 SeitenMethod Statements For Earth Work ExcavationKrm Chari100% (1)

- Offshore Bored Piles Using Permanent CasingsDokument19 SeitenOffshore Bored Piles Using Permanent CasingsMohamedAbdelnasser100% (1)

- Bored PileDokument20 SeitenBored PileIwan Dana100% (1)

- Method Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)Dokument7 SeitenMethod Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)MAYMODERN STEELNoch keine Bewertungen

- Saline Water Conversion Corporation Kingdom of Saudi Arabia: Ras Alzaur - Hafar AlbatinDokument174 SeitenSaline Water Conversion Corporation Kingdom of Saudi Arabia: Ras Alzaur - Hafar AlbatinBurak Baş100% (2)

- Method Statement For Pile DrivingDokument2 SeitenMethod Statement For Pile DrivingLim Han Jian100% (5)

- Bored Piles - Production MethodDokument10 SeitenBored Piles - Production MethodFrank Stephens100% (1)

- Method Statement Bored PileDokument9 SeitenMethod Statement Bored PileAsma Farah100% (3)

- Method Statement of Jack-In Pile PDFDokument3 SeitenMethod Statement of Jack-In Pile PDFAMIR ASYRAF ZAINUDIN100% (1)

- Method Statement of Crossing Box CulvertDokument2 SeitenMethod Statement of Crossing Box CulvertNur EmalinNoch keine Bewertungen

- Jet GroutingDokument8 SeitenJet GroutingiskeletorsNoch keine Bewertungen

- Plant & Guide Wall ConstructionDokument10 SeitenPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPNoch keine Bewertungen

- Use of Bentonite in Bored Cast in Situ PilesDokument4 SeitenUse of Bentonite in Bored Cast in Situ Pilesdev_dip_donNoch keine Bewertungen

- TNB Sub-Station Pile Foundation Method StatementDokument3 SeitenTNB Sub-Station Pile Foundation Method StatementAishah Zakaria86% (7)

- Transportasi (Tambang) Bawah Tanah # 1Dokument73 SeitenTransportasi (Tambang) Bawah Tanah # 1januar789Noch keine Bewertungen

- Construction Joints in in Situ ConcreteDokument5 SeitenConstruction Joints in in Situ ConcreteTAHER AMMARNoch keine Bewertungen

- STATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มDokument11 SeitenSTATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มWilrutstien WilrutstienNoch keine Bewertungen

- Work Method Statement FOR Laying of Box Culvert and Sump ConstructionDokument3 SeitenWork Method Statement FOR Laying of Box Culvert and Sump ConstructionLynn Mail100% (2)

- Bored Pile - Method StatementDokument13 SeitenBored Pile - Method Statementbtcong93100% (2)

- Work Method Statement of Piling WorkDokument11 SeitenWork Method Statement of Piling Worksangamesh yadahalliNoch keine Bewertungen

- Method Statement For Pile Integrity Test ProcedureDokument3 SeitenMethod Statement For Pile Integrity Test ProcedureDeny Cahyo N100% (2)

- Method Statement For Shrinkage CracksDokument2 SeitenMethod Statement For Shrinkage Cracksluvvie87Noch keine Bewertungen

- MS For Bored Pile Hacking and Pile Head Treatment RevisedDokument7 SeitenMS For Bored Pile Hacking and Pile Head Treatment RevisedK H V V MADUSHANKA100% (1)

- Caisson Method Statement For Pipe JackingDokument2 SeitenCaisson Method Statement For Pipe JackingTeddy TP100% (1)

- Concreting MethodologyDokument2 SeitenConcreting Methodologyervnglen08Noch keine Bewertungen

- Method Statement of Open CutDokument7 SeitenMethod Statement of Open CutMuditha Indeewarie GunarathnaNoch keine Bewertungen

- Pile ShoesDokument8 SeitenPile ShoesfarahazuraNoch keine Bewertungen

- Draft PPT Pile FoundatationDokument14 SeitenDraft PPT Pile FoundatationDwijendra ChanumoluNoch keine Bewertungen

- Scientific American Supplement, No. 312, December 24, 1881Von EverandScientific American Supplement, No. 312, December 24, 1881Noch keine Bewertungen

- Household Population PDFDokument9 SeitenHousehold Population PDFMichael RootNoch keine Bewertungen

- On the Scientific Relevance of eSportsDokument5 SeitenOn the Scientific Relevance of eSportsMichael RootNoch keine Bewertungen

- Case-Study Garland Event Center PDFDokument5 SeitenCase-Study Garland Event Center PDFMichael RootNoch keine Bewertungen

- 2015 Psy PDFDokument606 Seiten2015 Psy PDFMichael RootNoch keine Bewertungen

- Code On Sanitation Phils PDFDokument23 SeitenCode On Sanitation Phils PDFMichael RootNoch keine Bewertungen

- Philippine Regulation On Sanitation and Waste Water Systems by Bonifacio MagtibayDokument193 SeitenPhilippine Regulation On Sanitation and Waste Water Systems by Bonifacio MagtibayRenee Rose GregorioNoch keine Bewertungen

- Mice PDFDokument8 SeitenMice PDFMichael RootNoch keine Bewertungen

- Case-Study Garland Event CenterDokument5 SeitenCase-Study Garland Event CenterMichael RootNoch keine Bewertungen

- Mice PDFDokument8 SeitenMice PDFMichael RootNoch keine Bewertungen

- Lighting Materials and FixturesDokument11 SeitenLighting Materials and FixturesMichael Root100% (1)

- Code of Practice for Underground Winding SystemsDokument58 SeitenCode of Practice for Underground Winding SystemsSteve PennNoch keine Bewertungen

- Guidelines For Good Occupational Health and Safety Practice in Tunnel Construction - Nov2008 PDFDokument44 SeitenGuidelines For Good Occupational Health and Safety Practice in Tunnel Construction - Nov2008 PDFAnita VillablancaNoch keine Bewertungen

- Description Datasheet FieldDokument6 SeitenDescription Datasheet FieldAshok SrivatsanNoch keine Bewertungen

- Figure 1: Tunnel ShaftsDokument3 SeitenFigure 1: Tunnel ShaftsNiyibizi PromesseNoch keine Bewertungen

- MDG-33 TotDokument205 SeitenMDG-33 TotSteve PennNoch keine Bewertungen

- Headframe Conversion Project HandH Paper No.21Dokument11 SeitenHeadframe Conversion Project HandH Paper No.21Kandousi YassineNoch keine Bewertungen

- Project Report For Tunnel ExcavationDokument19 SeitenProject Report For Tunnel ExcavationAbhishek Sarkar50% (2)

- Midas Vent Rise EADokument102 SeitenMidas Vent Rise EAnevadablueNoch keine Bewertungen

- Brochure 1100 - Turbina VerticalDokument4 SeitenBrochure 1100 - Turbina Verticalcarolina PortocarreroNoch keine Bewertungen

- Coal Mining VocabularyDokument2 SeitenCoal Mining VocabularyPaulo de CastroNoch keine Bewertungen

- Shafts For Tunnels and Deep Pipelines in Urban NZ (Wharmby, ATS 2011) PDFDokument6 SeitenShafts For Tunnels and Deep Pipelines in Urban NZ (Wharmby, ATS 2011) PDFDavidNoch keine Bewertungen

- UG Mine Design for Fishmeri Gold DepositDokument97 SeitenUG Mine Design for Fishmeri Gold DepositLiNoch keine Bewertungen

- Peerless Pump: Vertical Lineshaft Turbine PumpsDokument2 SeitenPeerless Pump: Vertical Lineshaft Turbine PumpsArgenisNoch keine Bewertungen